Tescom ER3000 User manual

ER3000 Electronic

Pressure Controller

User Manual

PRODUCT WARRANTY

Tescom ("Tescom") warrants to the party who purchases products for initial use

directly from Tescom, its affiliates or authorized distributors or representatives

("Initial Purchaser") that products manufactured and sold by its Industrial Controls

Group (“IC”) are free from defects in materials and workmanship under normal use

and service for a period of 365 days from the date of delivery of the products

("Warranty Period"). This warranty applies only to the Initial Purchaser. This

warrantyis not transferable to subsequent purchasers or users of the products.

During the Warranty Period, Tescom will, in its sole discretion, repair or replace, free

of charge at its factory in Minnesota, any product or part thereof that is found by

Tescom, after reasonable notification by the Initial Purchaser, to have been defective

in materials or workmanship. The Initial Purchaser must pay all shipping costs for

warranty service and is responsible for risk of loss or damage of products during

shipment. Tescom does not warrant, and will not pay for, any repairs or replacement

made during the Warranty Period by anyone other than personnel authorized by

Tescom or its IC Group to make such repairs or replacement.

THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES.

TESCOM AND ITS IC GROUP MAKE NO OTHER EXPRESS OR IMPLIED

WARRANTY, AND IN PARTICULAR AND WITHOUT LIMITATION MAKE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

PARTICULAR PURPOSE. The Initial Purchaser's only remedy under this warranty

is repair or replacement of the products during the Warranty Period. This warranty

does not apply to any product which has been damaged by accident, abuse, misuse,

modification or lack of proper maintenance. NEITHER TESCOM, NOR ITS IC

GROUP WILL BE LIABLE FOR ANY CONSEQUENTIAL, SPECIAL,

INCIDENTAL OR INDIRECT DAMAGES, INCLUDING WITHOUT

LIMITATION, LOST PROFITS.

INDUSTRIAL CONTROLS

12616 Industrial Boulevard

Elk River, Minnesota 55330-2491

1-800-447-1250 (763) 241-3238

FAX (763) 241-3224

e-mail: na.tescom@emerson.com

www.tescom.com

Windows3.1, Windows95, WindowsNT, DOS, and Visual Basicare trademarks of Microsoft

Corporation. LabVIEWand LabWindows/CVI are trademarks of National Instruments

Installation & Operation Precautions

TESCOM Industrial Controls

INTRODUCTION

Prior to installing or operating any equipment, read and follow all the information listed. Improper

application and operation can result in damage to equipment or severe personal injury.

All possible hazards and precautionary measures cannot be covered here. It is recommended that

prior to using this equipment, you fully understand and comply with existing safety regulations.

OXYGEN SERVICE

Specification of the materials in regulators used for oxygen service is the USER’S

RESPONSIBILITY. Cleaning for oxygen service to 3000 PSIG is supplied standard by Tescom at

no additional cost for mechanical regulators. Cleaning for service above 3000 PSIG may be

contracted through an outside source.

COMPATIBILITY

Tescom may suggest material for use with specific media upon request. Suggestions are based on

technical compatibility resources through associations and manufacturers. Tescom does NOT

guarantee materials to be compatible with specific media - THIS IS THE RESPONSIBILITY OF

THE USER! Users must test under operating conditions to determine suitability of materials in an

application.

PRESSURE RATING

Verify the designed pressure rating of the equipment. Check supply lines, fittings, connections,

filters, valves and gauges. All must be adequate for the supply and operating pressure.

RELIEF PROTECTION

A regulator is not intended to be used as a shut-off device. A pressure relief device should be

installed downstream of the regulator to protect the process equipment in the case of a rise in

operating pressure. When the regulator is not in use, the supply pressure should be closed.

FILTRATION

An auxiliary upstream filter is recommended for use in all media. Gaseous media should be free of

excessive moisture to prevent icing of the equipment.

MAINTENANCE

Periodic inspection and scheduled maintenance of your equipment is essential for continued safe

and satisfactory operation. The frequency of servicing will depend on the application.

REPAIR SERVICE

Any equipment in need of service should be returned to your equipment supplier for evaluation and

prompt service. If repairable, your equipment will be restored to the original factory performance

specifications. A flat fee repair charge has been established for each standard model and the

original equipment warranty will be reinstated after a complete overhaul.

