Texas Instruments TMDSHVMTRPFCKIT User manual

Other Texas Instruments Controllers manuals

Texas Instruments

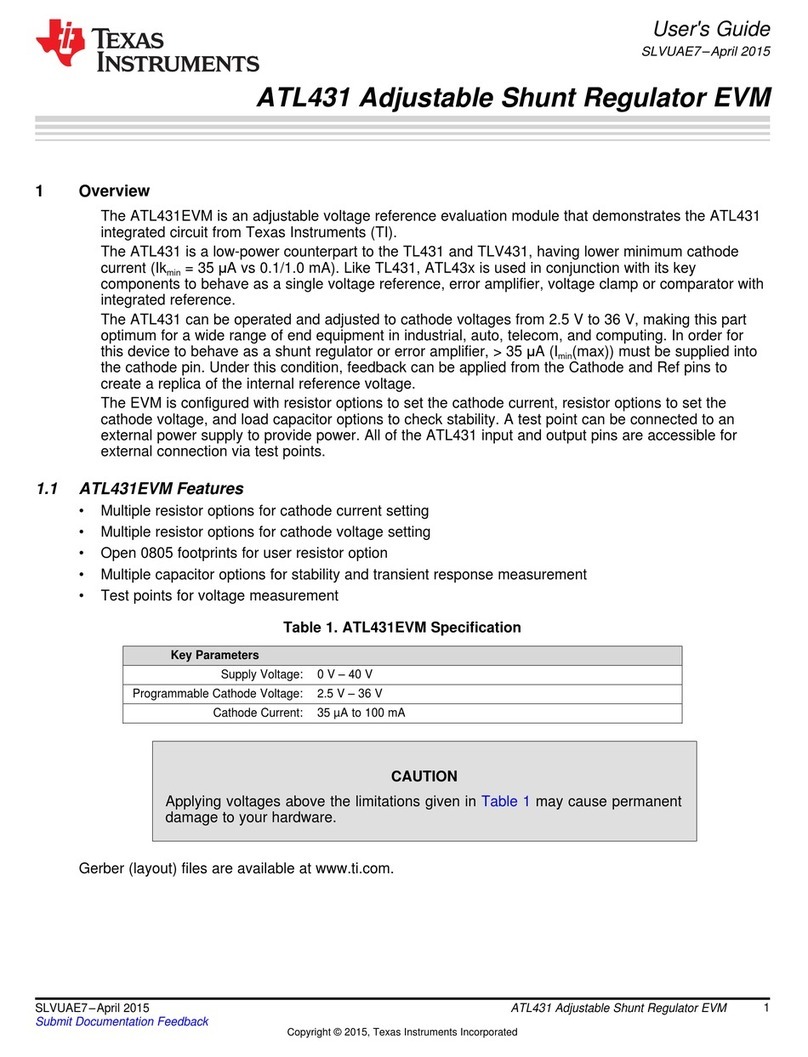

Texas Instruments ATL431 User manual

Texas Instruments

Texas Instruments TMS320C28 series User manual

Texas Instruments

Texas Instruments bq24010/2 User manual

Texas Instruments

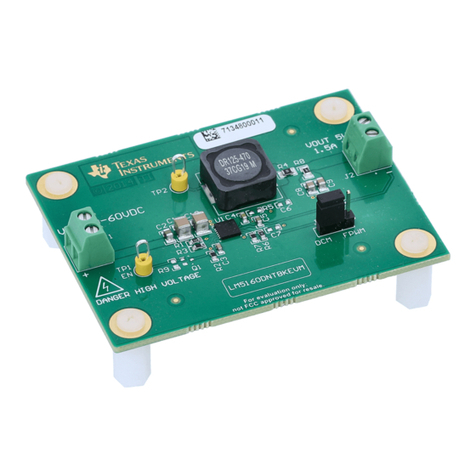

Texas Instruments LM5160A User manual

