User's Guide

SLUUA08A–March 2013–Revised April 2013

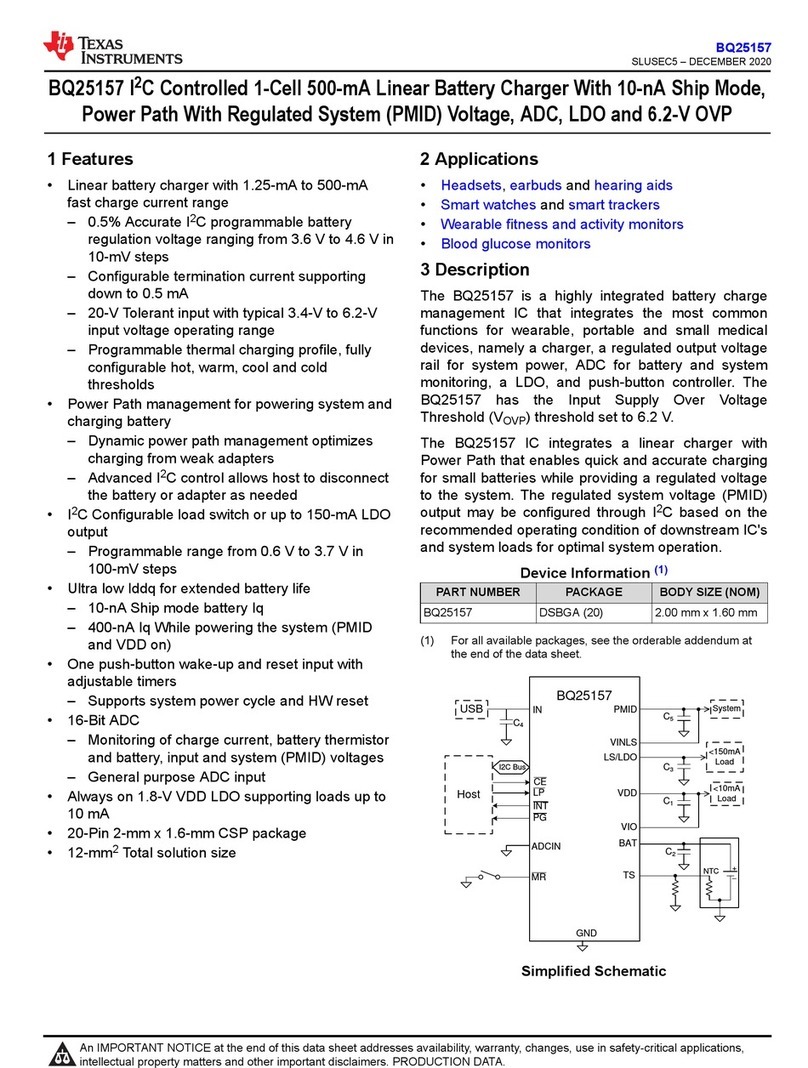

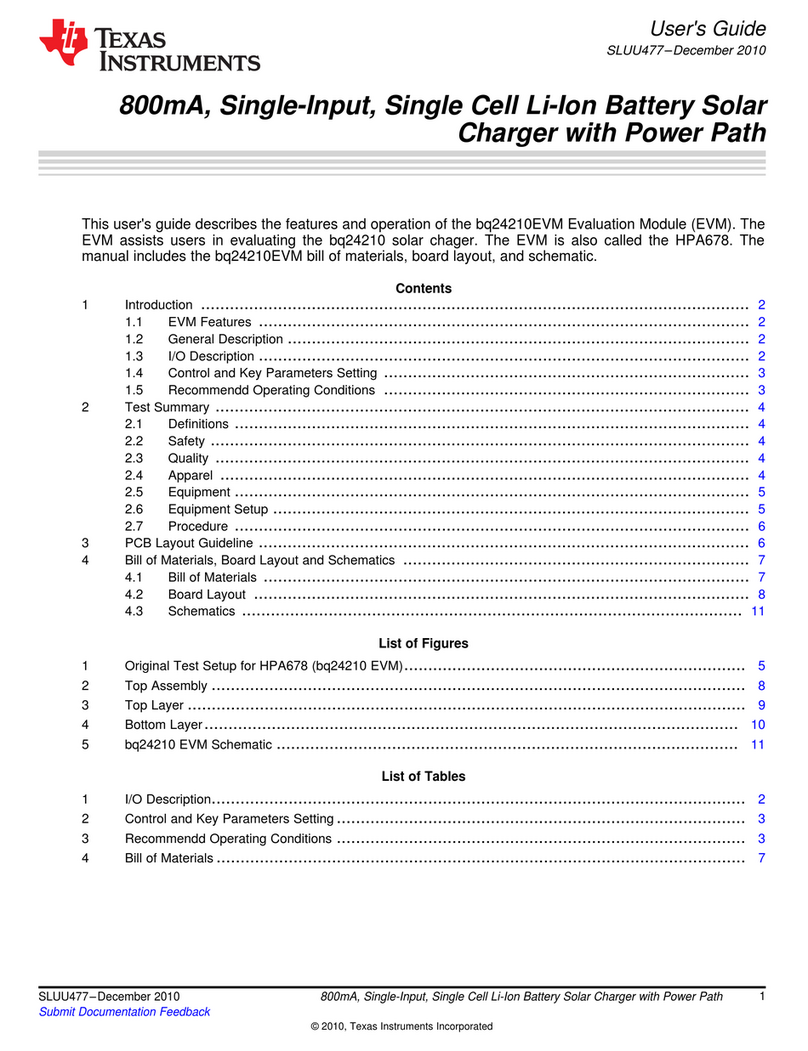

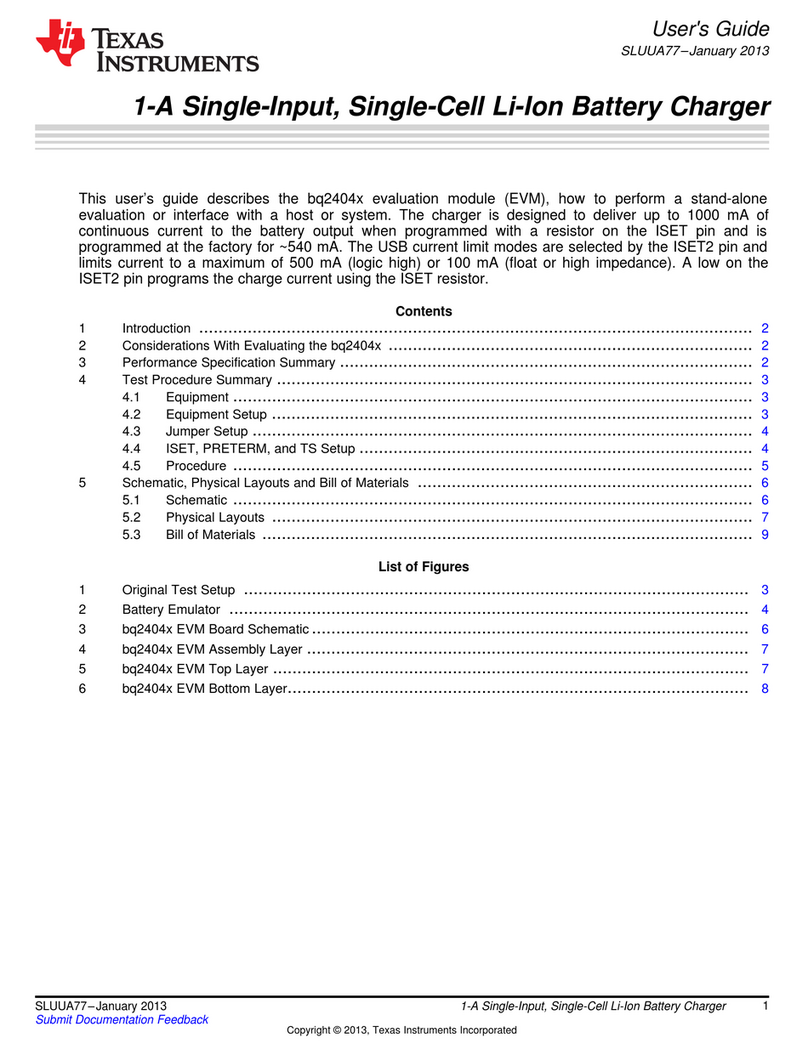

bq2425xEVM-150, Single-Cell Li-Ion Switch-Mode Charger

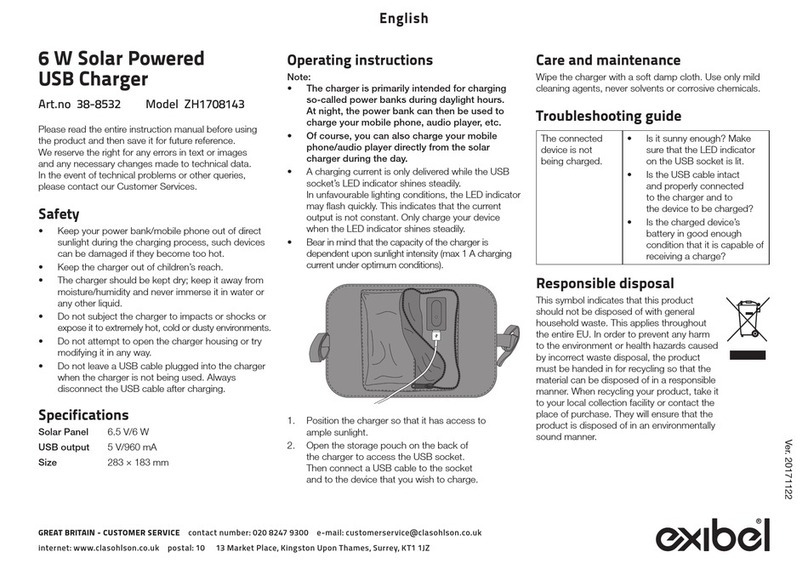

This user's guide describes the characteristics, operation, and use of the bq24250EVM-150,

bq24251EVM-150, and bq24257EVM-150 evaluation modules (EVM). These EVMs enable test and

evaluation TI's bq24250, bq24251, and bq24257 devices. The bq2425x series are highly integrated,

single-cell, Li-Ion battery chargers targeted for space-limited, portable applications with high-capacity

batteries. This user's guide includes EVM specifications, the schematic diagram, test procedures, test

results, a bill of materials, and board layout.

Contents

1 Introduction .................................................................................................................. 2

2 EVM Considerations ........................................................................................................ 3

3 Recommended Operating Condition ..................................................................................... 3

4 Equipment and EVM Setup ................................................................................................ 4

4.1 Schematic ........................................................................................................... 4

4.2 I/O Description ...................................................................................................... 5

4.3 Test Points .......................................................................................................... 5

4.4 Pin Descriptions .................................................................................................... 6

4.5 Control and Key Parameters Setting ............................................................................ 6

5 Test Procedure .............................................................................................................. 7

5.1 Definition ............................................................................................................ 7

5.2 Recommended Test Equipment ................................................................................. 7

5.3 Software ............................................................................................................. 7

5.4 Recommended Test Equipment Set Up ........................................................................ 8

5.5 Recommended Test Procedure ................................................................................ 10

6 Test Results ................................................................................................................ 12

6.1 Output Regulation Ripple ........................................................................................ 12

6.2 Efficiency Data .................................................................................................... 12

6.3 Thermal Performance ............................................................................................ 13

7 Layout and Bill of Materials .............................................................................................. 13

