11050/30250/31080/20250/40600 2

WARNING

FAILURE TO OBSERVE THESE WARNINGS COULD RESULT IN INJURY

THIS INSTRUCTION MANUAL CONTAINS IMPORTANT

SAFETY INFORMATION.

READ THIS INSTRUCTION MANUAL CAREFULLY AND

UNDERSTAND ALL INFORMATION BEFORE OPERATING

THIS TOOL.

• Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric

shock, fire, explosion and/or serious personal injury. It is

the responsibility of the owner to make sure all personnel

read this manual prior to using the device. It is also

the responsibility of the device owner to keep this

manual intact and in a convenient location for all to

see and read. If the manual or product labels are lost

or not legible, contact Sunex Tools®for replacements.

If the operator is not fluent in English, the product

and safety instructions shall be read and discussed

with the operator in the operator's native language by

the purchaser/owner or his designee, making sure that

the operator comprehends its contents.

• To safeguard torque accuracy avoid keeping tool set at

high loads for long periods of time. When finished reset

back to zero.

• Do not operate without eye and hand protection (users

and bystander).

• Keep body working stance balanced and firm. Do not

overreach when operating the tool.

• Keep fingers and hands away from pinch point region of

this tool at all times.

• Do not force tool beyond its rated capacity. Overtorqueing

can cause breakage.

• Use of a "cheater bar" or leverage multipliers will result

in an inaccurate reading and can possibly damage the

wrench. Use of unapproved accessories could push the

unit beyond its rated capacity and will void your warranty.

• Do not use torque wrench to loosen fasteners.

• The wrench should be sent in for calibration once every

year or every 5,000 cycles for re-calibration.

• The wrench should be cleaned and stored properly after

every use. Do not submerge this unit in any fluid.

• Wrenches should be re-calibrated if dropped or

accidentally mishandled.

• The torque wrench should be "exercised" a minimum of

three times at 100% of full scale before use.

• Do not remove any labels. Replace damaged labels.

• This product may contain one or more chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands

thoroughly after handling.

• Failure to heed these warnings may reuslt in personal injury

and/or property damage.

