IQECO31/230 BACnet MS/TP Terminal Unit Controller Installation Instructions - Mounting TG201224 Issue 13, 13-Jan-2021.

Installation Instructions - Mounting IQECO31/230

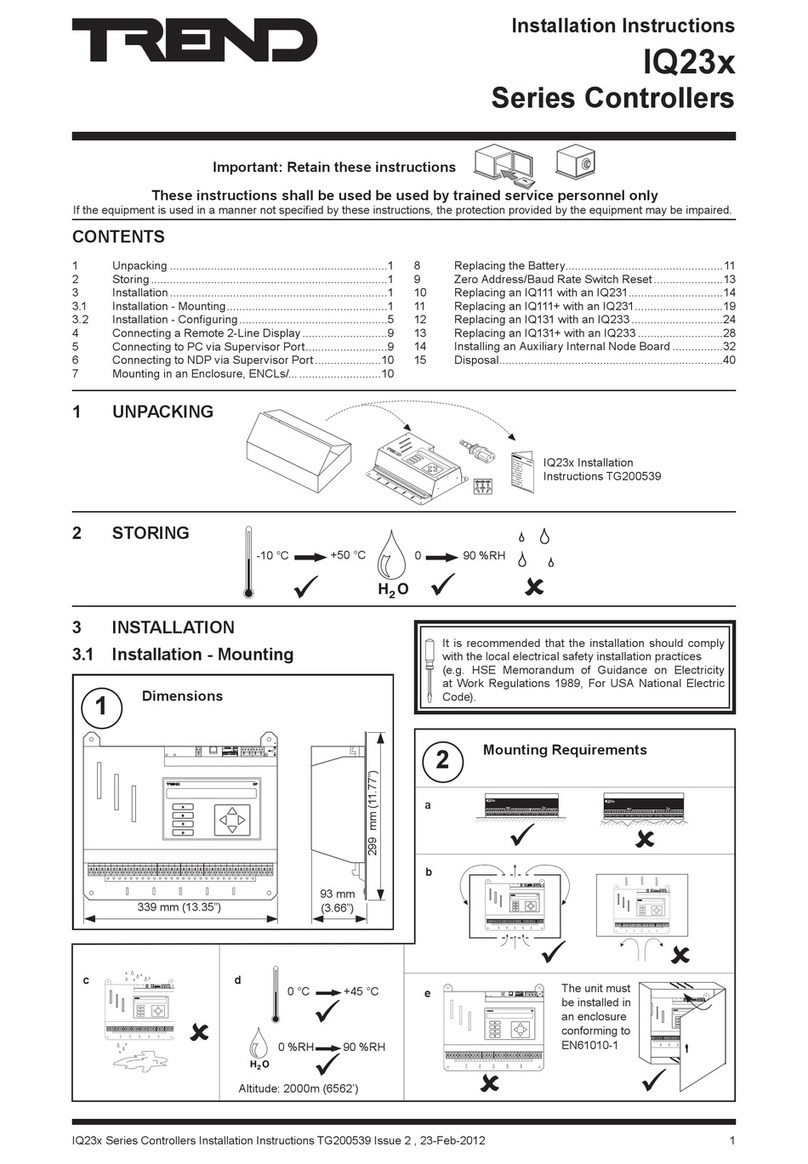

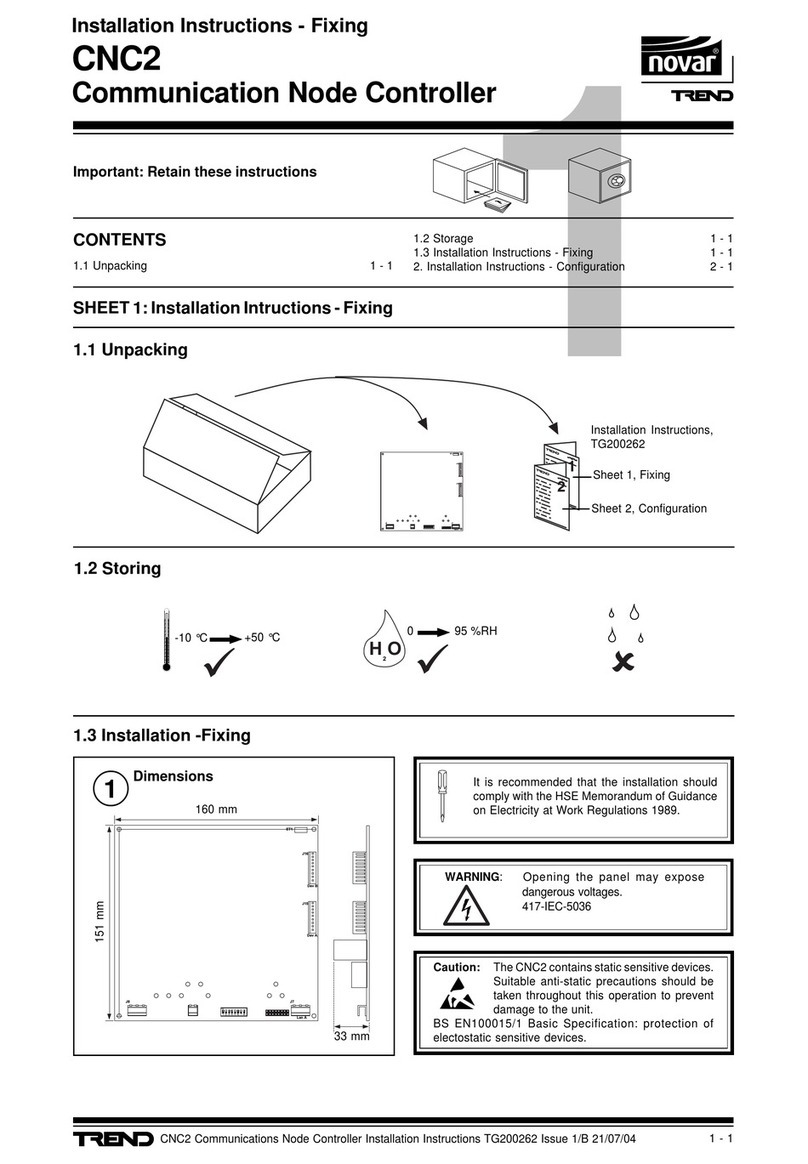

13 Connect MS/TP Trunk

Cable tie

Cable support

3.1 Installation - Mounting (continued)

Lay cable as bus topology (not loop or star).

Ensure correct polarity. Ensure maximum number of devices

described below is not exceeded.

Earthing: Connect all ground terminals and 24 Vac power

supply neutrals to the panel/enclosure ground. Ensure normal

safety earthing (grounding) practice.

Cable specication/Maximum length: Use tinned copper,

screened, twisted-pair cable with characteristic impedance

between 100 and 130 ohms. Distributed capacitance between

conductors shall be less than 100 pF per meter (30 pF per foot).

Distributed capacitance between conductors and screen shall

be less that 200 pF per meter (60 pF per foot). Foil or braided

screens are acceptable. The maximum recommended length

of an MS/TP segment is 1200 meters (4000 feet) with AWG

18 (0.82 mm2) conductor area) cable. There may be up to

3 repeaters between devices. The use of greater distances

and/or dierent wire gauges shall comply with the electrical

specications of EIA-485. Details of recommended cable are

given in the Trend TP Cable Data Sheet (TA200541).

*Screen Each MS/TP segment must have a single point

screen ground. Screen should be continuous. Do not ground

the MS/TP screen using a controller terminal. Ground screen

at one end and cut back at the other end. At connecting points,

tie the screen through a terminal.

Additional Terminal

**Terminators: The bus must be terminated at each end

with a resistor matched to the cable characteristic impedance

(i.e. ±1%, ¼ Watt, range 100 to 130 ohms). If the IQ4NC is at

one end of a 120 ohm cable, switch in its built-in terminator,

otherwise switch it out and t a resistor at that end of the cable;

the other end must be terminated with a matching resistor.

Maximum number of devices: There may be IQ4NC with

up to 64 IQECO’s or other manufacturers’ devices on the

MS/TP trunk. A separate limitation is that the MS/TP segment

supports up to 32 ‘unit’ loads. IQECO, IQ4NC and IQ3/BINC

present a ¼ BACnet ‘unit’ load; other manufacturers’ devices

may have dierent ‘unit’ loads.

Biassing The IQ4NC provides network biassing (470 ohms);

a maximum of two devices on the network can provide

network biassing.

Failure to comply with these practices will result

in signicant impairment of the communication

performance.

+

+

+

+

Cut back

Screen

Either; Or

120 ohms

(nominally)

Ensure correct

polarity

Ensure correct

polarity

Ensure correct

polarity

Ground

Screen

120 ohms (nominally)

Additional

Screen

Additional

Screen

Screen

82 83

33 34

1 2 3

1 2 3

2 1

0V V+

120 ohms

IQ4NC

230 Vac

230 Vac

IQECO/31 /35 /38

24 Vac

24

Vac

IQECO/VAV /39

24 V

24

Vac

34 33

MS/TP 0V

MS/TP

N L