Thank you for purchasing our product. Any Improper operation may cause personal injury damage to the

product and related equipments. This high power system for R C model can be dangerous ,we strongly

recommend reading the user manual carefully and completely. We will not assume any responsibility for any

losses caused by unauthorized modifications to our product. We have the right to change the design,

appearance, performance and usage requirements of the product without notice.

ATTENTION

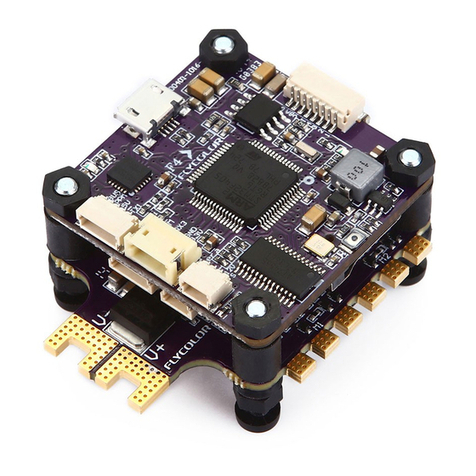

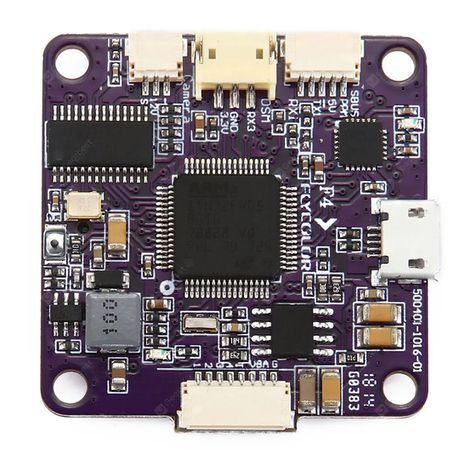

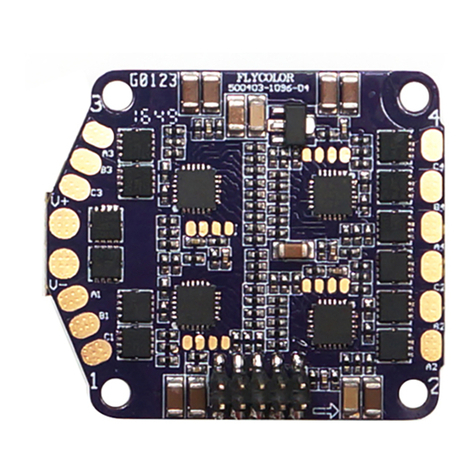

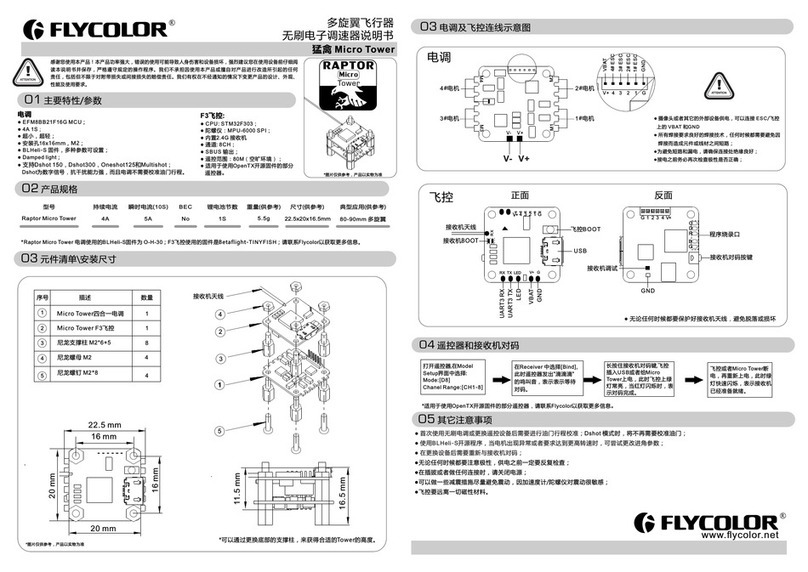

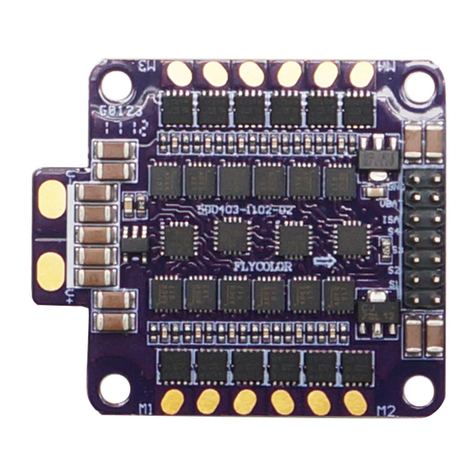

