4

with ExPro-TT thermoelectric activation device

(hereinafter only actuator).

After connection to supply 230V AC or 24V AC/DC the actuator moves the damper leaf to the

"OPEN" operating position and at the same time biases its return spring. As long as the actuator

is energised, the damper leaf is in the "OPEN" position and the return spring is preloaded. The

time for completely opening the damper leaf from the "CLOSED" position to the "OPEN" position

is approximately 30 sec. If the actuator's power supply is interrupted (loss of supply voltage,

activating the temperature sensor or by pressing the reset button on the temperature sensor), the

return spring moves the damper leaf to the emergency position "CLOSED. The time for moving

the leaf from the "OPEN" position to the "CLOSED" position is approximately 10 sec. If the supply

voltage is restored (the leaf can be in any position), the actuator starts moving the damper leaf

again to the "OPEN" position, but only if the temperature sensor has not been activated. The

sensor's temperature activation occurs when the temperature exceeds +72°C. Then the supply

voltage is permanently and irrevocably interrupted and the actuator moves the damper leaf to

emergency "CLOSED" position by means of a pre-loaded return spring.

a) by interrupting and re-applying the supply voltage, e.g. by a signal from the EFS.

b) directly on the built-in damper using the button on the temperature sensor (simulates fuse failure).

Using a special key (supplied with the actuator), the damper leaf can be manually adjusted to any

position and the position secured. Unlocking is done manually with a key or automatically by

applying the supply voltage.

