ADJUSTING THE FILM TENSION

The top and bottom supply rolls should have about the same tension. By turning the top roll with one

hand and the bottom roll with the other, it can be determined if one of the rolls is tighter than the other.

Also, if the tension is not equal between the top and bottom rolls, the laminated product will curl. If it

curls up when it comes out of the machine, the top roll is likely tighter than the bottom. If it curls

down, the bottom roll is likely tighter. To increase tension, turn the adjusting knob clockwise. To

decrease tension, turn the knob counter clockwise. Even tension on the top and bottom rolls ensures

flat lamination.

ADJUSTING THE HEAT

1. After turning on the power switch, please press the “1” key to start the heating process. The heater

light for the 1.5mil roll laminating film will turn on.

2. Once the set temperature is achieved and the roller temperature is stabilized, the ready light will turn

on. The machine operator can start laminating as soon as the ready light stays on.

Note: It is vital that the ready light is steadily on when laminating. If the light starts blinking or

fading, it means the rollers are losing heat from continuous lamination. Please wait until

temperature stabilizes and the ready light becomes steady again before proceeding with the

lamination.

. For mil thick laminating film, please press “2” on the machine.

LAMINATING PROCEDURES

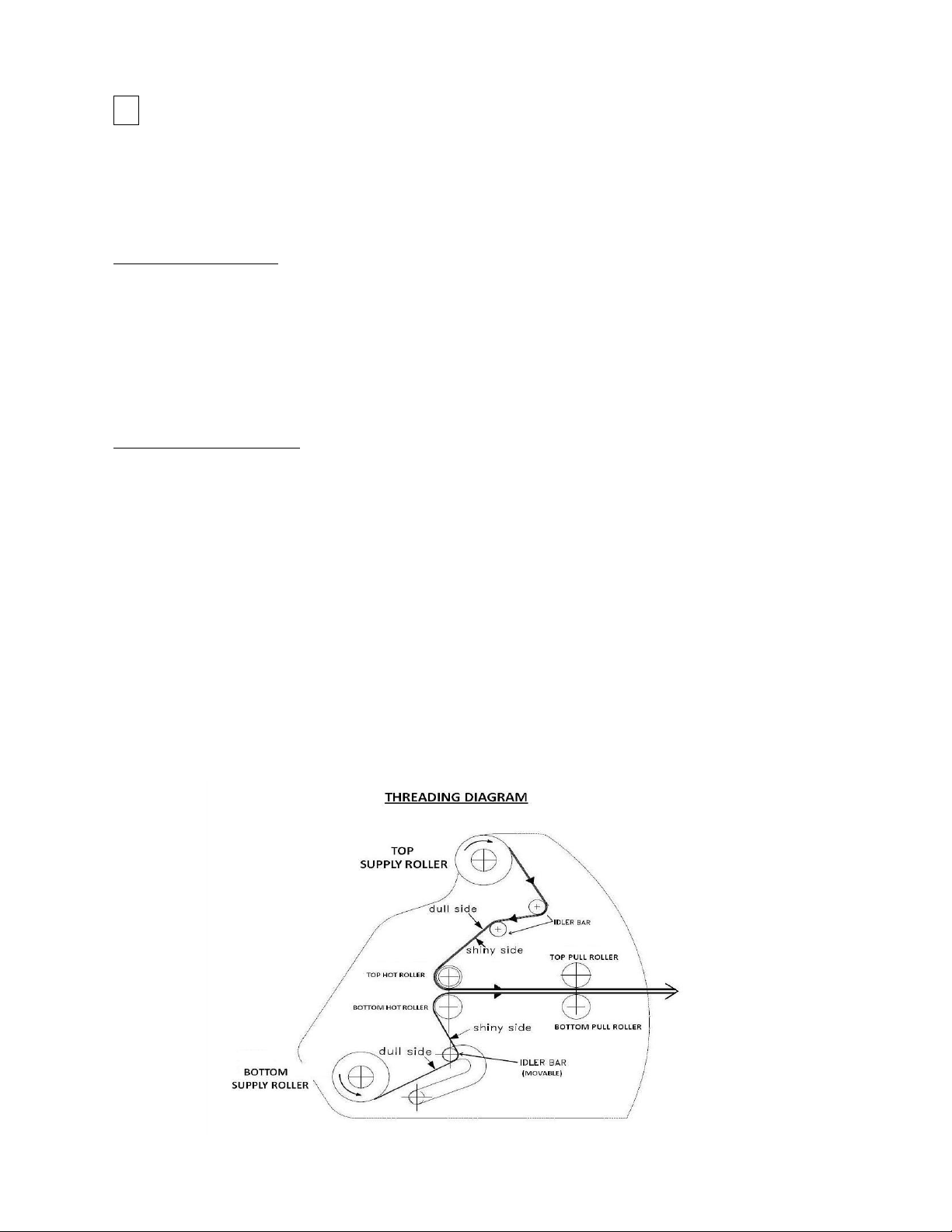

1. Push the handle to the “0” position to engage the rollers. The user can now start laminating as the

machine starts feeding in film.

2. To put the lamination temporarily on hold without turning off the machine, press the "ON/ REV."

switch on left side panel that controls the forward/reverse function and leave it on neutral position.

. Press the switch back to “ON” position to resume the lamination job.

B. GUIDE PLATES

This machine is equipped with guide plates on the left and right sides of the feed tray for proper

alignment of materials to be laminated. Aside from being able to laminate 27" wide sheets one at a time,

the user can also laminate up to two (2) 8.5"x11" prints simultaneously in either orientation by aligning

them on each of the plates on both sides of the tray.

C. REVERSE UNCTION

The machine is equipped with a “REVERSE” function. By pressing the “REVERSE” key, the machine

will release the documents out from the front of the machine to prevent any jam or damage.