TECNA S.p.A. ITEM TE700 Instruction Manual

7/128

1.1 – MAIN TECHNICAL FEATURES

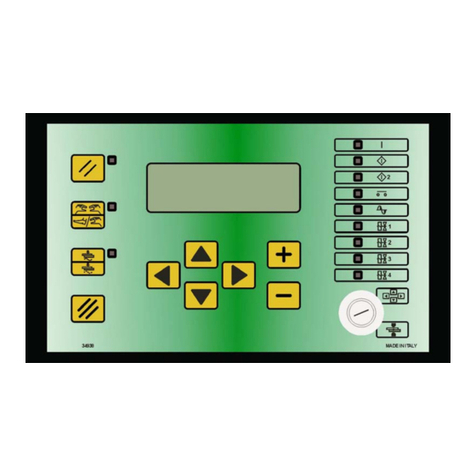

Simplified programming via 6 keys and a backlit alphanumeric LCD.

Inverter command with medium frequency IGBT, with possibility of choosing the operating

frequency of the inverter between 1000 Hz and 4000 Hz.

Storage of up to 300 welding programs; 255 may be called from external devices.

Possibility of associating an 8-character alphanumeric identifier with each weld program.

Possibility of managing as many as 4 different welding transformers or one transformer and 4

different types of electrodes.

Overheating protection for the welding transformers.

Up to 32 programmable parameters for each program.

Slope up, Slope down, pulses, pre-weld, post-weld functions and adjustment of the welding times

with units of 1 mS.

Display of the RMS of the welding current, energy, power, RMS of voltage to the electrodes, of the

initial and final resistance, of the machine's thermal use percentage, of the machine's use

percentage and, as an option, of the initial thickness of the welded material and the indentation at

the end of the weld.

6 WORKING MODEs: conventional, constant current, constant power, constant voltage, FIX,

constant energy, DYNAMIC mode.

Limit indicators for: Current, voltage at the electrodes, energy, power, inverter use percentage,

initial and final resistance of the material to be welded; thickness and indentation limit of the

material (optional).

Double stroke function.

Stepper function to compensate the wear and tear of the electrodes with programmable curves and

possibility of intervening independently on the time and the welding current through differentiated

stepper laws. Possibility of using 4 different stepper options associated with 4 different spot

counters associated with each weld program.

Single and automatic cycle. WELD and NO-WELD function.

Control of 5 solenoid valves 24 VDC max. 5 W with self-protected output.

Self-adjustment to the mains frequency 50/60 Hz.

Serial communication with insulated RS232 as an option.

Output for proportional solenoid valve.

Key for selecting foot control or two-hand control.

Selectable languages: Italian, English, French, German, Spanish, Hungarian, Swedish or

Portuguese.

Possibility of upgrading control unit Firmware via appropriate software.

Electrode tip dressing for up to max of 4 different spot counters (optional).