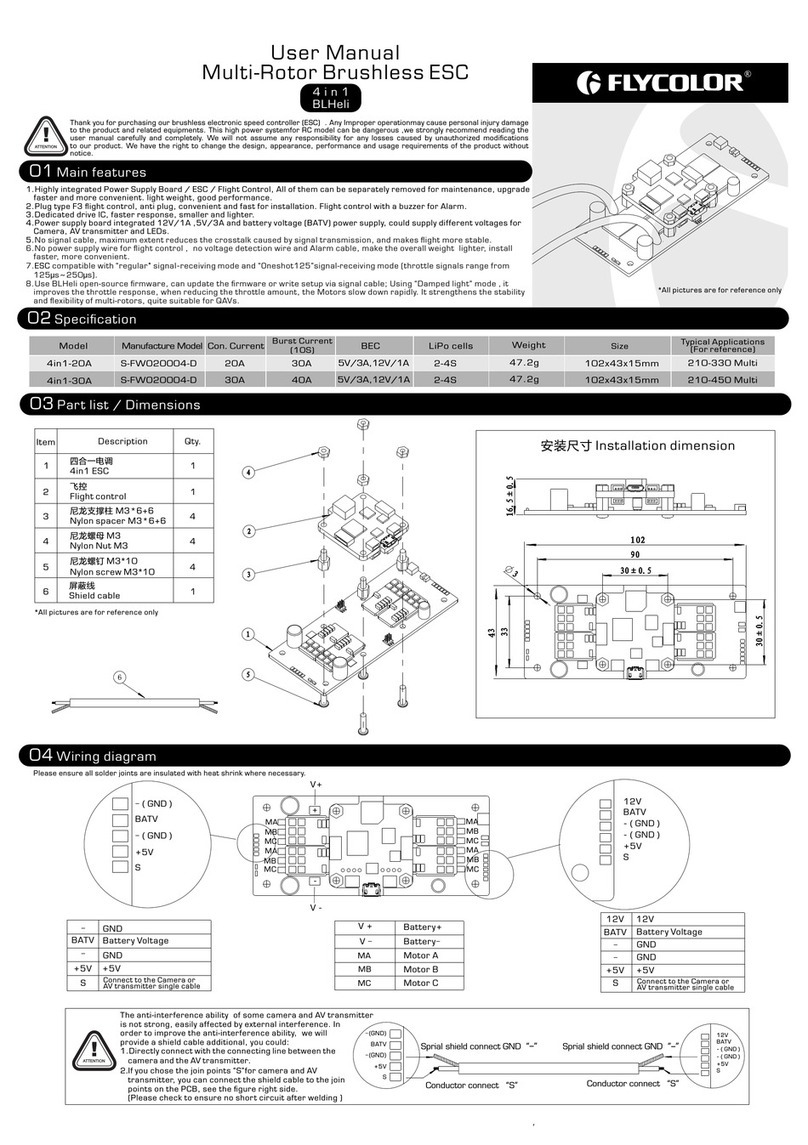

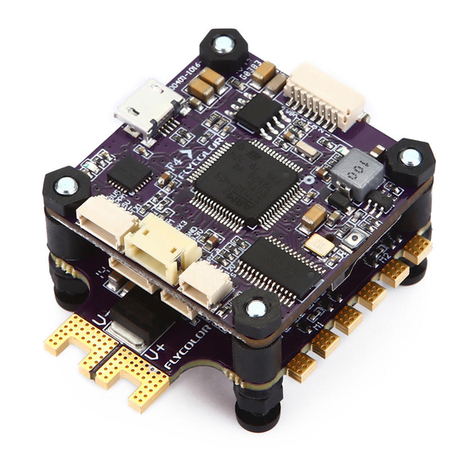

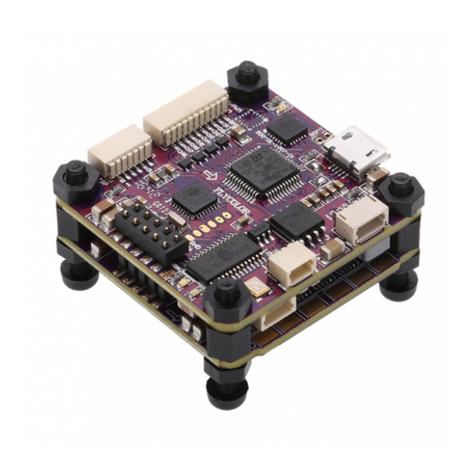

01 Main features

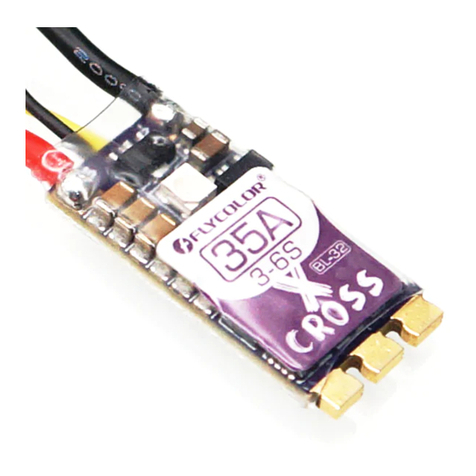

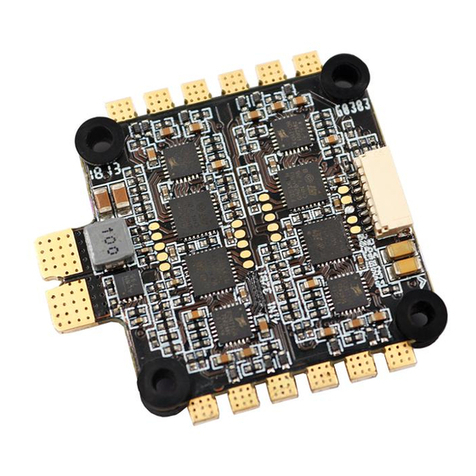

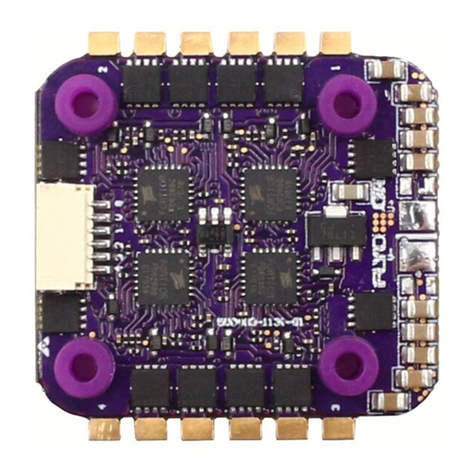

02 Specification

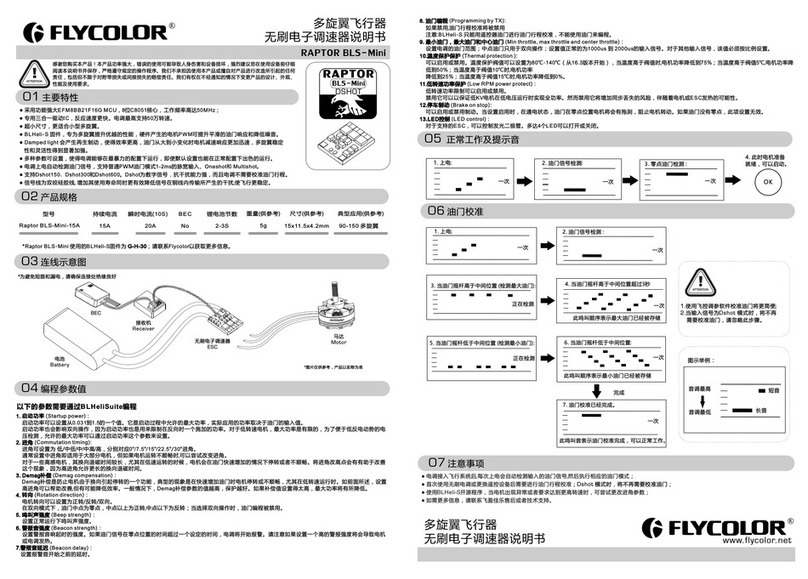

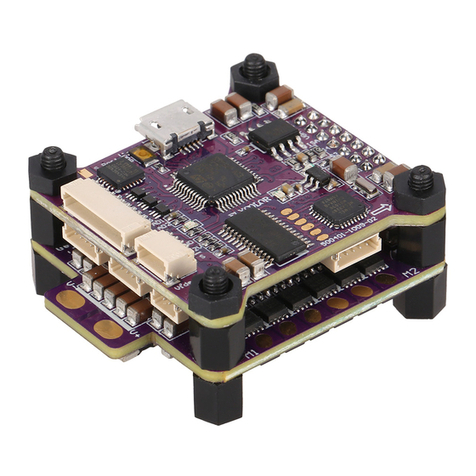

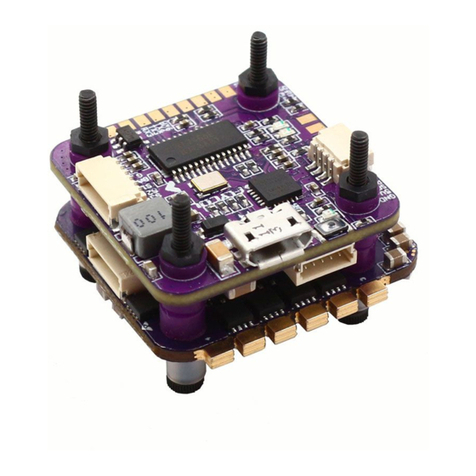

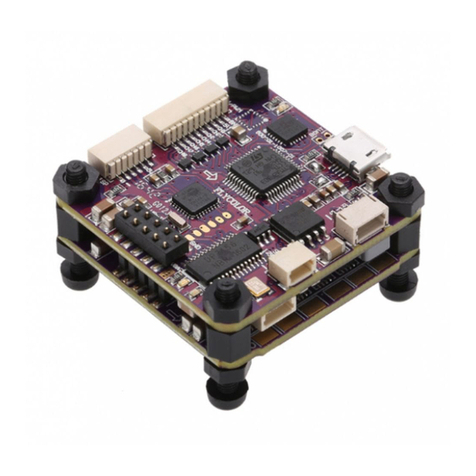

03 Connection diagram

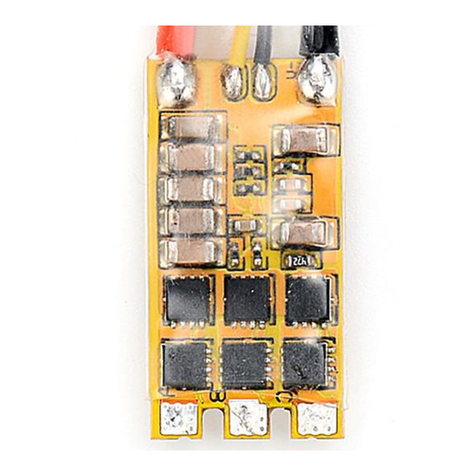

04 Dimensions

05 Operation instruction

2.Calibrate Throttle Range

1.Normal start-up

ATTENTION

● Start-up Protection:E S C will cut off output if it fails to start the motor within 3 seconds by accelerating throttle. you need to move the throttle stick

back to the bottom position and restart the m otor.( The possib le causes : Bad connection or disconnection between E SC & motor , propellers are

blocked, etc)

● Over-load Protection: E SC will cut off power or output when the load suddenly increases to a very high value, normal operation will resume after

moving the throttle stick to the b ottom position. ES C will automatically try to restart when E SC and motor are out-of-step.

● Throttle Signal Los s Protection: When ES C detects the loss of throttle signal for over 0.32 seconds, it will cut off power or output immediately to

avoid an even greater loss caused by the continuous high speed rotation of propellers. E SC will resu me the corresponding output after the normal

signal is restored.

06 Protections

07 Attentions

3.Set Timing

08 Trouble shooting

User Manual

Multi-Rotor Brushless ESC

● ES C uses high erformace M CUp with 48 M Hz frequency.

● Optimized firmware is specialized for disc motor, excellen t compatibility.

● The firmware is specialized for multi-rotor , uses AS CF technology ( ),higher Active Switch Continued Flow

efficiency, significantly reduce the heat when E SC’s working.

● S Nano coating, splash waterproof.maller volume;

● Strong self-adaptable firmware, 4 timing options, very sim ple to use.

● Supports frequency of throttle signal to 500Hz max , c ompatible with various kinds of flight control.

( ≥500Hz throttle signal is nonstandard signal )

● Supports single LiPo battery voltage up to 4.35V.

● Switches on the bottom Support :1.Motor rotation change .2. ASCF function on/off .

*Please ensure all solder joints are insulated with heat shrink where necessary.

All pictures are for reference only.

Turn on the transmitter, move the

throttle stick to the bottom position

Connect E SC & battery packs, wait for 2 seconds, motor emits

continuously 1 long and 1 short tone. It means the ES C is ready

for working.

Turn on the

transmitter,

move the

throttle stick to

the top position.

Connect the receiver to

the battery, ensure the

communication is normal

between the transmitter

and receiver, then power

on the E S C.

Wa i t fo r 2 s eco n d, a fter

motor emits 2 short "BE EP-

B E E P " ,mo ve t he t hrot tle

stick to the bottom position

in 3 seconds.

Wait f o r 2 seconds, motor

emits continuously 1 long and

1 short tone. It means the ESC

is ready for working.

Attention:Please calibrate throttle range when first time to use E SC or chang e transmi tter.

Wait for 2 seconds, motor

emits continuously 1 l ong

and 1 short tone. It means

the ESC is ready for working.

Turn on the

transmitter,

move the

throttle stick

to the top

position.

Connect the receiver

to the battery, ensure

the communication is

normal between the

transmitter and

receiver, then power

on the ES C.

The motor will

emit different

tone circularly.

Move the throttle stick

to the bottom position

in 3 seconds after

hearing corresponding

tone, the setting will be

completed.

“Beep-beep-”T hrottle rag e;

“Beep-beep-beep-” 15° t iming

“Beep-beep-beep-beep-”18.75° timing

“Beeeep--” 22.5° timin g

“Beeee p--beep-” 26.25° timi ng

( When motor emits tone times ≥5 time s, long " Bee p--" will represent 5 times)

When E SC drives disc type motor with acc elerati ng throttle , motor may be out-of-step ,

stalling or requires higher speed , you could try to change timing ( ES C factory default

value is 22.5°). Higher timing can accelerate motor speed, bu t also caus e more heat .

After changing timing, please test on the ground before flying .

● Reasonable use of E S C can prolong the service life. please clean up the water and stains on the ES C after a certain period of time , to avoid electric

short circuit.

● User need to calibrate the throttle range when starting to use a ne w ES C or change another transmitter.

● When some abnormality occurs in ES C driving the motor or need the motor to reach a higher R PM, user can try to change the timing.

● AS CF O N/OF F function, mu st ensure all E SCs setting consistent, it will take effect after power on again.

● Motor rotation function ,it will take effect after po wer on agai n.

● Please contact Flycolor sales or technical support for more i nformat ion.

Trouble

ESC was unable to

start the motor

ESC was unable to

start the motor

“Beep beep beep…”

Urgent short tone

Warning Tone

“Beep,beep,beep…”

Time interval is 1 second

Possible Cause

The throttle stick is not at the bottom

position or throttle range is too small.

No output signal from the throttle

channel on the receiver.

ESC was unable to

start the motor

“Beep-beep,beep-beep-beep,…

Beep--beep-” Circular tones

The”Normal/Reverse”direction of the

throttle channel on transmitter is incorrect.

Solution

Move the throttle stick to the bottom posit ion or reset

the throttle range.

Check if the communication is normal between

transmitter and receiver; Check throttle chann el

connection well.

Refer to the transmitter instruction an d adjust th e

setting of “Normal/Reverse”direction of the th rottle

channel.

251400 -1069, V1.0

11.7 mm

29.5 mm

46 mm

64.6 mm

BEC

Con. Current Burst Current

(10S)

Size

(for reference)

Weight

(for reference)

LiPo cellsModel

FlyDragon SLIM-60A 60A 80A 4-6S 56g

No

SLIM

TM

FlyDragon

FlyDragon SLIM

64.6x29.5x11.7mm

BEC

Battery

Receiver

Motor

Si g n a l c a ble

ESC

ASC F

ON OFF

Rotation

Rev. Nor.

Switches Support to:

1.Change Motor rotation .(Normal is default)

2. ASC F function On/Off .(O N is default)

www.flycolor.net