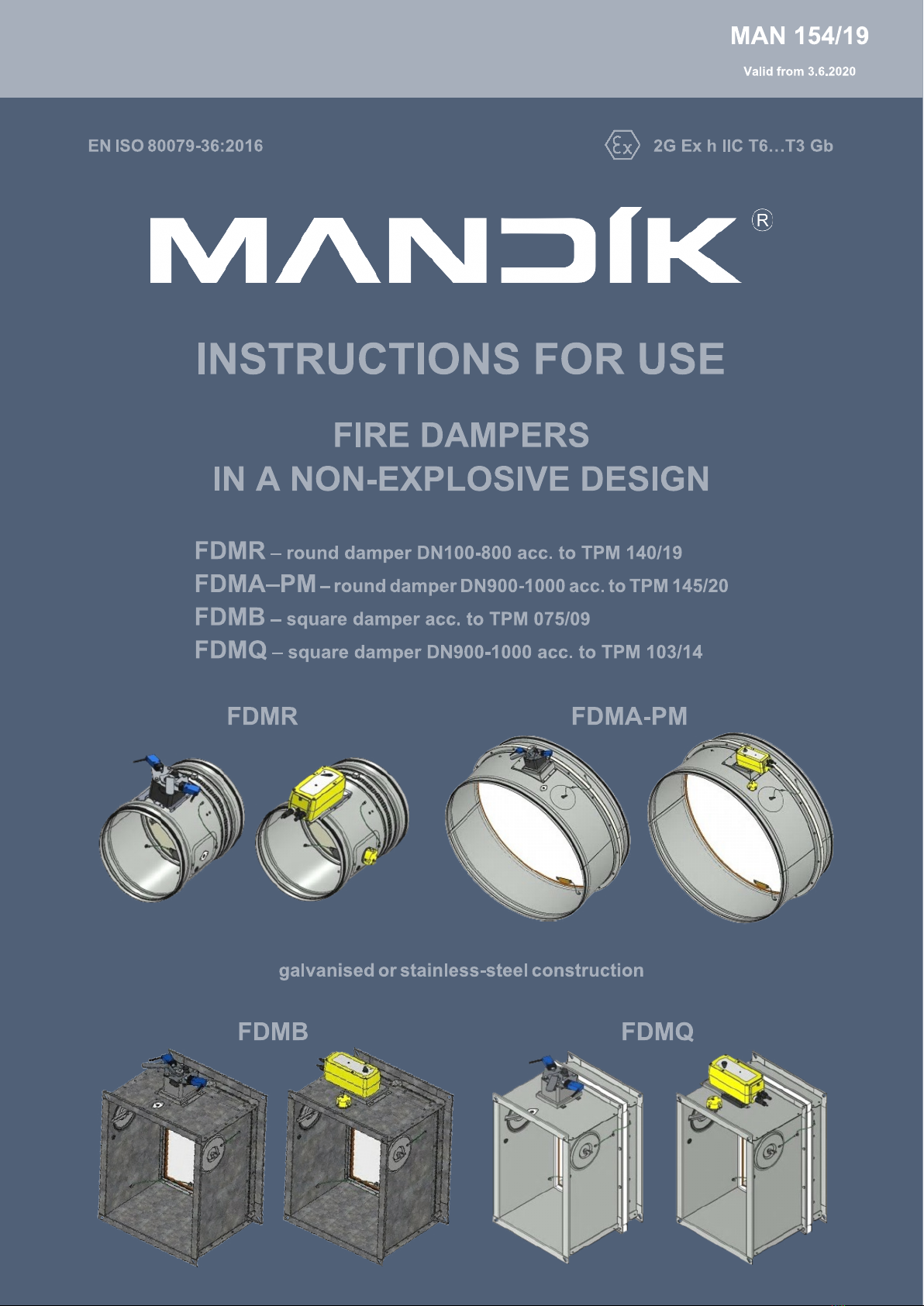

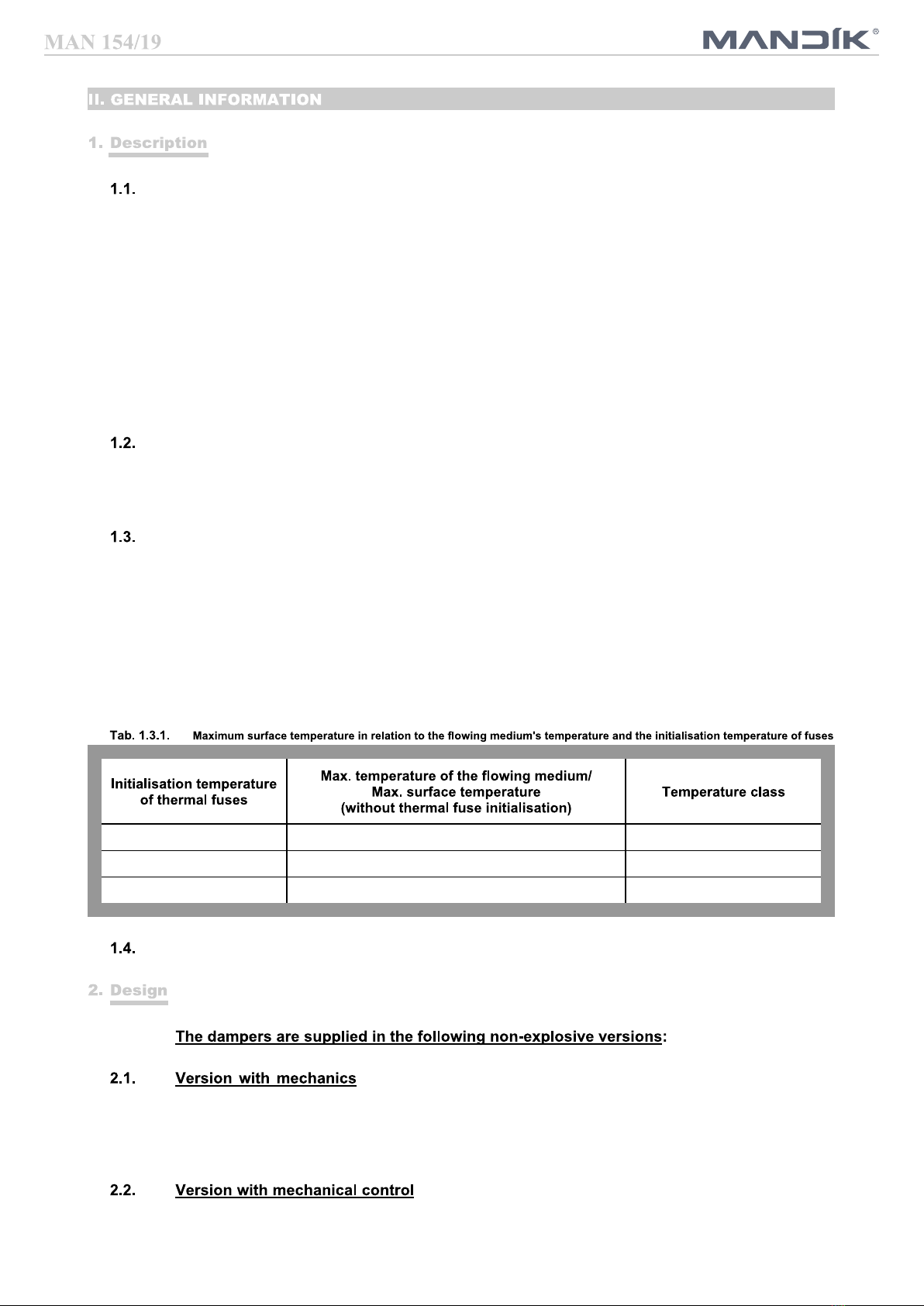

manual and temperature (ZONE 1, 2) .02 II 2G

manual and temperature with limit switch ("CLOSED") (ZONE 1, 2) .12 II 2G

with actuator ExMax-15- BF AC 230V, with thermoelectric activation

ExPro-TT equipment (ZONE 1, 2) .42 II 2G

with actuator ExMax-15- BF AC/DC 24V, with thermoelectric activation

ExPro-TT equipment (ZONE 1, 2) .52 II 2G

Manual and thermal with two limit switches ("OPEN", "CLOSED") (ZONE 1, 2)