Texas Instruments

Texas Instruments TMS320C6457 User manual

Texas Instruments

Texas Instruments TUSB3210 Installation and user guide

Texas Instruments

Texas Instruments TMS320C2000 User manual

Texas Instruments

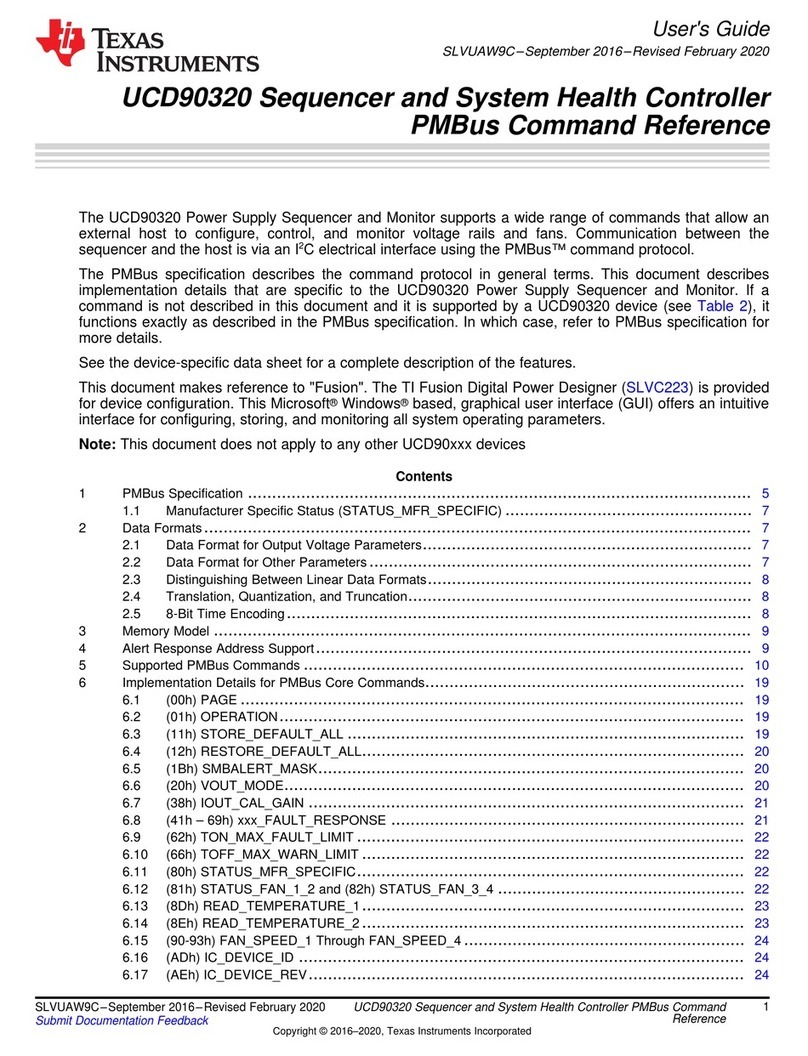

Texas Instruments UCD90320 User manual

Texas Instruments

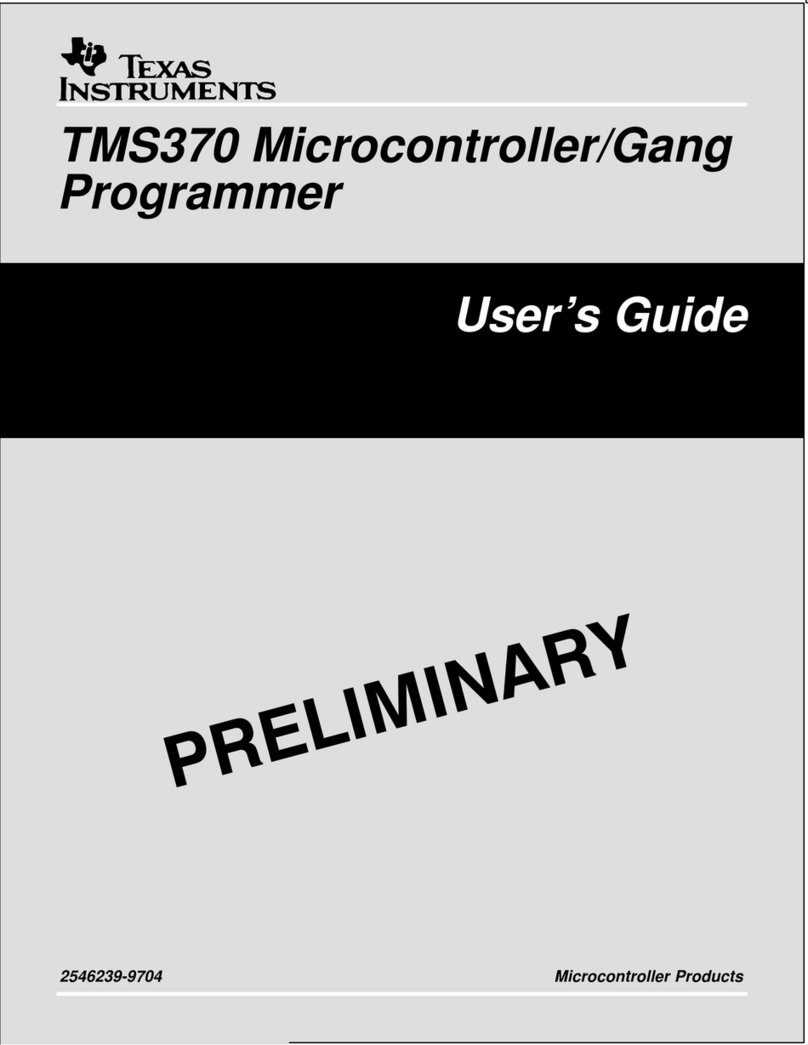

Texas Instruments TMS370 Series User manual