7.1 Printed-Circuit Board Layout Guideline ........................................................................ 13

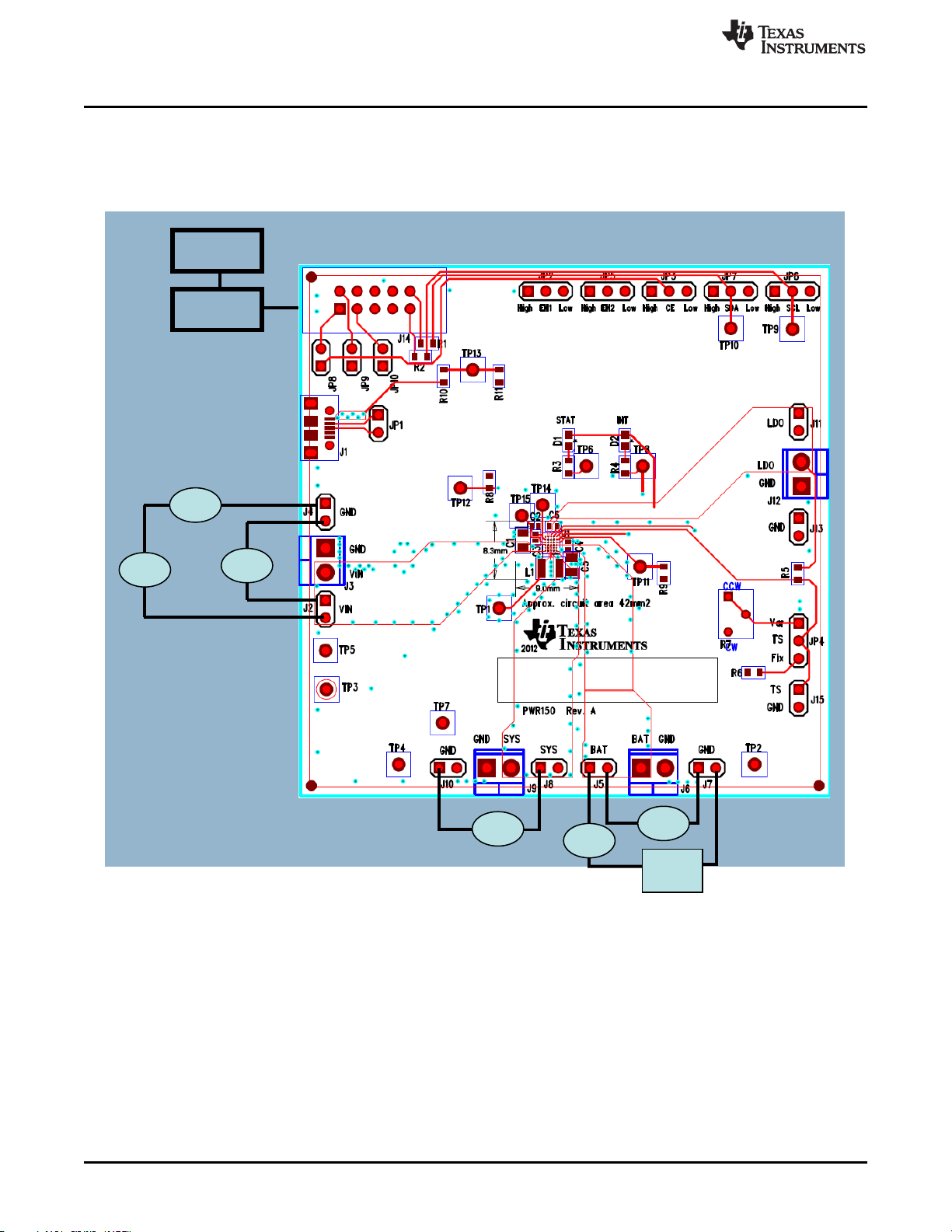

7.2 Layout .............................................................................................................. 14

7.3 Bill of Materials (BOM) ........................................................................................... 20

List of Figures

1 bq2425xEVM-150 Schematic ............................................................................................. 4

2 Original Test Setup ......................................................................................................... 8

3 Battery Emulator ........................................................................................................... 9

4 Connector Kit................................................................................................................ 9

