TRANSPORT, STORAGE & CLEANING /

REGULAR CHECKS / MAINTENANCE / SERVICE LIFE

Protected from light (UV radiation, welding

machines,…)

Not in the proximity of chemicals (acids, lyes,

liquids, vapours, gases,…) and other

aggressive environments

Protected against sharp-edged objects

Therefore, store the product dry and ventilated in a

moisture-repellent bag that is impervious to light.

For cleaning, use lukewarm water (<40°C) and

mild-action detergents. Then, rinse the equipment

with water of drinking quality, and dry it prior to put-

ting it into storage. Dry the product in a natural way,

not near fires or other heat sources.

For disinfection, use only substances that do not

have an impact on the synthetic material and metals

used.

If you fail to observe these provisions, you will be

putting yourself into danger!

Checking the equipment at regular intervals is abso-

lutely necessary: your safety depends on the effec-

tiveness and durability of the equipment!

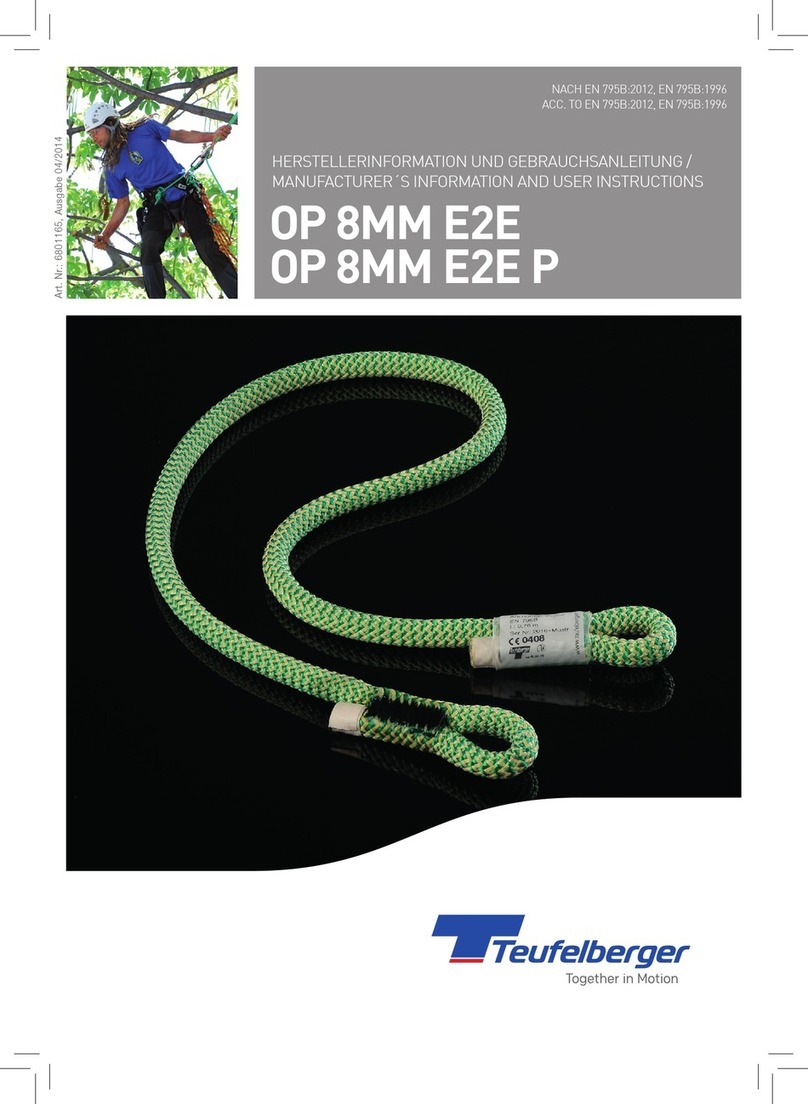

Following each use, the rope and the eye terminati-

on [slaice]

®

in particular should be checked

for possible damage.

Check the eye termination for worn or broken sew-

ing yarns.

Check the eye of the eye termination [slaice]

®

with

special attention. In the eye the core of the rope is

removed and it is only the (visible) cover that bears

the load. In some versions of the slaice termination,

a bight of Dyneema

®

webbing is a redundant load-

bearing component.

If the cover is damaged, the product must be dis-

carded:

Protruding fibres / yarns are a sign of abrasion.

Cuts provide evidence of rope damage.

Deformation and squashing may point to local

overloading. Melted or hardened parts are signs of

thermal and / or chemical impact.

In any of these cases or if there is the slightest dou-

bt, the product must be withdrawn or

inspected by a competent person.

Systems that have been damaged or affected by a

fall must be withdrawn from use

immediately.

When using the equipment in occupational health

and safety to EN 365, it must be checked at least

every 12 months by a duly qualified person strictly

observing the instructions, or else by the manufac-

turer, and it must, whenever necessary, be replaced.

These inspections must be documented (documen-

tation of equipment; cf. attached Inspection Sheet).

Refer to national regulations for inspection intervals.

Such inspections must comprise:

Check of general state: age, completeness,

discolouration, correct assembly

Check of label: Does it exist? Is it legible? Is

there a CE marking? Does it specify the year

of manufacture?

Check of all individual parts for mechanical

damage such as: cuts, cracks, indentations,

abrasion, formation of ribs, kinks, crushing.

Check of all individual parts for thermal or

chemical damage such as: fusing, hardening.

Check of metal components for corrosion,

deformations.

Check of condition and completeness of termi-

nations, stitching (e.g. no abrasion of sewing

thread), splices (e.g. no slippage), knots.

Again, the following rule applies: If there is the

slightest doubt about the suitability of the product

to perform its required task, the product must to be

retired or quarantined and then subjected to testing

by a competent person.

Repairs may be carried out only by the manufac-

turer.

The service life of the [slaice]

®

may be up to 5 years

from the date of manufacture if used infrequently

and if stored correctly (see item Transport, storage

and cleaning).

The actual useful life depends solely on the condi-

tion of the product, which in turn is influenced by

various factors (see below). Extreme influences may

shorten service life to a single use only or to even

less if the equipment is damaged prior to its first

use (e.g. in transport).

Mechanical wear and other influences such as the

impact of sunlight will decrease the life span consi-

derably. Bleached or abraded fibres, discoloration,

and hardened spots are certain indicators that the

product needs to be retired.

It is clearly not possible to offer a general statement

about the product’s service life, as

lifespan depends on various factors, e.g. UV light,

type and frequency of use, handling, climatic

REGULAR CHECKS

MAINTENANCE

SERVICE LIFE