3

1 Introduction ............................................................................................................................................ 4

1.1 Instructions............................................................................................................................................... 4

1.2 Intended Use............................................................................................................................................ 4

1.3 Safety Instructions.................................................................................................................................... 5

1.4 Environment ............................................................................................................................................. 5

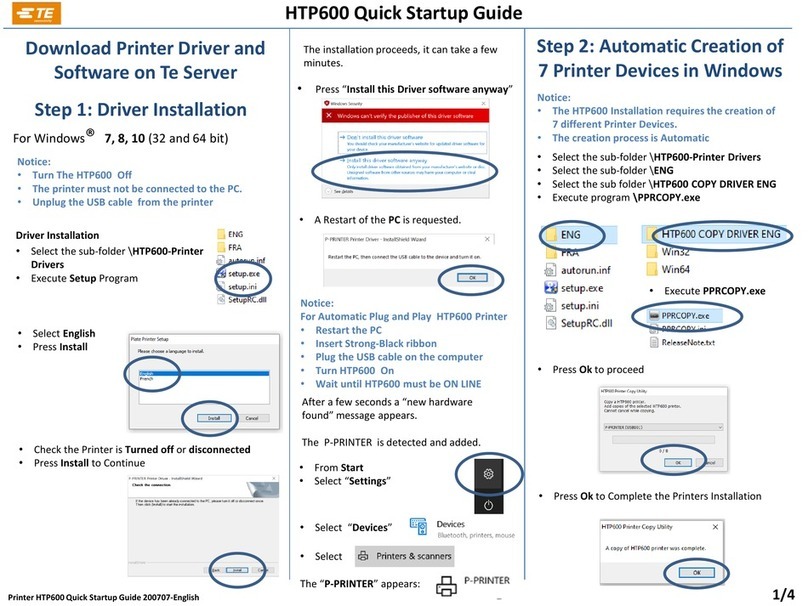

2 Installation .............................................................................................................................................. 6

2.1 Device Overview ...................................................................................................................................... 6

2.2 Unpacking and Setting-up the Printer ...................................................................................................... 8

2.3 Installing the Wi-Fi Stick........................................................................................................................... 8

2.4 Connecting the Device ............................................................................................................................. 9

2.4.1 Connecting the Power Supply ............................................................................................................ 9

2.4.2 Connecting to a Computer or Network ............................................................................................... 9

2.5 Switching on the Device........................................................................................................................... 9

3 Touchscreen ......................................................................................................................................... 10

3.1 Start Screen ........................................................................................................................................... 10

3.2 Navigating the Menu .............................................................................................................................. 12

4 Loading Material................................................................................................................................... 13

4.1 Loading Media from the Roll .................................................................................................................. 13

4.1.1 Inserting the Media Roll.................................................................................................................... 13

4.1.2 Inserting the Media into the Printhead.............................................................................................. 14

4.1.3 Setting the Label Sensor .................................................................................................................. 14

4.2 Loading Fanfold Media........................................................................................................................... 15

4.3 Setting the Head Locking System .......................................................................................................... 16

4.4 Loading Transfer Ribbon........................................................................................................................ 17

4.5 Setting the Feed Path of the Transfer Ribbon........................................................................................ 18

5 Printing Operation................................................................................................................................ 19

5.1 Synchronization of the Paper Feed........................................................................................................ 19

5.2 Tear-off Mode ......................................................................................................................................... 19

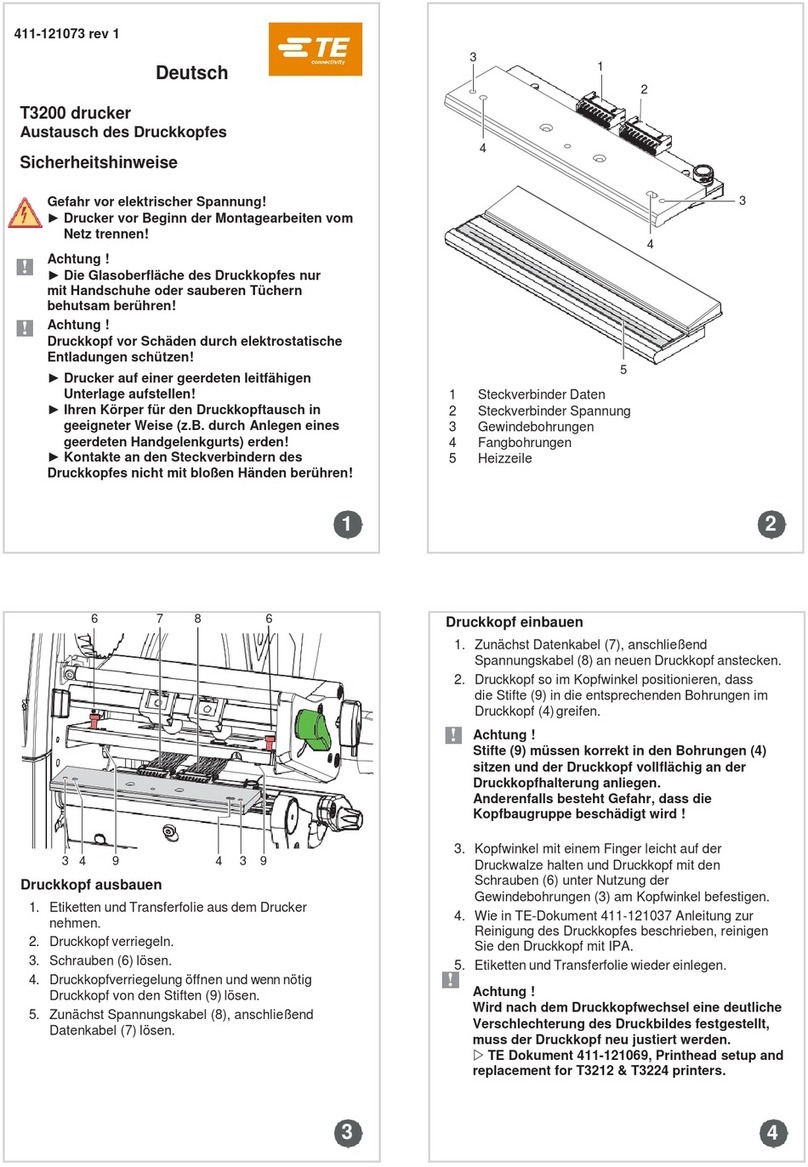

6 Cleaning ................................................................................................................................................ 20

6.1 Cleaning Information .............................................................................................................................. 20

6.2 Cleaning the Print Roller ........................................................................................................................ 20

6.3 Cleaning the Printhead........................................................................................................................... 20

6.4 Cleaning the Label Sensor..................................................................................................................... 21

7 Fault Correction ................................................................................................................................... 22

7.1 Error Messages...................................................................................................................................... 22

7.2 Error Messages and Fault Correction .................................................................................................... 22

8 Licences................................................................................................................................................ 24

8.1 Reference to the EU Declaration of Conformity ..................................................................................... 24

8.2 FCC........................................................................................................................................................ 24

9 Index...................................................................................................................................................... 25

Table of Contents