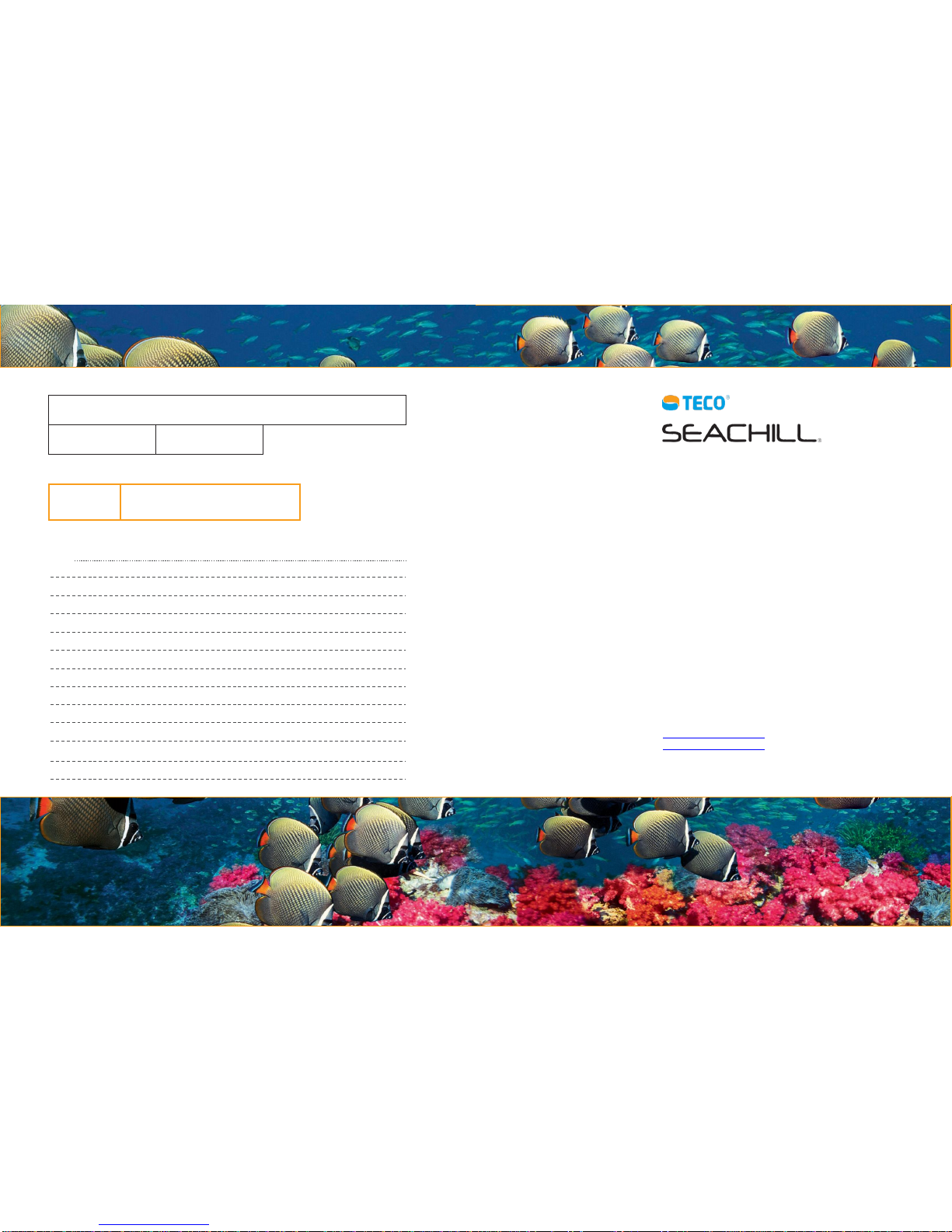

Valve Assembly

Plumbing

1

Unscrew the Ring Nuts for the

shut off valves from the chiller

inlet and outlet. Remove the In/

Out plugs from the In/Out ports

ofthe chiller. Removethe O-rings

SeaChill Chillers can be plumbed using flexible plastic tubing or hard

plumbedusingPVC.

Flexible Tubing

Above photos are of a TR5 model

from In/Out plugs. (do not discard

In/Out plugs–store for use should

you ever need to transport or ship

the chiller to another location).

2

Slide the Ring Nutsonto the Shut

Off Valves past the two small clips

of plastic projecting from the side

of the Shut Off Valves.

Note: Once Ring Nuts have been

pushed past the plastic clips on the Shut

Off Valves, do not remove Ring Nut

from Shut Off Valves, this will break the

plastic clips, causing the valve to leak.

3

Roll the O Rings onto the Shut

Off Valve below the Ring Nut.

Do not push O Ring past plastic

clips on Shut Off Valves.

4

Place the Shut Off Valve into

the Outlet of the chiller, do not

use much force. Hand tighten

the Ring Nuts to seat the O-Ring

and attach the Shut Off Valve

Securely to the chiller.

Note: the first nipple on the Shut Off

Valves will take 5/8” id tubing. The

second, larger nipple will accept 3/4” id

tubing. Remove compresssion fitting for

5/8” tubing before using 3/4” tubing.

Use the tubing size you prefer.

