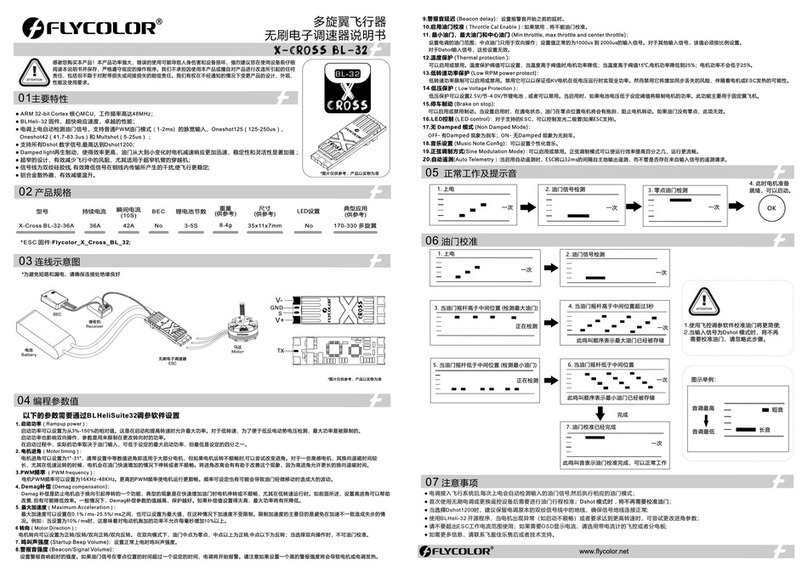

Start-up

Protection

Over heat

protection

ESC wil l cut off output if it fails to start the motor within 3 seconds by accelerating throttle. you need to move th e throttle

stick back to the bottom position and restart the motor.( The possible causes : Bad connection or disconnection between

ESC & motor , propellers are blocked, etc)

When ESC temperature is higher than 100 ℃,it will reduce output power (throttle will be limited below 40%) for protection,

leave some power for motor to land , when the temperature Reduced to 80℃ , ESC recover to normal running mode.

When ESC detects the loss of throttle signal for over 1 seconds, it will cut off power or output immediately to avo id an

even greater loss caused by the continuous high speed rotation of propellers. ESC will resume the corresponding output

after the normal signal is restored.

