3

Table of Contents

1 Introduction ............................................................................................................................................ 4

1.1 Instructions ............................................................................................................................................... 4

1.2 Intended Use ............................................................................................................................................ 4

1.3 Disclaimer ................................................................................................................................................ 4

1.4 Safety Instructions .................................................................................................................................... 5

1.5 Environment ............................................................................................................................................. 5

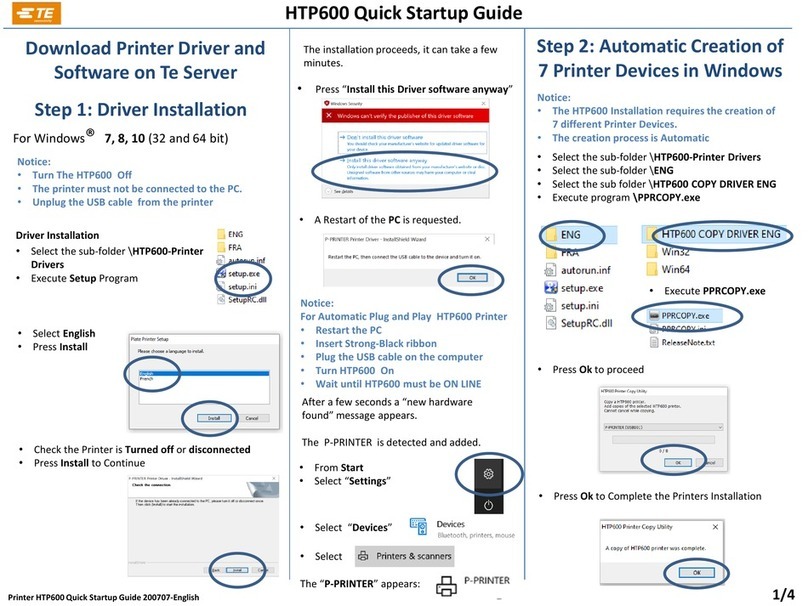

2 Installation .............................................................................................................................................. 6

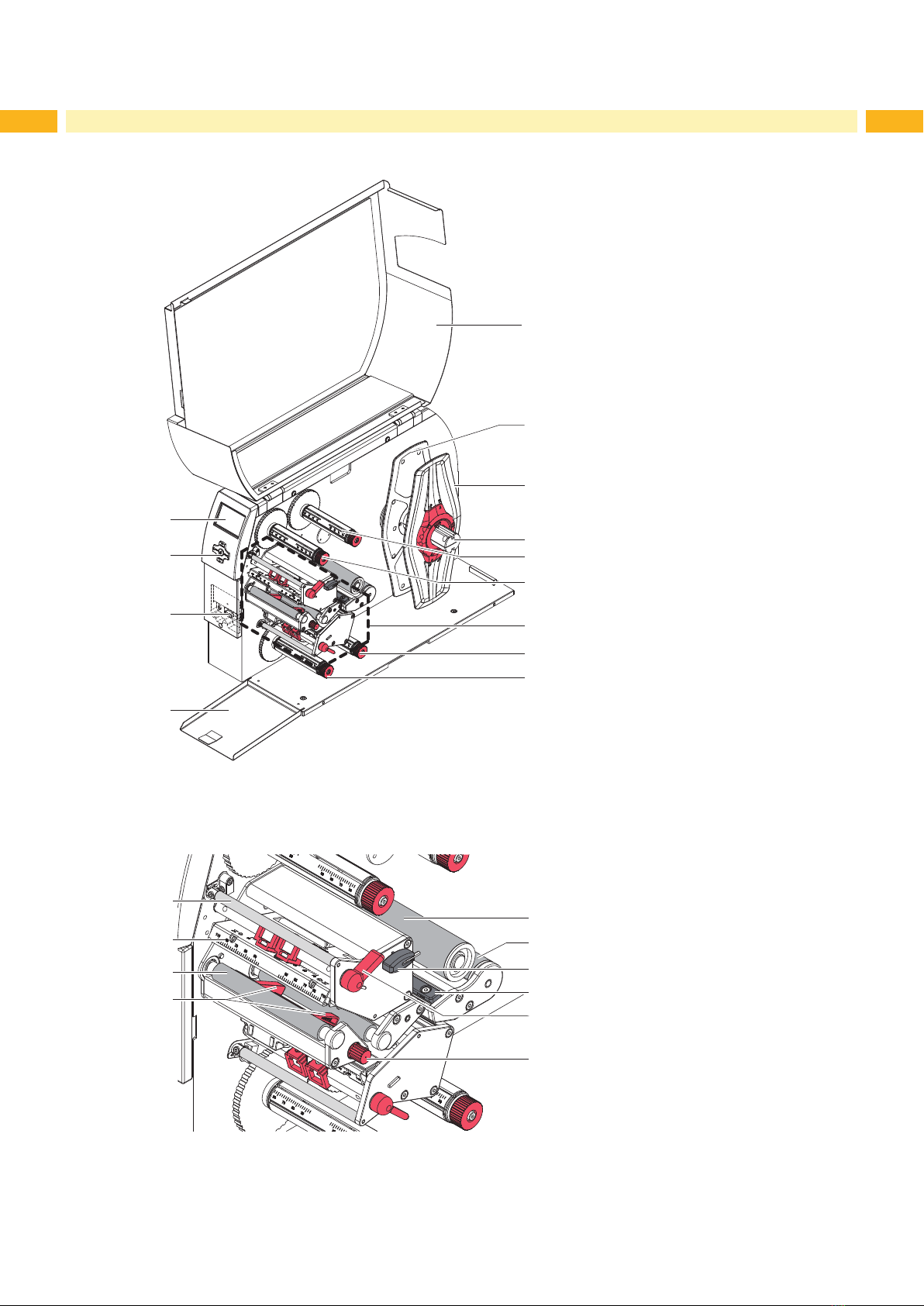

2.1 Device Overview ...................................................................................................................................... 6

2.2 Unpacking and Setting-up the Printer ...................................................................................................... 8

2.3 Connecting the Device ............................................................................................................................. 8

2.3.1 Connecting to the Power Supply ........................................................................................................ 8

2.3.2 Connecting to a Computer or Computer Network .............................................................................. 8

2.4 Switching on the Device ........................................................................................................................... 8

3 Control Panel .......................................................................................................................................... 9

3.1 Structure of the Control Panel .................................................................................................................. 9

3.2 Symbol Displays ....................................................................................................................................... 9

3.3 Printer States ......................................................................................................................................... 10

3.4 Key Functions .........................................................................................................................................11

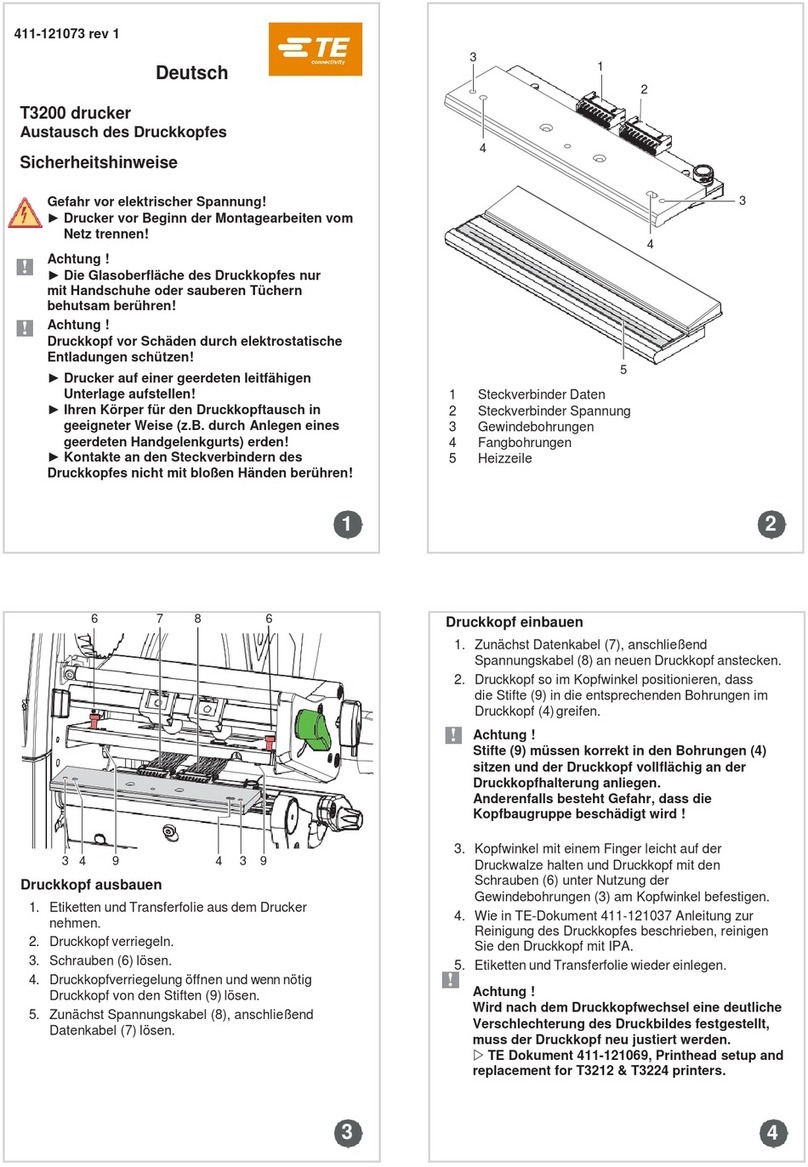

4 Loading Media ...................................................................................................................................... 12

4.1 Loading Media ........................................................................................................................................ 12

4.1.1 Positioning the Media Roll on the Internal Roll Retainer .................................................................. 12

4.1.2 Inserting media into the print mechanism ......................................................................................... 13

4.1.3 Setting the Material Sensor .............................................................................................................. 13

4.1.4 Loading Media from External Supply................................................................................................ 14

4.2 Loading Transfer Ribbon ........................................................................................................................ 15

4.3 Setting the Feed Path of the Transfer Ribbon ........................................................................................ 16

4.4 Setting the Head Locking Systems ........................................................................................................ 16

4.4.1 Setting the Plungers ......................................................................................................................... 16

4.4.2 Adjusting the Printhead Pressure ..................................................................................................... 17

5 Printing Operation ................................................................................................................................ 17

5.1 Printhead Protection ............................................................................................................................... 17

5.2 Synchronization in Cut Mode ................................................................................................................. 17

6 Cleaning ................................................................................................................................................ 18

6.1 Cleaning Information .............................................................................................................................. 18

6.2 Cleaning the Print Rollers ...................................................................................................................... 18

6.3 Cleaning the Printheads ......................................................................................................................... 18

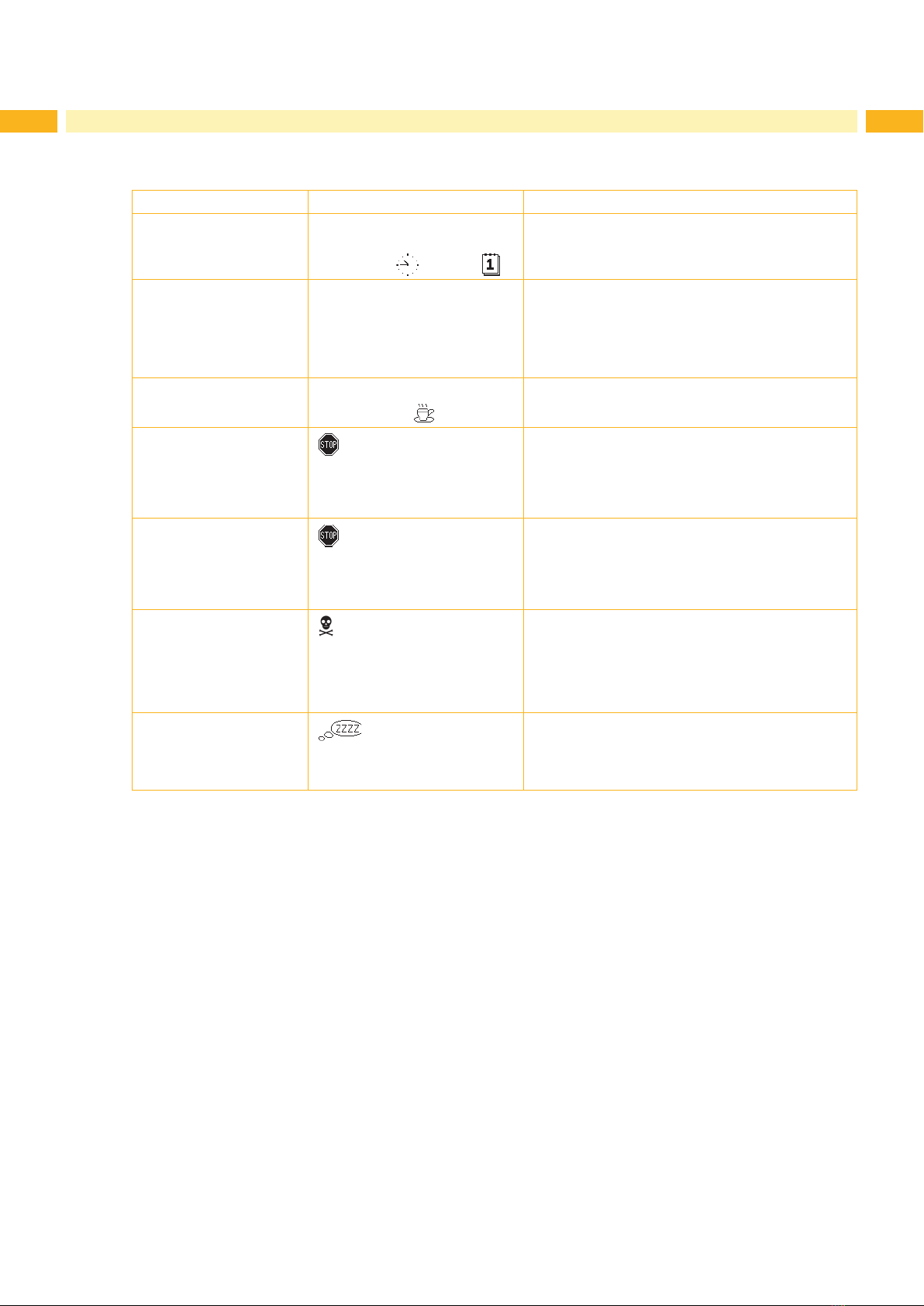

7 Fault Correction ................................................................................................................................... 19

7.1 Types of Errors ....................................................................................................................................... 19

7.2 Problem Solution .................................................................................................................................... 19

7.3 Error Messages and Fault Correction .................................................................................................... 20

8 Ofine Menu ......................................................................................................................................... 22

8.1 Structure of the Ofine Menu ................................................................................................................. 22

8.2 Navigating in the Ofine Menu ............................................................................................................... 23

9 Conguration ........................................................................................................................................ 24

9.1 Local Settings ......................................................................................................................................... 24

9.2 Machine Parameters .............................................................................................................................. 25

9.3 Print Parameters .................................................................................................................................... 26

9.4 Interfaces ............................................................................................................................................... 28

9.5 Status Line ............................................................................................................................................. 29

9.6 Security .................................................................................................................................................. 30

10 Licences ................................................................................................................................................ 31

10.1 EC Declaration of Conformity ................................................................................................................. 31

10.2 Other Licences ....................................................................................................................................... 31

11 Index ...................................................................................................................................................... 32