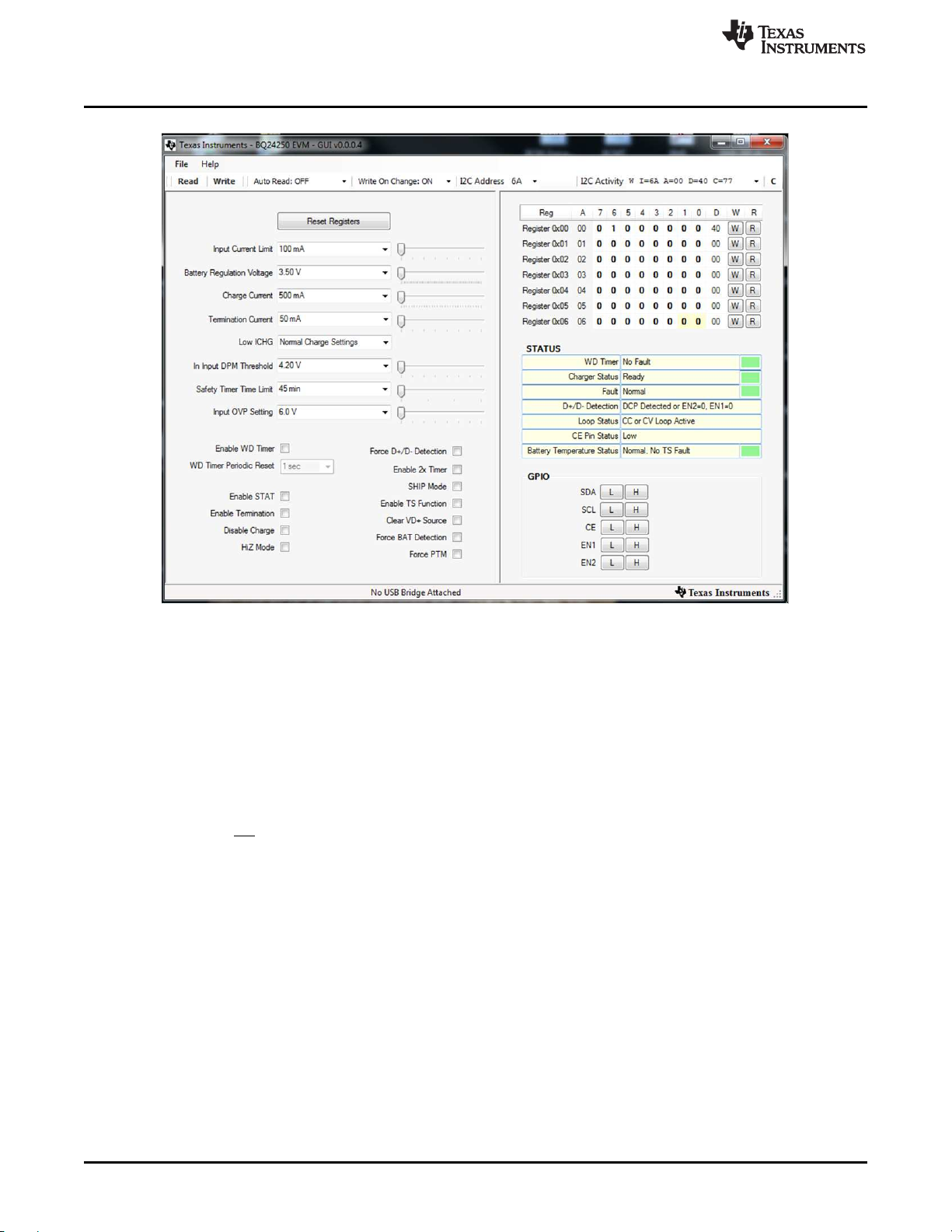

5 Main Window of the bq2425xSW Evaluation Software............................................................... 10

6 Output Regulation Ripple at ICHG = 1000 mA ....................................................................... 12

7 Output Regulation Ripple at ICHG = 120 mA ......................................................................... 12

8 Efficiency Versus Output Current While in Battery Voltage Regulation (4.2V)”................................... 12

9 Thermal Image............................................................................................................. 13

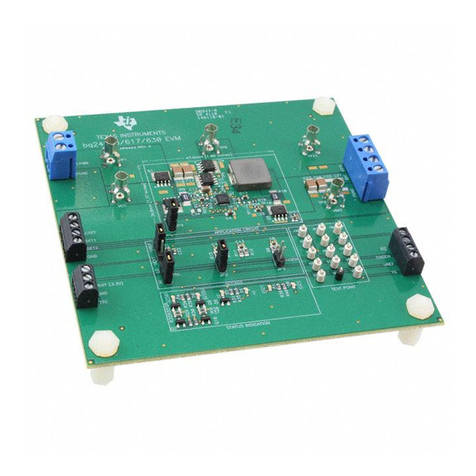

10 bq2425xEVM-150 Top Assembly ....................................................................................... 14

11 bq2425xEVM-150 Top Silkscreen ...................................................................................... 15

I2C is a trademark of NXP.

1

SLUUA08A–March 2013–Revised April 2013 bq2425xEVM-150, Single-Cell Li-Ion Switch-Mode Charger

Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated