Doc. No: 412-121033 BTT-02 card printer manual

Issue: 1

Date: Jul 2014

Author: Ian Ridgeway

Issue date: Aug 2014

Page: 2 of 18

While TE Connectivity has made every reasonable effort to ensure the accuracy of the information in this document, TE does not guarantee that it is

error-free, nor does TE make any other representation, warranty or guarantee that the information is accurate, correct, reliable or current. TE reserves

the right to make any adjustments to the information contained herein at any time without notice. TE expressly disclaims all implied warranties

regarding the information contained herein, including, but not limited to, any implied warranties of merchantability or fitness for a particular purpose.

The dimensions in this document are for reference purposes only and are subject to change without notice. Specifications are subject to change

without notice. Consult TE for the latest dimensions and design specifications.

If this document is printed it becomes uncontrolled

TABLE OF CONTENTS

Introduction........................................................................................3

System Contents and Initial Checks................................................3

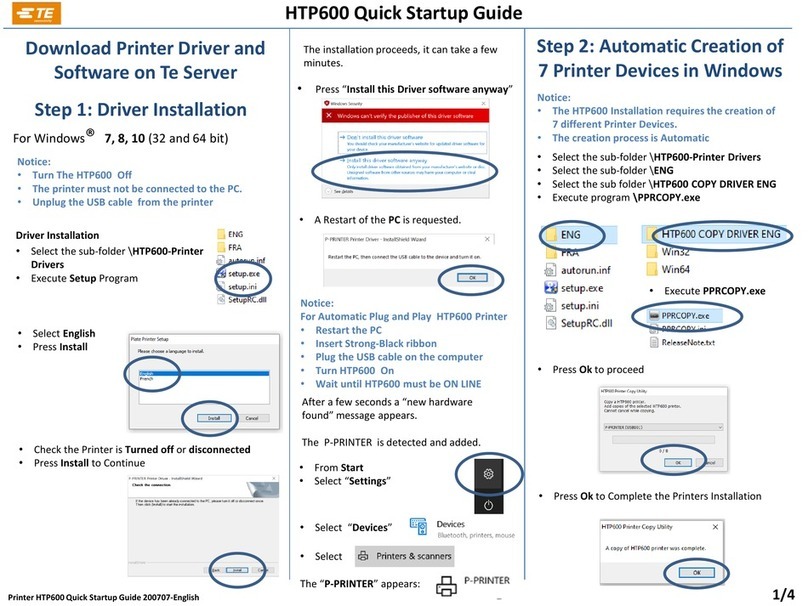

Installation..........................................................................................4

Preparation of Installation Site..........................................................4

Printer Connections..........................................................................5

Power Connections ..........................................................................5

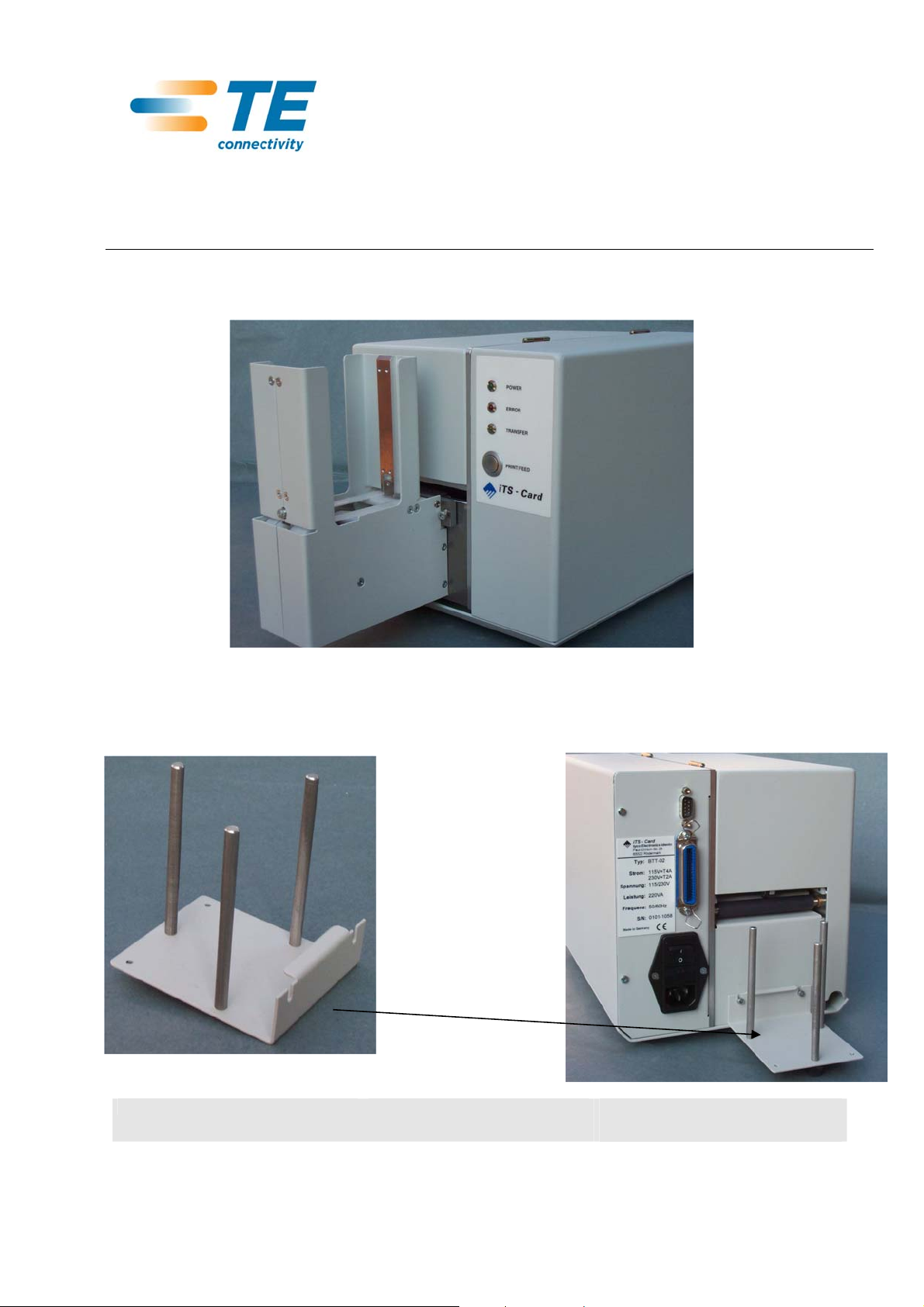

Mounting of Feed-In Tray.................................................................6

Mounting of Autofeed Unit................................................................7

Ribbon Installation............................................................................8

Adjusting The Feed-in Tray..............................................................9

Printer Controls ...............................................................................12

LED - Display Board / Reset Function............................................12

Printer - Generated Test Card........................................................13

Maintenance.....................................................................................14

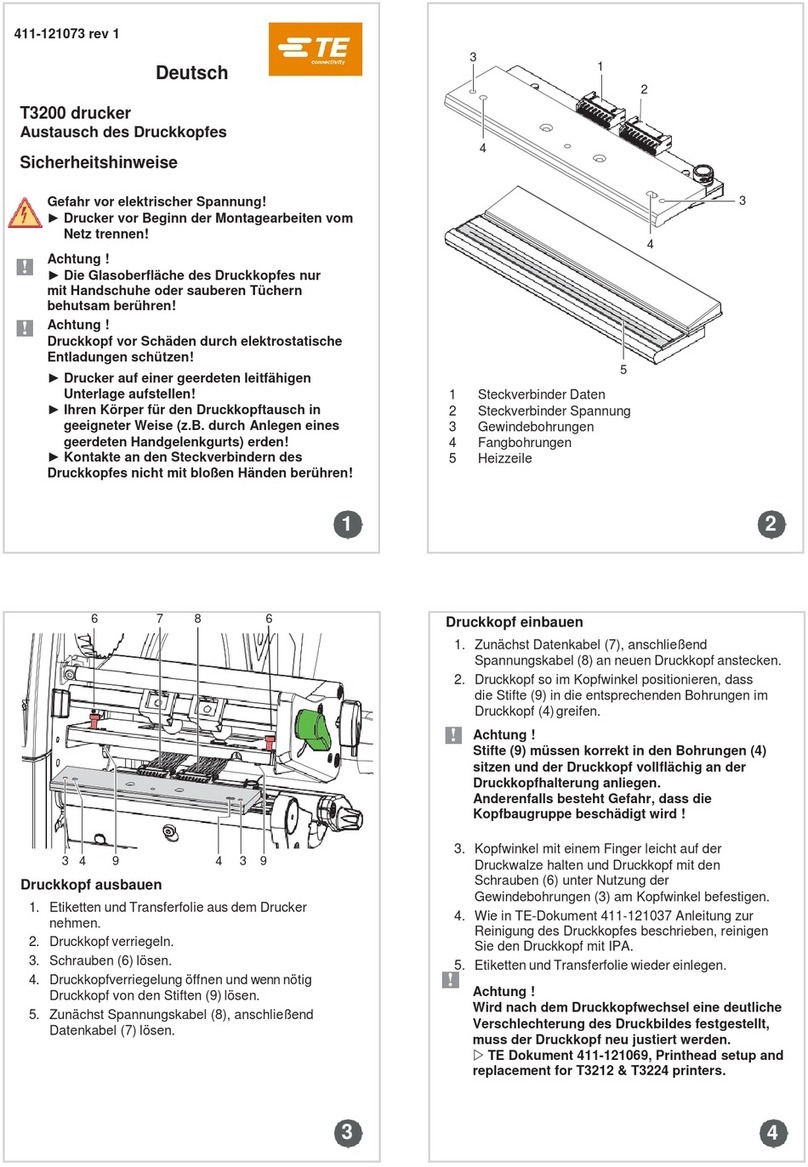

Changing The Print Head...............................................................14

Cleaning The Print Head and Transport Rollers.............................15

Trouble Shooting.............................................................................16

Problem Elimination........................................................................16

Solving Print Quality Problems.......................................................17

Unprinted, Grainy or Incorrect Coloured Areas ..............................17

Unevenly Printed Card Edges........................................................17

Alterations In Print Quality Following A New Ribbon......................17

Horizontal Lines..............................................................................17

Technical Information.....................................................................18