10

→

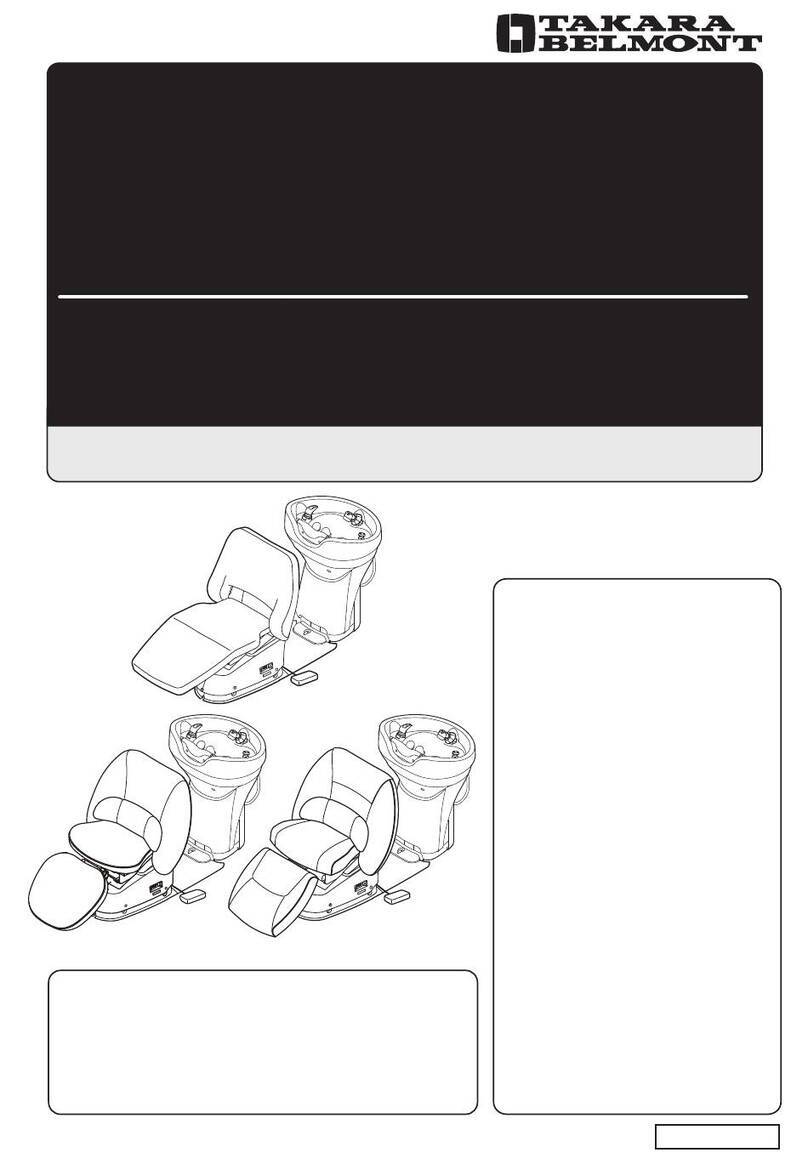

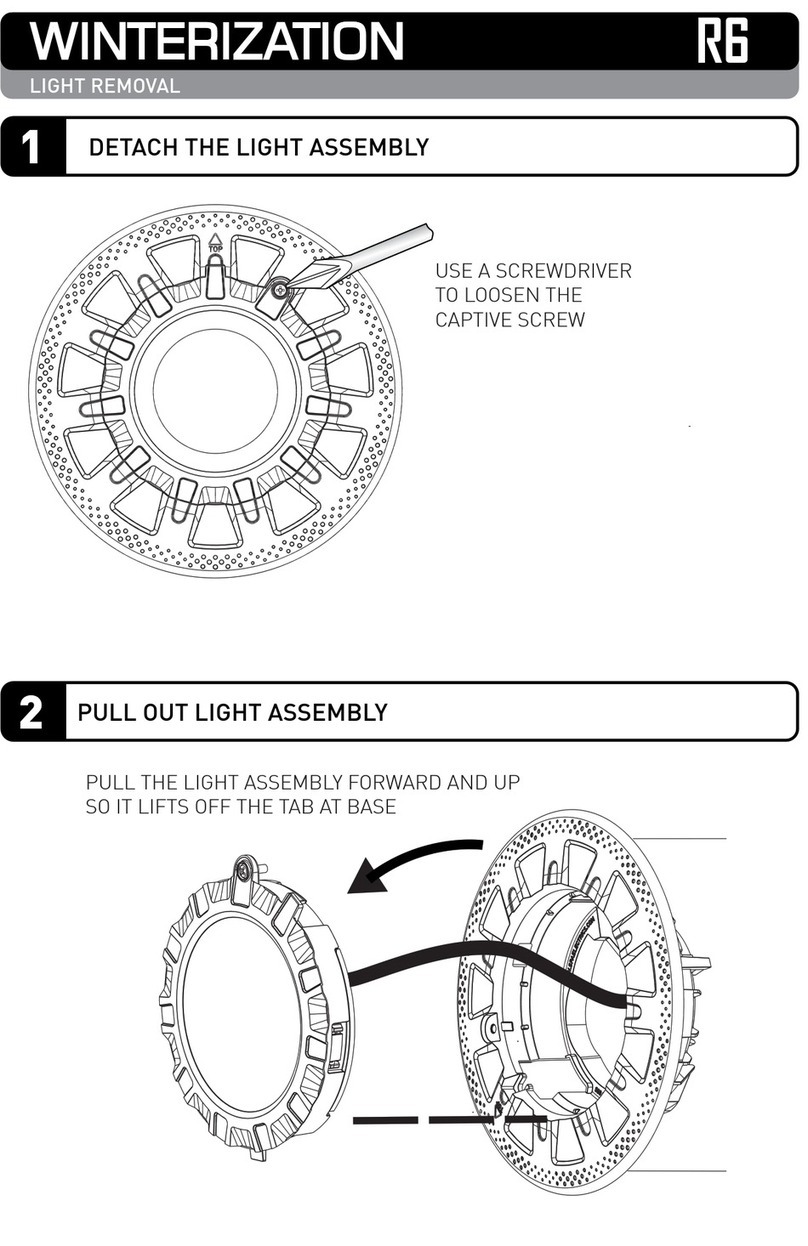

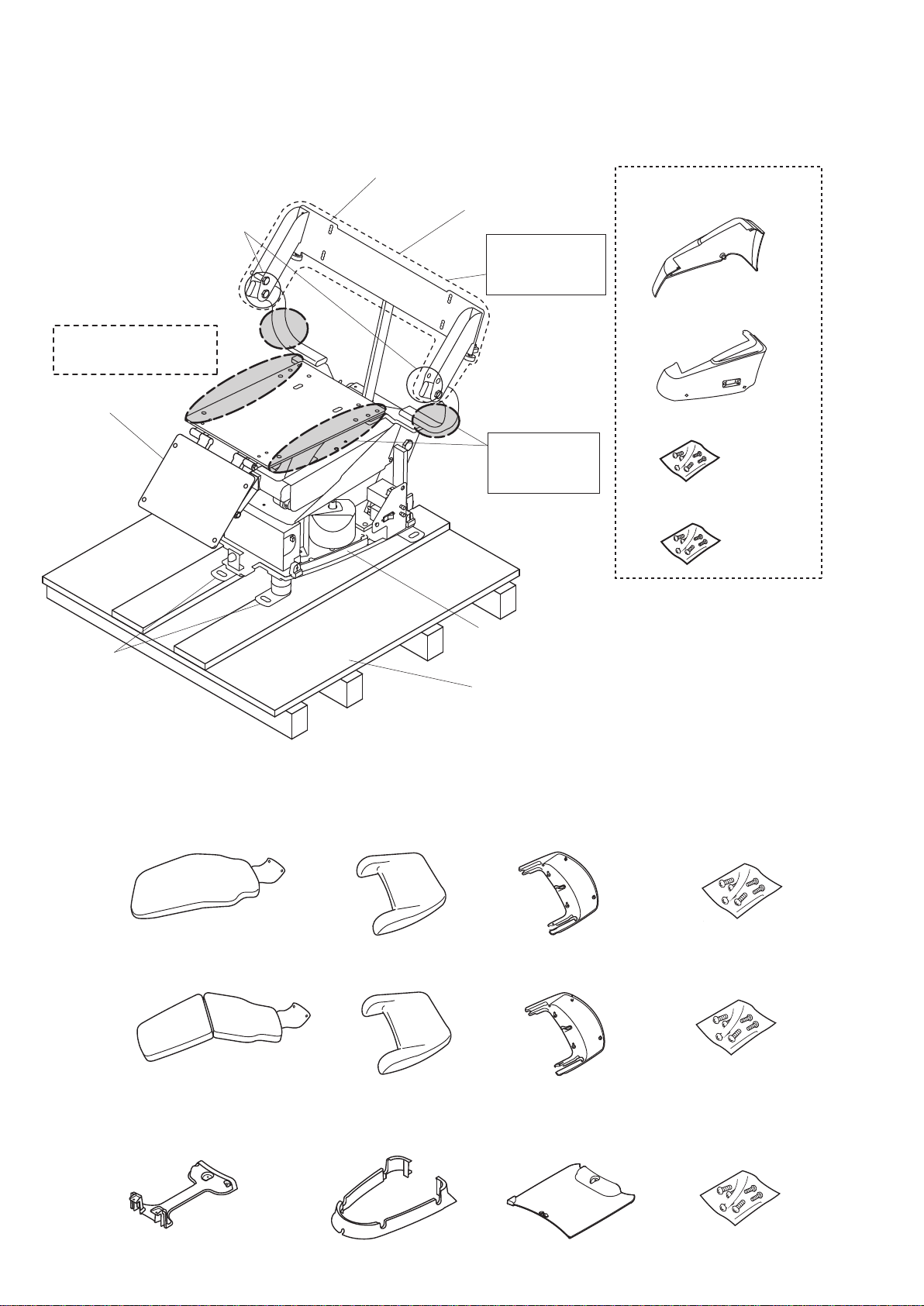

2 Attach pipe packing

(1)

Cut a slit in the pipe packing to suit the position of the pipes to be installed.

(2) Peel away the sheet from the adhesive surface of the pipe

packing and stick to the floor surface.

(3) Cut out a circle around the slit cut in the pipe packing to suit the

pipe surface, and fill in any gaps with caulking materials.

3 Install the basin

(1) Hold the stepped section at the bottom of the basin, align it with

the hole position that was opened previously, and install the basin.

* If the power cable (for installation) is being installed from the water

supply pipe and drain pipe area, pass the cable through the gap in the

center of the base and through to the seat side.

(2) If the pipe packing is trapped under the basin (base), move the

basin away temporarily and cut the pipe packing that is trapped.

(3) Attach the basin with bolts (anchor).

Adjust the basin so that it is not installed at an angle.

Precaution

•

