Printhead setup instructions for the

TE3124, TE3112 & T6112DS

Author: I Ridgeway

Print date: 24-Oct-12

Issue date: : Oct 2012

Page: 6 of 8

While TE Connectivity has made every reasonable effort to ensure the accuracy of the information in this document, TE does not guarantee that it is

error-free, nor does TE make any other representation, warranty or guarantee that the information is accurate, correct, reliable or current. TE reserves

the right to make any adjustments to the information contained herein at any time without notice. TE expressly disclaims all implied warranties

regarding the information contained herein, including, but not limited to, any implied warranties of merchantability or fitness for a particular purpose.

The dimensions in this document are for reference purposes only and are subject to change without notice. Specifications are subject to change

without notice. Consult TE for the latest dimensions and design specifications.

If this document is printed it becomes uncontrolled

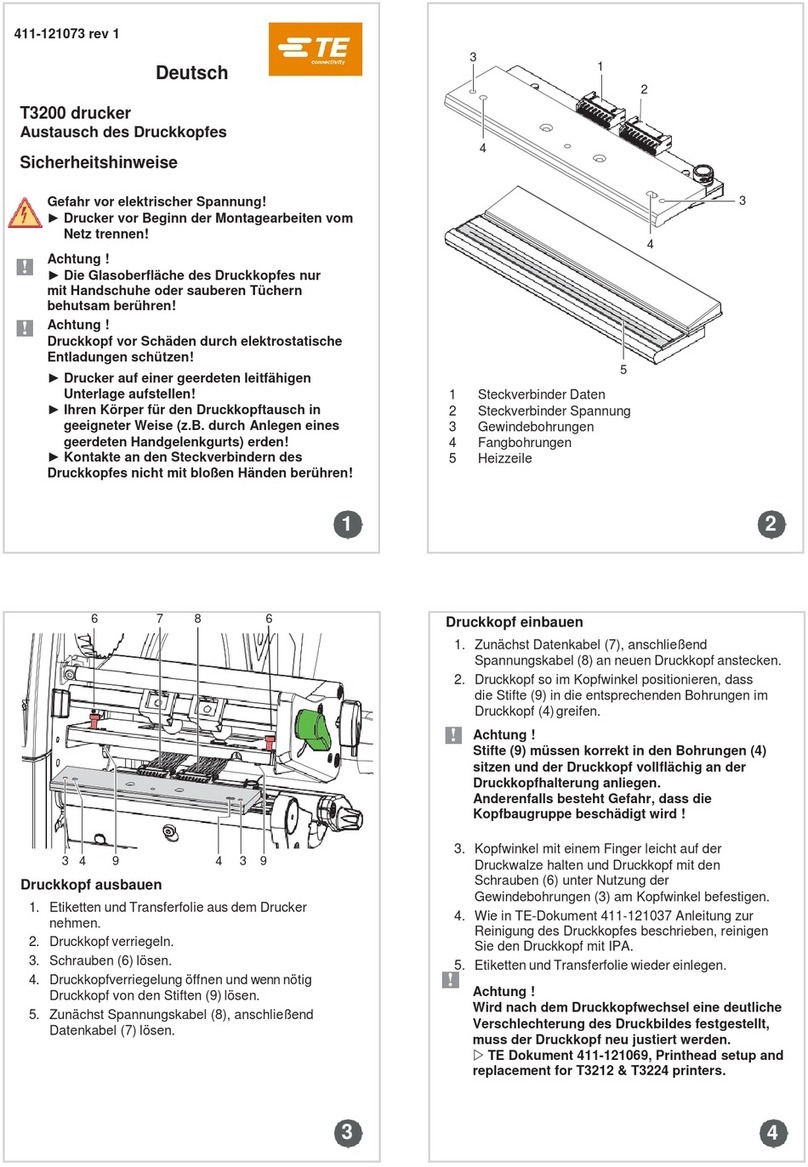

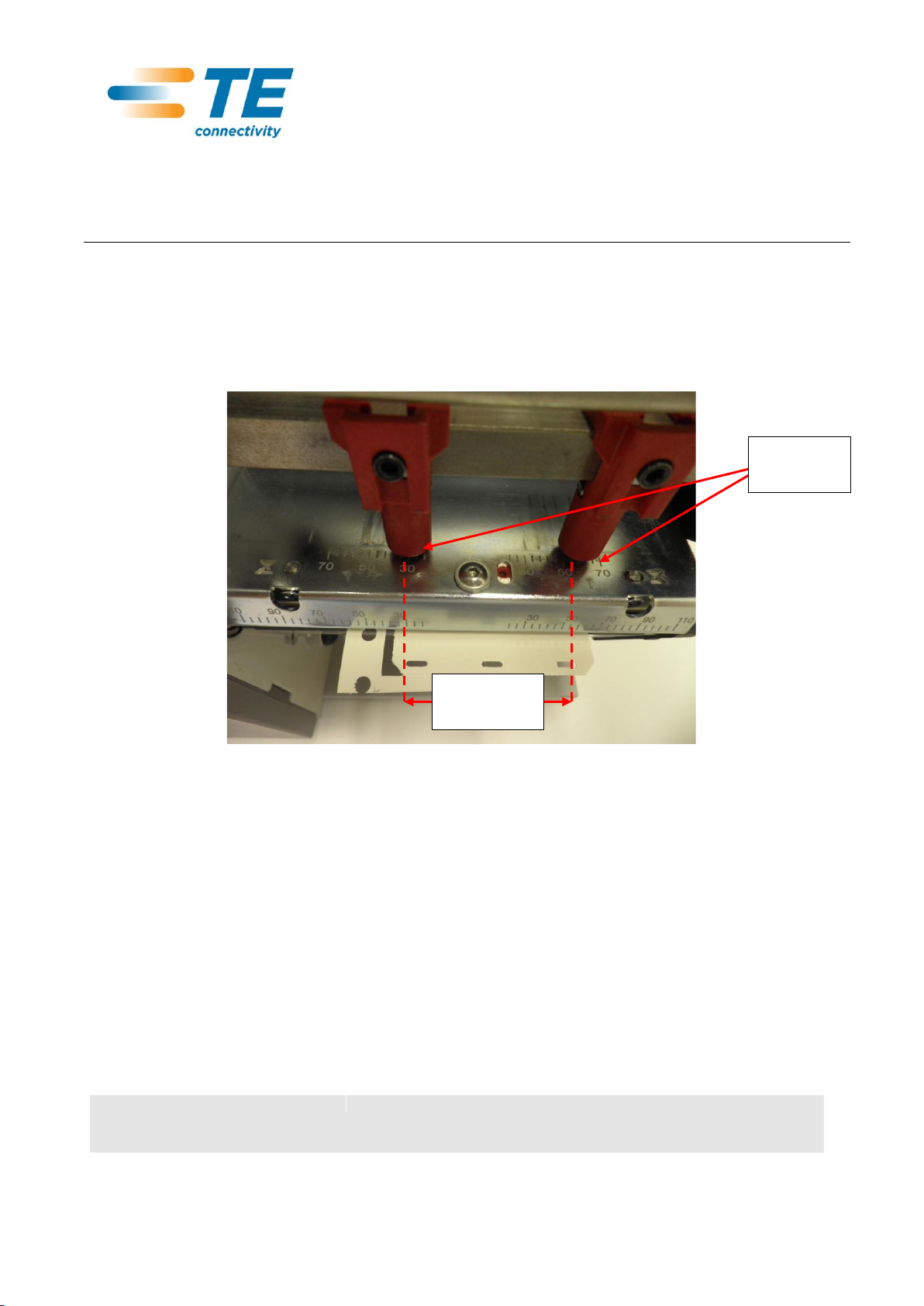

3.5.With screw “A” loose, ensure printhead starting position is with alignment marks in

factory set position. If the print head is not in the factory default position then

adjustment has been previously carried out and this may be the cause of the print

quality issue. In this instance it is advisable to adjust the print alignment screws B

and C (see Figure 7) back to Factory Default, retighten screw A and repeat the

print test (step 3 & 3.1).

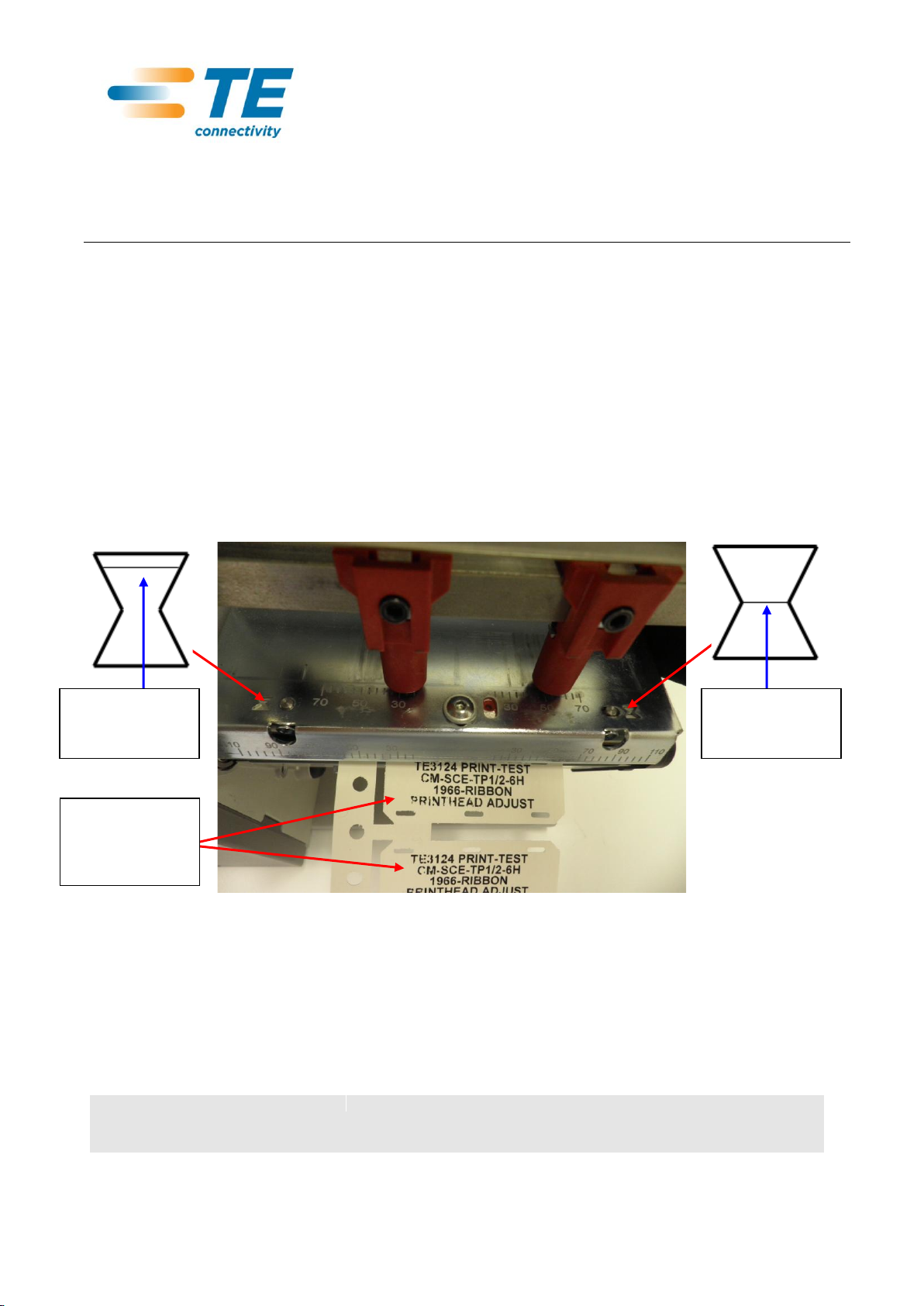

3.6.If the printhead is in the Factory Default then printhead adjustment may be

required. Turn screw B and C one full turn clockwise, see Figure 7) , retighten

screw A and repeat the print test (paragraph 3 –3.1).

3.6.1. If the print test result shows an improvement in print quality loosen screw A

and repeat step 3.5.

3.7.If the print test result shows a deterioration in print quality loosen screw A and Turn

screw B and C two full turns counter-clockwise, see Figure 7) , retighten screw A

and repeat the print test (paragraph 3 –3.1).

3.7.1. If the print test result shows an improvement in print quality loosen screw A

and Turn screw B and C one full turns counter-clockwise, see Figure 7) ,

retighten screw A and repeat the print test (paragraph 3 –3.1).

