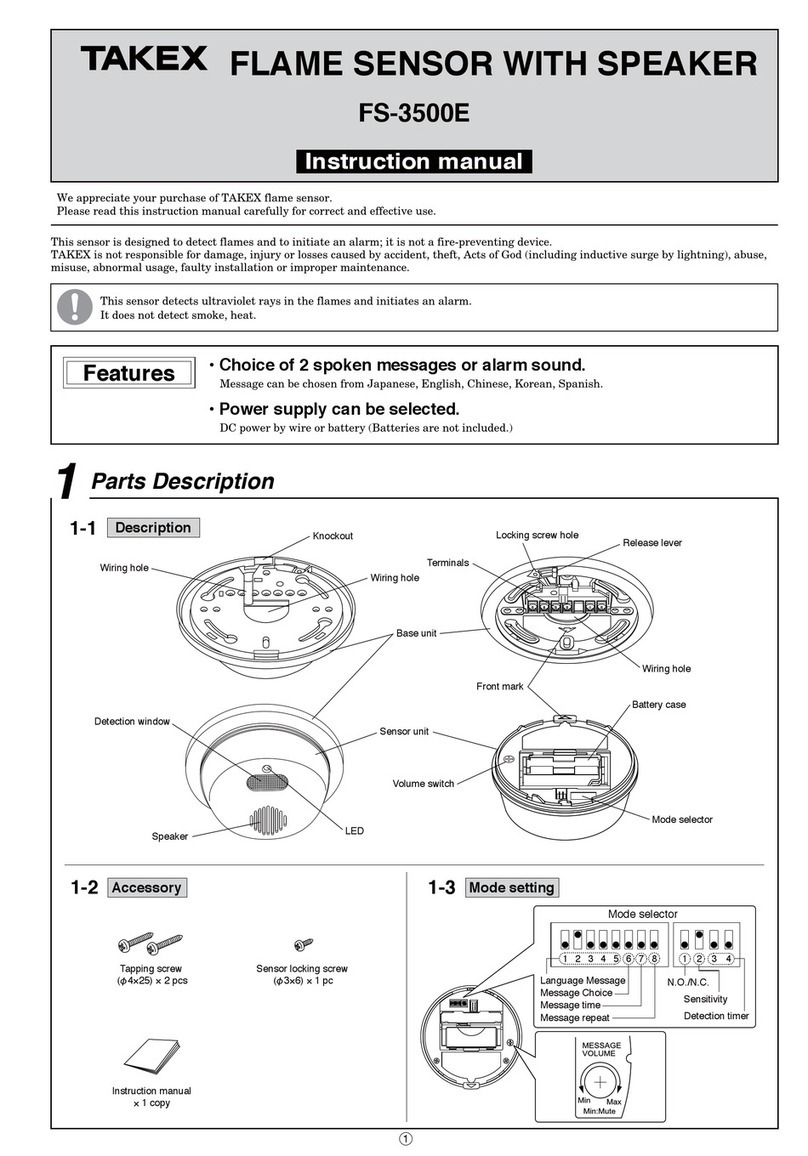

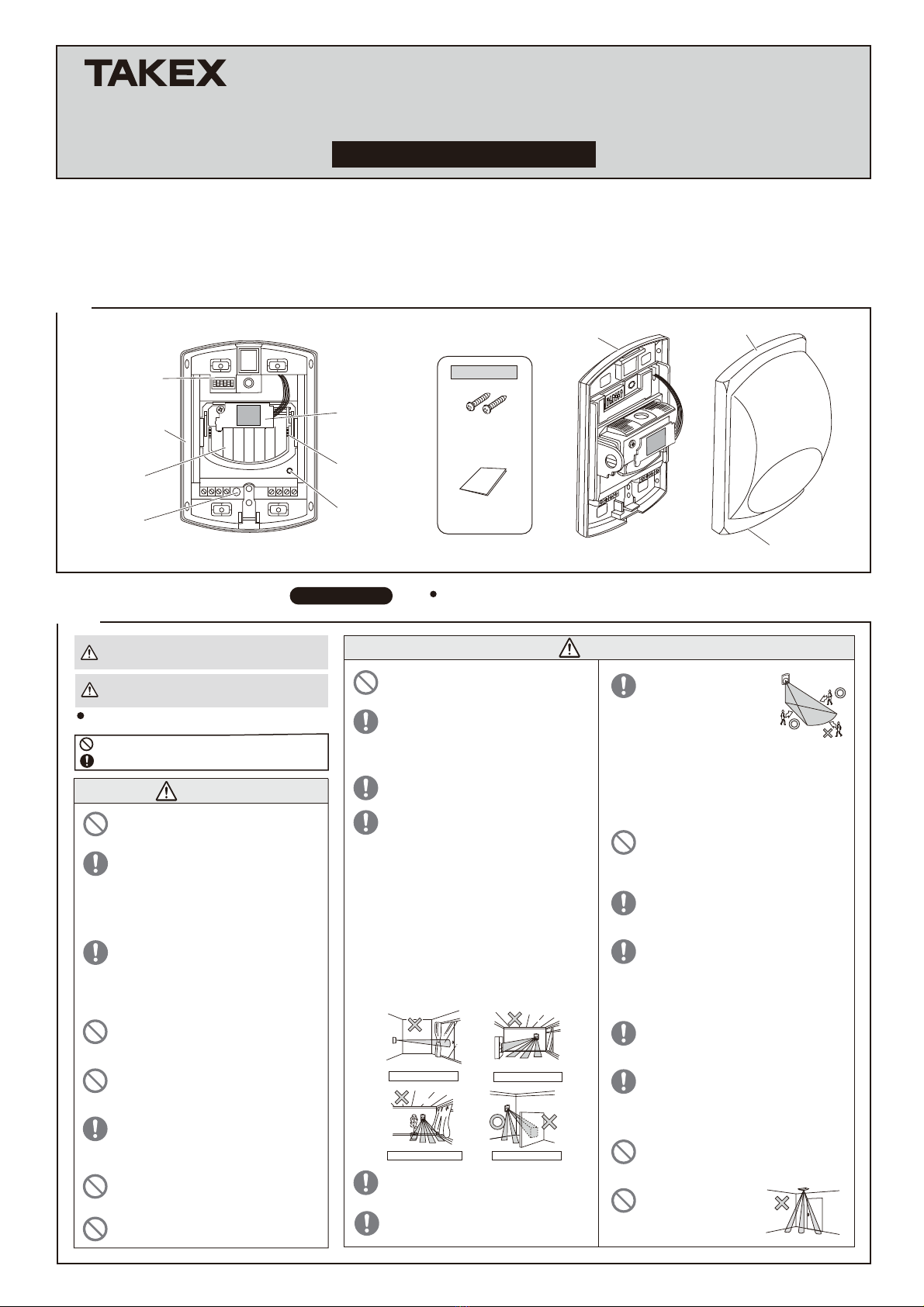

MODE SELECTOR Accessories

Instruction manual

: 1 pc

Self-tapping screw

(ø4 x 30)