.81 II 2G

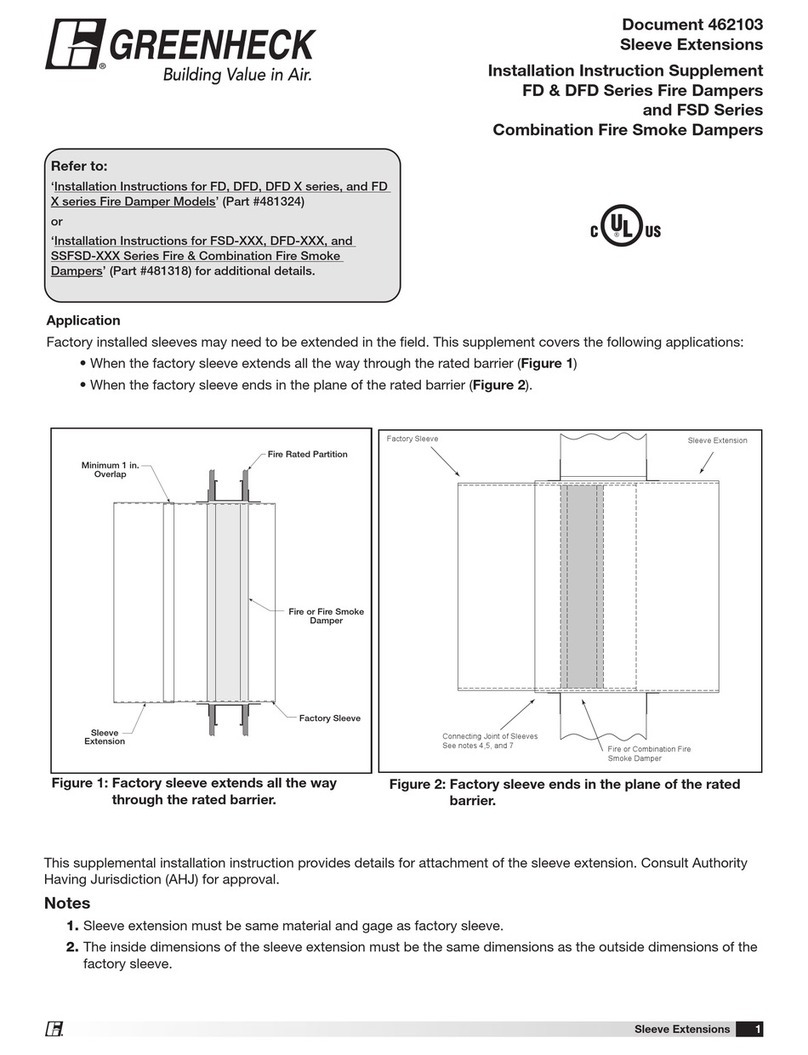

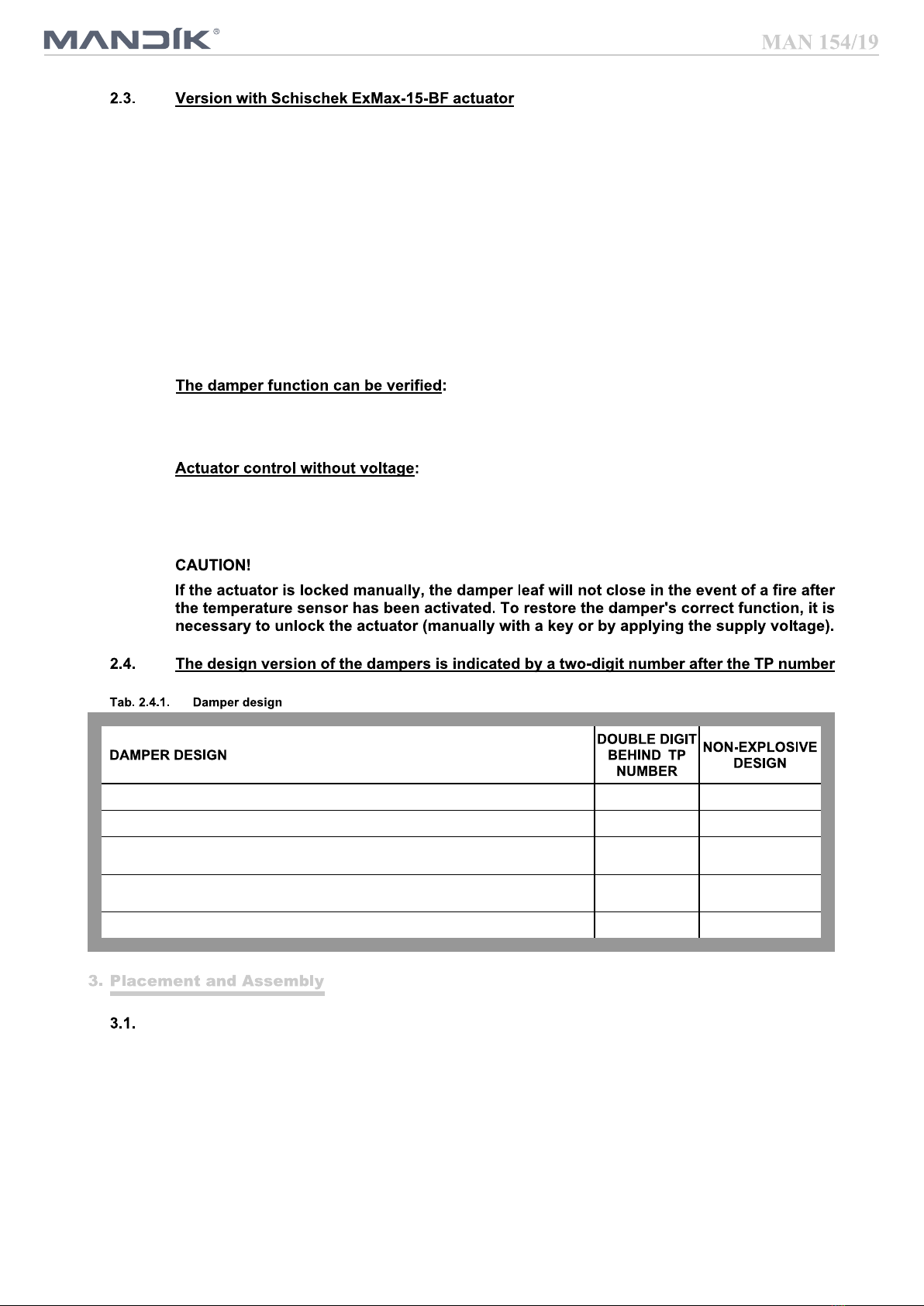

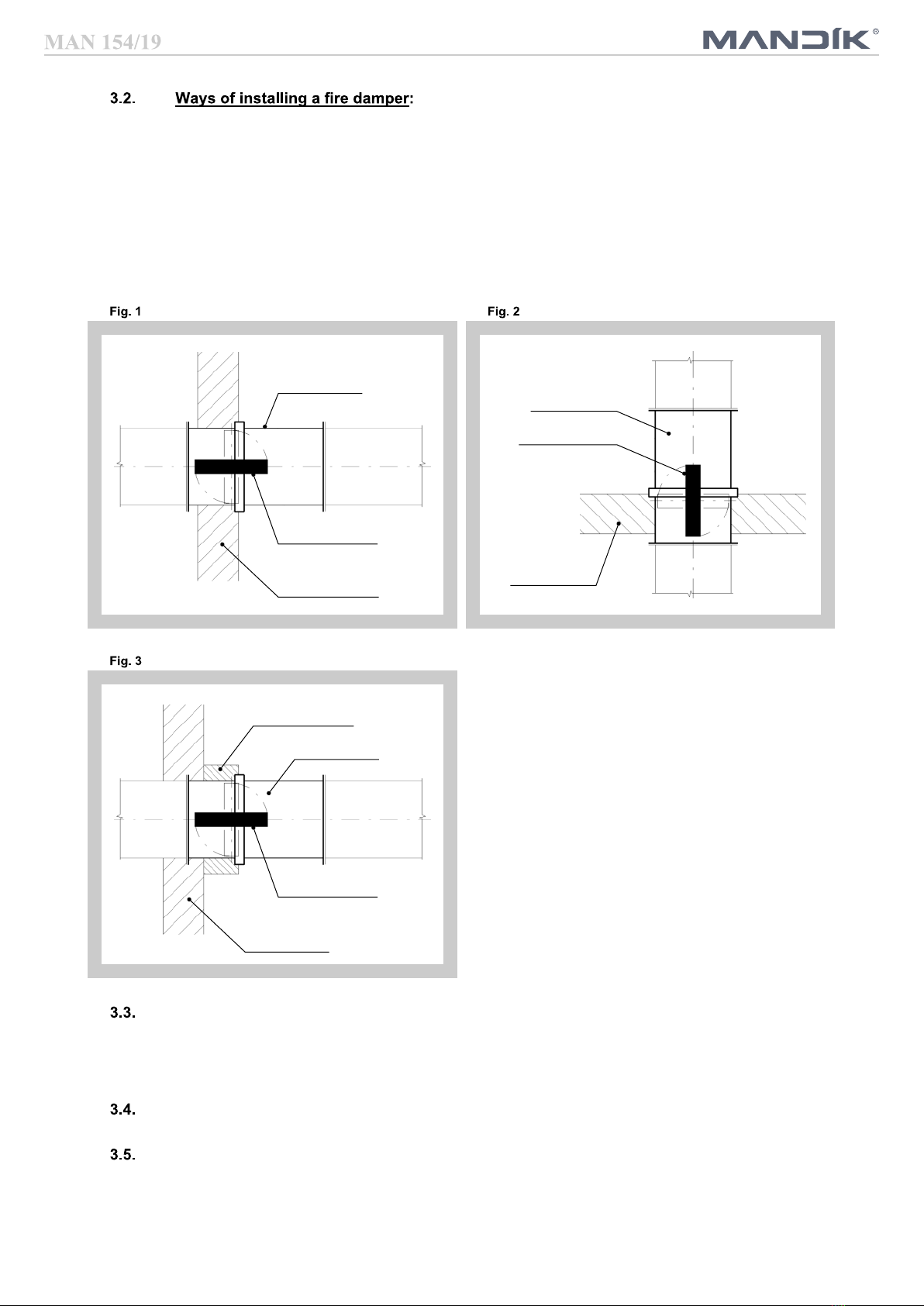

Fire dampers are suitable for installation in vertical and horizontal passages of fire dividing

structures. Penetrations regarding damper installation must be done in such a way that the

transfer of all loads from the fire dividing structures to the damper body is completely excluded.

The adjoining air duct must be suspended or supported in such a way that load transfer from the

adjoining duct to the damper flange is completely ruled out.

To ensure the necessary space for access to the control device, it is recommended that other

objects be at least 350 mm away from the control parts of the damper. At least one inspection

opening must be accessible.

The distance between the fire damper and the structure (wall, ceiling) must be at least 75 mm. If

two or more dampers are to be installed in one fire dividing structure, the distance between

adjacent dampers must be at least 200 mm.