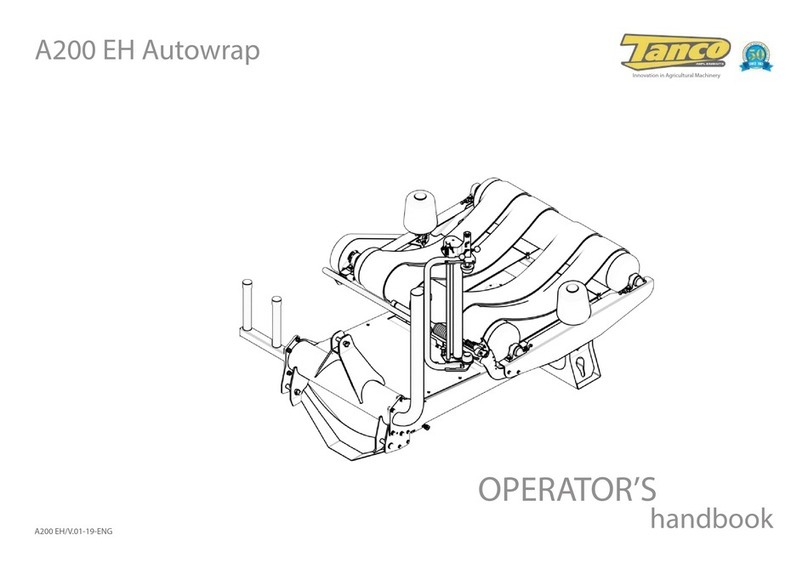

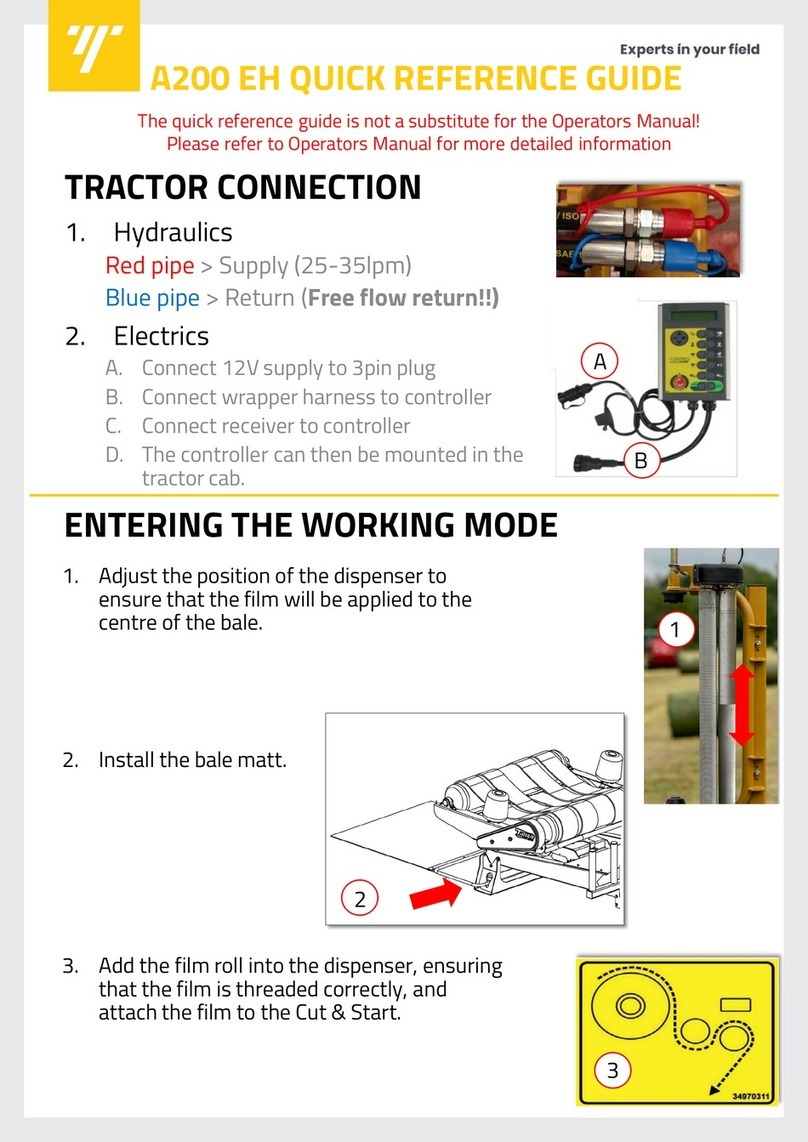

OPERATION

1. Activate the “Rollers out” (a) function

to open the rollers

2. Drive into the bale until the bale

contacts the bale support roller.

3. Activate “Rollers in” (b) to load the

bale.

4. Once the bale is loaded, pressing

“Auto start” (c) will commence

wrapping.

5. When wrapping is complete, press

“Rollers out” (a) to offload the bale.

Note: “Rollers in” & “Rollers out”

functions can be operated by “one touch”

meaning that the operator does not need

to keep the button pressed. To activate

“one touch” increase “Rollers in” & “Roller

out” time in the Operator Menu.

a

b

c

Using the End Tip

1. The End Tip must first be activated by

turning a hydraulic tap which is located

next to the hydraulic valve block

assembly.

2. When wrapping is complete, press the

“Rollers out” button (a). The End Tip

will first extend before the rollers

move out to unload the bale.

a

Auto mode (A)