: 2 pcs

HORIZONTAL

ADJUSTMENT

WIRING CHANNEL

BASE

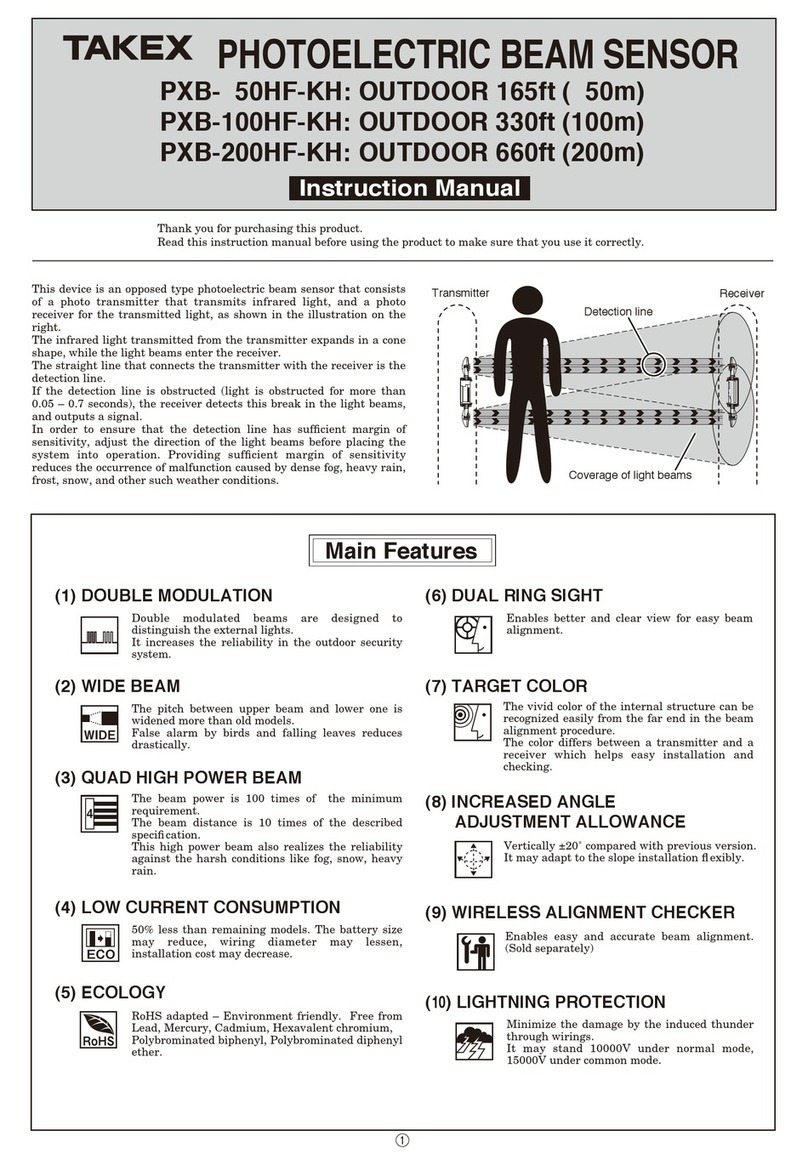

1PARTS DESCRIPTION

Instruction Manual

PASSIVE INFRARED SENSOR

PA-4810E ・PA-4820E

(WIDE ANGLE) (LONG RANGE)

ALARM LED /

MEMORY LED

(Red)

COVER

MIRROR UNIT

HEAD UNIT

COVER LOCKING SCREW

TAMPER SWITCH

We appreciate your purchase of a TAKEX passive infrared sensor. This sensor will provide long and dependable service when properly installed.

Please read this Instruction Manual carefully for correct and effective use.

Please Note : This sensor is designed to detect intrusion and to initiate an alarm ; it is not a burglary-preventing device.

TAKEX is not responsible for damage, injury or losses caused by accident, theft, Acts of God (including inductive surge by lightning),

abuse, misuse, abnormal usage, faulty installation or improper maintenance.

Caution

Plants/Curtain

Refrigerator

Shielding objects

Warning

2PRECAUTIONS Be sure to observe

We categorize these precautions throughout the manual using

the following symbols.

Warning

Caution

An action you must do, and information you should keep in mind

A prohibited action, you must not do.

Facing the window

This manual describes precautions by classifying them based on degrees of danger and

damage that would be generated if using the unit incorrectly.

This indicates the possibility of severe injury, and

even death, if ignored or a user handles the unit

incorrectly.

This indicates the possibility of minor injury and/or

damage to properties, or of a notification delay in your

system due to false operations and/or non-detection, if

ignored or a user handles the unit incorrectly.

