Page <3> V1.025/03/22

Newark.com/exclusive-brands

Farnell.com/exclusive-brands

Element14.com/exclusive-brands

1. Overview

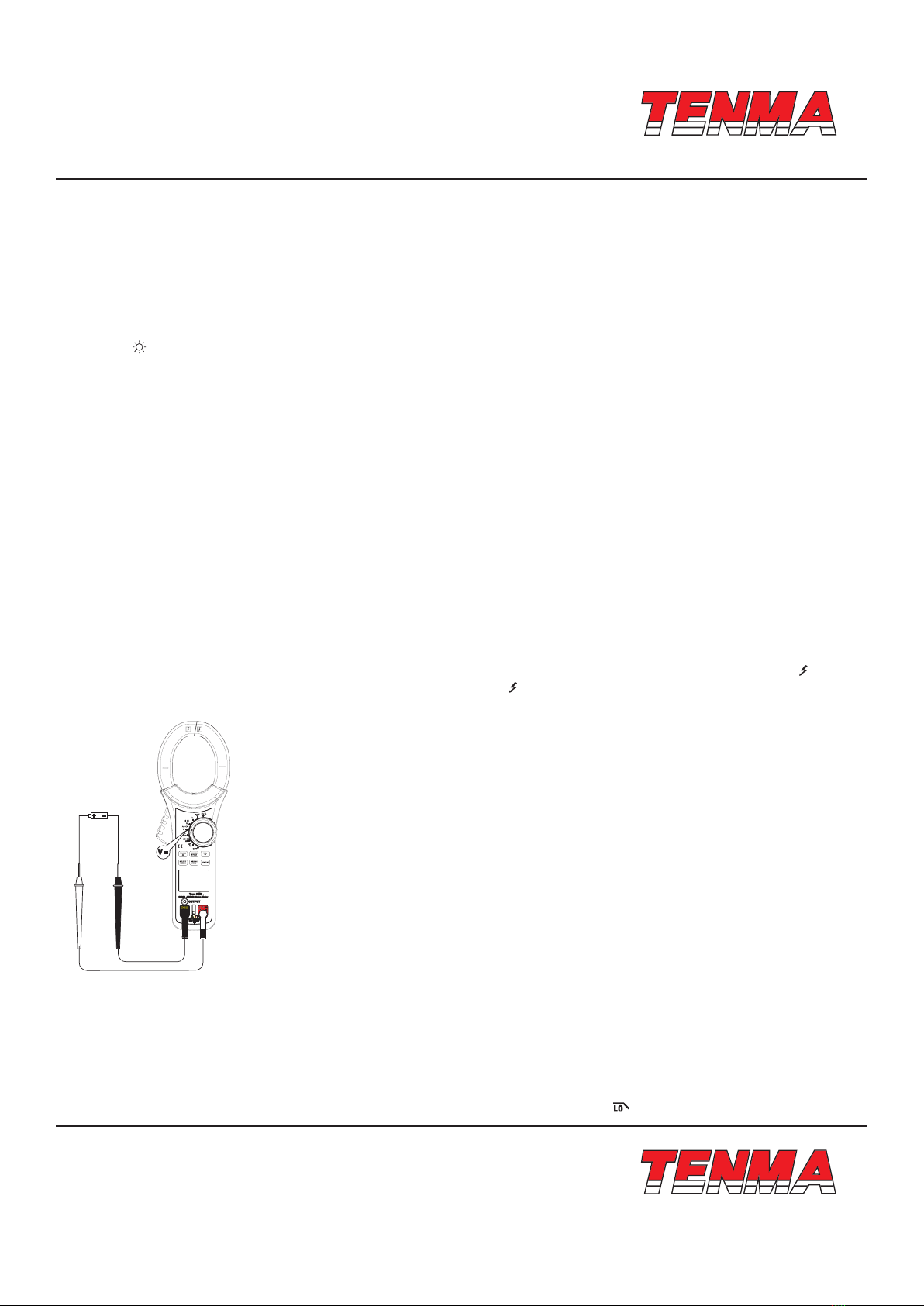

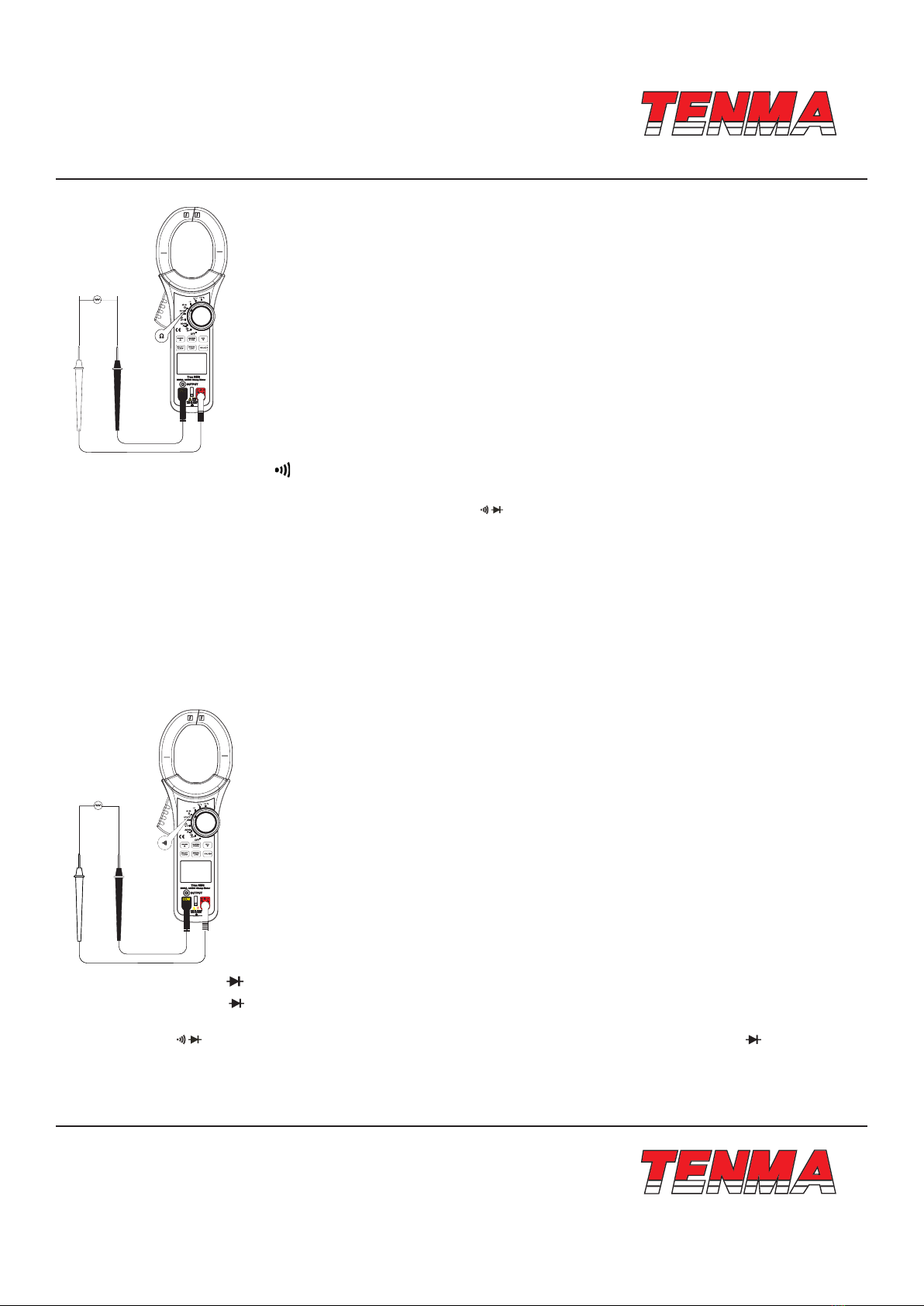

72-7800 is a portable true RMS 5-5/6 bit (6000 Counts), auto range clamp ammeter with analog simulation bar graph. The clamp

ammeter featuring full-function on screen display, full-range overload protection and unique design makes this a highly featured

clamp ammeter with incredible performance. The clamp ammeter is applicable to following measurements: AC/DC voltage, AC/

DC current, surge current, resistance, frequency, maximum/minimum value measurement, relative value measurement, data

recording and read-back, under-voltage display and automatic shutdown function.

The instruction manual includes relevant safety information and warning indication, please read them carefully and strictly

observes all warnings and notes.

2. Open Case and Check

Unpack and remove the instrument. Check the instrument for any damage and verify that the following items are included in

the box. If anything is damaged or missing, please contact your supplier.