Always attach pipe packing and apply caulking materials to the areas around

the pipes so that there are no gaps, in order to prevent condensation within

YUME ESPOIR or water seeping on the floor in the event of water leaks.

•

If pipe packing is not used, condensation may cause water to pool on the

floor, structural parts may start degrading and malfunctions may occur.

•

If the power cable (for installation) is to be installed from the water supply pipe and

drain pipe area, apply caulking materials to any gaps in the same way as above.

Precaution

Do not pull the basin when attempting to move it. Doing so may

damage the floor.

Precaution

Ensure that the power cable (for installation) is not trapped by the

base. Doing so may cause fires, electrocution or angled basin.

Precaution

The basin may be installed at an angle, or may even topple over if the

basin (base) is attached with the pipe packing trapped underneath.

Pipe packing

(sponge)

Cut a slit

* Attach pipe packing

* Apply caulking materials to any gaps

* If the power cable (for installation) is being installed

from the water supply pipe and drain pipe area,

pass the cable through to the seat side.

(able must be 1300 mm or longer from the installation

position)

Power cable (for installation)

* Only when installing from

the water supply pipe and

drain pipe area

Gap

Base

Pipe packing

Basin body

* Hold the stepped

section at the

bottom of the basin.

Installation process for anchor bolts

Precaution

•

The strength of the anchor bolts will be reduced if they are hammered into the hole while touching the bottom. Open up a gap.

• When installing anchor bolts, insert them so that there is 2 to 5 mm of the threaded section of the head protruding. If the

bolts are inserted with more than 5 mm protruding, the head may interfere with the cover.

(1) Drill open a hole of the

specified diameter and

depth.

(2) Remove the dust from each

anchor hole by cleaning

with a vacuum cleaner.

(3) Insert the anchor bolt and

tap it with a hammer until

the center pin makes

contact with the base plate.

(4) Adjust the fastening

strength of the nut

using a wrench.

Floor

Supplied

template

8.5 mm

Hole depth

50 mm or

more

Nut

Flat washer

Center pin

2 to

5 mm