8

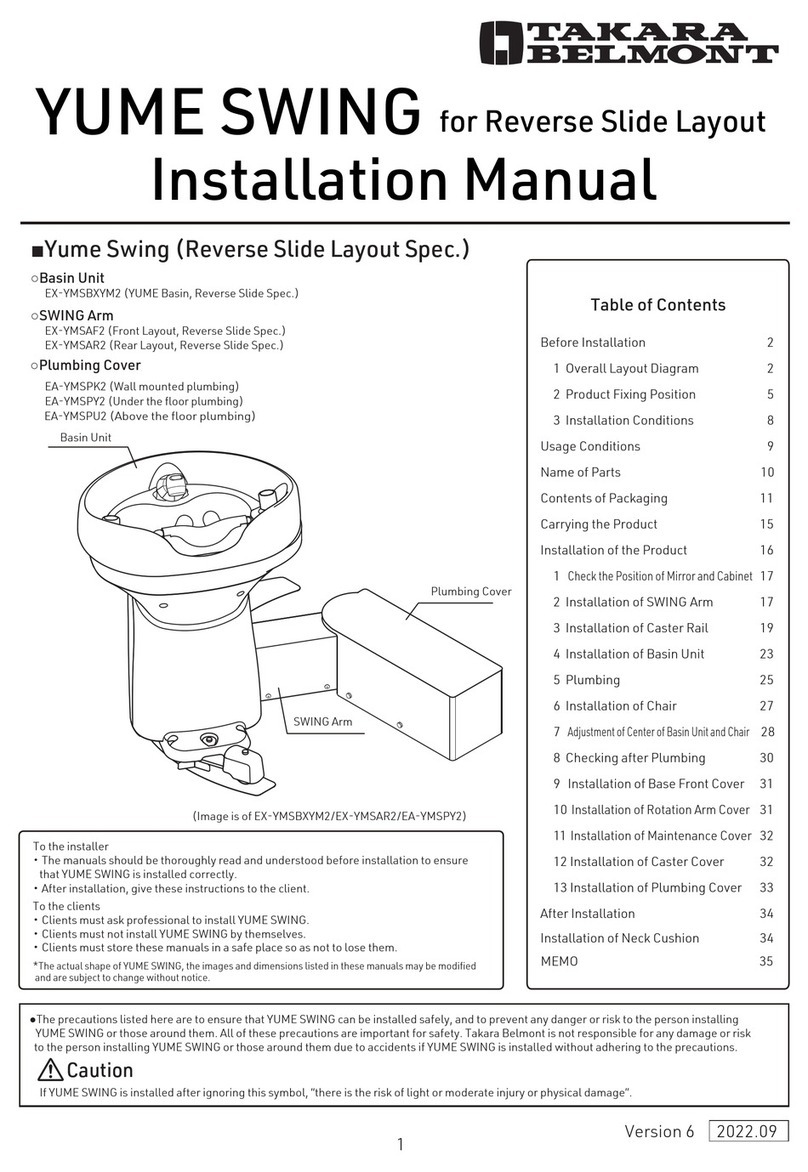

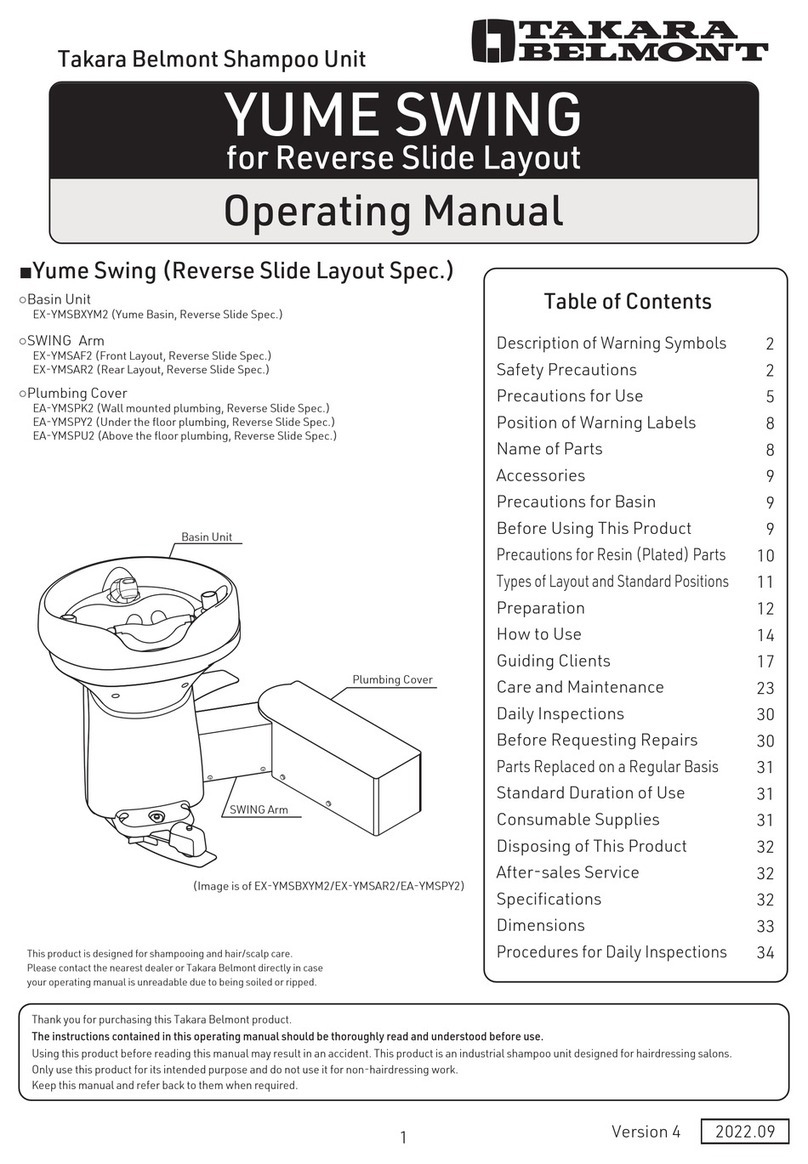

[Pipe specifications] [Height from floor] * Only height H is available for the Back Wash basin

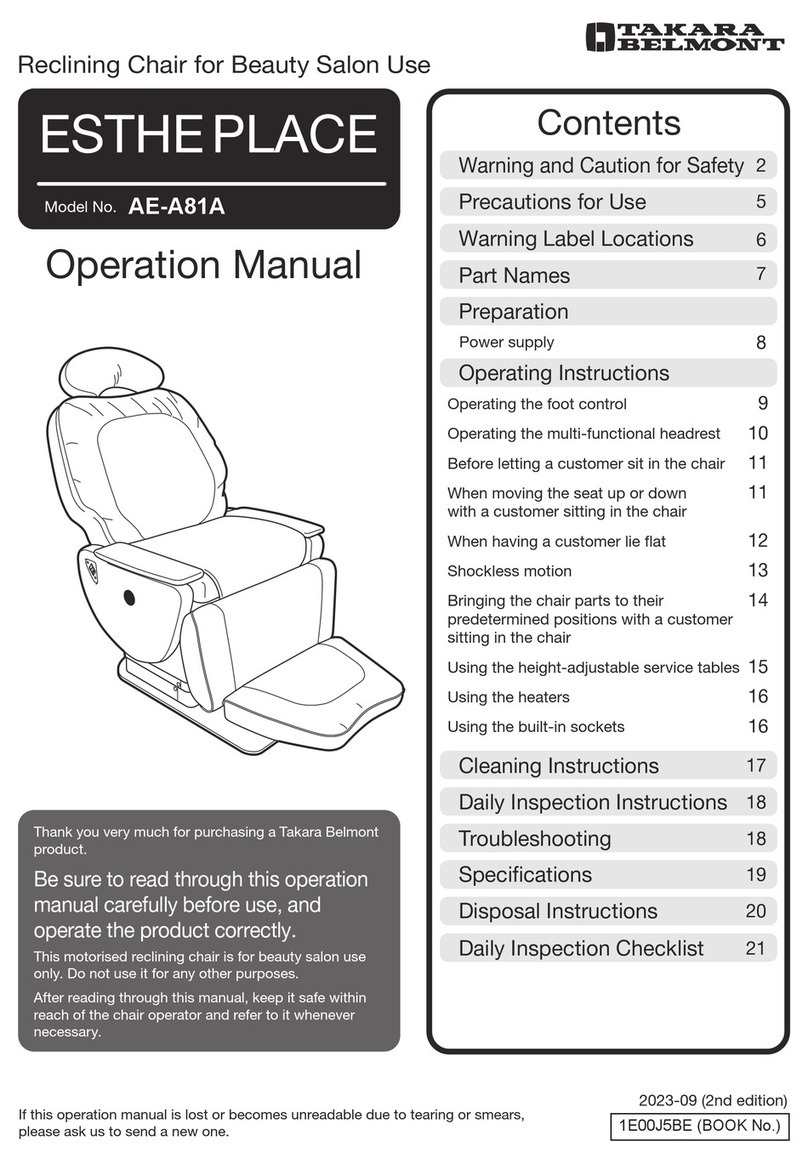

Wooden floor

Mortar floor Mortar thickness of 50 mm or more

Special floor (stone finish)

A foundation with levels of strength listed above around the installation areas is required.

