1

ZVL933.00 Mod: 12-05-2016

ITALIANO

ENGLISH

FRANÇAIS

DEUTSCH

ESPAÑOL

ATTENTION! Before installing this device read the

following instructions carefully!

Conformity declaration Page 2

Important remarks Page 8

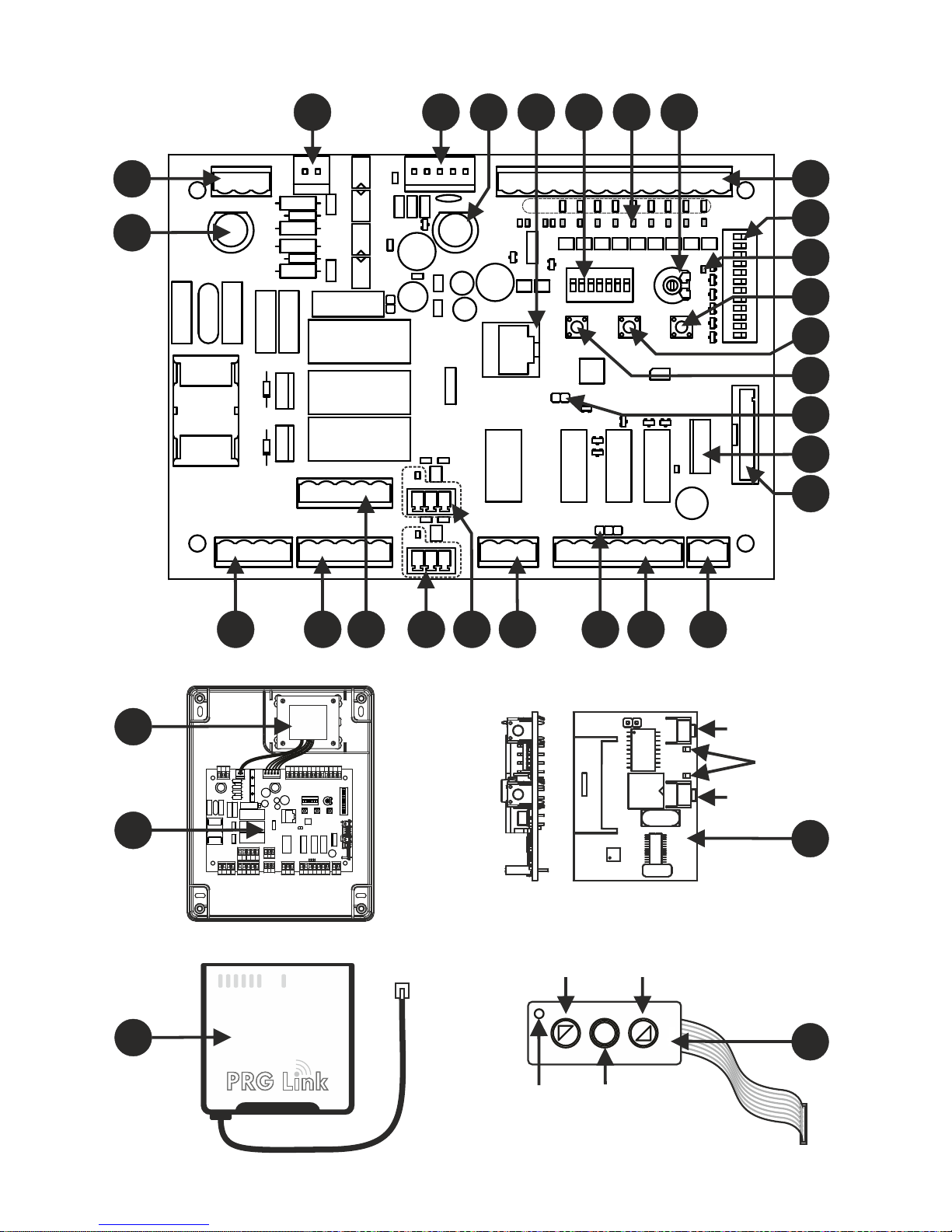

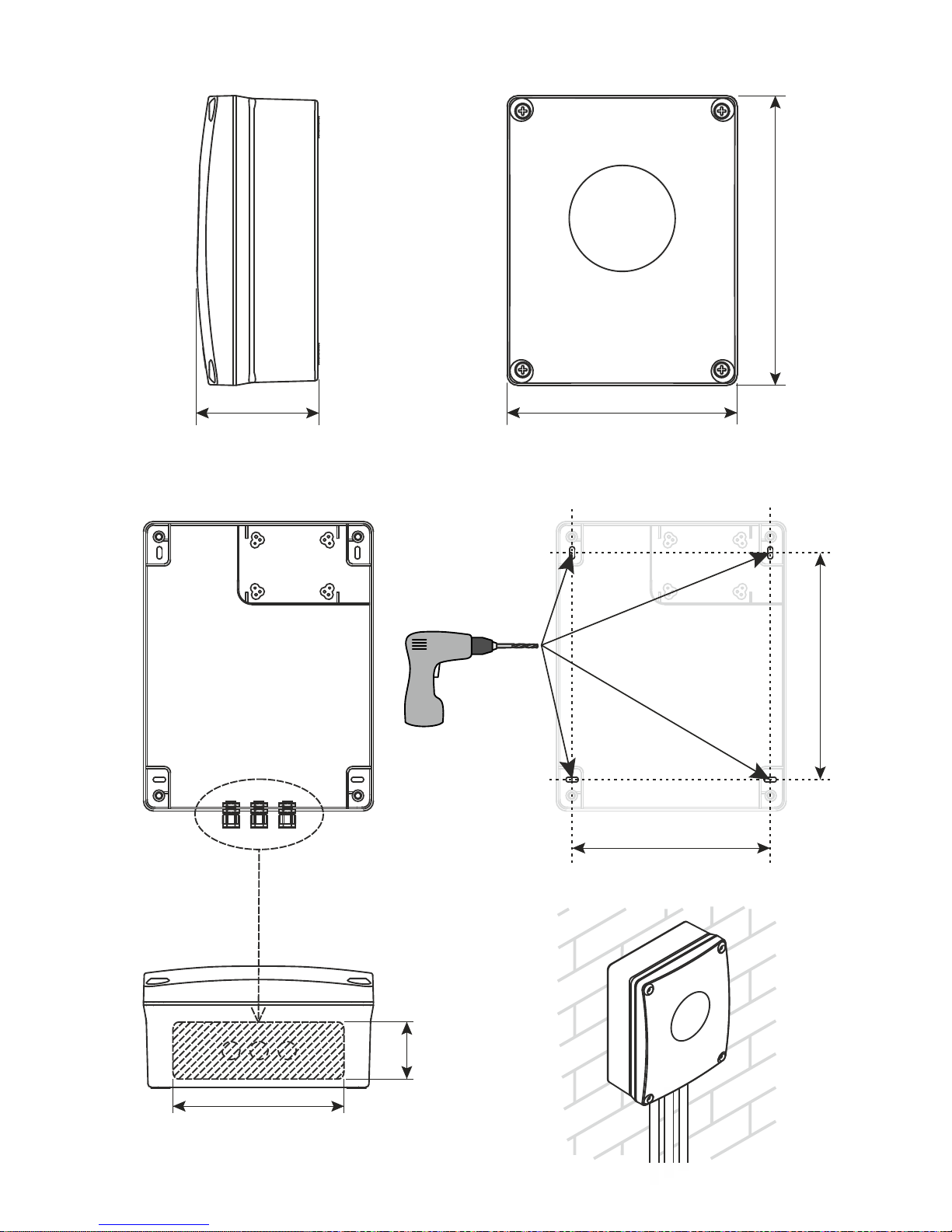

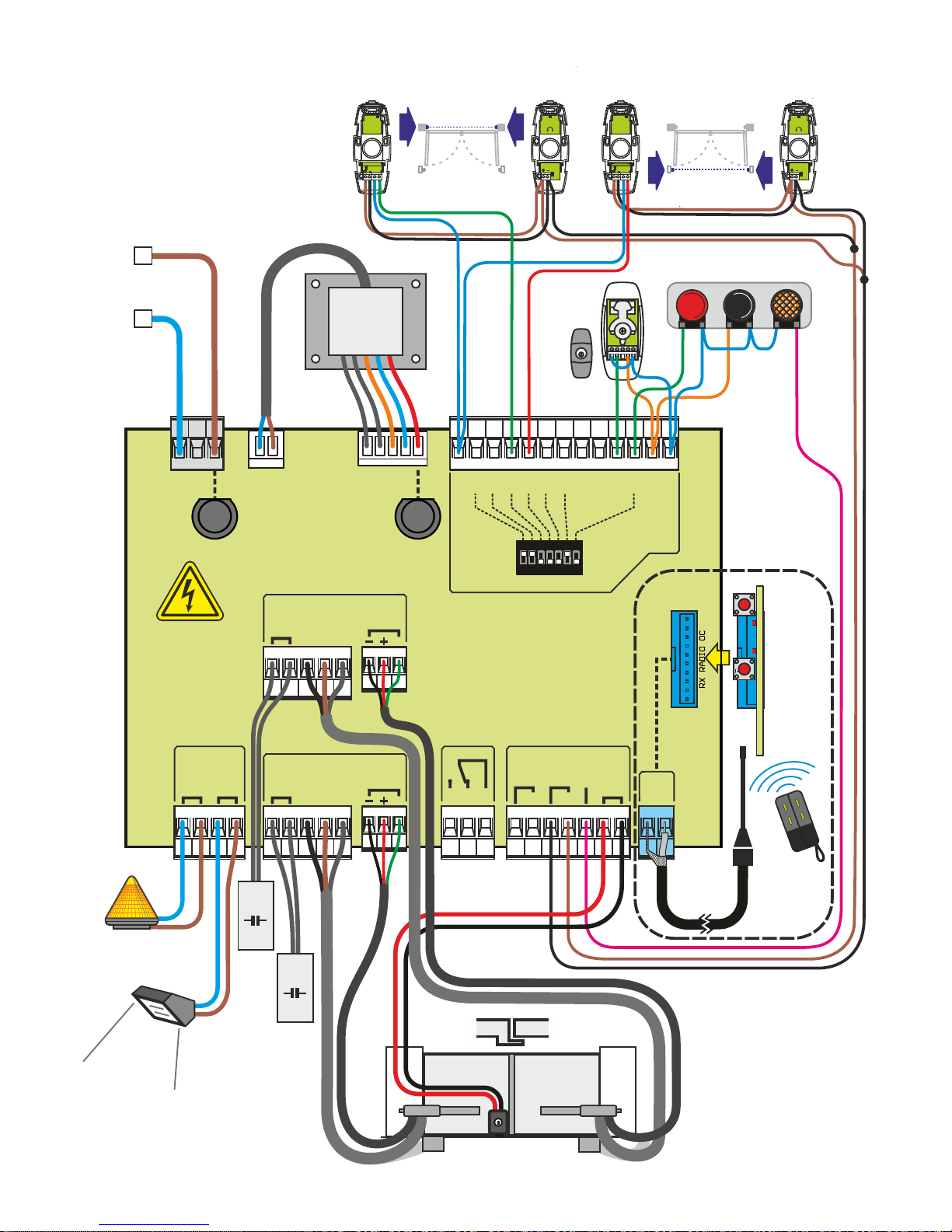

Electrical connection Pages 8-9

Programming procedure Pages 10-11

Remote control Page 12

Function modes Page 12

Indications on the display Page 12

Technical specications Page 28

ATTENTION! Avant de commencer la pose, lire atten-

tivement les instructions!

Déclaration de conformité Page 2

Consignes importantes Page 13

Branchement électrique Pages 13-14

Procédé de programmation Pages 15-16

Commande via radio Page 17

Modes de fonctionnement Page 17

Indications de l’afcheur Page 17

Caractéristiques techniques Page 28

ACHTUNG! Bevor mit der Installation begonnen wird,

sollte die Anleitung aufmerksam gelesen werden.

Konformitätserklarung Seite 2

Wichtige Hinweise Seite 18

Elektrischer Anschluss Seiten 18-19

Programmierverfahren Seiten 20-21

Funkbefehl Seite 22

Betriebsmodus Seite 22

Displayanzeigen Seite 22

Technische Eigenschaften Seite 28

¡ATENCIÓN! Antes de iniciar la instalación del sistema,

leer atentamente las instrucciones.

Declaración de conformidad Página 2

Advertencias importantes Página 23

Conexionado eléctrico Páginas 23-24

Procedimiento de programación Página 25-26

Mando vía radio Página 27

Modalidad de funcionamiento Página 27

Indicaciones en el display Página 27

Datos técnicas Página 28

ATTENZIONE! Prima di iniziare l'installazione leggere

le istruzioni attentamente!

Dichiarazione di conformità Pagina 2

Avvertenze importanti Pagina 3

Collegamento elettrico Pagine 3-4

Procedura di programmazione Pagine 5-6

Comando via radio Pagina 7

Modalità di funzionamento Pagina 7

Indicazioni del display Pagina 7

Caratteristiche tecniche Pagina 28

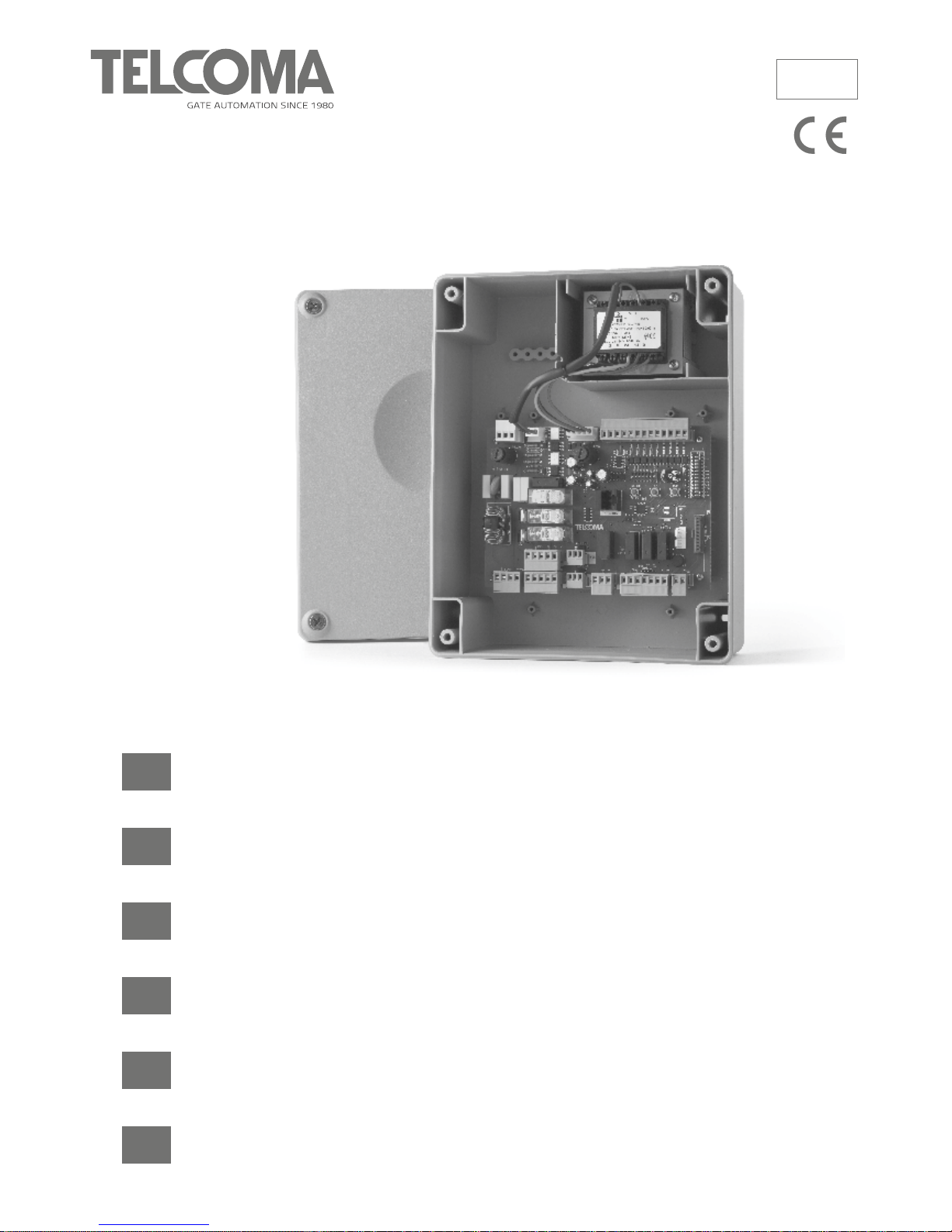

230 Vac Motors

PROGRAMMATORE ELETTRONICO PER IL COMANDO DI PORTE E PORTONI MOTORIZZATI

ELECTRONIC PROGRAMMER CONTROLLING MOTORISED GATES AND DOORS

PROGRAMMATEURÉLECTRONIQUE POURLACOMMANDEDEPORTESETPORTAILSMOTORISÉS

ELEKTRONISCHERSTEUERUNGSEINHEIT FÜRDIE AUTOMATISIERUNGVON TÜRENUND TOREN

PROGRAMADOR ELECTRONICO PARA EL CONTROL DE LAS PUERTAS MOTORIZADAS

Questo prodotto è stato testato e collaudato nei laboratori della casa costruttrice, la quale ne ha verificato la

perfetta corrispondenza delle caratteristiche con quelle richieste dalla normativa vigente. This product has been

tried and tested in the manufacturer's laboratory who have verified that the product conforms in every aspect to

the safety standards in force. Ce produit a été testé et essayé dans les laboratoires du fabriquant. Pour l'installer

suivre attentivement les instructions fournies. Dieses Produkt wurde in den Werkstätten der Herstellerfirma

auf die perfekte Übereinstimmung ihrer Eigenschaften mit den von den geltenden Normen vorgeschriebenen

getestet und geprüft. Este producto ha sido probado y ensayado en los laboratorios del fabricante, que ha

comprobado la perfecta correspondencia de sus características con las contempladas

por la normativa vigente.

Model Date

Instruction manual Series

PRG230M2 V0.2

01-04-2016

ZVL593.00

CARDIN ELETTRONICA spa

Via del lavoro, 73 – Z.I. Cimavilla

31013 Codognè (TV) Italy

Tel: +39/0438.404011

Fax: +39/0438.401831

Http: www.cardin.it