Manual 1080A & 580A TANCO CONTROLLERS Page9 of 28

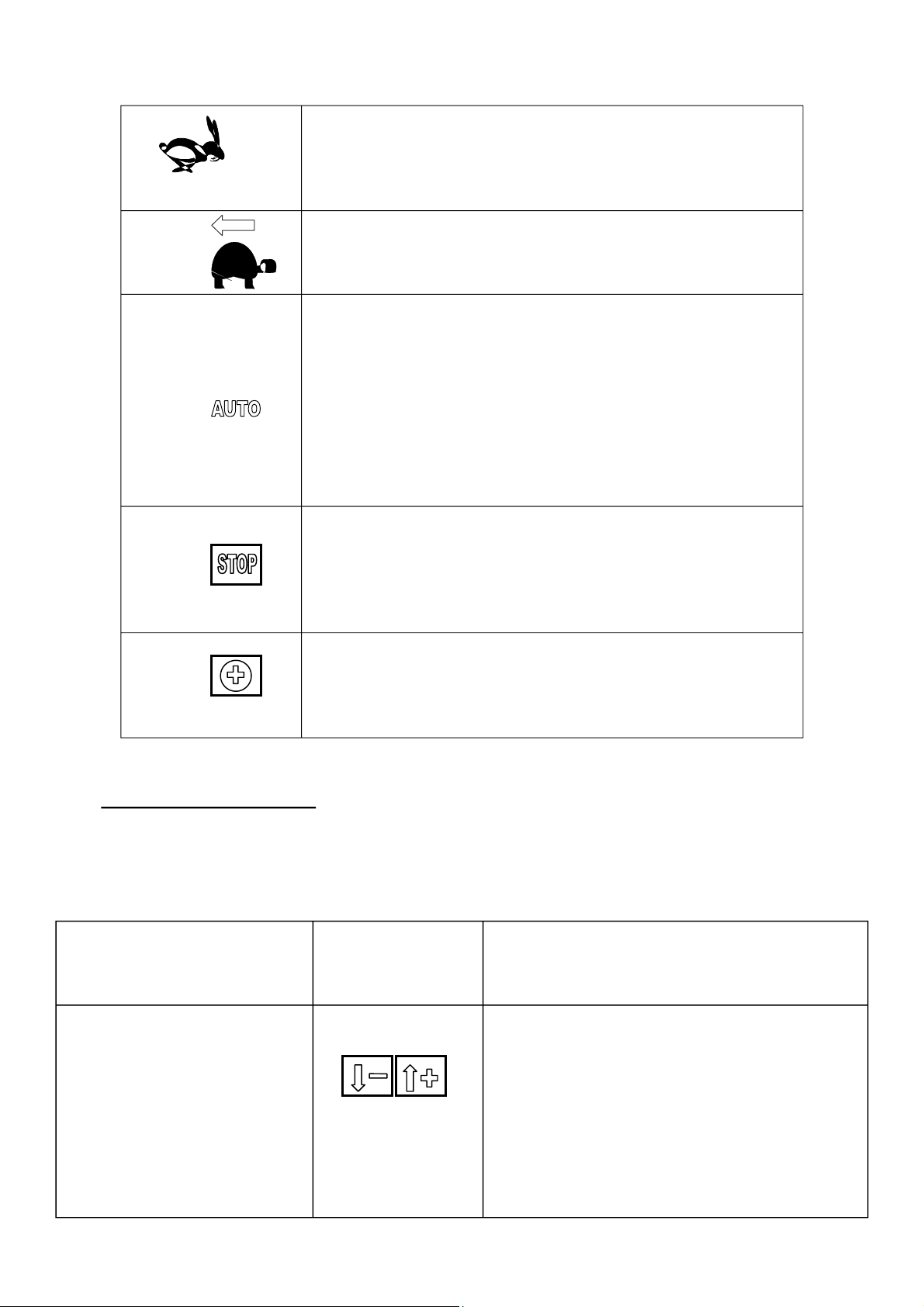

DISPLAY.

A

b

c

d

90 degrees

d=

10 : 20 0

235 d

A= Offload position.

C= Load position.

b= Between Offload and load position

Between Load and offload 270 degrees.

WRAP CYCLE:

COUNTER 1

Loss of orientation may occur if the controller suffers power loss during a

wrap cycle and the power loss occurs less than 3-4 revolutions before the

cycle is completed. If there are 2 or more fast speed revolutions left of the cycle, the system

will automatically regain the orientation.

In case of loss of orientation, less than 3-4 revolutions before the end of the wrap cycle, the

l

will

h

n

in L

in

i

i

n. N

w

iv

h

i

i

nin

wi

h

rin

h

Turntable into the offload position and manually offload the bale. Now tip the table to horizontal

Position. The system now shows the correct position (A) on the display and will now seek load

osition

C

on the next auto start command.

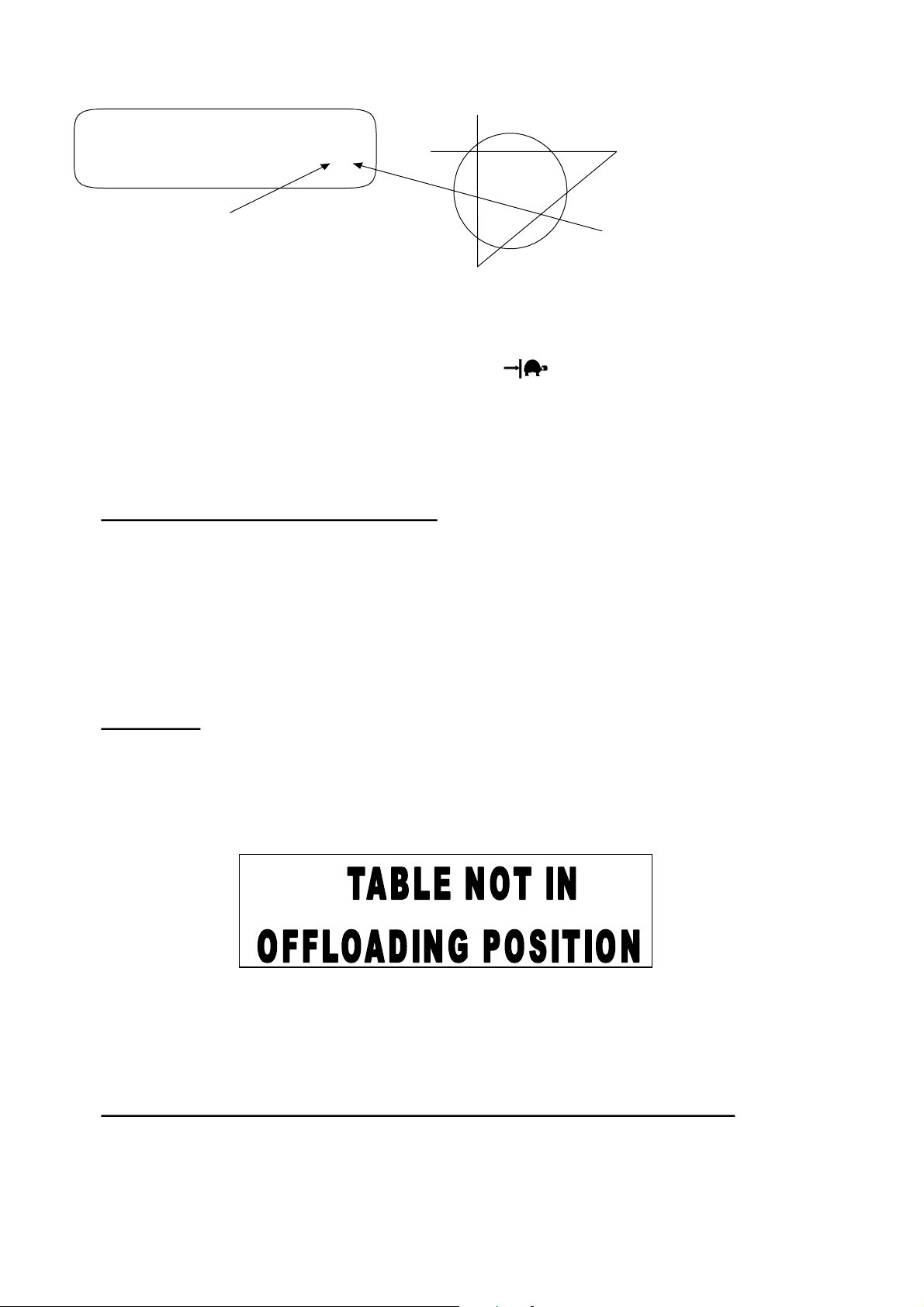

ERROR MESSAGES ON THE DISPLAY.

The machine will in all cases monitor the status of the moving machine parts. Should the

expected position or status of a sensor or device not comply with the safety requirements

specified in the software program, the system will stop the machine cycle at the point where an

error has occurred or when the operator requests an illegal or hazardous command. It will then

via the display announce the reason for the command refusal. When restarting the machine the

system will memorize the point where the cycle was interrupted and continue from the point

where it stopped.

EXAMPLE:

A bale has been wrapped in the manual mode. The operator stops the wrapping cycle with the

turntable away from the offload position. Now if an offload command then is given, the system

will via the display announce that this is an illegal command, writing TABLE NOT IN

OFFLOADING POSITION..”

In order to bring the machine into the correct status the operator must then using the manual

TABLE position command to bring the system back to the logical sequence state.

Similarly if a manual wrap cycle is requested and the table is not horizontally positioned, the

display will write that the table is not lowered to the horizontal position.

LOADING A SECOND BALE ONTO THE LOAD ARM WHILE WRAPPING.

When loading a bale onto the turntable, and an auto start command is given, the load arm will

automatically return to STANDBY position and the wrapping cycle will automatically begin if

the setup defines this. See SETUP, (AUTO LOAD BALE WITH LOAD-ARM: YES / NO).

During an auto cycle the operator has permanent manual access to operate the load arm within

limits defined in the program. When the operator approaches the 2nd bale and the load arm is