Swegon ADAPT Sphere b Guide

Other Swegon Fan manuals

Swegon

Swegon REACT V SKNXa User manual

Swegon

Swegon EAGLE Ceiling Guide

Swegon

Swegon CRTc Guide

Swegon

Swegon CASA PR085LKA User manual

Swegon

Swegon GOLD series Quick start guide

Swegon

Swegon COLIBRI Ceiling b Guide

Swegon

Swegon CASA W100B Programming manual

Swegon

Swegon COLIBRI Ceiling CR Guide

Swegon

Swegon PARAGON Wall c NC User manual

Swegon

Swegon PELICAN Ceiling User manual

Swegon

Swegon PARASOL m X User manual

Swegon

Swegon ADAPT Colibri Guide

Swegon

Swegon PARAGONc User manual

Swegon

Swegon Parasol Zenith VAV 600 Guide

Swegon

Swegon ADAPT Free b Guide

Swegon

Swegon ADRIATIC VAV d Guide

Swegon

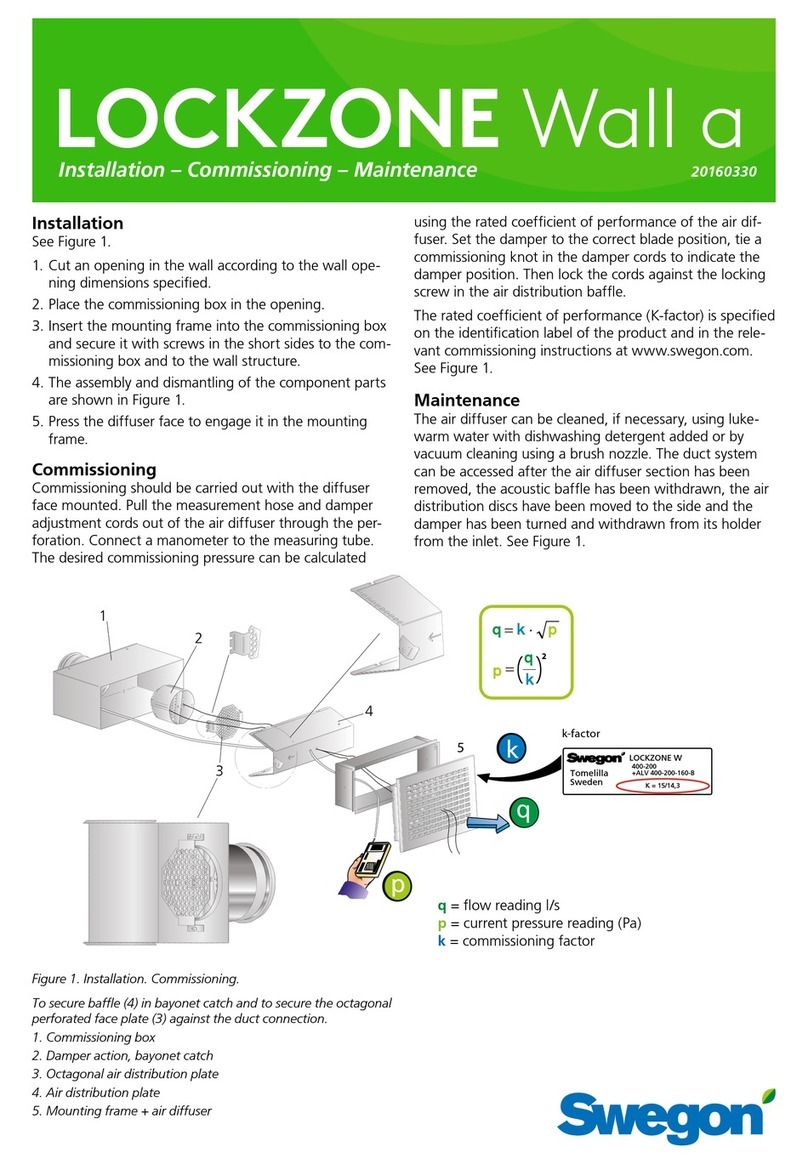

Swegon LOCKZONE Wall a User manual

Swegon

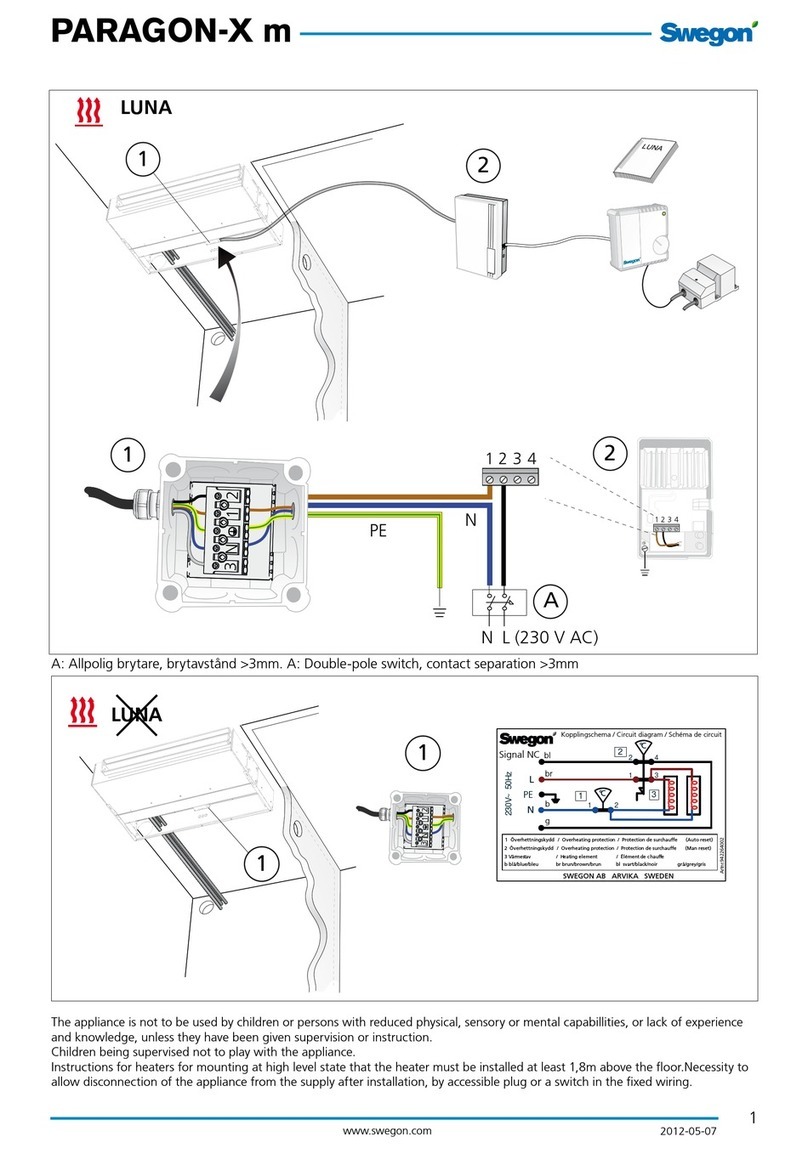

Swegon PARAGON-X m User manual

Swegon

Swegon WISE Kite Ceiling a User manual

Swegon

Swegon SILVER C series User manual

Popular Fan manuals by other brands

ELTA FANS

ELTA FANS H03VV-F installation guide

Hunter

Hunter 20714 Owner's guide and installation manual

Emerson

Emerson CARRERA VERANDA CF542ORB00 owner's manual

Hunter

Hunter Caraway Owner's guide and installation manual

Panasonic

Panasonic FV-15NLFS1 Service manual

Kompernass

Kompernass KH 1150 operating instructions