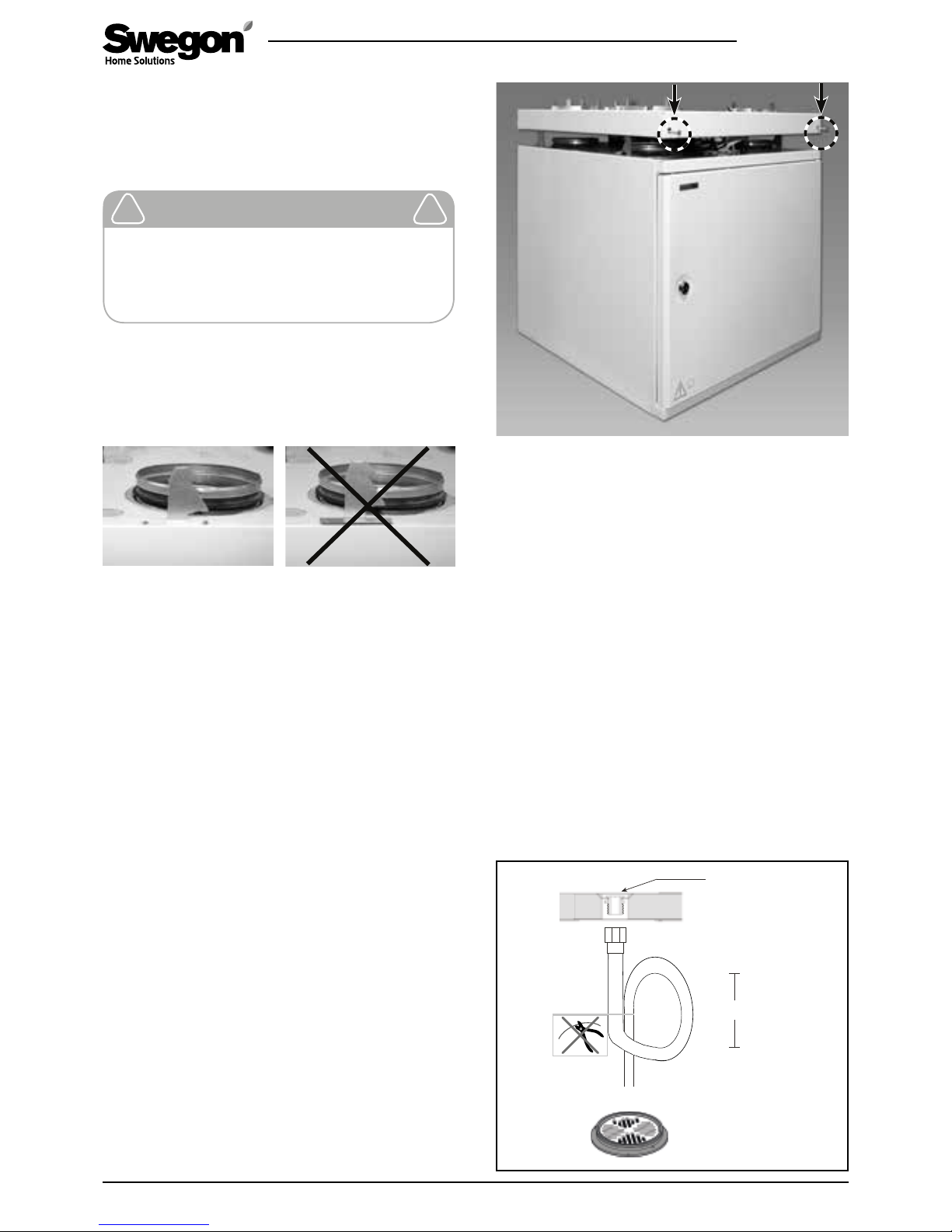

There is a metal water trap available as an accessory

(UVL).

Check that the condensate discharge outlet is not

clogged and check its outflow by pouring water on

the bottom of the ventilation unit. The condensate

discharge connection is located on the rear of the unit

under the rotary heat exchanger.

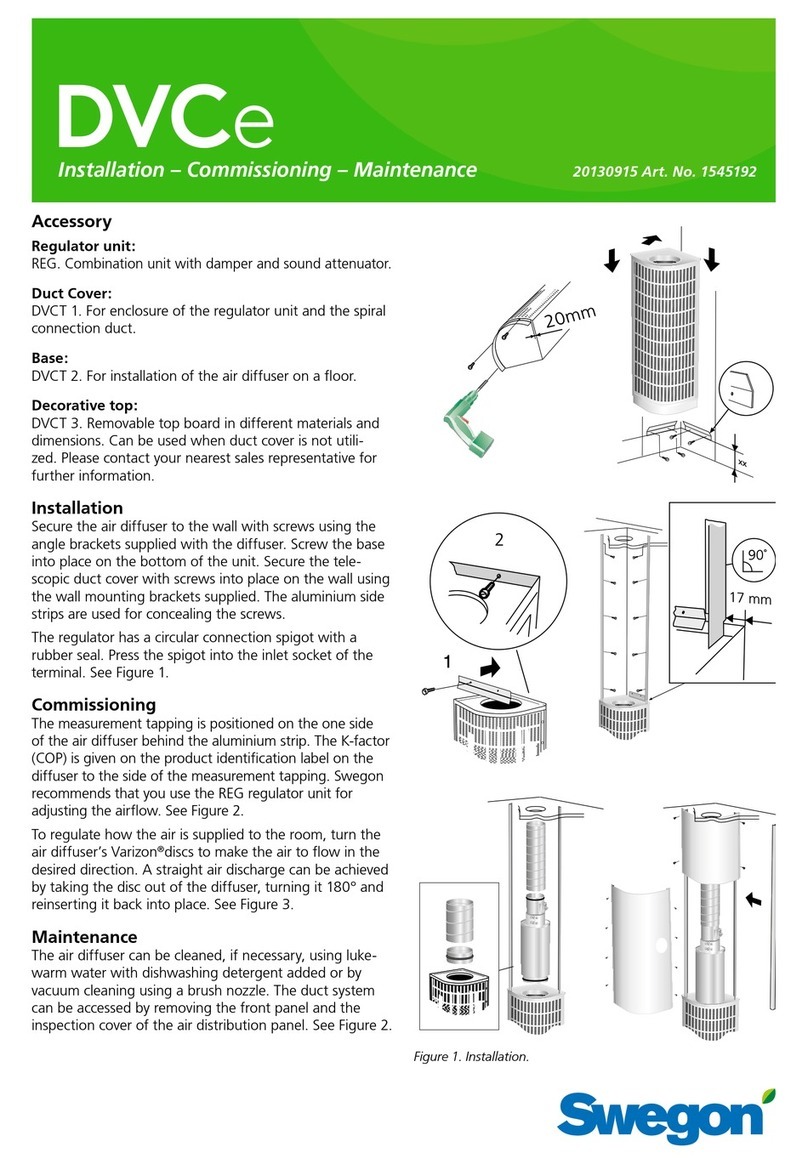

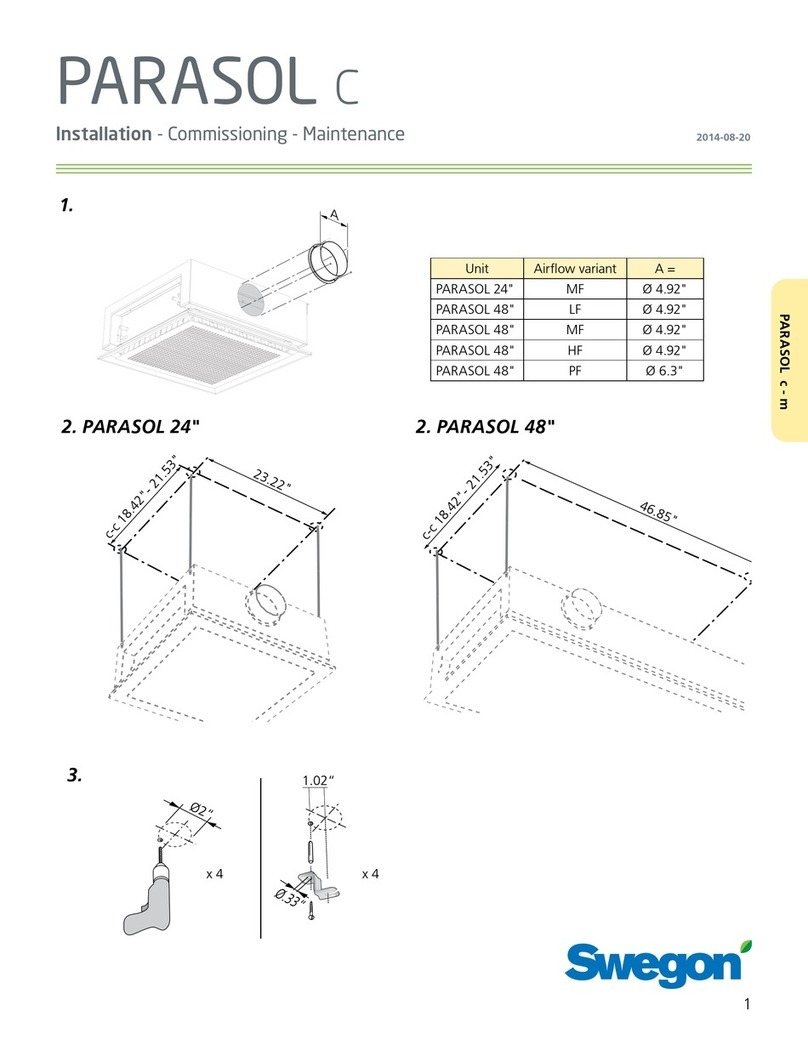

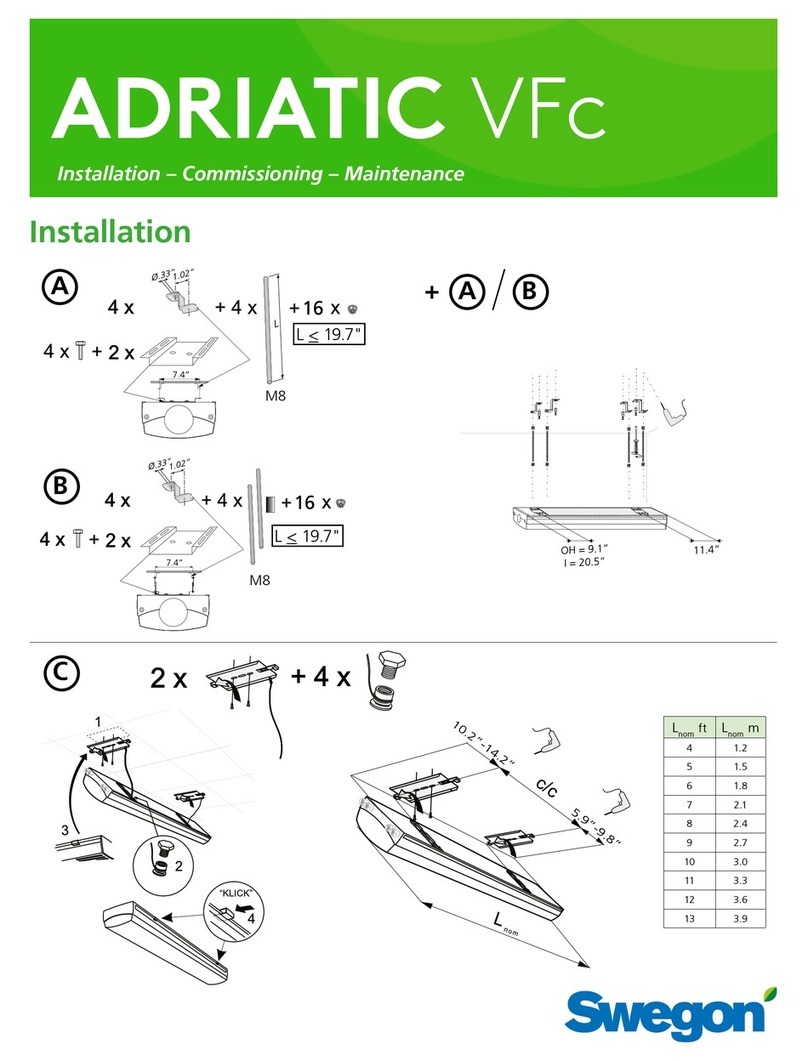

2.3 Ducts

Install the ventilation ducts, sound attenuators, sup-

ply air diffusers, air intake grilles and exhaust air ducts

as shown in the ventilation drawings. To prevent the

propagation of sound, do not install the ducts directly

against structural building elements.

Insulate the ventilation ducts in order to reduce loss of

heat or cooling energy and to prevent water from con-

densing on surfaces. In addition, it is advisable to insulate

the ducts to prevent the spread of fire. It is of greatest

importance to insulate cold ducts without gaps in

the insulation, so that moisture cannot condense.

2.4 To seal around duct penetration collars

It is advisable to use a mounting frame for sealing the

moisture barrier in the attic tie beams.

It is important to the preserve the tightness of the

vapour barrier at the duct penetration collars. A building

element penetration seal (accessory) will facilitate this.

This item is available in sets of 3 pieces, for diameters:

100, 125 and 160 mm and are attached to the moisture

barrier with tape.

Cut up the openings with approx. 10 mm smaller diam-

eter than that of the ducts. Secure the mounting frame

in the ceiling with screws through the holes on the

sides. The plastic film of the vapour barrier should either

be stretched and fastened between the mounting frame