Throttle Signal

Loss Protection

ATTENTION

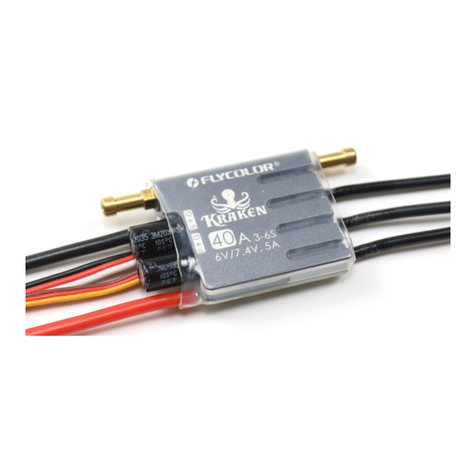

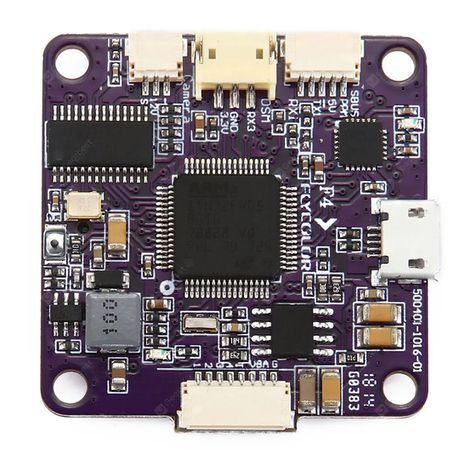

User Manual

Brushless ESC for airplane

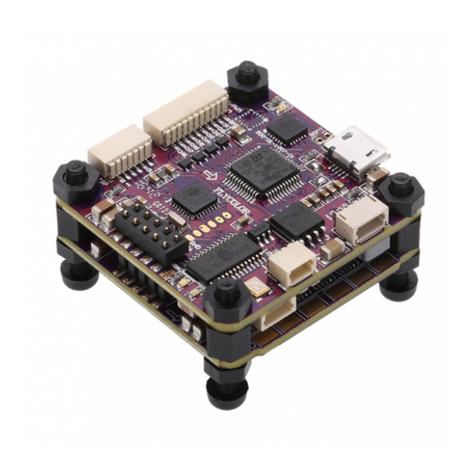

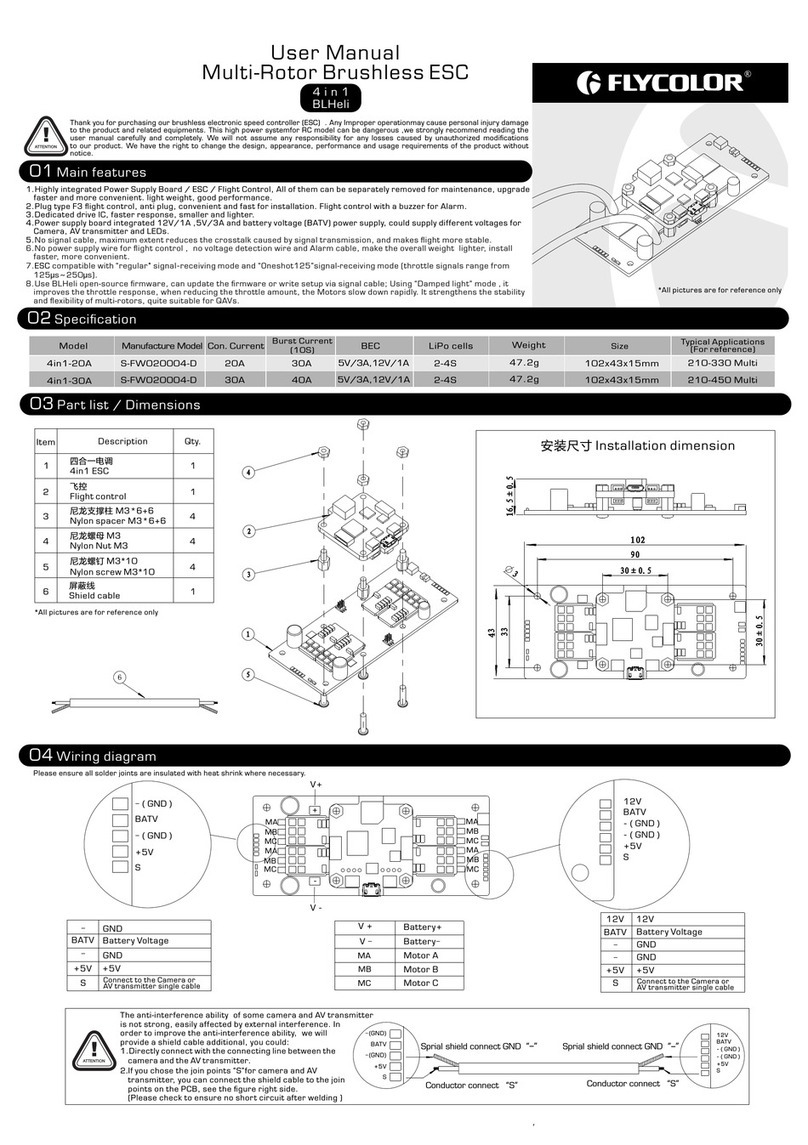

01Main features

Turn on the

transmitter,

move the

throttle stick to

the top position.

Connect E SC with battery. Wait for 2seconds,

motor emits 2 short " BEEP-BE EP". Then still

wait for 5 seconds. motor emits special tone

“♪12321”,it has entered programming mode.

Select Items

After entering programming mo de, you wil l hear groups tone which

emits in a loop as following sequen ce .

Note:

Usuall y,1 long to ne

"Beeee p- -" equals to

5 short to ne "b eep-",

for exam pl e: 1 long

tone"B ee ep--" and 1

short to ne “ be ep-”

equals t o 6.

*80-130A have

reverse function.

When motor emits

“ ” tone, Exit

move throttle to the

zero position in 3

seconds, then motor

emits special tone

“♪765765”, it will

exit the programming

mode.

If don't want select

other parameter,

move throttl e to the

zero positio n in 3

seconds, the n motor

emits specia l tone

“♪765765”, it will

exit the programming

mode. Or power off,

it will exit the

programm ing mode.

After motor emits a

Item tone ,move

the throttle to the

zero throttle position,

then will enters this

item, and motor will

emits the parameter

tone in a loop .

please see the table

below)

♪12321

Brake 1s ho rt

Batter y ty pe 2short

3short

Tim ing

Startu p mo de

Govern or m od e

PWM frequency

BEC voltage

4short

Batter y ce ll s

Restore facto ry d ef au le

Exit

1long

1long& 1s hort

1long& 2s hort

1long& 3s hort

1long&4 sh ort

2long

2long&1short

2long&2short

Beep-

Beep-Beep-

Beep-Be ep -Beep-

Beep-Be ep -Beep-Beep-

Beeeep --

Beeeep --Beep-

Beeeep --Beep-Beep-

Beeeep --Beep-Beep-Beep-

Beeeep --Be ep-Beep-Beep-Beep-

Beeeep --Be eeep--Beeeep--

Beeeep --Beeeep--Beep-

Beeeep --Beeeep--Beep-B ee p-

1

2

3

4

5

6

7

8

9

10

11

12

Item parameter

*Please ensure all solder joint s are insul ated with heat shrink where necessar y.

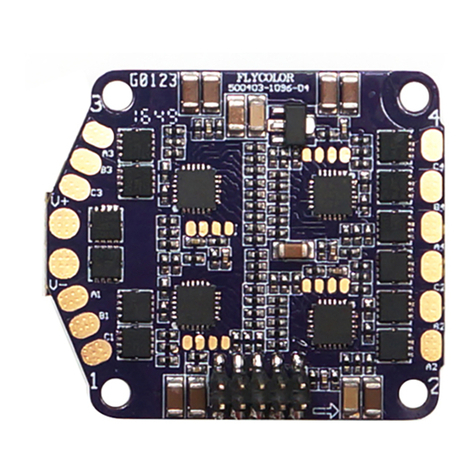

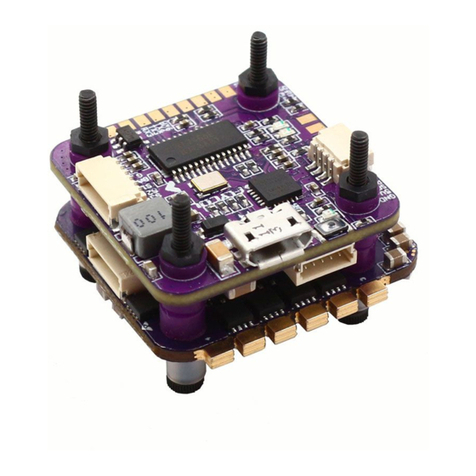

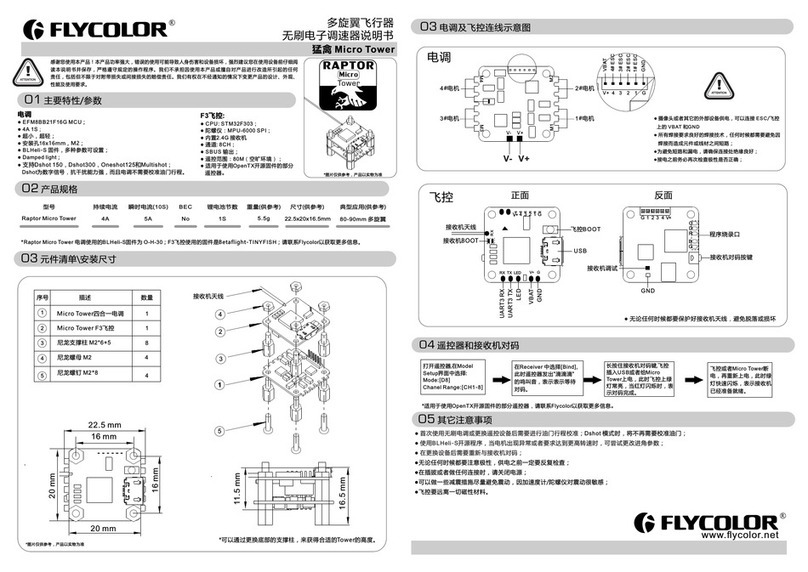

03 Wiring Diagram

13*

14

Motor ro ta ti on

ASC F

*Shadow parts are factory default value

*80-130A have reverse function.

04 Operation instruction

1.Normal start-up

2.Throttle Range calibration

3.Programming

It is recommended to use Flycolor app to change para meters through Flycolor Wi-Fi Trans.

In addition the program card can also change param eters.

[1]NO(default) [2]Soft [3]Heavy [4 ]Very heavy 1. Brake:

: [1] LiPo(default) [2] NiCd/NiMh 2. Battery type

3. Cutoff voltage: Low-voltage protection threshold, [1 ] Low [2] Medium (default) [3] High

For Ni-xx battery packs:Low/Medium/High cut off v oltage is 50%/65%/75% of the battery packs' initial voltage.

For LiPo battery: can count battery cells automatic. Low vol tage protection threshold :Low(2.8V)/ Medium(3.0V)/ High

(3.2V).Eg:For 4S/14.8V Lipo battery packs, low voltage protection threshold is 11.2V low/12.0V medium /12.8Vhigh.

4. Timing:

[1]0° [2]3.75° [3]7.5° [4]11.25° [5]15°(defau lt) [6]18.75° [7]22.5° [8]26.25°

Low(0°/ 3.75°/ 11.25°/15°/ 18.75 °)--for most i nner rotor motors

High(22.5°/ 26.25°)--For 6 poles or higher poles outer rotor motors

As usual, 15° applies to all the outer rotor motors , but for improv ing efficiency ,recommend that set low timing for 2 poles

motor( most inner rotor motors), set high timing for 6 poles and h igh poles motors( most outer rotor motors). If need high

speed motor, you can set high timing. Some motors sho uld set special timing, if not sure, you'd better to set timing as motor

manufacturer recommended ,or set 15°.

Note: After changing timing, please test on the ground before flying.

5. Startup Mode: Start up with linear accelerator

[1] Normal: It's preferred for fixed wing. (default)

[2] Soft: It's preferred for helicopter, it will take 6 seconds f rom 0% throttle to 100% throttle.

[3] Very soft: It's preferred for helicopter, it will take 12 seco nds from 0% throttle to 100% throttle.

6.Governor mode : [1]O F F (default) [2]Low [3]High

If the Governor mode is activated, E S C will try to keep the motor in a fixed speed ( usually the throttle curve is a hori zontal

line, you can change the preset motor speed by changing the height of the line).

[1] O F F(default)

[2] Low , "Low constant speed" mode , 10000-20000RPM for 2 poles brushless motor .

[3] High, "High constant speed" mode , above 20000 R P M for 2 poles brushless motor .

Note: Governor mode function is automaticall y disabled if the throttle value less than 60%.

7. PWM frequency: [1]8K Hz [2]16KHz(default) [3]24 K Hz

For high poles and high speed motors, the higher P W M frequency can make motor drive sm oothly, but the higher PWM frequency

will make ESC hotter .

8. B E C v oltage: [1]5.0V(default) [2]6.0V [3]7.4V [4]8.4V

(this option is available for partial models)

9. Voltage cutoff option:

[1] Reduce cutoff(default ): the voltage drops to the set low-voltage protection threshold , E S C will reduce the power then cut off the

motor output

[2] Cut off: the voltage drops to the set low-voltage p rotection threshold , E S C will cut off the moto r output immediately.

Battery cells Available for LiP o battery only.10. :

[1] Automatic judgment(default) [2]2S [3]3S [4]4S [5]5S [6]6S .

You also can select the options according to your battery cells.

11.Motor rotation:

[1]Normal(default):Default motor rotation;

[2]Reversed:Change the motor rotation.

12.Active Switch Continued Flow [1]Off (default) [2]On :

ASCF(Active Switch Continued Flow)technology,higher efficiency,reduce heat generation massively.

13.Reverse function [1]Off (default) [2]On :

Plug reverse signal wire into an tw o-stage s witch cha nnel on the receiver ,to reverse the mot or rotati on during the flight t o decelerate.

The lowe st point of the pulse width range of the two-stage sw itch chan nel must be less than the lowest point of throttle. ( e.g. the lo west poin t of

throttle is 1000, then the lowest p oint of pul se width of t wo-stage switch channel should be le ss than 100 0).

Effective conditions : 1. Revers e functio n - on; 2. Governor mode - off; 3. Brak e - on. (WinDr agon wifi 80-130A adaptable ).

14.Restore default settings

When the beeping indicates the mode of "Restore de fault settings", move the throttle stick to zero position in

5 seconds after the beeping can activate the mode. There is no sub-menu under this mode. Then the motors

makes indication tones of "♪765765" which means default settings are restored.

15.Exit program mode

After a sound “Beep-”, move throttle stick to the bottom position, enters the item of exi t program mode, motor emits

sound “♪765765”the same time, it represents ESC enters normal operation mode.

05 Programming parameter

www.flycolor.net

06 Protections

07 First time to use ESC

08 rouble ShootingT

2long&3short

2long&4short

Beeeep --Beeeep--Beep-B ee p-B eep-

Beeeep --Beeeep--Beep-Beep-Beep-Beep-

Thank you for using our product. Any improper operation may cause personal injury or damage the

product and relevant equipments. This high power system for RC model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

● Use powerful & high performance m icropro cessor. Unique circuit design, stro ng anti-i nterfer ence.

● Start mode can be set. throttle res ponse fas t, and it has a v ery smooth speed control linearity. Compatible with

fixed wing aircraft and helicopt ers.

● Multiple protection feature s ensure th e equipme nts safety.

● High power safety performance , when powe r up the moto r will not start immediately wherever the throttle stick is.

● Beeping alarm can indicate work ing condi tion.

● Cycle programming menu for easy o peratio n. Compatible with all kinds of remote controll ers.

● Supports programming and dete ction of re al-time data at close range via mobile p hone AP P (extra Flycolor Wi-Fi

Trans needed); Also su pport programming via programmin g card (ext ra Flycol or programming card neede d).

● 8.4V/7.4V/6V/5V,5A adjustable B E C , high output power ,less powe r loss.

● ASCF(Active Switch Cont inued Flo w)technology,higher efficiency,reduc e heat gene ration ma ssively.

● Reverse function, supports to reverse the motor rot ation during the flight to decelerate(W inDrago n wifi 80-130A ada ptable) .