Texas Instruments

Texas Instruments TPS23755 User manual

Texas Instruments

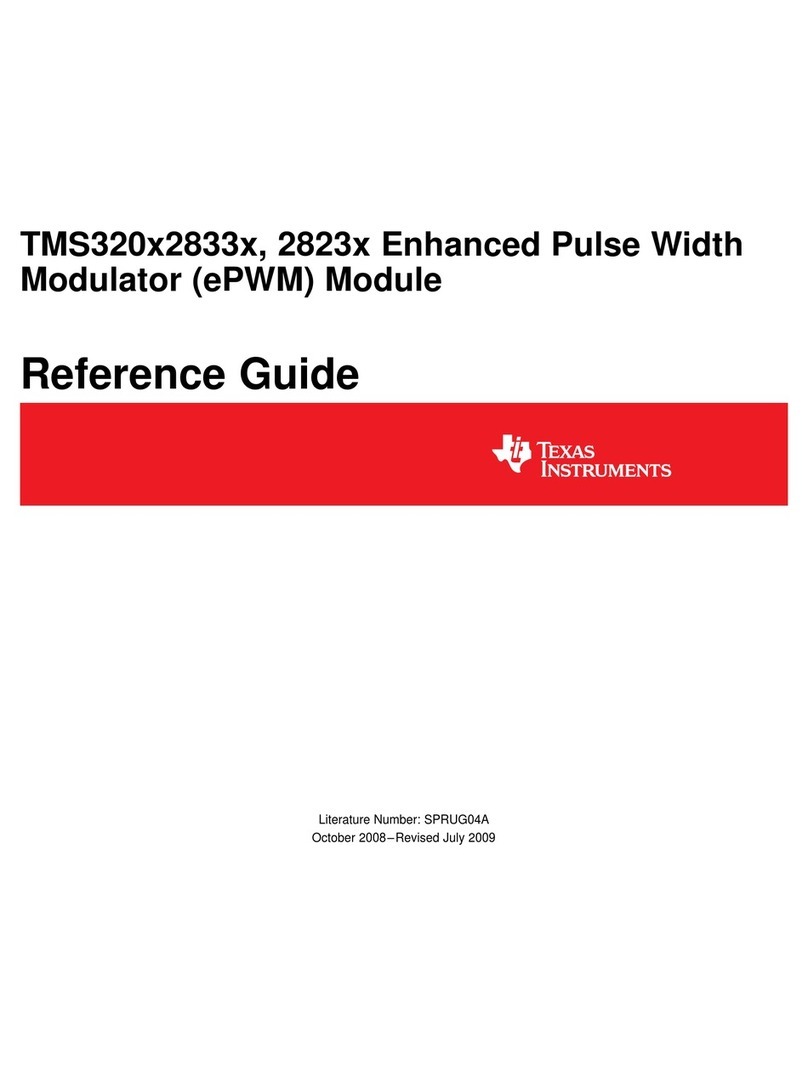

Texas Instruments TMS320x2833x User manual

Texas Instruments

Texas Instruments OMAP5910 User manual

Texas Instruments

Texas Instruments TMS320C6455 User manual

Texas Instruments

Texas Instruments UCC14240EVM-052 User manual

Texas Instruments

Texas Instruments TPS53647 User manual

Texas Instruments

