BQ25157 I2C Controlled 1-Cell 500-mA Linear Battery Charger With 10-nA Ship Mode,

Power Path With Regulated System (PMID) Voltage, ADC, LDO and 6.2-V OVP

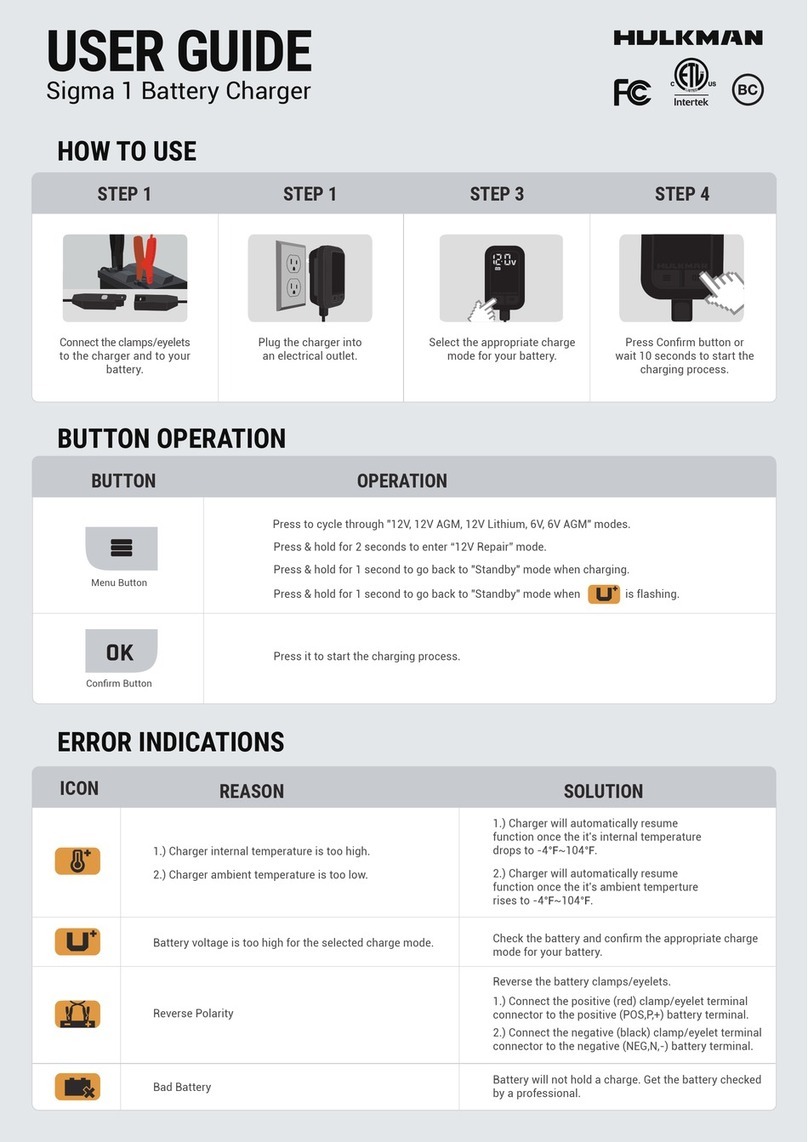

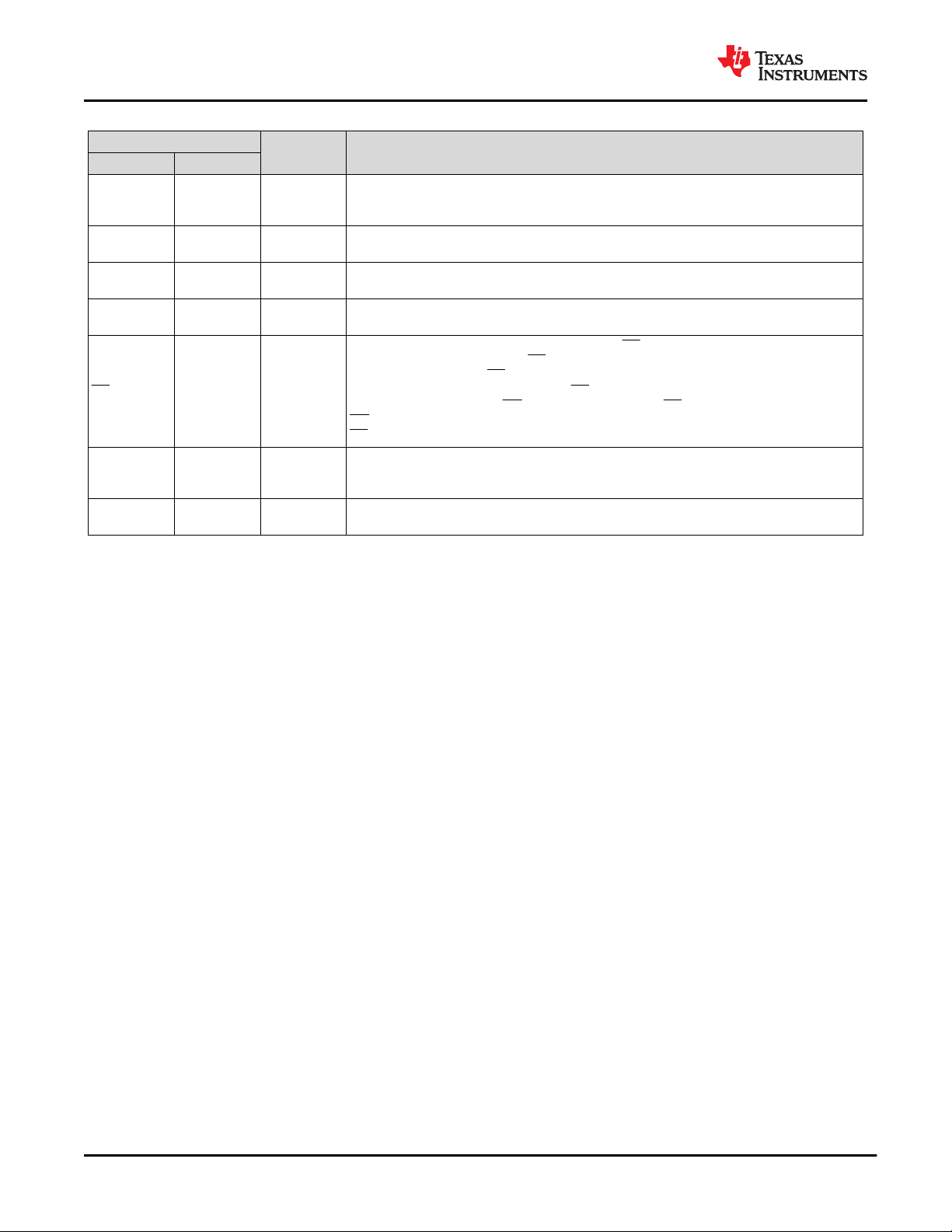

1 Features

• Linear battery charger with 1.25-mA to 500-mA

fast charge current range

– 0.5% Accurate I2C programmable battery

regulation voltage ranging from 3.6 V to 4.6 V in

10-mV steps

– Configurable termination current supporting

down to 0.5 mA

– 20-V Tolerant input with typical 3.4-V to 6.2-V

input voltage operating range

– Programmable thermal charging profile, fully

configurable hot, warm, cool and cold

thresholds

• Power Path management for powering system and

charging battery

– Dynamic power path management optimizes

charging from weak adapters

– Advanced I2C control allows host to disconnect

the battery or adapter as needed

• I2C Configurable load switch or up to 150-mA LDO

output

– Programmable range from 0.6 V to 3.7 V in

100-mV steps

• Ultra low Iddq for extended battery life

– 10-nA Ship mode battery Iq

– 400-nA Iq While powering the system (PMID

and VDD on)