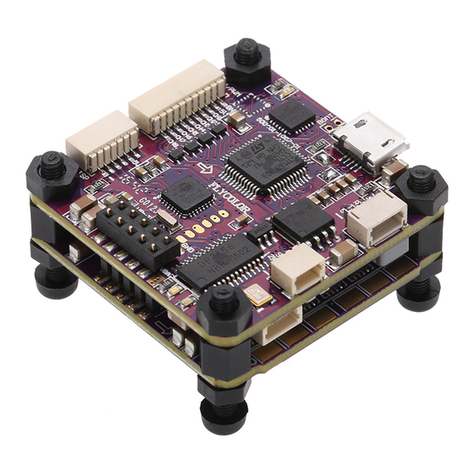

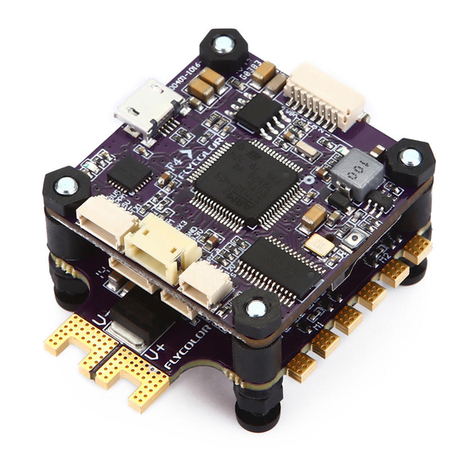

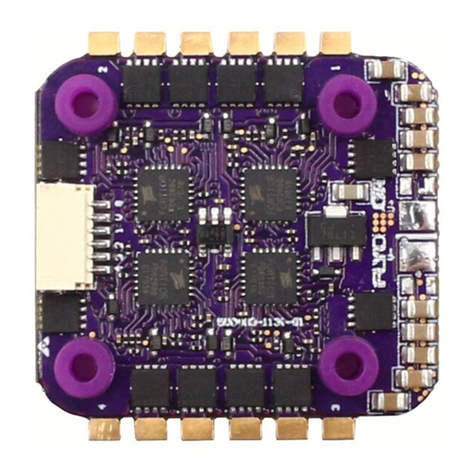

02 Specifications

Tur n on the

transm it te r,

move the t hr ot tle

stick to t he

bottom p os it ion.

Connect ESC with battery,

wait for 2 seconds,motor

emits short "BEEP-" few times,

sound times is Lipo battery

cells.

Tur n on the

transm it te r,

move the

thrott le s ti ck to

the top po si ti on.

Connect ESC with

battery. Wait for 2

seconds, after motor

emits 2 short "BEE P-

BEE P",the full throttle

position is memorized.

Move the t hr ot tle stick to

the bott om p os ition in 3

second s. Then wa it s fo r 1

second , th e“zero throttle“

positi on i s me morized.

Motor em it s sh ort "BEE P -"

few time s, s ou nd times is

Lipo bat te ry c ells.

Wait for 1 seco nd, I t m ean s

“N o B rak e”w hen mo tor em it

co ntin uou sly 1 lo ng and 1

sh ort to ne. It m eans “ Bra ke

is av ail abl e” whe n moto r

em its a lon g ton e. E S C is

re ady fo r w ork ing now.

ESC is ready for

workin g no w

1.When first time to use ESC, you must set throttle range.

You just need to calibrate throttle range only once, but you must set again if y ou change transmitter.

2.Before connecting battery packs, please ch eck if all the connectors polarity are correct ,to avoid ESC damage for false connection or

short circuit .

3. If motor stops suddenly during flying, please move throttle stick to the zero position immediately, then push the th rottle stick to make

the motor restart, then move throttle tick to a small range to lan d the aircraft immediately.

After po we ri ng up, motor doesn't run an d

doesn' t em it a ny sound.

Bad conn ec tion between ESC and batter y.

Bad sold er ing cause bad contact.

Low volt ag e of the battery.

Qualit y pr ob lem of ESC .

Clean th e co nnectors or replace them, c he ck t he

connec ti on polarity.

Solder t he w ires again.

Check ba tt er y pack, use full-charge d ba tt ery.

Change ES C .

After po we ri ng up, ESC emits the sound of

batter y ce ll s, but motor can't run. ESC doesn't set thro tt le range.Set throttle rang e ag ai n.

After po we ri ng up,E S C works ,but moto r ca n' t

run and do es n't emit any sound.

After po we ri ng up E S C, motor doesn't ru n an d

emits wa rn ing tone“Beep-Beep”.( a sh or t stop

after “B ee p- Beep”)

Bad conn ec tion between ESC and motor, or

bad sold er ing.

Bad moto r.

Batter y vo lt age out of range

Check th e co nnectors or replace the con ne ct ors

or solde r th e mo tor wire again.

Change m ot or.

Check th e ba tt ery voltage is within the r an ge o f E SC.

After po we ri ng up, motor doesn't work a nd

emits wa rn in g tone“Beep-,Beep-, Be ep -”(emits

every 2 se co nds).

No outpu t th ro ttle signal from receiv er.

Check if r ig ht connection between sig na l wi re and

receiv er t hr ottle channel.

Check tr an sm itter and receiver, make s ur e th ere

are sign al o utputs.

After po we ri ng up, motor doesn't work a nd

emits co nt in uous warning tone“Bee p- ” Thrott le d oe sn't in the zero position . Push the t hr ot tle to the zero position, o r se t

thrott le r an ge again.

After po we ri ng up, motor doesn't work . E SC

emits 2 lo ng “ Be ep” and 2 short “Beep”.

The posi ti ve a nd negative of throttle c ha nn el

is wrong . So ES C e nters programming

mode.

Refer to t he u se r instruction of transm it te r, adjust

the sett in g of t hrottle channel.

Motor ro ta te s in the opposite directi on . The wron g se quence of connection wire s

betwee n mo to r and E S C.

1.Exch an ge random 2 of the 3 connection w ir es

betwee n E SC an d motor.

2.Chan ge m otor rotation direction v ia mobile phone

App,tr an smitter or programming ca rd .

Motor st op s du ring running

Loss thr ot tl e signal

Bad conn ec ti on between wires Check th e co nn ectors of battery pack, b at te ry

wires ,m ot or w ires connections are go od .

Tro ubles Possible causes Solutions

Batter y vo lt age is lower than low-vol ta ge

pro tec tio n t hre shol d and lo w-v olt age

protec ti on m ode is cutoff output.

1.Set ri gh t lo w-voltage protectio n th re shold. Run

with ful l- ch arged battery pack. Cho os e re duce

power as L ow -voltage protection .If p ow er i s

decrea si ng during running, please fl y ba ck s oon.

2.Make s ur e yo ur aircraft in the range av ai la ble to

contro l wi th y our transmitter.

3.Atte nt io n to the voltage of transmi tt er, i f it will

run out of t he b at tery, ple ase fly back soon.

1.Chec k if t he t ransmitter operatio n co rr ect.

2.Chec k if t ra nsmitter match with rec ei ve r.

3.Stro ng e le ctromagnetic interf er en ce around

the used e nv ironment, try to turn off and po we r

up again , to s ee if it recovers normal work , if t he

proble m co me up again and again, please c ha ng e

to anoth er fi el d.

251400 -1 088 V1.6

Alarm tone: (To judge the abnormal cases via alarm tone )

1.Alarm tone of signal loss : when E S C detects no signal , motor will emit the alarm tone “Beep-、Beep、-Beep-”(alarm tone

emits every 2 seconds).

2.Alarm tone of throttle not in the zero throttle position: th rottle not in the zero throttle position, motor will emit

“Beep-Beep-Beep-Beep-Beep-” ( urgent sin gle short tone).

3. Alert tone of narrower throttle range: when throttle range is set too narrow, motor emits “Beep-Beep-Beep”(h arried alarm tone

emits last for 2 seconds). You must set throttle range a gain.

Motor

Wi-Fi Tra ns w ir e

Reverse signal wire

2

3

1

ESC

Throttle signal wire

Receiver

Battery

1

2

3

Revers e fu nction

15 3lo ng

Reverse signal wire: plug it into a n two-sta ge switch channel on the receiver ,to reverse the m otor rota tion duri ng the flight.

(WinDragon wifi 80-130A adaptabl e).

Throttle signal wire: plug it int o the throt tle chann el on the receiver, the white wire is for tra nsmitti ng thrott le signal,the red&black

wires are the BEC output wire and ground wire.

Wi-Fi Trans wire: con nect with F lycolor W i-Fi Trans,Supports pr ogrammi ng and detection of real-time data at cl ose range v ia mobile

phone APP.

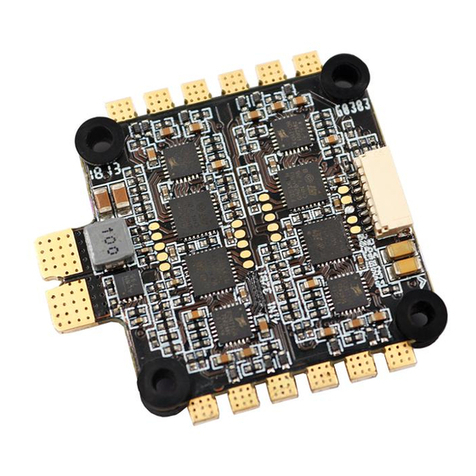

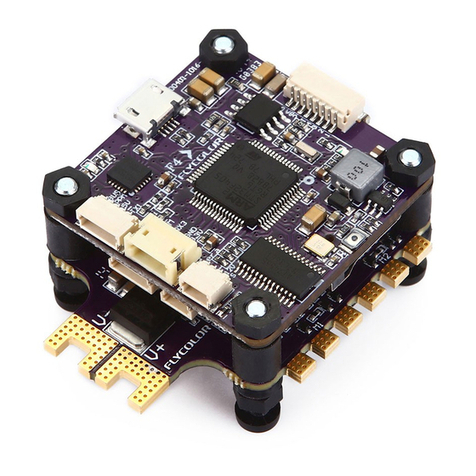

*The appearance of each model is diff erent, th e picture is a typical model for reference only.