Plywood thickness of 30 mm or more (two 15 mm sheets joined together)

Power

To turn the power on, install the C-4 plug.

When the plug is changed due to a reason related to the customer, install a power plug that is suitable for the product.

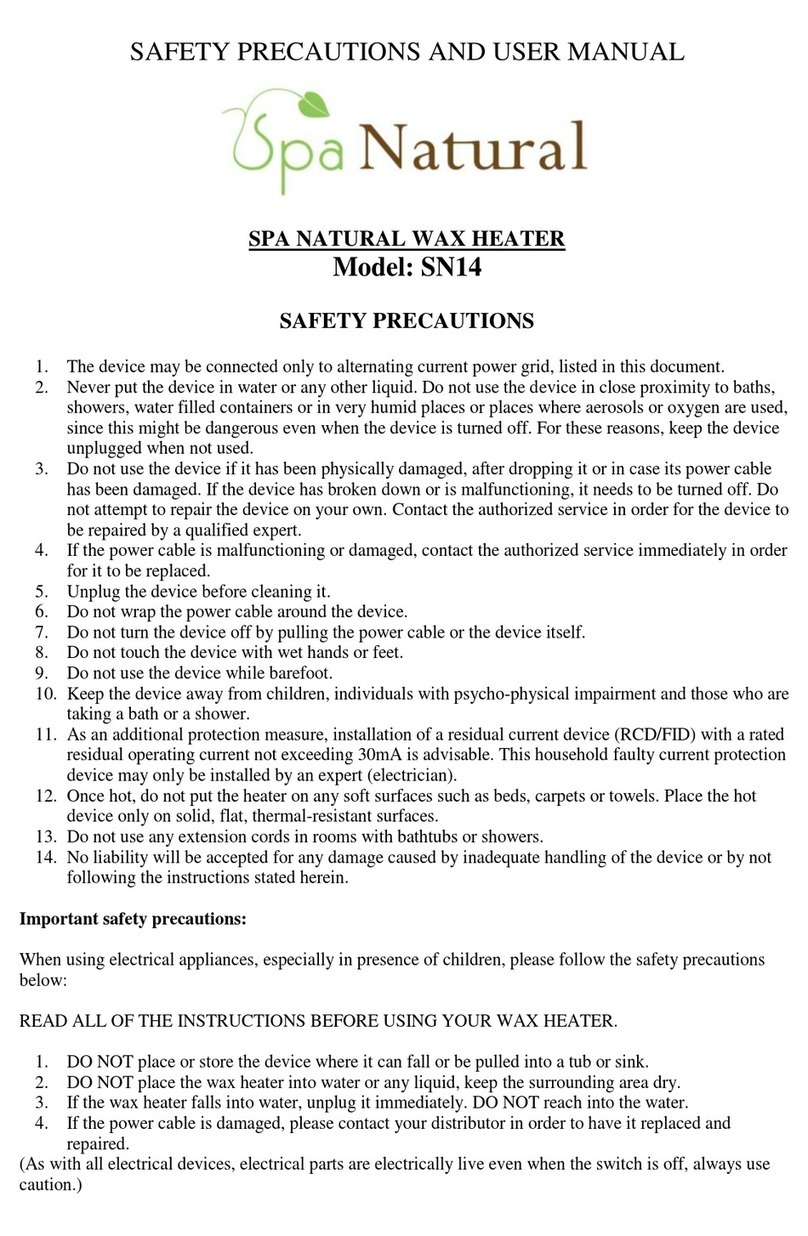

Connecting to ground

To prevent accidents from occurring in the unlikely event of electrocution, and to improve noise resistance within control circuits,

always install the ground designed for this product.

Do not connect the ground cable to any of the following:

Water pipes: any PVC pipes within the plumbing system will prevent a proper ground connection.

Gas pipes: there is a risk of an explosion or fire.

Telephone cables, lightning rods: there is a risk of a large current if there is a lightning strike.

Floor surface

Ensure that the material or finishing of the floor surface is waterproof or has a waterproof coating applied.

Always ensure that the floor surface is horizontally level.

Ensure that the floor surface is smooth and free from bumps around the attachment areas.

Installing pipes

If the floor surface is tiled, cracks may occur when fastening the bolts during installation of this product main body. If this looks

likely to happen, use the main body attachment diagram and template as a reference and change the material of the attachment

area that is in contact with the floor to another such as plywood or mortar.

Take care during installation as the entire base surface of the seat body is not in contact with the floor.

The following levels of strength are required for the floor surface.