• One push-button wake-up and reset input with

adjustable timers

– Supports system power cycle and HW reset

• 16-Bit ADC

– Monitoring of charge current, battery thermistor

and battery, input and system (PMID) voltages

– General purpose ADC input

• Always on 1.8-V VDD LDO supporting loads up to

10 mA

• 20-Pin 2-mm x 1.6-mm CSP package

• 12-mm2 Total solution size

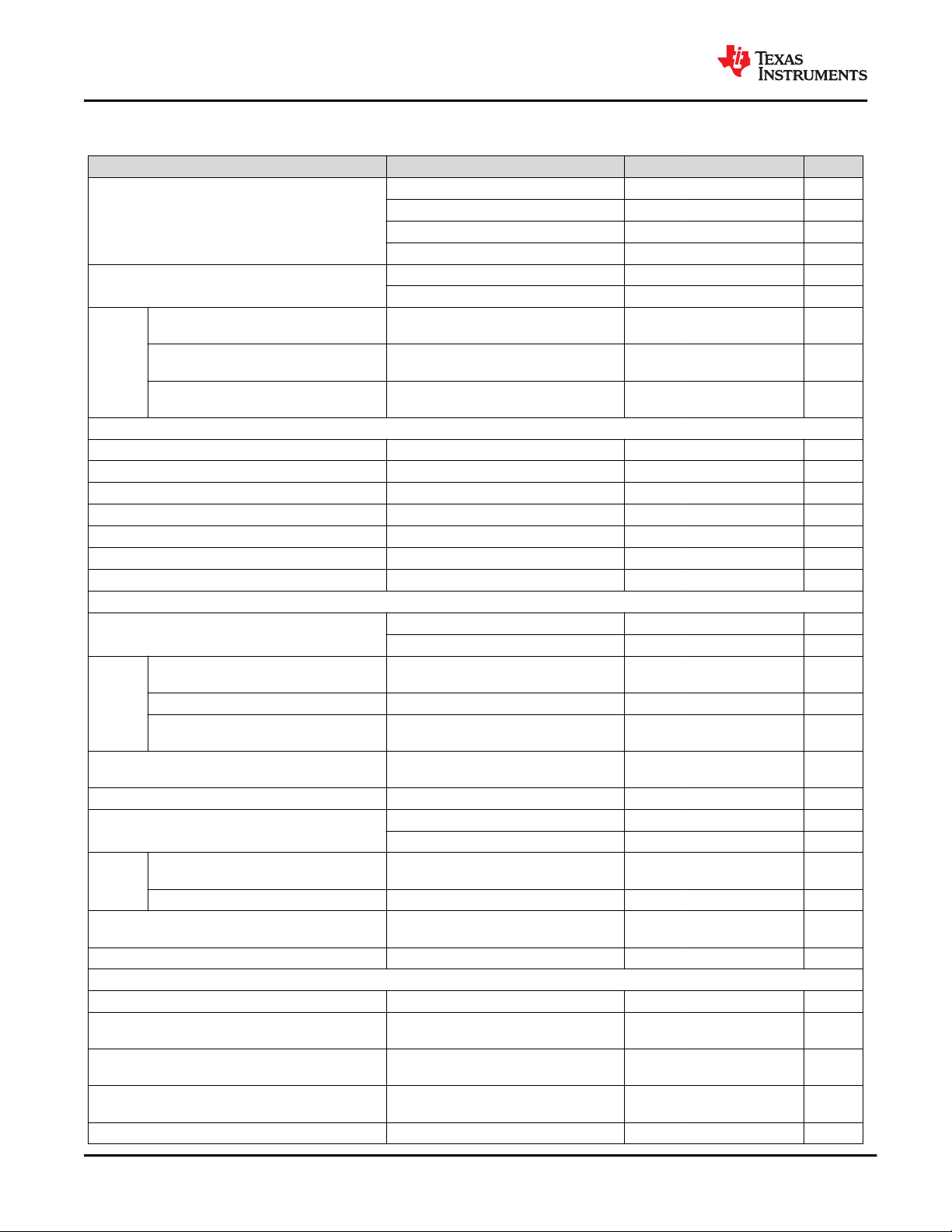

2 Applications

•Headsets, earbuds and hearing aids

•Smart watches and smart trackers