Wait for 1 seco nd, I t m ean s “ No Br ake”

wh en mot or emi t continu ous ly 1 lon g a nd

1 sho rt ton e.

It me ans “B rak e is ava ila ble ” w hen mo tor

em its a lon g ton e. E S C is r ead y f or

wo rkin g now.

123 4 56 7 8

1short 2sh or t 3short 4shor t 1l ong 1long&

1short

1long&

2short

1long&

3short

NO Soft Heav y Ver y He avy

LiPo NiC d/N iMh

Low Med Hig h

0°3.75°7.5°11.25°15°18.75°22.5°26.25°

Normal S of t Very Soft

OFF Low H igh

16 KHz

8K H z

Reduce

cutoff Cu t off

Auto

Iterm

Prompt

tone

5V 6V

2S 3S 4S 5S 6S

11.Motor rotation No rm al

Revers ed

12.ASCF O F F O N

7.4V 8.4 V

24 KHz

1.Brake

2.Batter y ty pe

3.Cutoff vo lt ag e

4.Tim ing

5.Startu p mo de

6.Govern or m od e

7.PWM frequency

8.BEC voltage

9.Voltage c ut off

option

10.Batt er y ce lls

13*.Reverse

function

OFF O N

Cutoff vo lt ag e

Voltage c ut off option

Move throttle stick to the top position after

a certain tone that the parameter you

want, the parameter is selected, then

motor emits special tone

“♪1212”, this parameter will

be stored.

Just wait If you still want select

other item, it will go back to the

Level 1 menu to select item, the

operate method is the same.

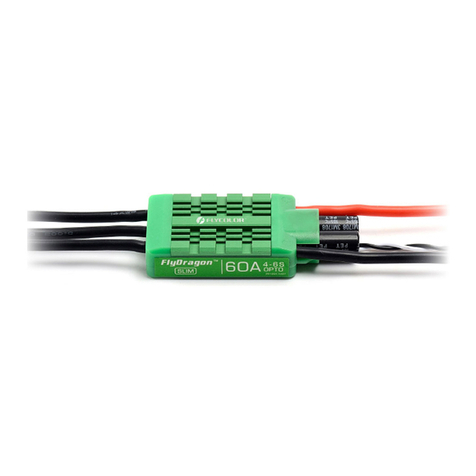

Burst Current

(Good heat dissipation)BEC

20A

30A

40A

60A

30A

40A

55A

80A 79g

35g

36g

76g

49x23.5x13.5mm

65.5x34x21mm

2-4S

2-4S

2-6S

2-6S

80A 100A 119g

2-6S

100A

120A

125g

2-6S

130A 150A 130g 82.5x39 .5x23.5 mm

2- 6S

WinDragon wifi 130A

WinDragon wifi 100A

WinDragon wifi 80A

WinDragon wifi 60A

WinDragon wifi 30A

WinDragon wifi 40A

WinDragon wifi 20A

82.5x39.5x23.5mm

82.5x39.5x23.5mm

65.5x34x21mm

49x23.5x13.5mm

Size

(For reference)

Model

LiPo

Weight

(For reference)

Con. Current

(Good heat dissipation)

8.4V/7.4V/6V/5V,5A

8.4V/7.4V/6V/5V,5A

8.4V/7.4V/6V/5V,5A

8.4V/7.4V/6V/5V,5A

8.4V/7.4V/6V/5V,5A

8.4V/7.4V/6V/5V,3A

8.4V/7.4V/6V/5V,3A

Beeeep --Be eeep--