• An operating instruction manual

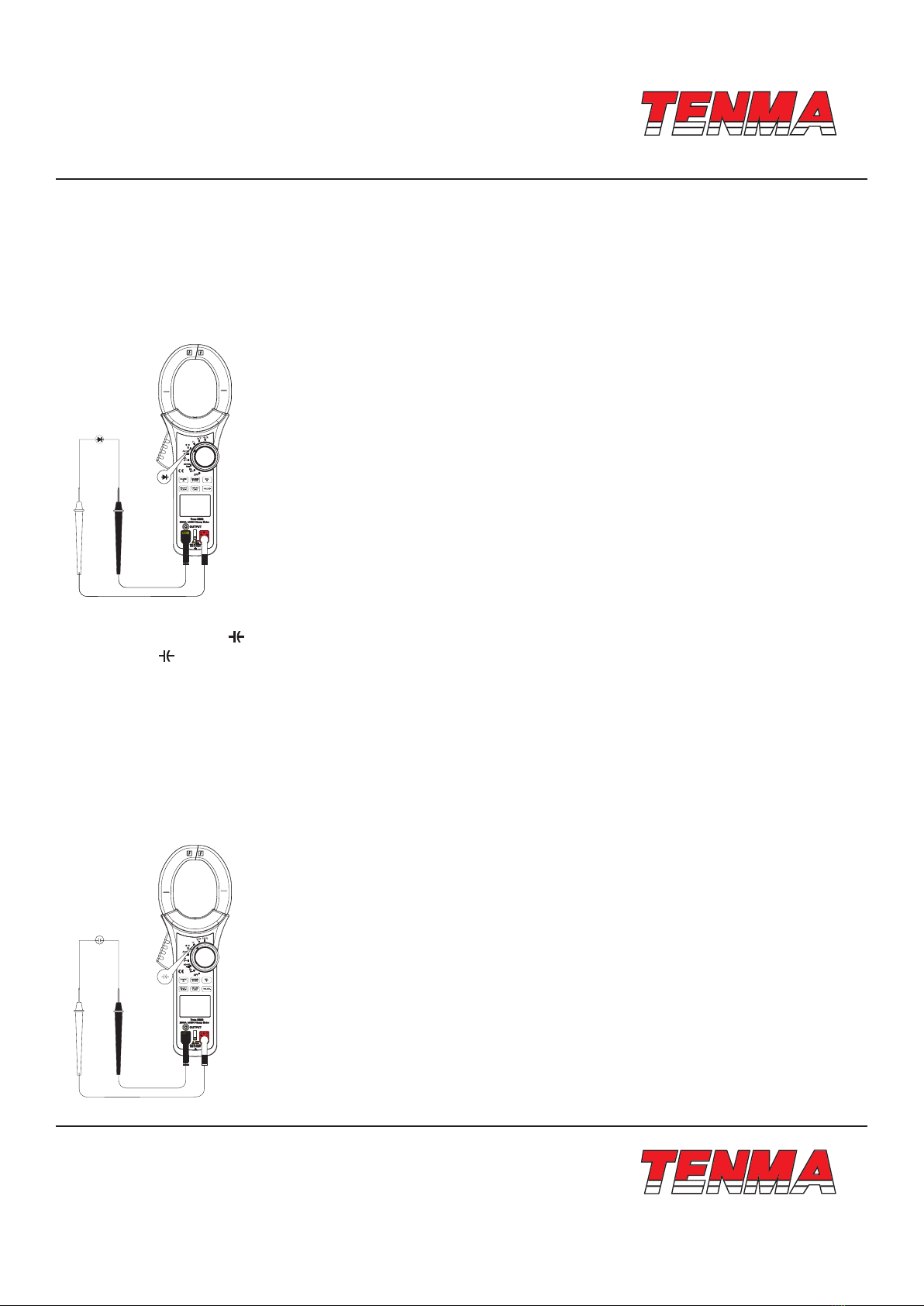

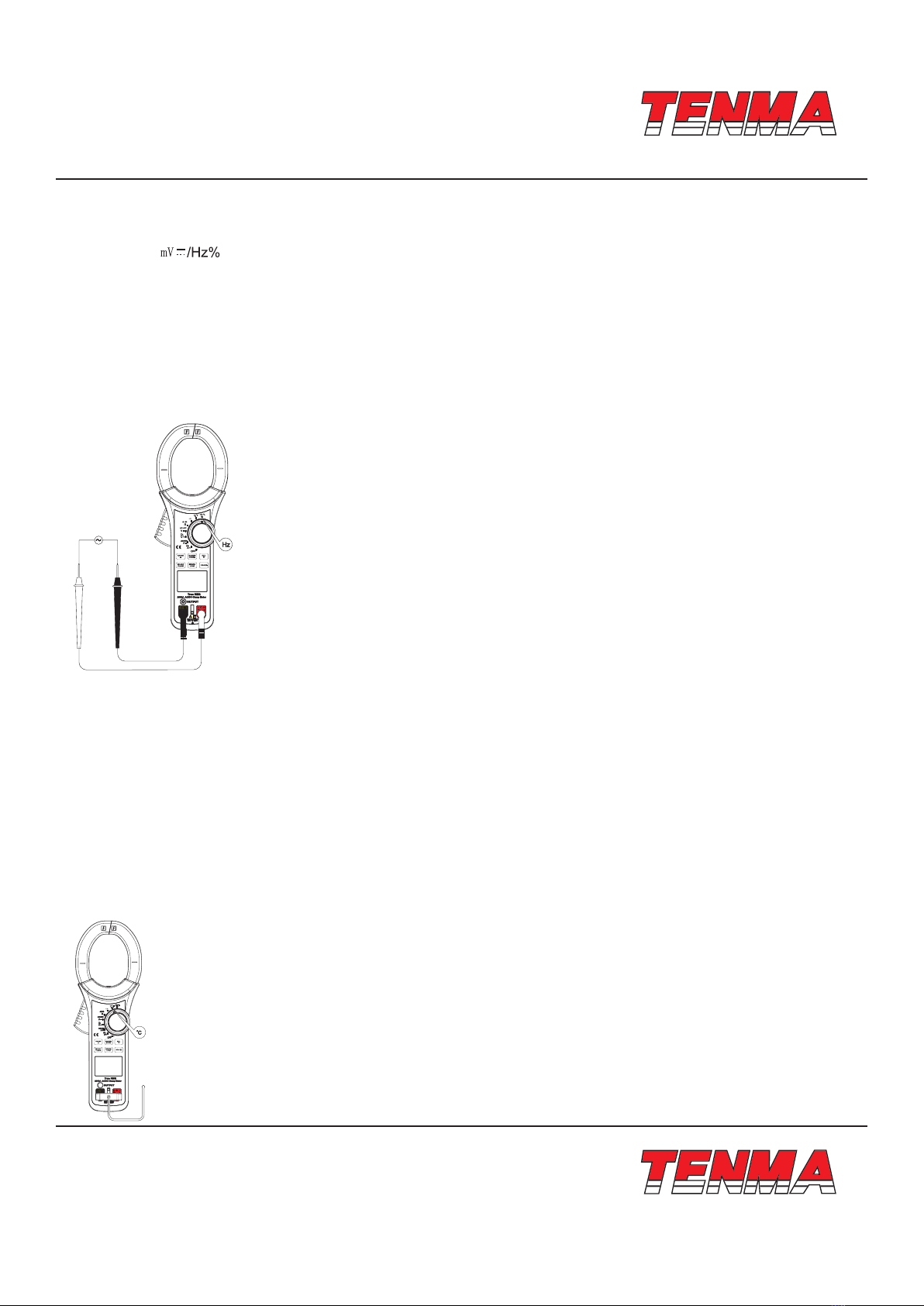

• A test lead

• A Temperature sensor

• A carry case

• A safety certicate

3. Safety Codes

The clamp ammeter is designed and produced strictly in accordance with IEC61010-1 safety standards. It meets the double

insulation over-voltage standardd CAT II 1000V. CAT III 600V and safety standards of pollution degree II. If failure to use the

meter under the relevant operation instruction, the protection provided shall be weakened or lost.

1. Check the clamp ammeter and test leads before use, guard against and damage or abnormal phenomenon. if abnormal

condition is found: bare test leads, damaged classic, no display or random display in LCD, please do not use it. It is forbidden

to use the clamp ammeter without rear cap or rear cap not in place, or otherwise there is risk of electric shock.

2. Damaged test lead should be replaced with a new one.

3. Do not touch the bare wire and connector, used input terminal or the circuit being measured when clamp ammeter is in

operation.

4. Be careful in measuring voltage higher than DC 42V or AC 30V and keep ngers behind the test lead nger guard to prevent

against electrical shock.

5. Set the function range switch at the maximum range position if the scope of measured value could not be dened.

6. Do not use voltage or current values greater than those dened by the clamp meter for safe use.

7. Set function switches to their needed positions before measurement. Before changing functions, remove the test leads from

their measured circuits to prevent damage to the meter.

8. Refrain from storing or using the clamp ammeter in explosive and ammable environment with high temperature, high

humidity and strong electromagnetic eld.

9. Refrain from altering the internal wiring in the clamp ammeter to guard against damage to meter and danger.

10. When LCD display shows the icon “ ”, it is required to replace the battery in time to ensure the measurement accuracy.

11. Power o immediately after measurement. Take out battery when the clamp ammeter is not be in use for a long time.

4. Electrical Symbols

Dual Insulation

Grounding

Warning prompt

AC (Alternating Current)