Mount the unit on a solid ceiling or wall surfaces

where reinforcement materials are used. If you

mount the unit on non-wood materials of plaster

board or concrete, securely mount it using

anchors and mounting screws that match the wall

materials. Unstable mounting may result in injury

and/or property damage if the unit falls.

Do not disassemble or modify this device. This

may cause a fire, electrical shock, or malfunction

of the device.

If the following events occur, turn off the power of

the unit immediately, and ask the place of

purchase for repair. Failure to follow this may

result in fire, electric shock, and/or malfunction.

• Smoke, abnormal odor, and/or sound are found

• Liquid, such as water, and/or foreign material

has entered the unit

• The unit has deformed and/or damaged parts

Do not apply impact to the unit.

Strong impact may result in performance

deterioration and/or damage to the unit.

Make sure to perform a sufficient operation

check on the whole system before operation.

Make sure to check operation when you move

tables and partitions and change the layout in

protected rooms.

Refer to the protection area figures, and select

the installation location. Then, check the actual

operation, and adjust the appropriate area.

The unit may not operate properly near devices

that generate a strong electric or magnetic field.

Also, devices near the unit may not operate

properly due to the magnetic field and/or

magnetism generated from the unit.

Make sure to confirm before operation.

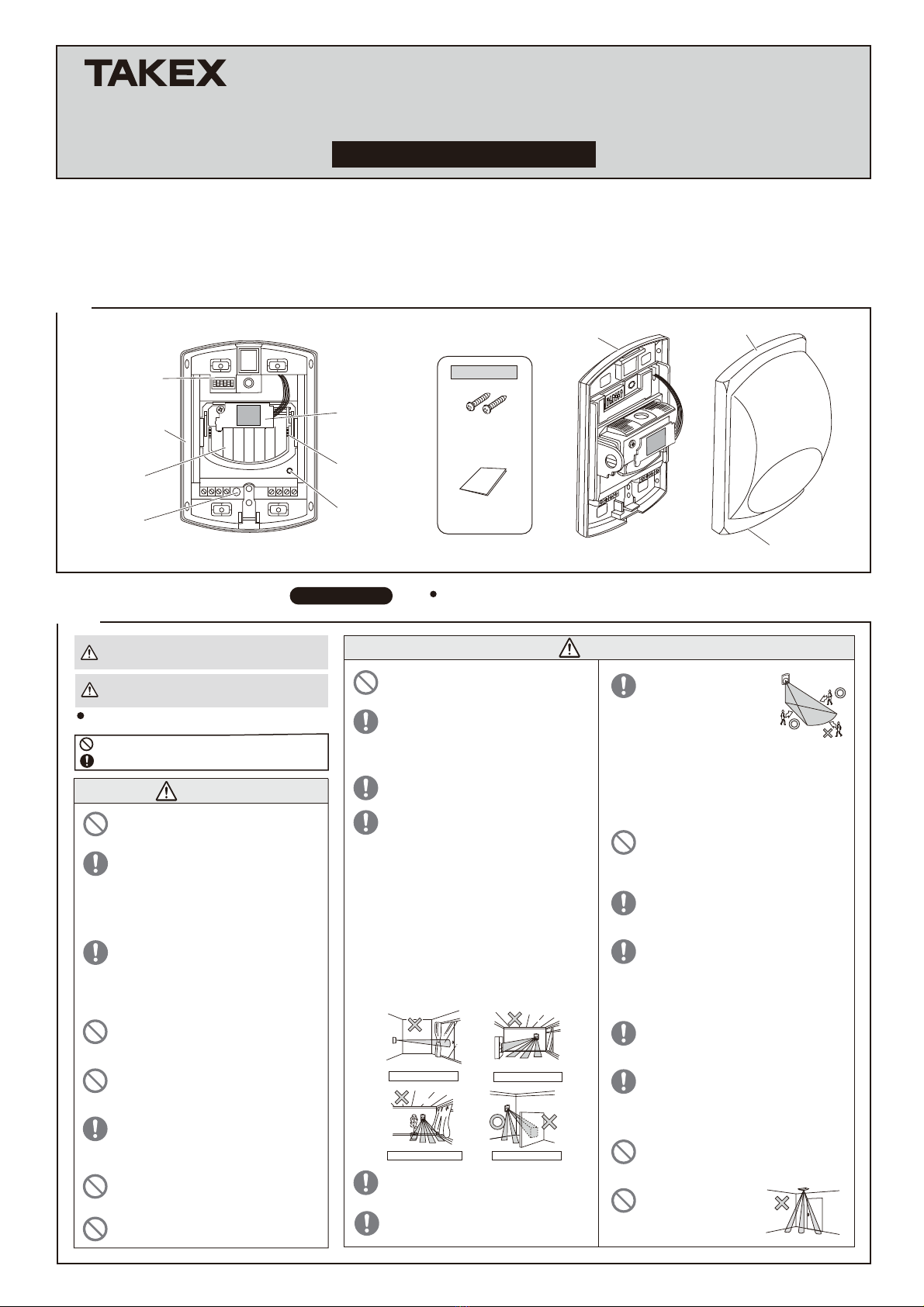

Avoid installing the unit in the following places.

Otherwise, non-detection and/or false detection

may occur.

• Places subject to strong direct or reflected light

(sunlight,spotlight)

• Places subject to rapid temperature fluctuations

(air outlets of air-conditioning equipment, etc.)

• Places where moving objects are included in

the protection area (plants, laundry, etc.)

• Places subject to strong vibration and/or

electric noise

• Places where pets, such as dogs and cats,

and/or automatic cleaning robots may pass

• Places where shielding objects (including glass

and transparent resin, etc.) are included in the

protection area (shading parts will not be

detected)

• Places that people can easily touch.

Passive infrared sensors are

designed to catch changes of

far-infrared ray energy.

Energy changes largely when

the human body moves

across the protection area,