and the structural element of the building, or be taped

tightly against the mounting frame.

The thickness of the insulation and the nature of the

surface layer of the ventilation ducts vary depending on

insulation material, climate zone and national standards

in force. For this reason, Swegon does not offer any rec-

ommendations for insulation thickness. Most manufac-

turers of insulation material offer calculation programs

for the calculation of sufficient and correct insulation.

In renovation projects, it is advisable to examine the

existing ducts to determine whether they are sufficiently

and correctly insulated. Insulating in the right way is

necessary for the ventilation unit to operate correctly. If

the ducts are uninsulated, even across a small area,

there is a high degree of risk of condensation and

indirect damage.

The supply air duct should be fitted with acoustic insula-

tion along the stretch between the unit duct outlet and

the sound attenuator, so that fan sound will not be

propagated out into the room.

In general, ventilation ducts should be insulated in the

following manner:

• Insulate outdoor air ducts run through warm spaces.

• Exhaust air ducts should always be insulated in ac-

cordance with national regulations. See separate pro-

ject planning instructions (for example Fire resistance

classification requirements).

• Insulate supply air ducts in cold spaces.

• Insulate extract air ducts in cold spaces.

• If the air inside the duct is colder than in the sur-

roundings; the insulation should be protected by a

vapour barrier.

2.5 Electric and control cables

A 1.5 m long cable with earthed plug-in contact is fitted

to the ventilation unit for measuring the voltage. The

cable extends from the top of the unit. The mains plug

serves as the ventilation unit’s main switch and it should

Important

Check whether the ventilation unit has

been supplied in the right-hand or left-

hand version to make certain that you are

connecting the ventilation ducts to the

correct duct connection spigots on the unit.

Check the ventilation plans to make sure

that the duct connections are correctly in-

stalled. See also the dimensional drawings

in the Section entitled: “Technical data”.

!!

Important

Even small gaps in the insulation impair the

sound attenuation and bring about a risk of

condensation and consequential damages.

!!

Important

Before commissioning the ventilation sys-

tem, check that the ventilation unit, filters,

condensation drain and ducts are clean and

that there are no loose objects inside them.

The ventilation ducts should be cleaned

regularly and always when the home is

renovated.

!!

Important

It is absolutely forbidden to operate the

ventilation system during the construction

period or if dust-raising work is carried out.

Before installing the unit, the ducts should

be blanked off with covers to prevent the

entry of impurities.

!!