ASSEMBLY/INSTALLATION DRAWINGS & BILLS OF MATERIAL

Drawings and parts lists for your product may be obtained by calling 1(800) 447-1204.

Tescom will provide these by fax or mail. Your local distributor can provide additional

assistance.

TABLE OF CONTENTS

1. INTRODUCTION ----------------------------------------------------------------7

2. SPECIFICATIONS---------------------------------------------------------------8

2.1 ENCLOSURE----------------------------------------------------------------------8

2.2 MEDIA----------------------------------------------------------------------------8

2.3 INLET PRESSURE ----------------------------------------------------------------8

2.4 ENVIRONMENT-------------------------------------------------------------------8

2.5 FLOW RATE ----------------------------------------------------------------------8

2.6 POWER REQUIREMENT----------------------------------------------------------8

2.7 RS485 COMMUNICATION INTERFACE -----------------------------------------8

2.8 ACCURACY -----------------------------------------------------------------------9

2.9 RESPONSE TIME -----------------------------------------------------------------9

2.10 PORTS ----------------------------------------------------------------------------9

2.11 WEIGHT --------------------------------------------------------------------------9

2.12 EXTERNAL ANALOG INPUT IMPEDANCE ---------------------------------------9

2.13 DIGITAL OUTPUTS---------------------------------------------------------------9

2.14 DIGITAL INPUTS -----------------------------------------------------------------9

2.15 ANALOG OUTPUT----------------------------------------------------------------9

2.16 SENSOR UPDATE RATE----------------------------------------------------------9

3. ER3000 PART NUMBERING SYSTEM------------------------------------ 10

4. INSTALLATION---------------------------------------------------------------- 11

4.1 INTERFACE CABLE ASSEMBLIES---------------------------------------------- 11

4.2 VOLTAGE/CURRENT SELECT JUMPERS -------------------------------------- 12

4.3 BASIC ER3000 TO PC WIRING----------------------------------------------- 13

4.4 SETTING UP A TYPICAL ER3000 PRESSURE CONTROL SYSTEM------------ 14

4.4.1 Plumb the External Regulator and Transducer ---------------------- 14

4.4.2 Mount the ER3000 ------------------------------------------------------- 15

4.4.3 Connect the Power Supply ---------------------------------------------- 15

4.4.4 Connect RS485 Interface Connections -------------------------------- 15

4.4.5 Install the “ER3000 (CVI)” Windows Program---------------------- 15

4.4.6 Communicate tothe ER3000, usingtheER3000(CVI)WindowsProgram 15

4.4.7 Connect Transducer Wiring--------------------------------------------- 16

4.4.8 Connect Pressure to the System ---------------------------------------- 16

4.4.9 Tune the System----------------------------------------------------------- 16

4.5 ADDITIONS AND VARIATIONS TO THE TYPICAL SYSTEM--------------------- 17

4.5.1 Transducer Wiring Configurations------------------------------------- 17

4.5.2 Analog Setpoint Source-------------------------------------------------- 19

4.5.3 Monitor the Feedback Signal ------------------------------------------- 21

4.5.4 Profile Control / Digital Inputs----------------------------------------- 23

4.5.5 Switch Feedback Control to a Second Feedback Source------------ 24

4.5.6 Monitor Analog Signals ------------------------------------------------- 24

4.5.7 Networking ER3000’s---------------------------------------------------- 25

4.5.8 Digital Outputs ----------------------------------------------------------- 26

4.5.9 Monitor Internal Sensor using the Analog Output------------------- 27

5. OPERATION-------------------------------------------------------------------- 28

5.1 THEORY OF OPERATION------------------------------------------------------- 28

5.1.1 PID Control--------------------------------------------------------------- 28

5.2 CONTROL MODES ------------------------------------------------------------- 29

5.2.1 Internal Feedback Mode ------------------------------------------------ 29

5.2.2 External Feedback Mode------------------------------------------------ 29

5.2.3 Cascade Loop Mode ----------------------------------------------------- 30

5.2.4 Manual Mode ------------------------------------------------------------- 30

5.3 SETPOINT SOURCES ----------------------------------------------------------- 30