3.7.2. Optimisation of print quality will occur when print quality starts to fall again, in

which instance loosen screw A and turn one full turn in the opposite direction,

retighten screw A and repeat the print test (paragraph 3 –3.1).

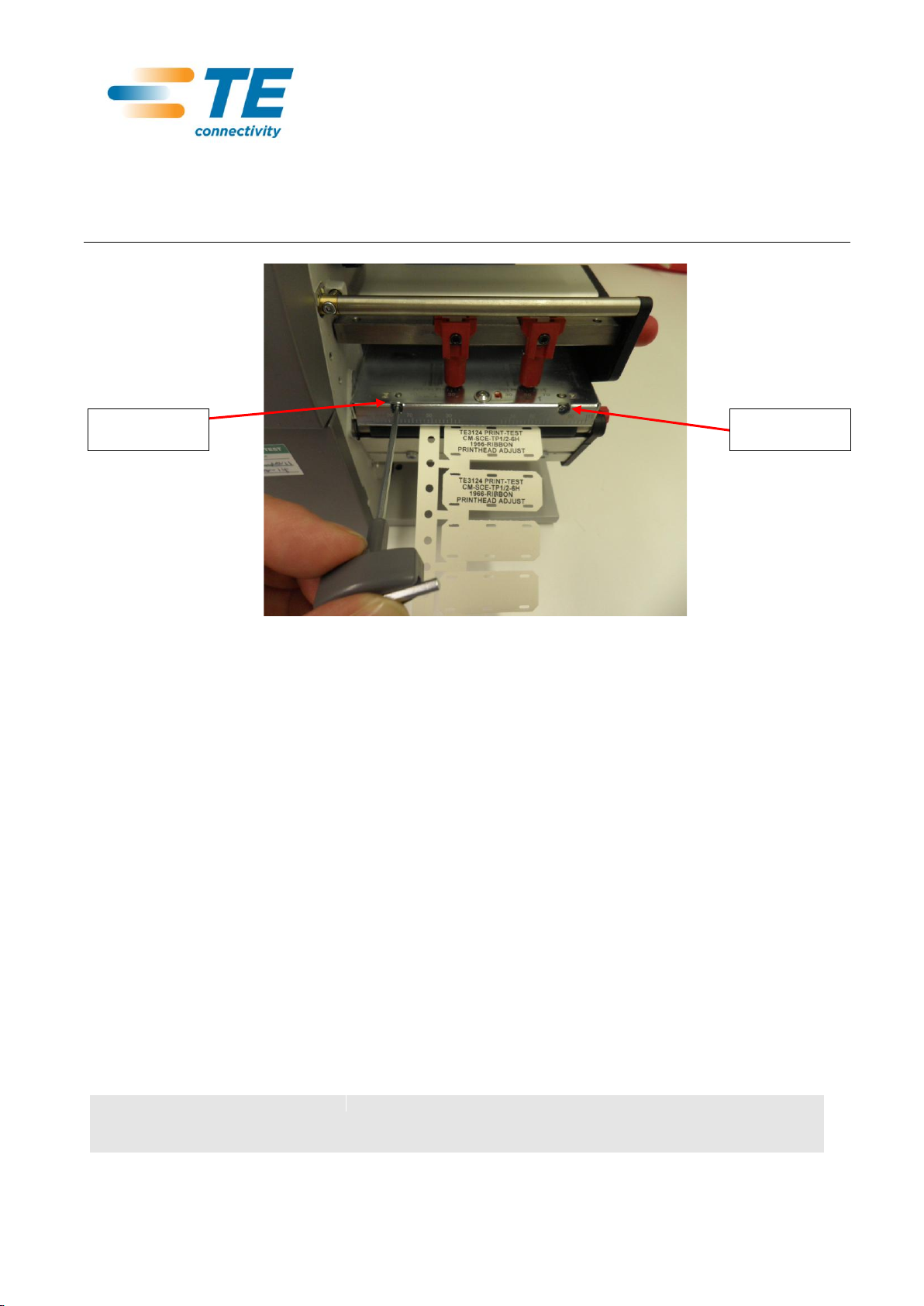

3.8.If print quality does not improve when adjusting the printhead then this may be a

printhead pressure issue, see step 4.