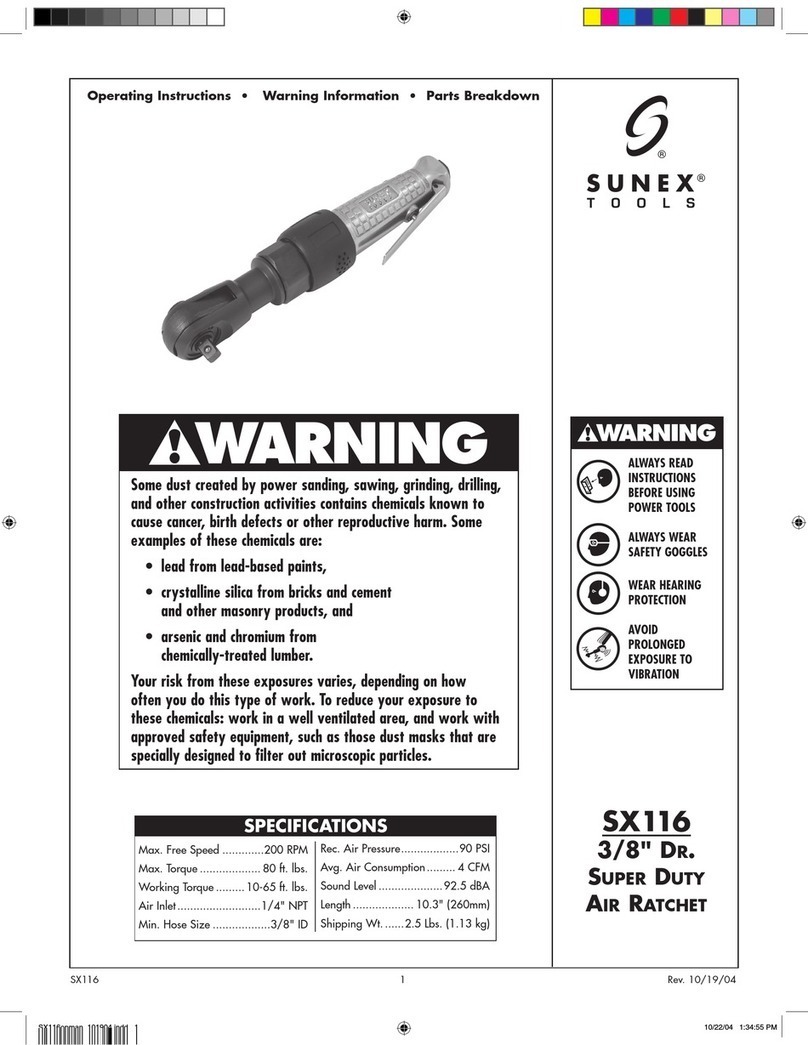

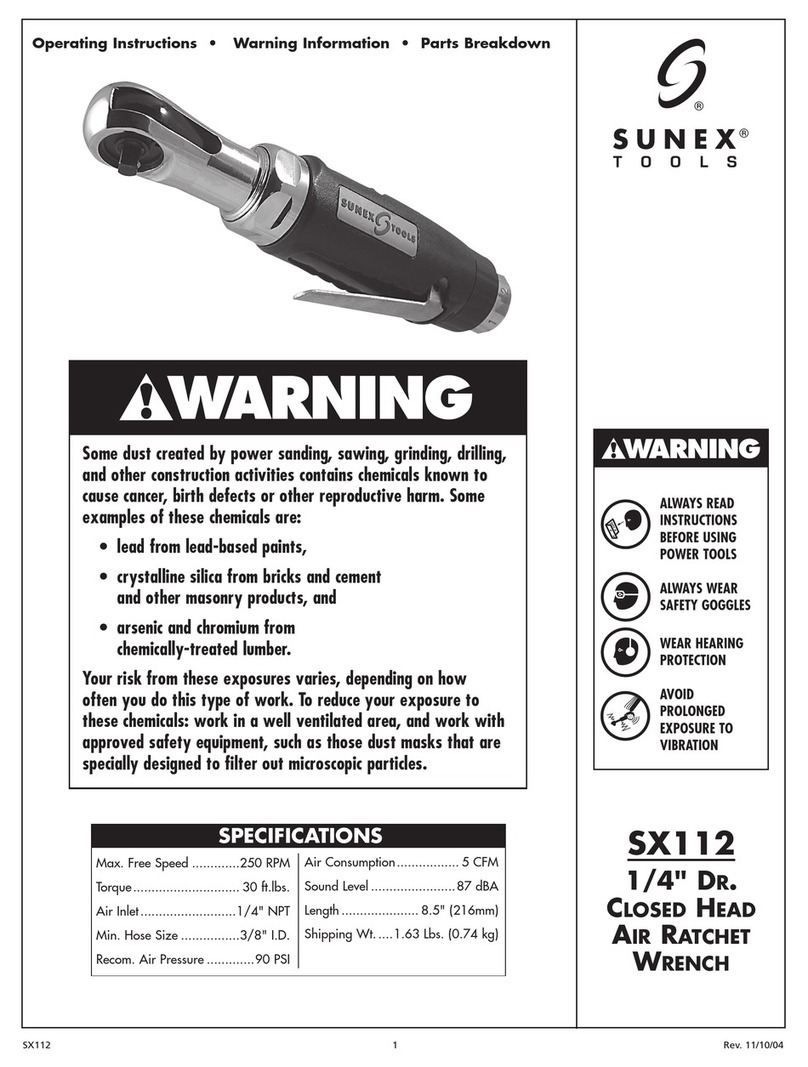

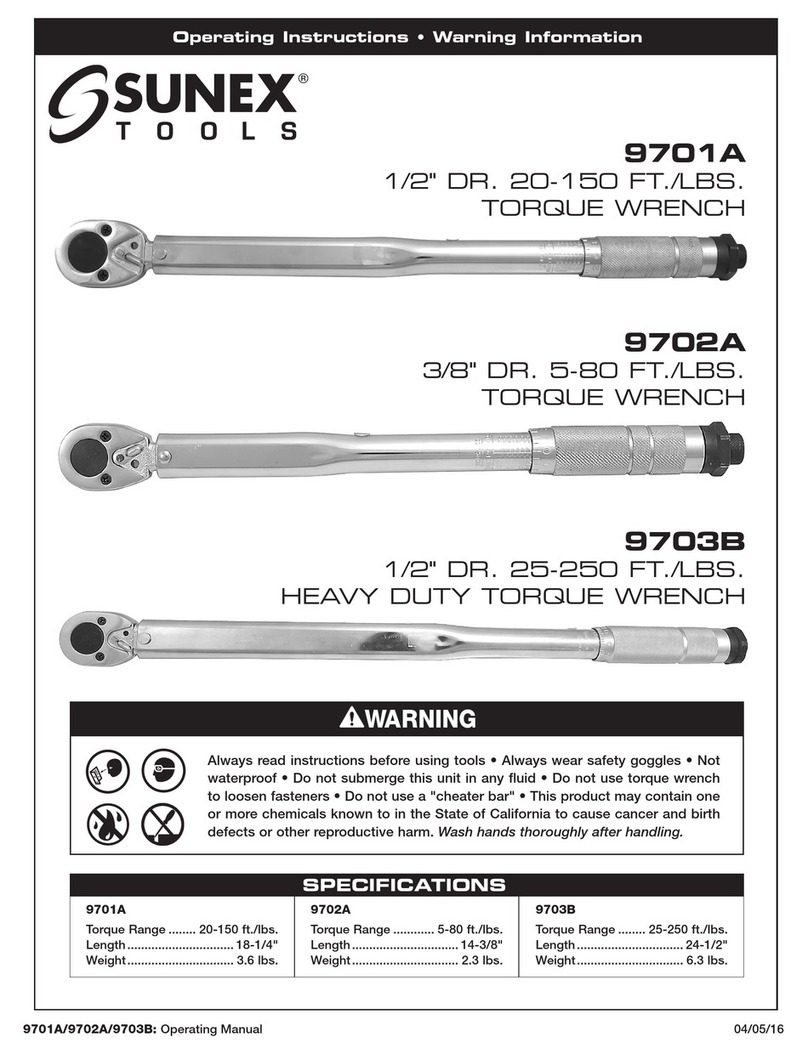

PARTS REFERENCE

1. Reversible Ratchet Head

2. Wrench Body

3. Major Scale

4. Minor Scale

5. Adjusting Ring

6. Ratchet Drive

7. Anti-slip Handle

1345

67

2

ft•lbs

ft•lbs

No internal parts are available to purchase due to the sensitivity of this professional model.

Please utilize the repair facility listed under the warranty statement for all repairs in and out of warranty.