•Wearable fitness and activity monitors

•Blood glucose monitors

3 Description

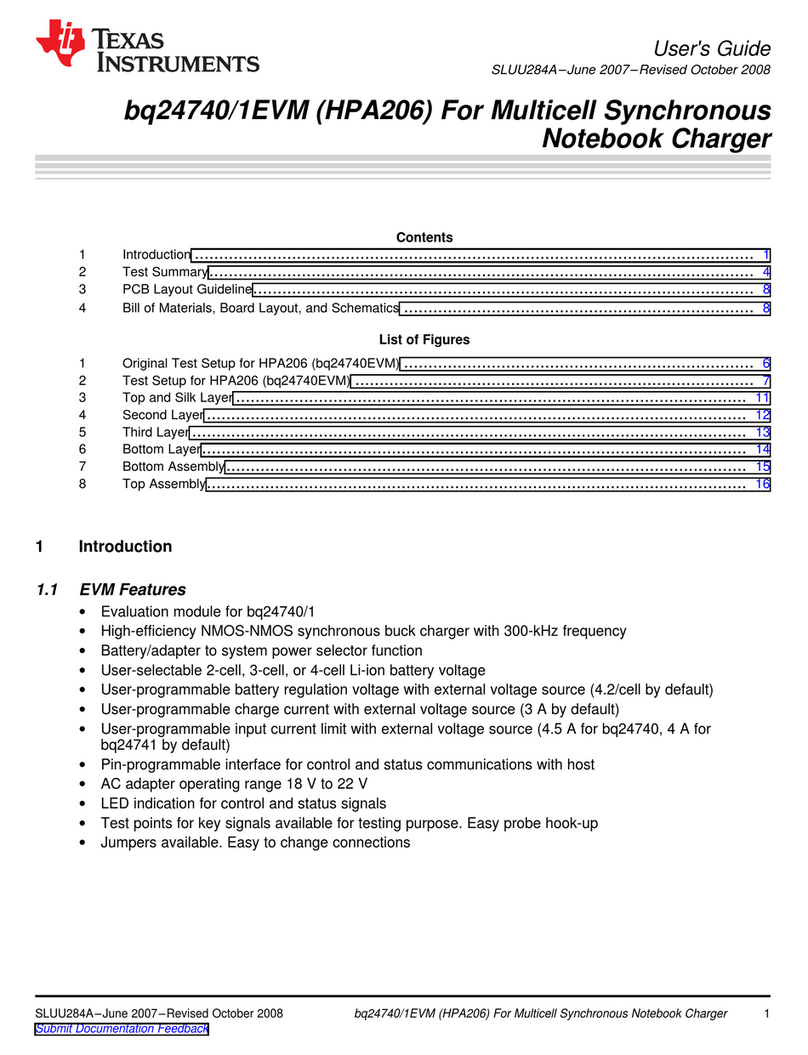

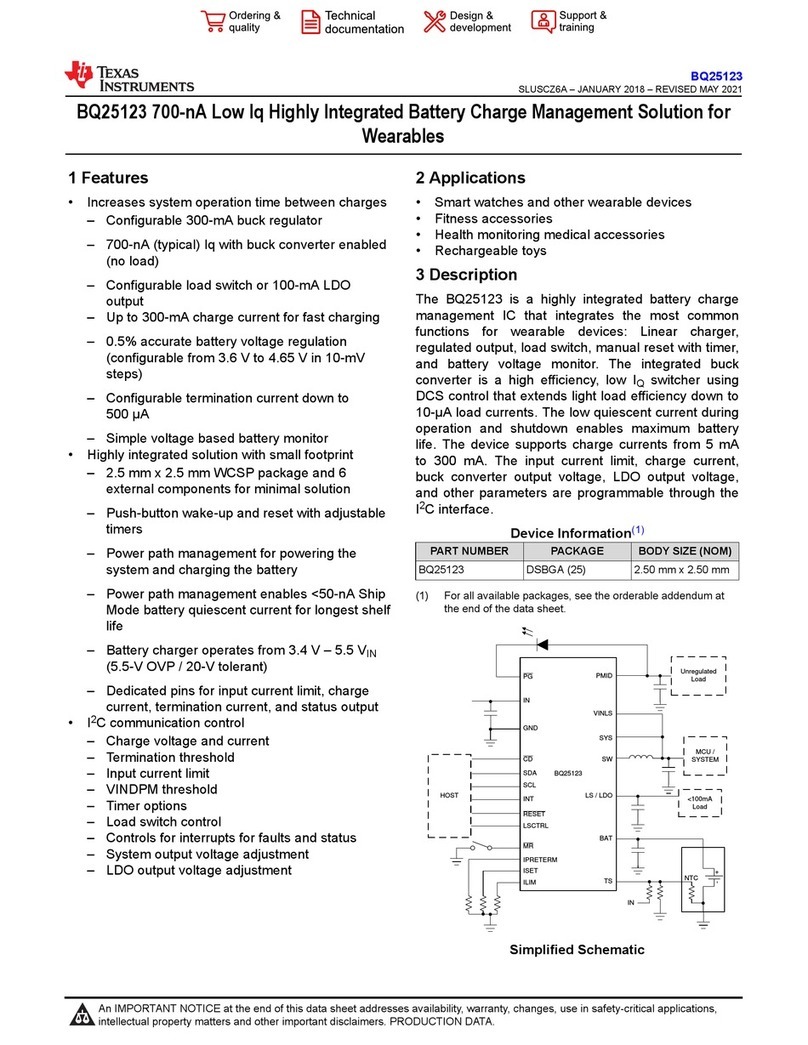

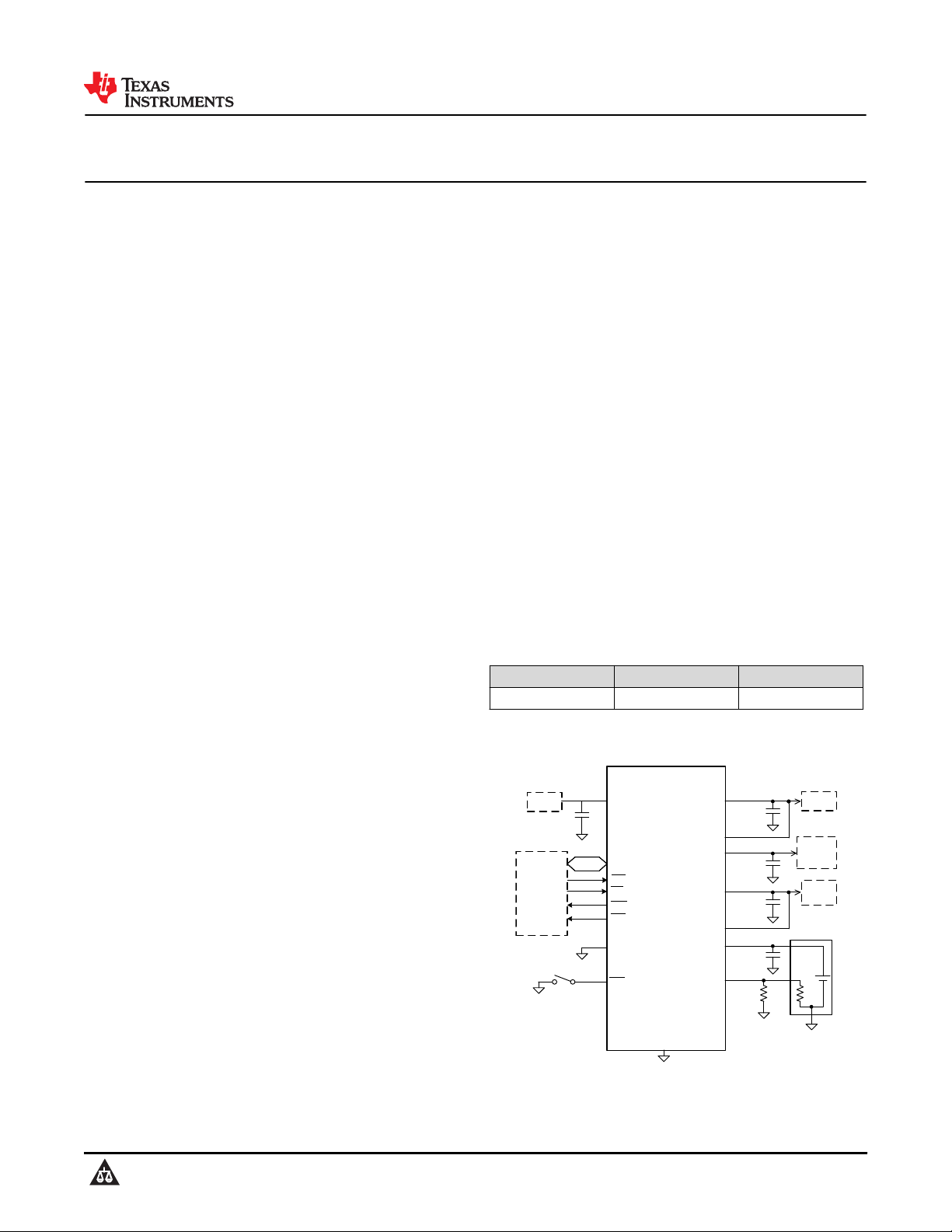

The BQ25157 is a highly integrated battery charge

management IC that integrates the most common

functions for wearable, portable and small medical

devices, namely a charger, a regulated output voltage

rail for system power, ADC for battery and system

monitoring, a LDO, and push-button controller. The

BQ25157 has the Input Supply Over Voltage

Threshold (VOVP) threshold set to 6.2 V.

The BQ25157 IC integrates a linear charger with

Power Path that enables quick and accurate charging

for small batteries while providing a regulated voltage

to the system. The regulated system voltage (PMID)

output may be configured through I2C based on the

recommended operating condition of downstream IC's

and system loads for optimal system operation.