5.4 FAILSAFE LIMITS -------------------------------------------------------------- 31

5.5 LEDS--------------------------------------------------------------------------- 31

5.6 RS485 COMMUNICATION----------------------------------------------------- 31

5.6.1 Protocol-------------------------------------------------------------------- 31

6. TUNING PROCEDURE------------------------------------------------------- 32

6.1 TYPICAL APPLICATION TO TUNE --------------------------------------------- 32

6.2 TUNE THE TYPICAL APPLICATION-------------------------------------------- 34

7. CALIBRATION ----------------------------------------------------------------- 39

7.1 ZERO/SPAN--------------------------------------------------------------------- 39

8. SOFTWARE PROGRAMS---------------------------------------------------- 40

8.1 WINDOWS TUNE PROGRAM--------------------------------------------------- 40

8.2 WINDOWS EXAMPLE PROGRAMS --------------------------------------------- 40

8.3 TESCOM PROTOCOL (PROVIDES CUSTOM SOFTWARE SUPPORT)---------- 40

8.3.1 DOS Library -------------------------------------------------------------- 41

8.3.2 Windows DLL------------------------------------------------------------- 41

8.3.3 Macintosh Custom Software -------------------------------------------- 42

8.4 DOS PROGRAMS -------------------------------------------------------------- 42

8.4.1 Tune------------------------------------------------------------------------ 42

8.4.2 Ertalk----------------------------------------------------------------------- 42

8.4.3 Profile---------------------------------------------------------------------- 42

8.4.4 Profile2 -------------------------------------------------------------------- 42

8.4.5 Data_log------------------------------------------------------------------- 43

8.4.6 Test_pr--------------------------------------------------------------------- 43

9. ER3000 INTERNAL VARIABLES ------------------------------------------ 44

9.1 SETPOINT AND FEEDBACK VARIABLES--------------------------------------- 44

9.2 CONFIGURATION VARIABLES ------------------------------------------------- 44

9.3 INNER LOOP TUNING VARIABLES--------------------------------------------- 45

9.4 OUTER LOOP TUNING VARIABLES-------------------------------------------- 45

9.5 ANALOG INPUT VARIABLES --------------------------------------------------- 46

9.6 PRESSURE PROFILE CONTROL VARIABLES ---------------------------------- 46

9.7 SINGLE “PUFF” SOLENOID CONTROL VARIABLE--------------------------- 47

9.8 PULSE MODE VARIABLES ----------------------------------------------------- 47

9.9 SCALING VARIABLES ---------------------------------------------------------- 47

9.10 ANALOG AND DIGITAL OUTPUT VARIABLES --------------------------------- 48

9.11 PWM CONTROL VARIABLES -------------------------------------------------- 48

9.12 GAIN/OFFSET VARIABLES----------------------------------------------------- 49

9.13 FAILSAFE VARIABLES --------------------------------------------------------- 50

9.14 TABLE OF ALL ER3000 INTERNAL VARIABLES ------------------------------ 51

10. TROUBLESHOOTING ---------------------------------------------------- 54

10.1 LED INDICATORS ------------------------------------------------------------- 54

10.2 THIRD PARTY RS232/RS485 CONVERTERS --------------------------------- 55

10.3 ER3000 POWER-UP TEST, USING LED INDICATORS ----------------------- 55

10.4 ER3000 DATA COMMUNICATIONS TEST, USING LED INDICATORS ------- 55

10.5 PRESSURE CONTROL PROBLEMS --------------------------------------------- 57

10.6 ACCEPTABLE RESISTANCE VALUES ------------------------------------------ 57

10.6.1 ER3000 RS485 Interface--------------------------------------------- 57

10.6.2 Converter RS485 Interface ------------------------------------------ 57

10.7 LEAK TEST --------------------------------------------------------------------- 58

10.7.1 Windows ER3000 Program------------------------------------------ 58

10.7.2 DOS Tune Program -------------------------------------------------- 58

11. ER3000 ACCESSORIES--------------------------------------------------- 60

12. MECHANICAL DIMENSIONS OF ER3000--------------------------- 61

Table Of Figures

Figure 1: Voltage/Current Select Jumpers........................................................ 12

Figure 2: ER3000 Basic Wiring Diagram........................................................ 13

Figure 3: ER3000 Typical System Wiring Diagram......................................... 14

Figure 4: Three-Wire External Feedback Cabling........................................... 17

Figure 5: Four-Wire External Feedback Cabling ............................................ 18

Figure 6: Passive PC or PLC D/A Card Analog Setpoint (4-20mA)................ 19

Figure 7: Active PC or PLC D/A Card Analog Setpoint(4-20mA, 1-5V, 0-10V).........19

Figure 8: Potentiometer Analog Setpoint......................................................... 20

Figure 9: Current/Voltage Analog Setpoint ..................................................... 20

Figure 10: Monitor 4-20mA External Feedback (Floating Input)..................... 21

Figure 11: Monitor 4-20mA External Feedback (Ground Referenced Input).. 21

Figure 12: Monitor voltage produced by 4-20 mAmp External Feedback....... 22

Figure 13: Monitor 1-5V/0-10V External Feedback ........................................ 22

Figure 14: External Profile Control................................................................. 23

Figure 15: Switch between two External Feedback Sources............................ 24

Figure 16: Networking/Daisychaining ER3000’s............................................. 25

Figure 17: ER3000 Digital Outputs ................................................................. 26

Figure 18: Monitor Internal Sensor (4-20mA wiring)...................................... 27

Figure 19: Monitor Internal Sensor (0-10V wiring)......................................... 27

Figure 20: Regulator and ER3000 Internal Operation.................................... 32

Figure 21: LED Locations................................................................................ 54

1. Introduction 7

ER3000 USER MANUAL

1. INTRODUCTION

The ER3000 (Electronic Regulator) is a versatile 0 to 100 psi pressure

controller. It can be used in conjunction with any pneumatically actuated

regulator or valve to control pressure from subatmosphere to 20,000 psi with

Cv’s of up to 45.

Setpoints can be provided via an analog input (4-20mA, 1-5V, or 0-10V), the

digital RS485 interface, or a downloaded profile.

The RS485 interface makes pressure control by a computer easier than ever

before. The controller can be wired quickly into the standard serial

communication port found on any PC using a low-cost RS232 to RS485 adapter.

This communication channel also provides for the programming of a number of

internal parameters, including PID tuning variables, zero and span, mode of

operation, limits, etc.

Feedback can be derived either from the ER3000’s internal temperature

compensated sensor or an external transducer (4-20mA, 1-5V, or 0-10V). This

second option allows for positioning the sensor downstream in the actual process

line.

Four modes of operation are available. Internal feedback mode (which makes

the controller an I/P when analog setpoints are used) and uses the internal sensor

as the source of feedback. External feedback mode uses an external sensor as

the feedback. Cascade mode creates a loop within a loop; the inner loop uses the

internal sensor for feedback and the outer loop uses the external transducer for

feedback. Manual mode allows for direct control of the solenoid valves (useful

for troubleshooting the system).

In summary, the ER3000 electronic pressure regulator is easy to get up and

running, yet offers the flexibility required by the most demanding user.

8 ER3000 User Manual

2. SPECIFICATIONS

2.1 Enclosure

NEMA 4X.

To prevent any interference from electromagnetic radiation, use rigid metal

conduitto enclosethe wiringenteringthe ER3000. Two1/2NPTwireportshave

beenprovidedfor thispurpose. Ifunused,properlysealwithametalplug.

2.2 Media

The preferred media is clean, dry instrument grade air or nitrogen. Use

of an in-line 40-micron filter is highly recommended to prevent damage

to the solenoid valves.

2.3 Inlet Pressure

Minimum: Outlet pressure + 1 PSIG.

Maximum: 120 PSIG.

Typical: 110 PSIG.

Note: Response time is affected by input pressure.

2.4 Environment

Temperature: -30ºC to 75°C (Dry nitrogen supply gas).

-20ºCto60ºC(KEMAExplosionProofVersionsM&N)

5ºC to 75°C (Shop air).

Pressure: 28 - 32 inches Hg

Humidity: To 100% R.H (non-condensing) @ 0°C to 75ºC.

2.5 Flow Rate

Cv: 0.01.

Note: The flow rate can be increased using a booster regulator.

2.6 Power Requirement

Voltage: 24V (22V to 28V)

Current: 340mA Max, 180mA Nominal

2.7 RS485 Communication Interface

Networking: Up to 32 controllers on one network.