Preventing water leakage

If this product is to be installed upstairs, ensure that the installation area has been coated with waterproof materials (waterproof

finish, installation of a stainless steel pan or a water leakage sensor).

Fill the space between the installation area and pipe with caulking materials.

Precaution

Handling power plugs

Check the power plugs are free from dust, and insert the plug all the way to the base so that there is no rattle.

Dusty power plugs or improper connections can cause electrocution or fires.

Handling power cables

Do not subject power cables to excessive forces, modify, twist or bend them.

Power cables can become severed if they are placed under heavy objects or become trapped within tight areas, and can cause

electrocution or fires.

Handling power outlets

Use power outlets for one appliance only, and always connect the ground terminal.

The use of multi-outlet extension cords can generate heat where the power outlet is divided, and can cause fires.

Handling circuit breakers and fuses

Always install a circuit breaker and fuse with the power outlet. Check that the white cable is neutral, and that the circuit breaker and fuse

are connected properly to the neutral side of the power outlet. Installing circuit breakers off users incorrectly can cause electrocution.

Remove the power plug during inspections

Remove the power plug before conducting inspections or adjusting settings within the main body of this product.

Coming into contact with electrical part while the power is connected may cause electrocution.

Drain

Rc 1 / 2“

VU40 / VP40

Hot water supply,

water supply Height specifications

Hot water supply, water supply

Drain

Underfloor pipe specifications

L M H

50 mm

50 mm 75 mm 100 mm

75 mm 100 mm

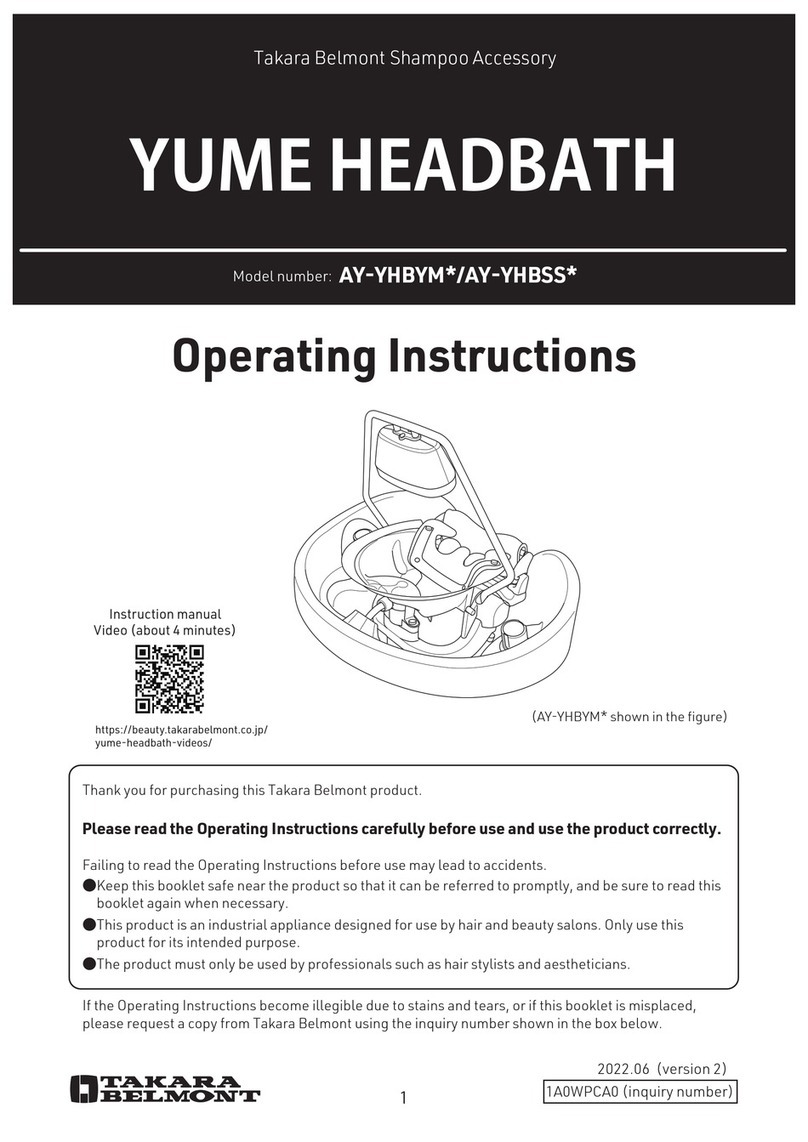

[Rated current]

110V Specifications

220V Specifications

230V Specifications

240V Specifications

[Rated frequency]

50/60Hz

50/60Hz

50/60Hz

50/60Hz

[Rated electricity consumption]

4.3/2.8A

1.7/1.6A

1.9/1.6A

2.1/1.7A