Texas Instruments TMS320C2000 User manual

Texas Instruments

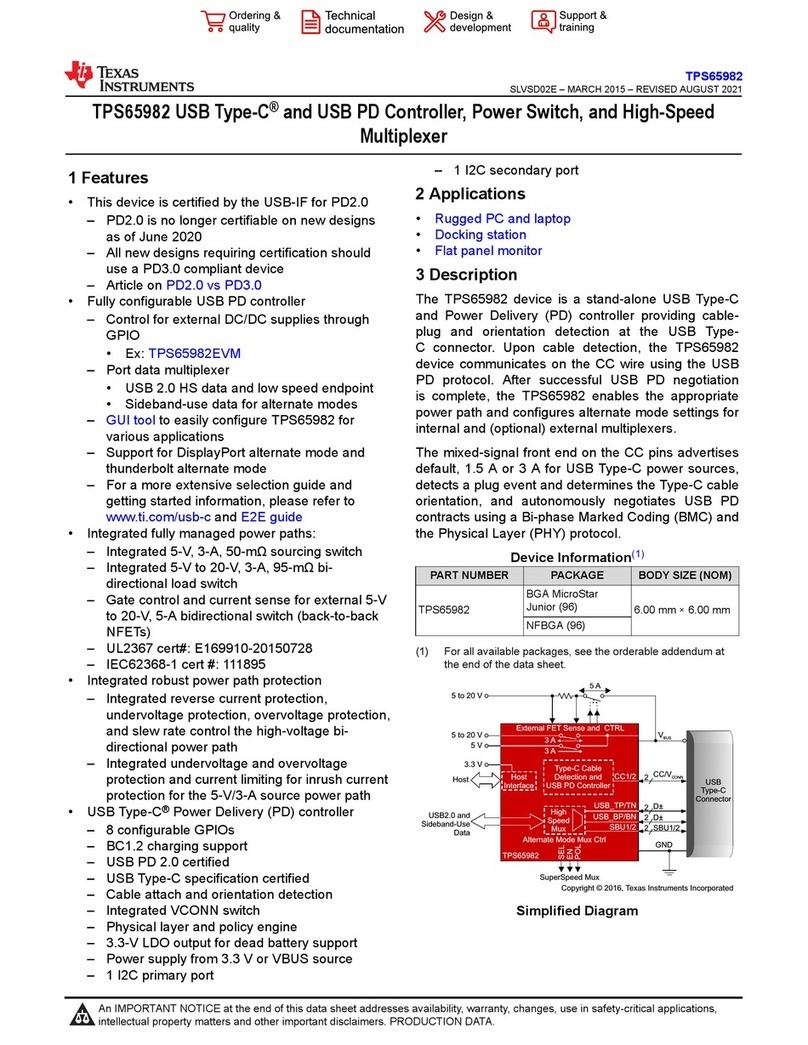

Texas Instruments TPS65982 User manual

Texas Instruments

Texas Instruments TUSB5052 User manual

Texas Instruments

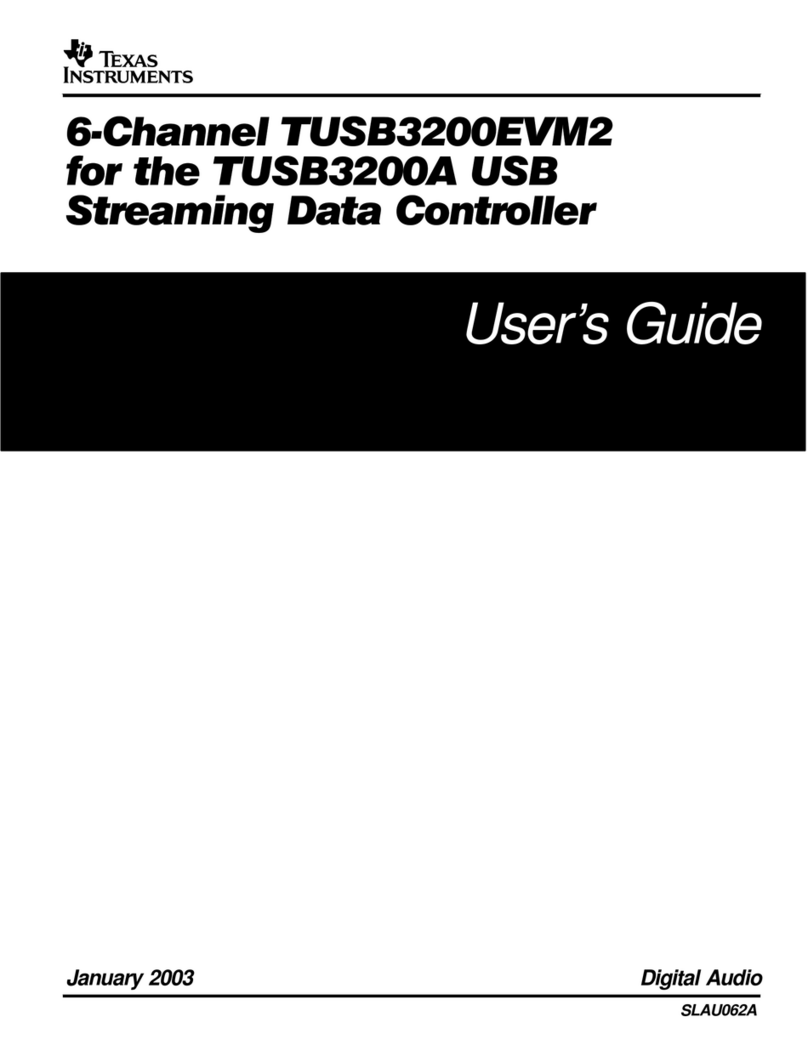

Texas Instruments TUSB3200EVM2 User manual

Texas Instruments

Texas Instruments TCAN4550-Q1 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions