Texas Instruments PGA460-Q1 User manual

Other Texas Instruments Microcontroller manuals

Texas Instruments

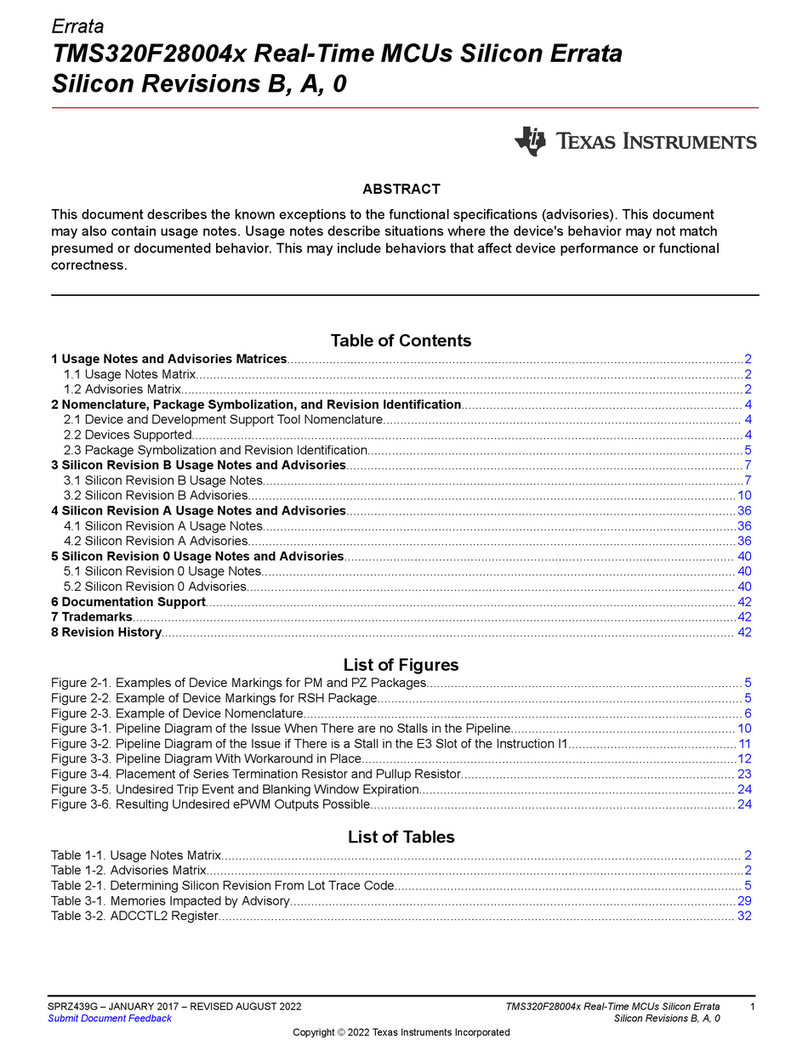

Texas Instruments TMS320F28004 Series User manual

Texas Instruments

Texas Instruments MSP430FG461x series User manual

Texas Instruments

Texas Instruments CDT370 User manual

Texas Instruments

Texas Instruments Errata MSP430F6736A User manual

Texas Instruments

Texas Instruments TMS320DM357 User manual

Texas Instruments

Texas Instruments CC1125 User manual

