tecn@

WELDERS ITEM 8201N ÷ 8214N

EDITION: MAY 2008 PAGE 9 OF 32

3 INSTALLATION

These paragraphs are addressed to the specialised personnel in charge of both welder transport

and installation. The welder dimensions diagram in the technical documentation booklet provides

useful information for carrying out these operations.

3.1 PLACE OF INSTALLATION

The welder must be installed in a position fulfilling the following features:

•In an inner place. The use of the welder in an open place is not foreseen.

•Room temperature included between 0 and 40 °C (If water is removed, storage is allowed

down to 20°C below 0); 1000 m. maximum altitudes.

•In a well ventilated area, free from dust, steam, and acid exhalations.

•The working place must be free from inflammable materials because the working process can

produce spatter of melted metal.

•Around the welder there must be enough room to carry out both working and maintenance in a

comfortable manner and without any risk.

•In a place with a suitable lighting system in comparison with the work to be carried out.

•The place of installation must necessarily be flat and the ground must be without unevenness

which can be dangerous during the working.

If the welder is used to carry out welding processes which can cause smoke exhalations, there

must be installed a proper aspirator. The welder must be properly fixed to the ground through the

proper holes placed on the welder basement. Do not install nearby the welder neither supporting

tables nor equipment limiting the approaching to the devices and/or making inaccessible or

ineffectual the safety devices.

3.2 UNPACKING AND TRANSPORT

On receipt of the welder, verify the perfect integrity of the outer package; communicate to a

responsible in charge possible anomalies which should be noticed. Possible damages on the

outer package should arise some doubts on the integrity of its content. Remove the package and

visually verify the welder integrity. Check that the welder is equipped with all the standards

components; immediately inform the manufacturer in case some components should lack. All the

material forming the package must be removed according to the present environmental

protection regulations.

The welder barycentre is high from ground. For this reason, the welder must be moved only by

means of the proper attachment placed on the unit upper side. Consider the welder weight stated

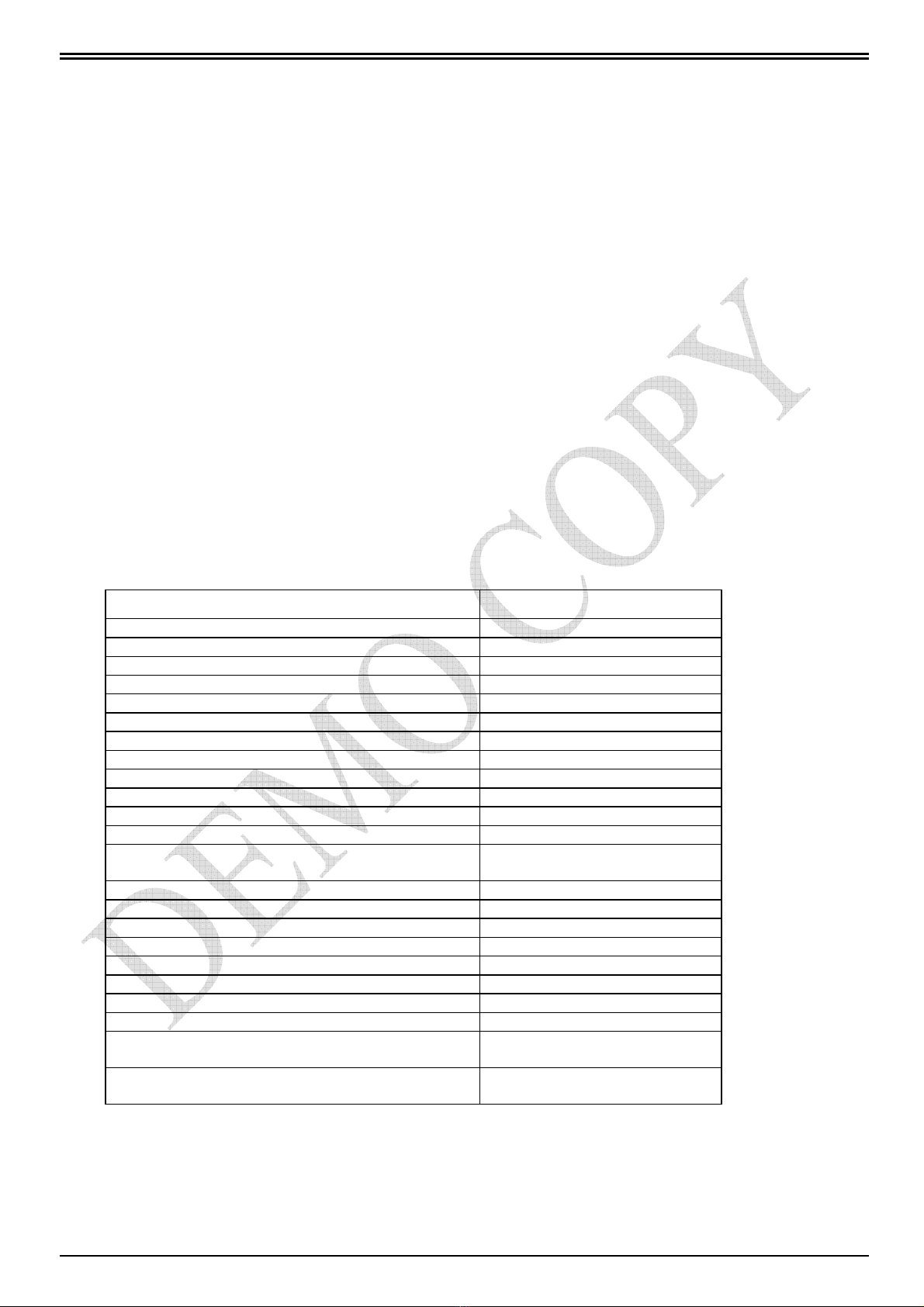

on the “TECHNICAL FEATURE” paragraph.

3.3 PNEUMATIC INSTALLATION

For a correct compressed air supply to the welder, it is necessary either a centralised system or a

compressor capable of supplying dry air cooled within the maximum pressure and in the quantity

stated in the paragraph “Technical Features”. Pay attention to the hoses minimum diameter

stated in the same paragraph.

In case the line is subject to great pressure variations, it is advisable to supply the welder by

means of a tank of at least 50-100 litres equipped with a gauge-pressure supplied by means of a

one-way valve.

The machine is equipped with a filter unit, the moisture of which must be discharged periodically.

Periodically discharge also the moisture eventually present in the built-in small air tank, by means

of the tap placed on the bottom of the tank itself.