10 00001996 (REV AC) 627NH October 2014

INSTALLATION

UNPACKING INFORMATION

When received, the hoist should be carefully inspected

for damage which may have occurred during shipment or

handling. Check the hoist frame for dents or cracks, the

external cords for damaged or cut insulation, the control

station for cut or damaged enclosure, and inspect the

load chain for nicks and gouges. If shipping damage has

occurred, refer to the packing list envelope on the carton for

claim procedure.

Before installing the hoist, make sure that the power supply

to which it will be connected is the same as that shown on

the nameplate located on the side of the hoist.

NOTE: See Electrical Installation instructions

INSTALLING THE SUSPENSION

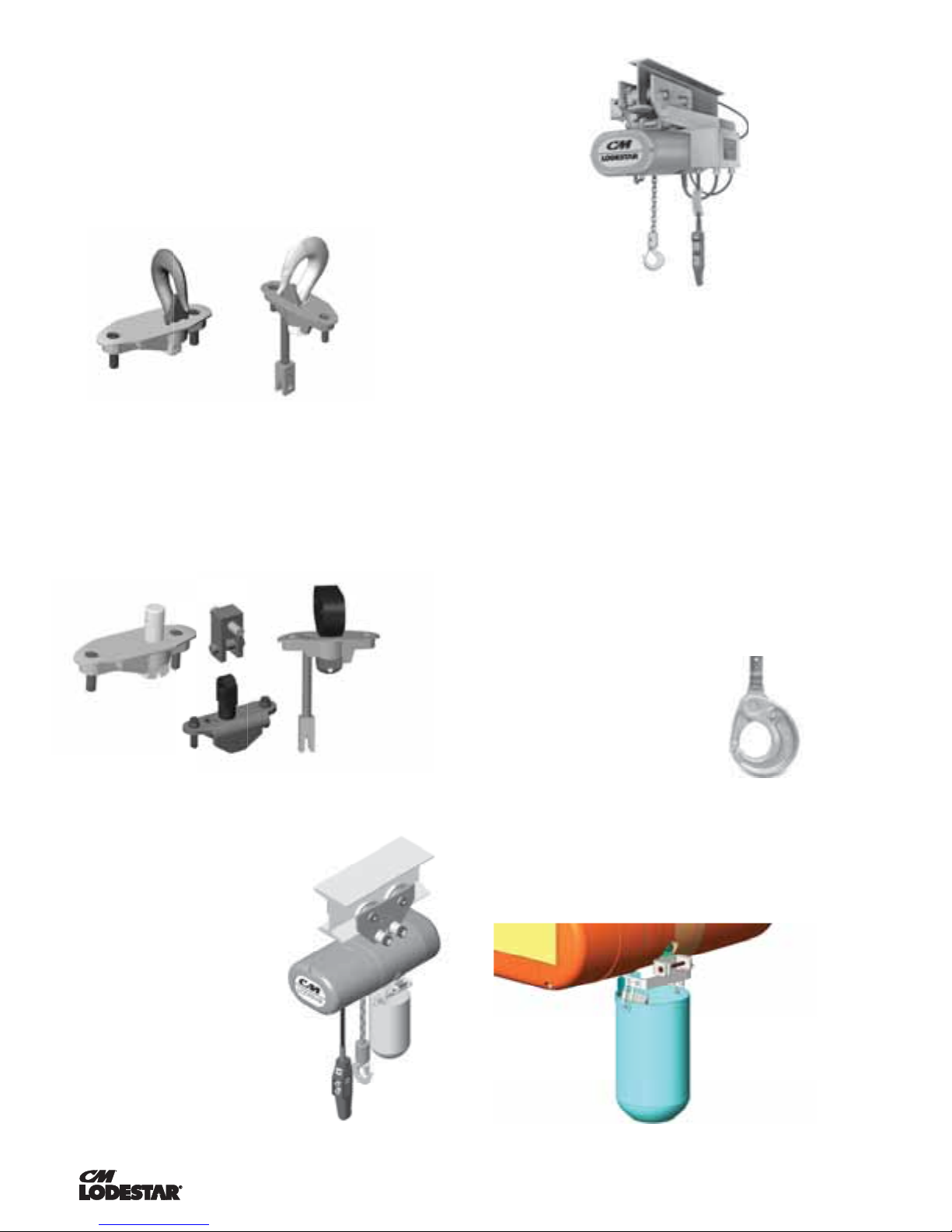

A. Single Reeved Units:

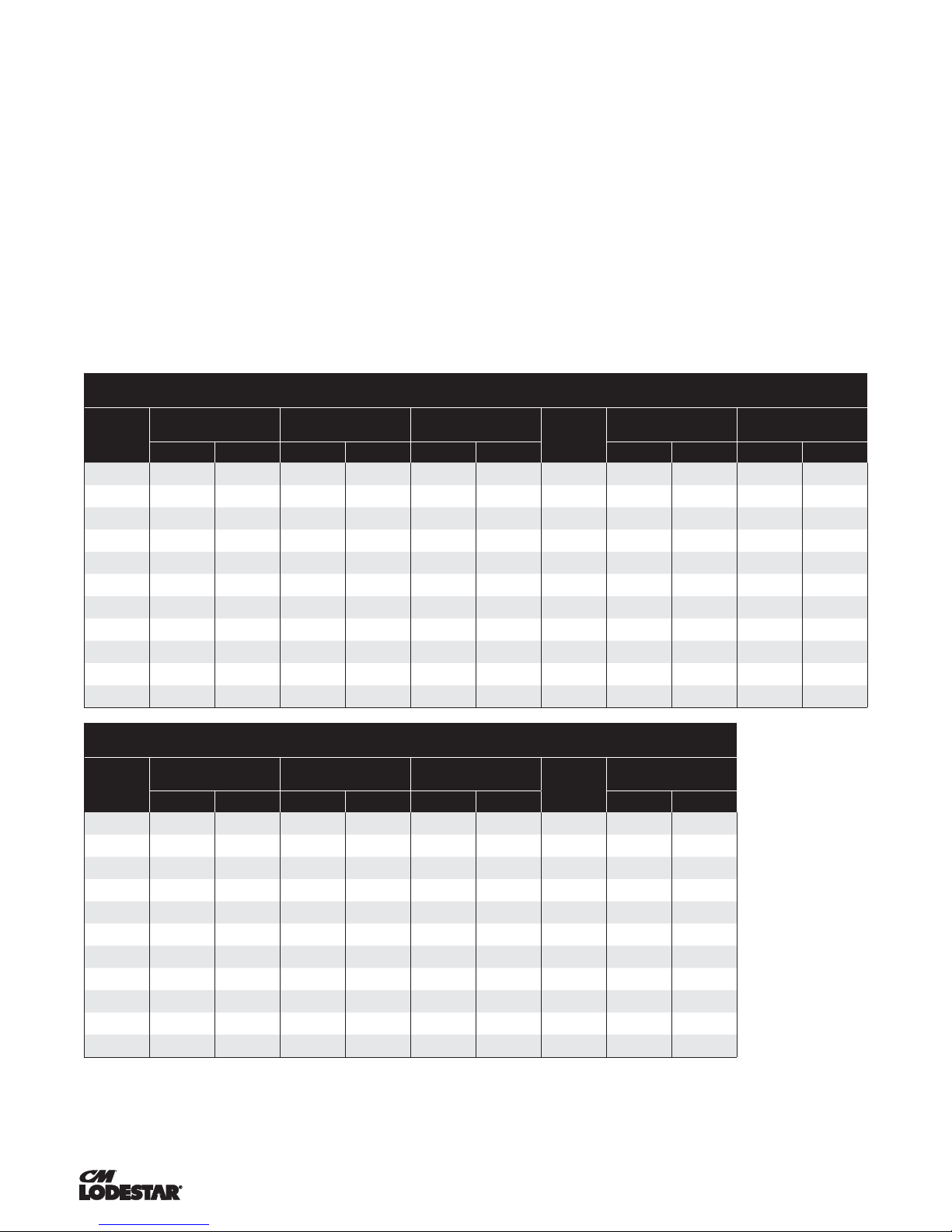

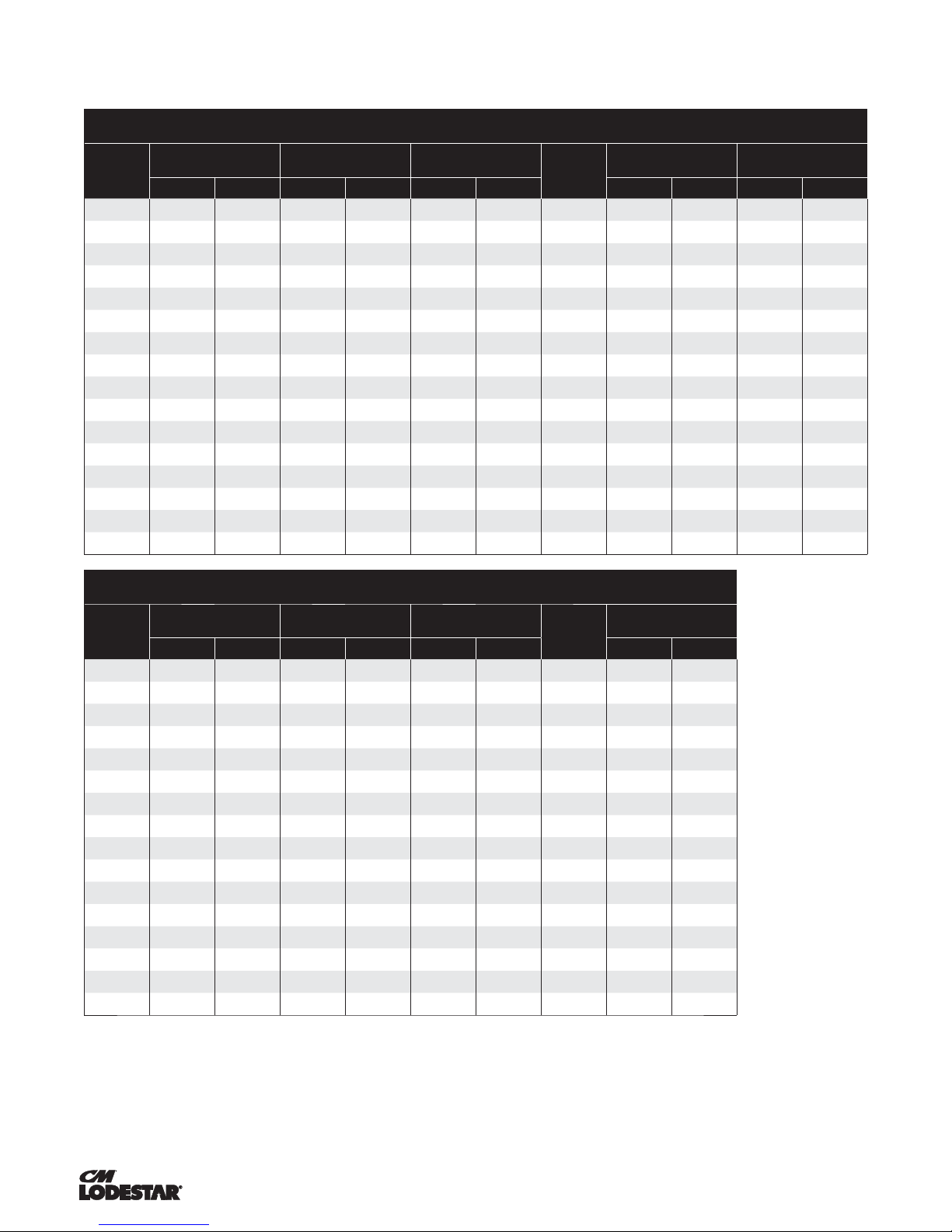

For Models A,B,C,F, J, JJ, L, & LL:

Remove the hook suspension and (2) suspension screws

from the packaging. Place the suspension assembly into the

recess on top of the hoist so that the adaptor body follows

the contour of the hoist. Insert the suspension screws

through the holes in the adapter and hand thread these into

the self-locking nuts enclosed in the hoist.

Securely tighten the screws to the recommended seating

torque (see Table 2) using a 12 point socket: 3/8" for Models

A, B, C, & F and 1/2" for Models J-LL.

For Model RRS:

Remove the hook suspension, screw and locknut from

the packaging. Slide the suspension assembly into the

channel in the top of the hoist. Insert the locknut into the

hex recess on the side of the suspension riser, insert the

screw through opposite side and hand thread the screw

into the self-locking nut.

Securely tighten the screw to the recommended torque (see

table 2), using a 3/16" hex bit socket.

Use of impact tools (electric or pneumatic) may cause premature failure

of attaching hardware.

B. Double Reeved Units:

Remove the hook suspension,(2) suspension screws,

(1) dead end pin, (1) washer, and (1) cotter pin from the

packaging. It should be noted that the suspension includes a

dead end bolt and block for supporting the dead end of the

load chain as shown in Figure 7.

Place the suspension assembly into the recess on top of

the hoist. The dead end block should project through the

bottom of the hoist with the pin hole and slot aligned to the

underside of the hoist as shown in Figure 7. If these are

not aligned as shown, lift the head of the bolt from the hex

recess in the adapter and turn the bolt and block assembly

and reseat the bolt head to obtain the proper alignment. Do

not change the position of the dead end block on the bolt to

attain this alignment.

Check the position of the pin hole in the dead end block to

make sure it has not been disturbed from its factory setting.

The distance from the top of the pin hole to the bottom of the

hoist should not exceed 1/4" (6.35mm) for Models E,E-2, H,

H-2 and 7/16" (11.11mm) for Models R, R-2, RR, RR-2. If the

distance is not correct, adjust the position of the dead end

block to obtain the proper distance (see fig. 21, p 73.)

Now, insert the suspension screws through the holes in the

adapter and hand thread these into the self-locking nuts

enclosed in the hoist frame. Securely tighten the screws to

the recommended seating torque (see Table 2) using a 12

point socket: 3/8" for Models E & H and 1/2" for Models R &

RR.

The dead end of the load chain is temporarily positioned ( a

few links from the end) by a wire tie. Do not remove this tie

before attaching the chain to the dead end block. (See Fig. 7)

C. Triple Reeved Units:

These hoists have a sheave hanger which is loosely

connected to the top of the frame by a thin metal plate for

shipping purposes. To attach the suspension, support the

sheave hanger from the underside of the hoist and remove

the nut and seat from the sheave stud. Remove and discard

the shipping plate and retain the sheave stud nut and seat

since they will be reused later.

Remove the suspension assembly from the carton and the

two suspension screws. Place the suspension assembly over

the sheave stud and into the recess on top of the hoist. Insert

the suspension screws through the holes in the suspension

adapter and hand thread these into the self-locking nut

enclosed in the hoist. Securely tighten the screws to the

recommended seating torque (see Table 2) using a 12 point,

1/2" socket.

After the suspension assembly is installed, secure the sheave

stud to the suspension adapter using the round slotted nut

and seat that were formerly used to attach the shipping plate

to top of the hoist frame. Place the seat over the stud with

the flat side down and then rotate the seat so that there is

clearance between the seat and the suspension lug or hook.

Assemble the nut to the stud and turn the nut by hand until

the nut seats in the seat and the sheave hanger is snug in

the frame. Then back off the nut until the hole in the stud is

in line with one of the slots in the nut. Using a hammer, drive

the retaining pin (packed with the suspension assembly) into

the hole in the sheave stud until the end of the pin is flush

with the edge of the nut.

Using other than CM supplied high strength suspension screws to

attach the suspension adapter to the hoist may cause the screws to

break and allow the hoist and load to fall.

TO AVOID INJURY:

Use only the CM supplied suspension screws to attach the

suspension to the hoist and hand torque these screws to the

recommended seating torque as specified in tables 2a and 2b. DO

NOT apply any type of lubricant to the threads of these screws.

Lubricating the threads will reduce the effort to seat the screws

and as a result, tightening the screws to the above recommended

torque may break the screw,damage the suspension adapter, strip

the nuts and/or damage the hoist frame.

SUSPENSION BOLT SHOULD BE REPLACED ANY TIME

THE SUSPENSION IS REMOVED FROM THE HOIST