Texas Instruments

Texas Instruments MSP430F6747 User manual

Texas Instruments

Texas Instruments MSP430 series User manual

Texas Instruments

Texas Instruments Chipcon Products CC1110DK User manual

Texas Instruments

Texas Instruments TMS570LS12x User manual

Texas Instruments

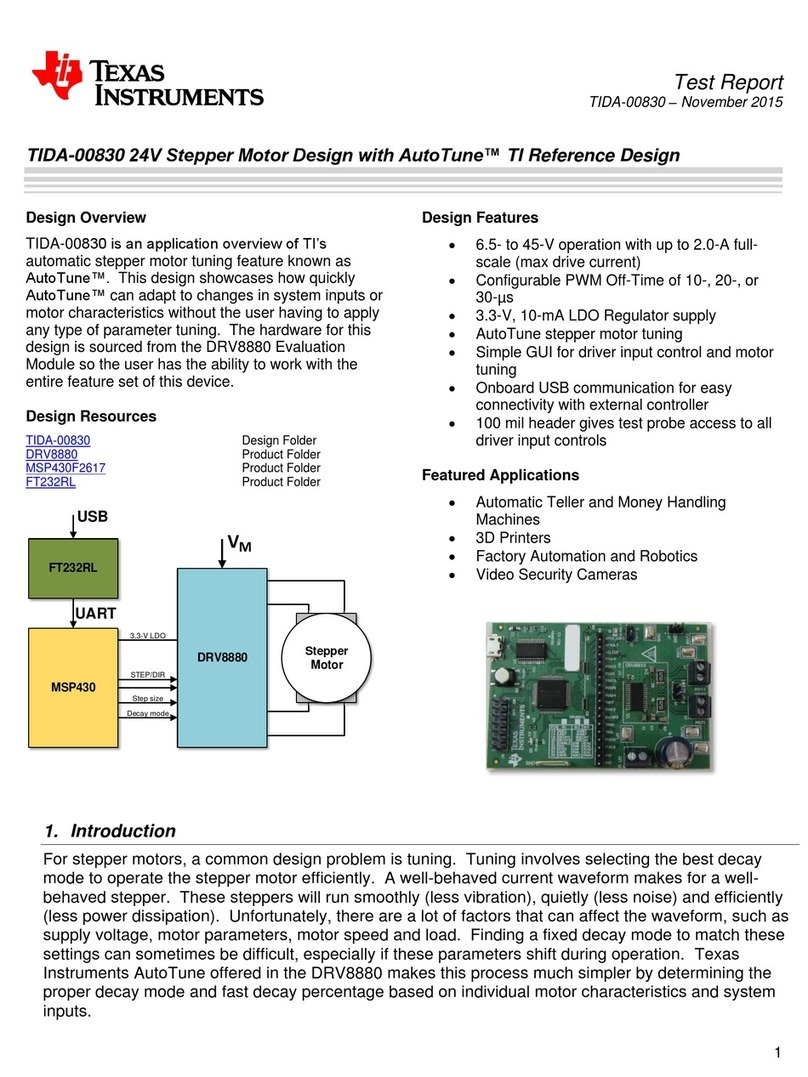

Texas Instruments TIDA-00830 User manual

Texas Instruments

Texas Instruments Serial Programming Adapter MSP430 User manual

Texas Instruments