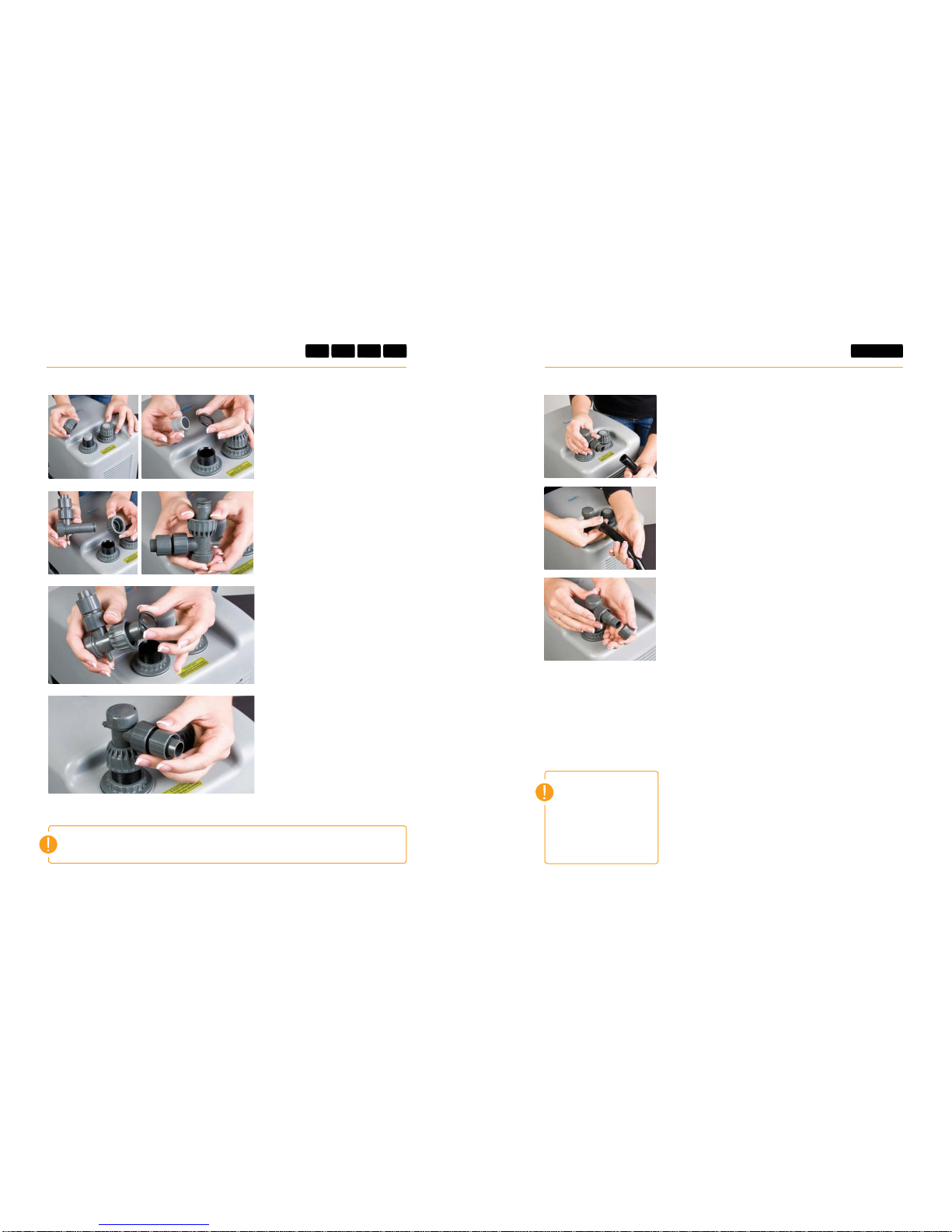

1

PVC

1

2

3

4

Attach flexible plastic tubing from the pump to the chiller

by sliding tubing over nipple on Shut Off Valves. Tighten

Compression Fitting over the end of the flexible plastic tubing

byturningfittingcounter-clockwise until tubing is secure.

Note: If the chiller should ever need maintenance, it will be necessary to remove the

chiller cover. Do not hard plumb PVC to the chiller. Plan ahead and use ball valves or

gate valves to allow water flow to be shut off. Install unions to allow for the removal

of the chiller cover.

Recommended PVC parts

(may be either schedule 40 or schedule 80 PVC)

For installation using PVC solvent socket type fittings:

•

1” FPT x Slip adapters (2)

•

1” PVC pipe, 1” Slip x Slip Ball Valves (2)

•

1” Slip X Slip Unions (2)

•

Teflon tape or pipe thread sealant with Teflon

Unscrewthe Ring Nuts for the shut off valves from the chiller inlet

andoutlet.RemovetheIn/OutPlugsfromthe In/Out portsof

the chiller (do not discard In/Out plugs –store for useshould you

everneedto transportor shipthechillerto anotherlocation).

Keep the Housing Ring Nuts in place, wrap the male threaded

inlet and outlet from the chiller in Teflon tape or pipe thread

sealant with teflon to prevent leaks. Wrap Teflon tape at least

twice around threads. Check carefully for leaks. Slow leaks

may occur.

Screw the 1” FPT x Slip adapters over inlet and outlet to chiller.

Tightenfirmly but do not use excessive force.

Assemble the remaining PVC as you wish making sure you can

easily unscrew the 1” FPT x Slip adapters to maintenance the

chillerifnecessary.