Device Information (1)

PART NUMBER PACKAGE BODY SIZE (NOM)

BQ25157 DSBGA (20) 2.00 mm x 1.60 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

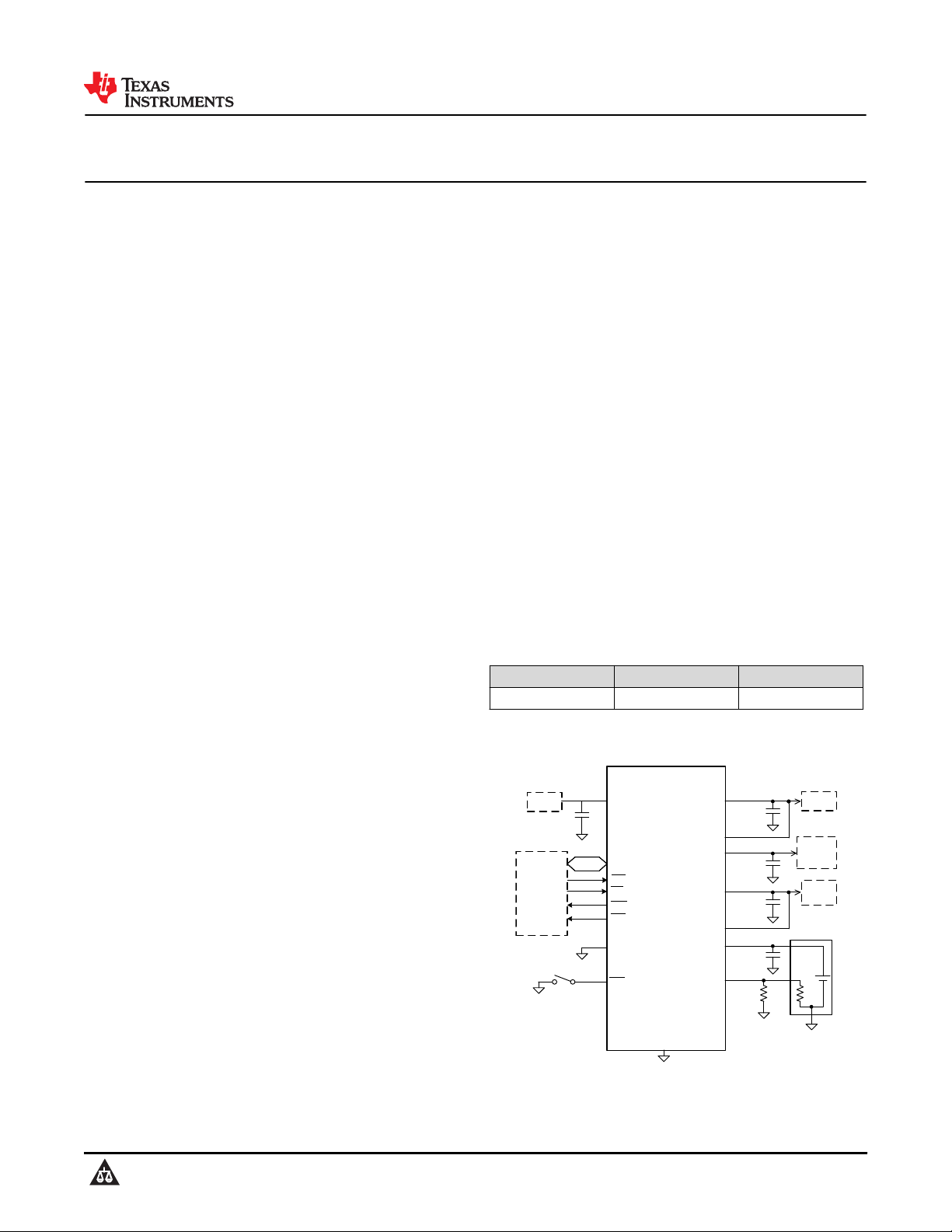

BQ25157

VINLS

PMID

LS/LDO

VDD

BAT

TS +

±

NTC

GND

IN

VIO

Host

USB

I2C Bus

<150mA

Load

<10mA

Load

System

ADCIN

MR

PG

INT

LP

CE

C4

C5

C3

C2

C1

Simplified Schematic

www.ti.com

BQ25157

SLUSEC5 – DECEMBER 2020

Copyright © 2020 Texas Instruments Incorporated Submit Document Feedback 1

Product Folder Links: BQ25157

BQ25157

SLUSEC5 – DECEMBER 2020

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.