Cable length: 4000 ft. Max.

Baud rate: 9600

2. Specifications 9

2.8 Accuracy

Room temp.: 0.1% of span max

Temp. effects: 0.002%/°F of span max.

2.9 Response Time

Rise Time: 257ms. - 10 psi to 90 psi

Fall Time: 552ms. - 90 psi to 10 psi

Note: Step response into dead-end system (1 cubic inch volume).

2.10 Ports

Conduit: 1/2” NPT

Pneumatic: 1/8” NPT - Inlet, exhaust and gauge ports.

1/4” NPT - Controlled outlet port.

2.11 Weight

34.8 oz. (1.0 kg).

2.12 External Analog Input Impedance

4-20mA:250Ω

1-5V: 220KΩ- Single Input Pin to Gnd.

1.7MΩ- Differential Input

0-10V: 100KΩ

2.13 Digital Outputs

Current: 50 mA Continuous, 100 mA Instantaneous

Voltage: 5V - 28V

Type: Open collector, grounded emitter

2.14 Digital Inputs

Voltage Range/Input Impedance:

4-20 mA: 250Ω

1-5V: 220KΩ- Single Input Pin to Gnd.

1.7MΩ- Differential Input

0-10V: 100KΩ

Type: Level Sensitive

2.15 Analog Output

4-20mA:0.5% Accuracy

2.16 Sensor Update Rate

25ms: Rate of sensor reading and processing task

10 ER3000 User Manual

3. ER3000 PART NUMBERING SYSTEM

Standard features:

RS485 communications included.

1/8” inlet and exhaust ports, 1/4” controlled output port.

Maximum inlet pressure = 120 psig.

0 to 100 psig internal sensor.

Windows/DOS software package included.

24 VDC power required.

As the table below indicates, other sensor ranges are available. Please consult

the factory for special modifications or requirements.

ER3 XX X X X - X

Base Style

00…Standard

02…Integrated with

26-1000and269-529

04…OEM style (no

cover)

10…Integrated with

44-4000

11…Integrated with

44-5200

Internal Sensor Configuration

0…0-100 psig, 0.1% accuracy

2…0-50 psia, 0.1% accuracy

3…0-150 psia, 0.1% accuracy

4 0-5 psig, 0.25% accuracy

Board Configuration

S…Standard

(setpoint/feedback)

F…2 extra analog

inputs/outputs

E…Explosion proof

G…Combines F & E

M…KEMA explosion proof

N…Combines F & M

Current/Voltage

I…4-20 mA/1-5 VDC

V…0-10 VDC

Cv

Configuration

1…Standard,

Cv=0.01

2…Low flow

(Cv=0.001)

4…High flow

(Cv=0.1)

4. Installation 11

4. INSTALLATION

The ER3000 has a number of variations and wiring options. The following

pages of the installation section detail a typical installation and many of those

options.

Note: Installation of explosion proof models shall be in accordance with the

specifications of the standards shown on the metal tag.

4.1 Interface Cable Assemblies

The following tables give the complete wiring layout of the ER3000 wiring

assemblies, which are connected to the J3 and J4 terminal blocks. Refer to the

tables to ensure proper wiring of external devices.

Note: The (+) and the (-) refer to the differential inputs. Both must be connected

for the system to work properly.

Table 1: Main Cable Assembly

J3 Pins Description Color

1 +Setpoint Input. Brown

2 -Setpoint Input. Red

3 +Feedback Input. Orange

4 -Feedback Input. Yellow

5 -RS485 Network connection. Green

6 +RS485 Network connection. Blue

7 + 24 Volt DC Power. Violet

8 24 Volt Return, (Power Ground). Gray

9 +5 Volt output (5mA Max.). White

10 Analog Signal Ground. Black

11* Analog Signal Output. Pink

12 Analog Signal Ground. Tan

Table 2: Auxiliary Cable Assembly (ER3000F and ER3000G models)

J4 Pins Description Color

1 +Aux. Input #1. Brown

2 -Aux. Input #1. Red

3 +Aux. Input #2. Orange

4 -Aux. Input #2. Yellow

5 Analog Signal Ground. Green

6 Digital Output Ground. Black

7 Digital Output #1. Blue

8 Digital Output #2. White

* Active in ER3000F and ER3000G Models only.

12 ER3000 User Manual

4.2 Voltage/Current Select Jumpers

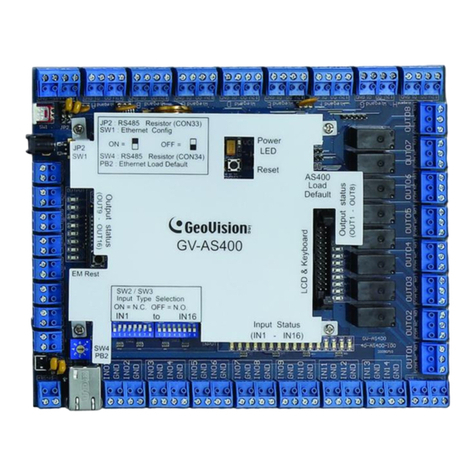

Figure 1 shows the J5 voltage/current select jumpers location on the ER3000.

Use them to select between 4-20mA and 1-5V. The 0-10V models of the

ER3000 do not have the jumpers.

The jumper on the bottom board is for factory installation of the embedded

software only and the jumper should not be installed for normal operation.

LED1

LED2

LED3

J5

J3 J4

1 2 3 4

1 2 3 4 5 6 7 8 9 101112 1 2 3 4 5 6 7 8

Figure 1: Voltage/Current Select Jumpers

Jumper J5 (top board) - Voltage/Current Select (not on 0-10V models)

1: Analog Setpoint

2: External Feedback

3: Auxiliary input #1

4: Auxiliary input #2

For all the above jumper positions:

Jumper not installed - configured for 1-5V input.

Jumper installed - configured for 4-20mA input.

LED’s Refer to Section 10.1, LED Indicators, for an explanation of the LED

indicators.

4. Installation 13

4.3 Basic ER3000 to PC Wiring

The necessary wiring for the ER3000 communicating to a PC is shown in Figure

2. A PC is typically used to communicate to the ER3000 digitally, but any

device capable of the interface protocol could be used, such as a PLC.

Note: For USB-RS485 converter, see instructions included with converter.

Figure 2: ER3000 Basic Wiring Diagram

14 ER3000 User Manual

4.4 Setting up a Typical ER3000 Pressure Control System

One of the most commonly used modes of operation is shown in Figure 3. The

configuration shows the ER3000 with a 24 Volt power supply, pressure

regulator, 4-20mA transducer, RS232/RS485 converter, and an optional 25-9 pin

adapter cable. Note: For USB-RS485 converter, see instructions included with

converter.

Figure 3: ER3000 Typical System Wiring Diagram

4.4.1 Plumb the External Regulator and Transducer

If higher pressures or flows are required by the application or it is necessary to

isolate the controller from the process media, an air actuated mechanical

regulator can be used to boost the output and/or provide isolation.

Additionally, an external transducer may be used to sense the process pressure

supplied by the external regulator.

4. Installation 15

4.4.2 Mount the ER3000

Four 8-32 UNC screw holes are provided for the physical mounting of the

ER3000. For details, reference mechanical drawings at the back of the manual.

4.4.3 Connect the Power Supply

Connect a 24 Volt power supply to the ER3000, as shown in Figure 2.

Power up the ER3000.

Visually check the LED indicators to ensure that power is supplied to the

ER3000. The red LED, LED1, on the top board should be ON indicating power

applied and the red LED, LED1, on the bottom board should be blinking

indicating the embedded software is running.

Power down the ER3000.

4.4.4 Connect RS485 Interface Connections

Connect the ER3000 to the Tescom RS232/RS485 converter, as shown in Figure

2. Consult our Troubleshooting section if using a third party converter, not all

converters are capable of the mode of operation expected by our software.

Connect the RS485 converter directly to a COMM port (default=COM2) of the

computer, if necessary include the 25 to 9 pin adapter cable.

4.4.5 Install the “ER3000 (CVI)” Windows Program

Insert the “ER3000 User Software” CD into your PC and the install program

should start automatically. If it does not, choose and run the “autorun”

executable on the CD. Click on the INSTALL button in the “CD Menuing

System” menu to get to the “Installation Menu”. From the “Installation Menu”,

chick on the Windows Tune (32 BIT) button. Follow the on-screen instructions

during the installation process. The installation will automatically create the

directory ER3000 and install the Windows Tune program, including support

files (e.g. TESCOM.DLL).

The Windows program contains a complete online help manual and a manual.rtf

file of all the online help pages that may be easily printed out.

4.4.6 Communicate to the ER3000, using the ER3000 (CVI) Windows

Program

Power up the ER3000.

Execute the ER3000 (CVI) program. The program is executed by pressing the

Start button, choosing the Programs menu, choosing the ER3000 (CVI) folder,

and then selecting the ER3000 (CVI) program. If an error occurs, go to the

Troubleshooting section.

Power down the ER3000.

16 ER3000 User Manual

4.4.7 Connect Transducer Wiring

If the downstream process pressure regulation is required by the application, a

pressure transducer can be used to provide a 4-20mA, 1-5V, or 0-10V feedback

signal. Figure 3 shows wiring for a 2-wire 4-20mA transducer. The wiring of

three and four wire transducers are shown in section 4.5.1, Transducer Wiring

Configurations.

Check to ensure that the external feedback voltage/current select jumper is

installed for 4-20mA or removed for 1-5V operation. There is no jumper on the

0-10V external feedback ER3000 models.

4.4.8 Connect Pressure to the System

Figure 3 illustrates the typical pressure connections for the ER3000. The

ER3000 inlet pressure is the supply pressure (max 120 psi). The exhaust port on

the ER3000 is used for venting when a pressure reduction is required. The inlet

pressure to the regulator depends on the capability of the regulator and the

system requirements. The output pressure is the regulated pressure being

supplied to the process.

The gauge port can have a pressure gauge attached or simply plugged. If

desired, the gauge port can be used as the output (the normal output port must

then be plugged).

4.4.9 Tune the System

The system should now be fully installed. The system performance can be

checked using the Windows ER3000 (CVI) program or the DOS Tune program

provided. The tuning parameters can be updated using these programs to alter

the ER3000 and system performance. Refer to the Tuning Procedure section for

details on tuning the pressure control system.

4. Installation 17

4.5 Additions and Variations to the Typical System

This section shows variations and additions to the Typical ER3000 control

system shown in Figure 3. Alternatively, use Figure 2 as a baseline for systems

without an external transducer.

4.5.1 Transducer Wiring Configurations

The wiring for the two-wire transducer is shown in Figure 3.

The wiring for the three wire and four wire transducers are shown in Figure 4

and Figure 5 respectively. Connect the ER3000 to the transducer, or other

feedback source, as shown in the respective diagrams.

Check to ensure that the external feedback voltage/current select jumper, J5:2, is

installed for 4-20mAmp or removed for 1-5 Volt operation. There is no jumper

on the 0-10 Volt ER3000 models.

Figure 4: Three-Wire External Feedback Cabling

NOTE: Wire power as shown in figures 2 & 3

18 ER3000 User Manual

Figure 5: Four-Wire External Feedback Cabling

NOTE: Wire power as shown in figures 2 & 3

4. Installation 19

4.5.2 Analog Setpoint Source

Check to ensure that the analog setpoint voltage/current select jumper, J5:1, is

installed for 4-20mA or removed for 1-5V operation. There is no jumper on the

0-10V external feedback models. Figure 6 and Figure 7 show how to provide a

4-20mA analog setpoint from a PC D/A card or a PLC D/A module.

Figure 6: Passive PC or PLC D/A Card Analog Setpoint (4-20mA)

NOTE: Wire power as shown in figures 2 & 3

Figure 7: Active PC or PLC D/A Card Analog Setpoint (4-20mA, 1-5V, 0-10V)

NOTE: Wire power as shown in figures 2 & 3

Other manuals for ER3000

1

Table of contents

Other Tescom Controllers manuals

Tescom

Tescom 04-1 Series User manual

Tescom

Tescom RMP-X1 User manual

Tescom

Tescom 44-3400 Series User manual

Tescom

Tescom PHE2600 Series User manual

Tescom

Tescom 64-3600 Series User manual

Tescom

Tescom 44-4600 Series User manual

Tescom

Tescom 56-2100 Operation manual

Tescom

Tescom ER1200 Series Installation and operating instructions

Tescom

Tescom D 43276 Series User manual

Tescom

Tescom 74-3000 Series User manual