which is easy to detect.

However, energy does not change greatly

when the human body comes closer in a

straight line, or stops, which may be difficult to

detect. In addition, if the protection area

environment generates similar changes due to

certain factors, the unit will set off an alarm

without being able to judge properly.

Do not install the unit in places subject to oil

smoke or steam, high humidity, and/or a lot of

dust.Electricity that travels through these

substances may result in fire, electric shock,

and/or false operation.

Securely conduct installation work according to

the instruction manual.

Also, make sure to use the supplied

accessories and specified components.

Failure to follow this may result in injury and/or

property damage in the event of fire, electric

shock or fall of the unit.

This unit is not a waterproof (moisture

proof/rainproof) or dust-proof structure. Do not

use the unit in places subject to water and/or

high humidity, such as bathrooms, and/or

subject to large amounts of dust or sand.

Failure to follow this could result in malfunction.

Ask qualified personnel for any electrical work

necessary for installation, if required.

Failure to follow this may result in fire and/or

electric shock.

Do not touch terminals with wet hands. Failure to

follow this may result in electric shock.

Do not connect devices that exceed the indicated

capacity to the output contact of the unit. Failure

to follow this may result in electric shock, fire,

and/or malfunction.

Use the sensor lock to fix the sensor unit for

operation.

This can prevent injuries, and/or damage to the

unit if the unit falls, as well as prevent the sensor

from being tampered.

Do not use the unit with power voltage levels

other than those specified. Failure to follow this

may result in fire, electric shock, and/or

malfunction.

Do not install this device in a location that cannot

support its weight. This may cause the device to

fall and cause an injury or malfunction of the

device.

This unit is for indoor use. Do not use the unit in

places subject to water and/or high humidity.

Failure to follow this may result in malfunction if

water gets into the unit.

Do not perform aerial wiring of power and signal

cables.

Failure to follow this may result in electric shock,

fire, and/or malfunction.

Do not install the sensor

directly on the ceiling

(When installed on ceilling,

use optional attachment

BCW-401)