③

4COVERAGE

5INSTALLATION

【Terminal arrangement】

Power (non-polarity)

9V to 30VDC 30mA

POWER COM N.C. TAMPER

Tamper (N.C.)

Opens when cover is detached

Alarm

Dry contact relay (N.C.)

Turn round when an alarm is initiated.

Capacity : 30V (AC/DC) 0.1A or less

Reset : approx. 2 sec.

【Allowable wiring distance between sensor and power source】

Size of wire used

AWG 22 (φ0.65mm)

AWG 20 (φ0.8mm)

AWG 18 (φ1.0mm)

Distance at 12VDC

250m (830 ft.)

450m (1460 ft.)

700m (2300 ft.)

The maximum wire length, when two or more units are

connected, is the above distance divided by the number of

units.

The protection circuit can be wired to a distance of max.

1,000m (3,300 ft) with AWG 22 (φ0.65mm) wire.

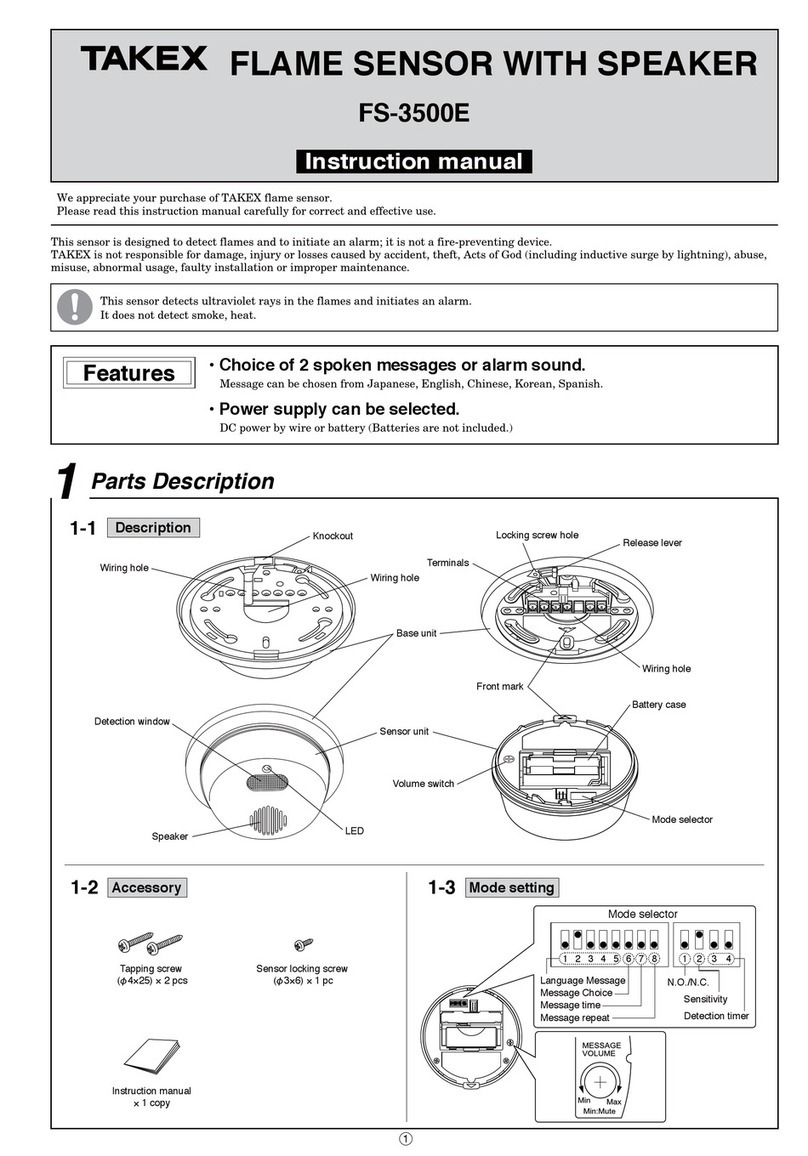

【Horizontal direction】

Use the Microphone holder to set a coverage that corresponds to

the installing position. (Adjustable by 40º)

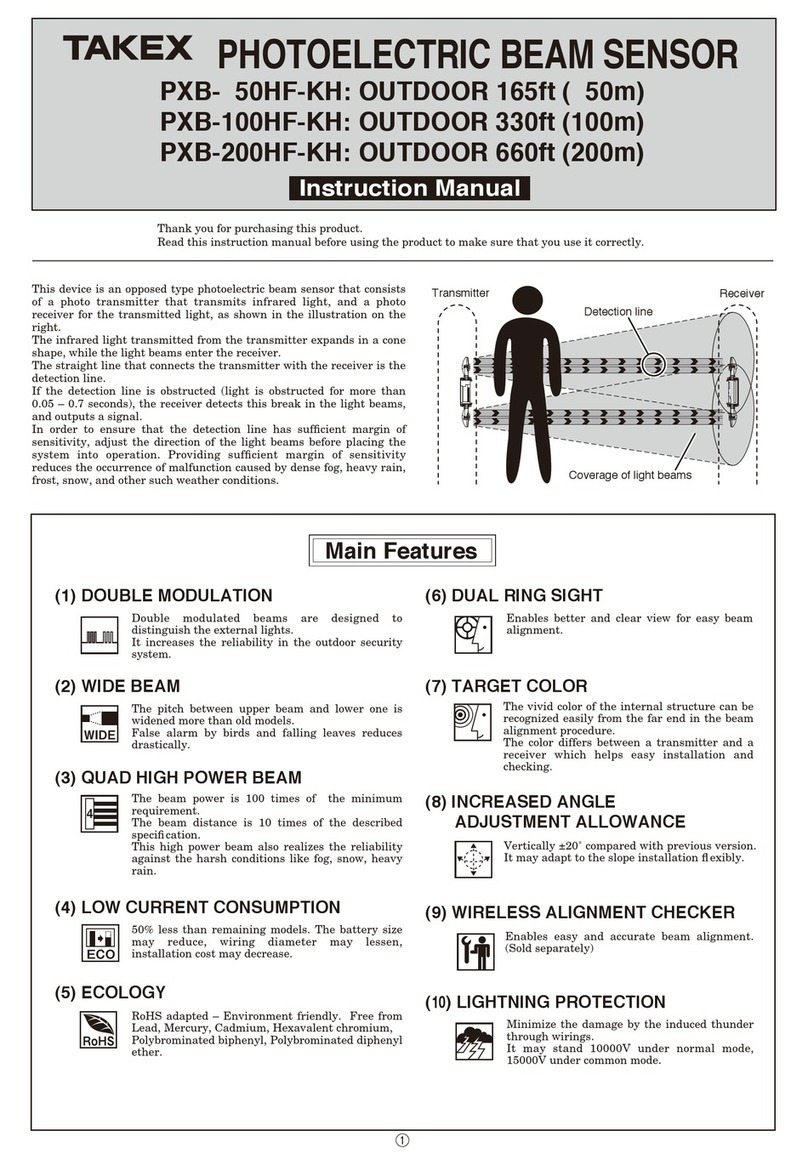

(1) Installation

(2) Wiring

(3) Area setting

*The coverage indicated in the diagram does not

have surrounding walls or other objects that

would reflect ultrasonic waves, and the sensitivity

volume is turned all the way to H.

*Install the sensor so that sensor coverage could

cover all surface of protected window. For

reference, glass surface to be protected is 5m or

less square.

*Confirm the install position of the sensor and the

position of the surface of protected window.

Determine the optimal area angle, and use the

Microphone holder inside the sensor to set it.

Loosen cover locking screw to detach cover.

Check protection direction and install base on wall.

*Break knockouts and attach sensor with supplied

screws.

Connect as per wiring diagram 5. (2).

Set coverage and check operation.

Refer to 5. (3) Area setting and 6.

Operation check.

Replace cover and tighten cover locking

screw.

Rotate Microphone holder

to set area direction to

center of protected glass.

80°

(Area adjustable range)

[TOP VIEW]

6m [20ft]

3m [10ft]

3m [10ft]

6m [20ft]

4m [13ft]

3m [10ft]

3m [10ft]

4m [13ft]

8m

6m3m

[20ft][10ft] [26ft]

[SIDE VIEW] 8m

[26ft]

6m

[20ft]

3m

[10ft]

2 pitches 76mm (3") or

83.5mm (3.29") are available

for mounting hole.

Mounting hole.

Knockout

(Break with slender-driver)

Mark pitch by 10°

Microphone

holder

Center Direction of

area

⑤

①

②

③

④

Note 1)

2)

( )

6OPERATION CHECK

7OPERATION DESCRIPTION

EG-2000 operation

(Output selector "L")

Alarm generating sound

(EG-2000 operation Output selector "H")

Other device

activation

High sens.

47min. ON

3min. flashing

Low sens. Good sens. Success in noise test

Adjustment completed.

Environmental LED (Orange)

Environmental LED (Orange)

Alarm LED (Red)

Alarm output

Alarm LED (Red)

Alarm output

approx. 2 sec.

【Check mode】

Select "Check" mode for operation check and sensitivity adjustment.

In this mode, both environmental LED (Orange) and alarm LED (Red) activate.

【Operation mode】

When the unit has been activated the Alarm LED will flash for 3 minutes, and then it will remain constantly lit for

47 minutes.

This will enable identification of triggered devices in a multiple use scenario.

This can be manually reset either by interrupting the power supply or by switching the unit to "Check" mode, (please

note removal of cover will initiate tamper alarm).

Tamper function

This function is for detecting tampering or intentional removal of the cover. It detects the removal of the cover from the sensor

unit and outputs an alarm.

It is reset if the cover is returned to its original position, but check the operation of the sensor immediately if this situation

For precise operation, use EG-2000 (sold separately), and perform the following operation and sensitivity checks.

* Follow the EG-2000 instruction manual when performing these checks.

While checking that the sensor environmental LED lights ON, check the range of

the coverage and the optimal sensitivity.

Set the internal output switch of the EG-2000 to L for use.

①Supply power to the sensor with its cover removed, and select "Check" mode

with the mode switch.

Refer to 7. Operation description.

②First, begin activation by pressing the EG-2000 Send Button

near the sensor. Ensure that both the alarm LED (Red) and

the environmental LED (Orange) of the sensor are lit.

③From the surface of protected window, point the wave transmission part of the

EG-2000 at the sensor. Operate the equipment and check the sensitivity. Check

the sensitivity of the sensor at all positions at the surface of protected window.

Note: Some positions where light is reflected from ceilings, walls, and floors

make detection difficult for the EG-2000. Shift the position of the unit

slightly to the left or right. If only the environmental LED of sensor lights

ON, the sensor sensitivity is normal.

④Operate the sensor from the furthest point of required protection. Sensitivity is

correct when just the environmental LED lights. If neither alarm LED or

environmental LED light, then sensitivity is too low. If the alarm LED also

lights, sensitivity is too high. If sensitivity is not optimal in certain locations,

check the coverage again or adjust the sensor sensitivity by the sensitity volume.

⑤

If there is a possibility of sound or noise within

the same room, whether within or outside the

coverage, make some sound or noise and check

to make sure that the Environmental LED does

not light up. If it lights up from some sound or

noise, change the install position, or increase

the number of sensors, giving them each a

smaller range of coverage and lower sensitivity.

⑥After checking the sensitivity, set the mode

switch to operation mode, and then replace

the cover and tighten the cover lock screws.

①

Set the sensor mode

switch to Operation mode,

and check the operation of

the alarm.

②

From within the coverage

of the sensor, point the

wave

transmission

part of

the EG

-2000 at the sensor,

and operate by pressing

the send button. If the

sensor alarm LED is lit,

the operation of the sensor

alarm is correct.

Check the operation of the installed sensor.

Use for daily sensor operation checks and

during inspection ONLY.

Set the internal output switch of the EG-2000

to H for use.

Note: 1) A glass jar/bottle containing metal

coins can be used as a substitute for

the EG-2000.

Using 7 or more coins in a strong

sealed glass container, the shaking

of which replicates the EG-2000.

2)

This is an alternative method of testing

unit sensitivity and operational in the

absence of the correct equipment.

3) Obvious special care is needed if

this method is used as shaking to

vigorously may result in the glass

breaking and personal injury.

←

▼

▼

▼

▼

▼

▼

Sensitivity check

Alarm operation check

Retrigger 47min.

▼

Sensitivity is correct Sensitivity is too high

Lower the sensitivity

Environmental LED: OFF

Alarm LED: OFF

Environmental LED: ON

Alarm LED: OFF

Environmental LED: ON

Alarm LED: ON

Sensitivity is too low

Increase the sensitivity

Mode switch

Check

mode

Operation

mode

Environmental LED

Alarm LED

Environmental LED

Alarm LED

Environmental LED

Alarm LED

Alarm LED

Coverage

EG-2000