SVERO Smart Hoist 22 User manual

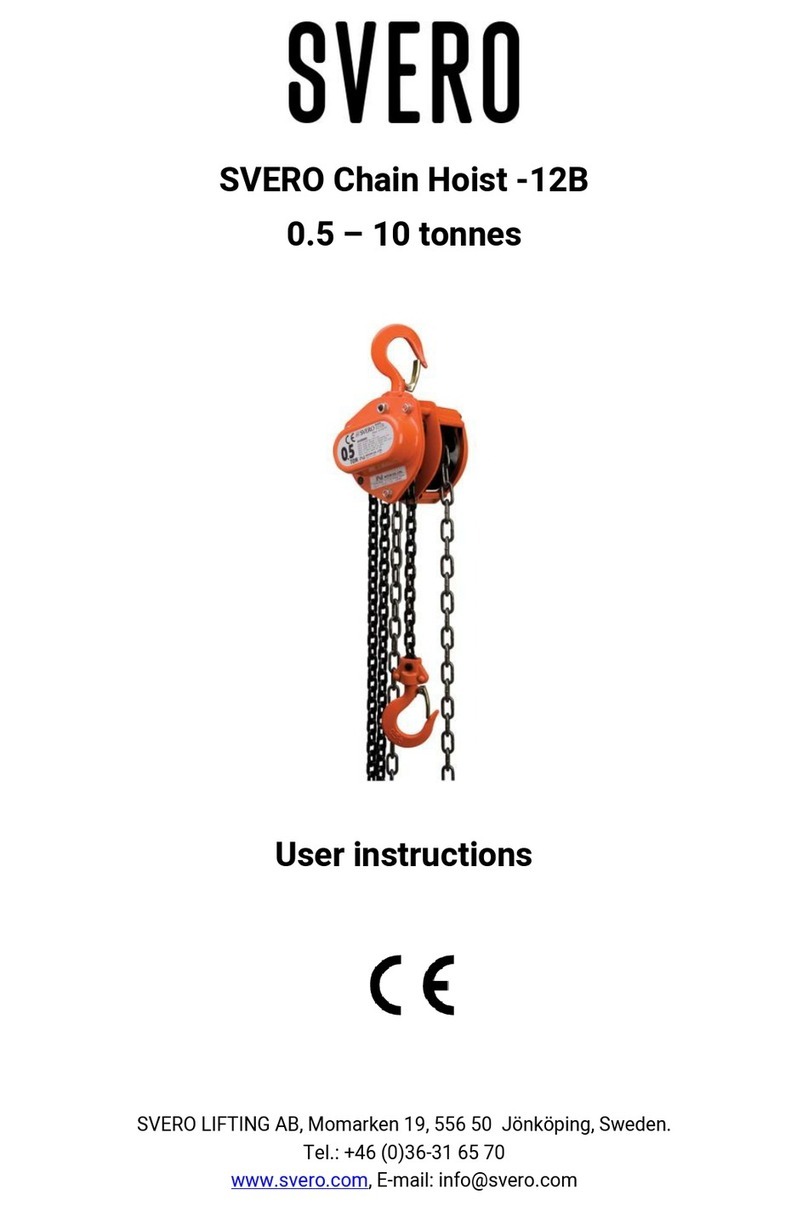

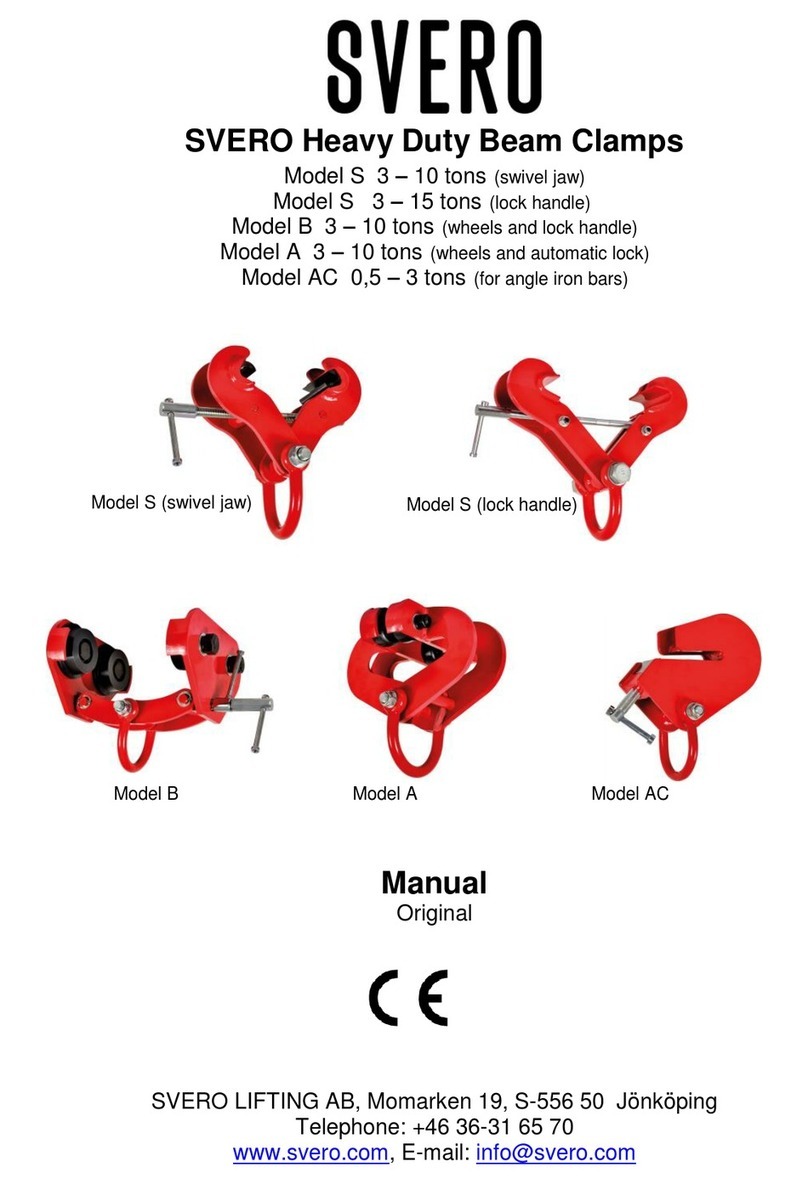

Other SVERO Chain Hoist manuals

Popular Chain Hoist manuals by other brands

EINHELL

EINHELL Herkules H-F 1000 operating instructions

RED ROOSTER

RED ROOSTER TCR-250 user manual

POWERTEX

POWERTEX PCB-S1 Instructions for use

Parkside

Parkside PSZ 250 A1 Operation and safety notes

Ingersoll-Rand

Ingersoll-Rand QCH Series Product information

Creative Conners

Creative Conners CM Varistar Smart Chain Hoist Reference manual

Coffing Hoists

Coffing Hoists EC Series Operating, Maintenance & Parts Manual

CM

CM 622A Series Operating, Maintenance & Parts Manual

KITO

KITO RY Series Disassembly and Reassembly

Haklift

Haklift LOABT800 Original instructions

Tractel

Tractel bravo Operating and maintenance instruction

Villager

Villager VEH 250 Original operating instructions