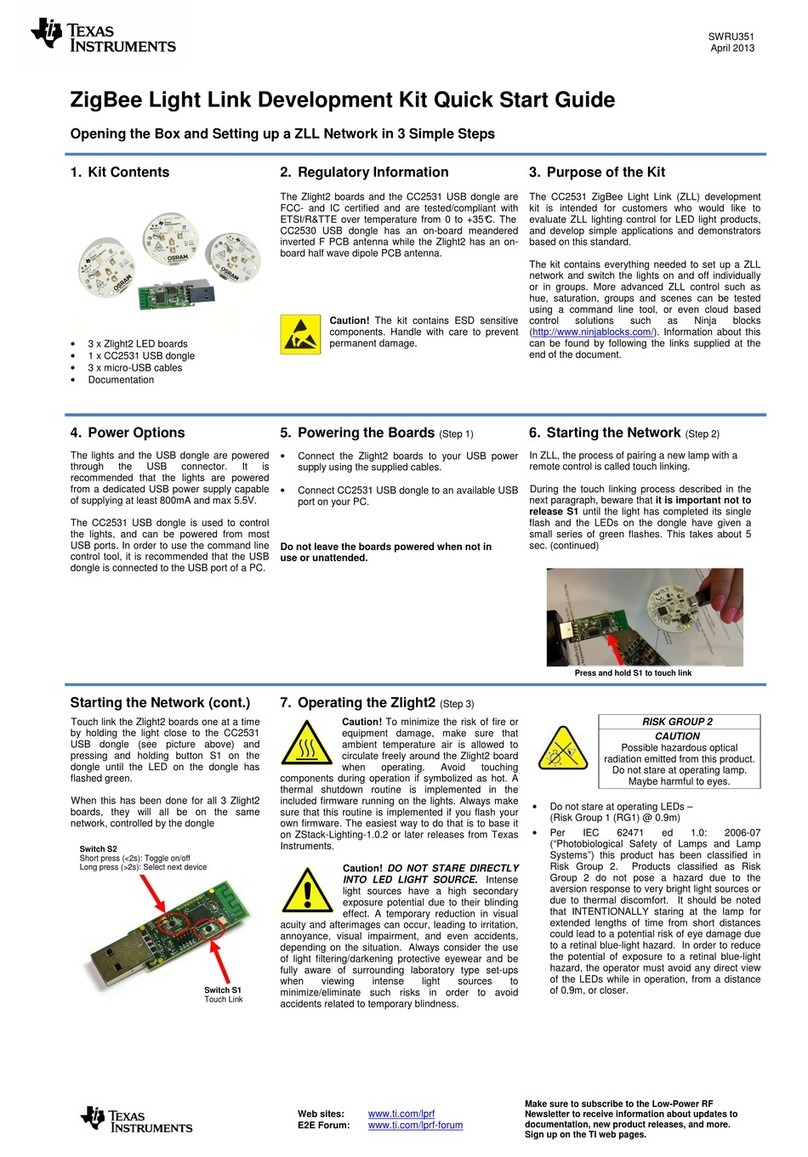

Texas Instruments SWRU351 User manual

Texas Instruments

Texas Instruments MSP430FG6626 User manual

Texas Instruments

Texas Instruments RM48 series Product manual

Texas Instruments

Texas Instruments TAS6584-Q1 EVM User manual

Texas Instruments

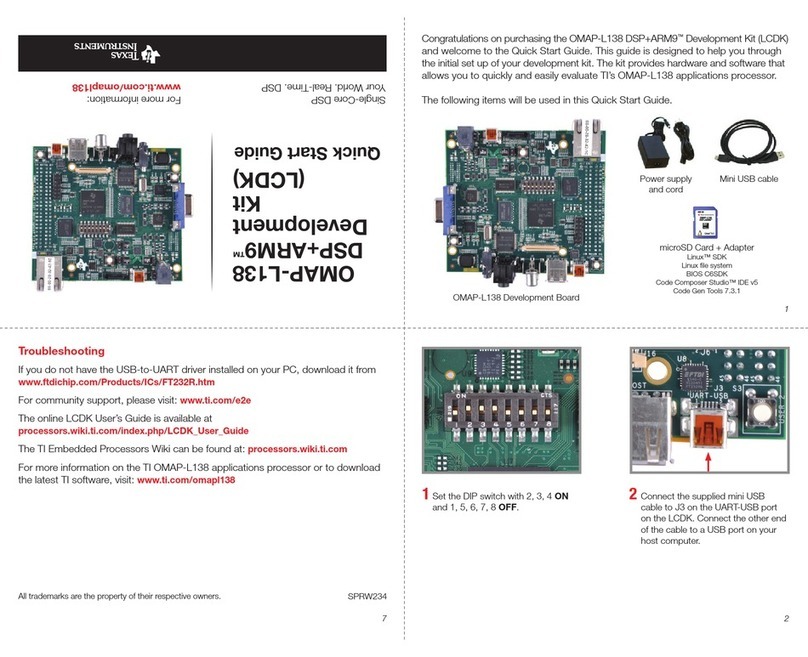

Texas Instruments OMAP-L138 DSP + ARM9 User manual

Texas Instruments

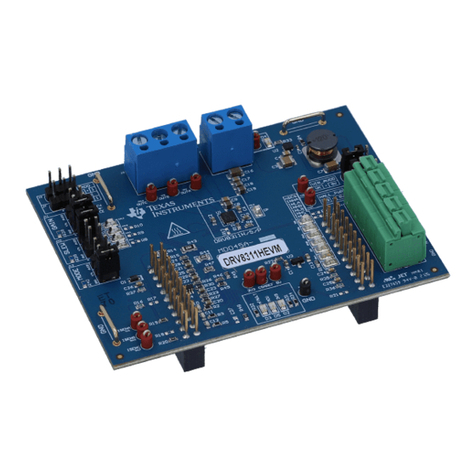

Texas Instruments DRV8311HEVM User manual

Texas Instruments

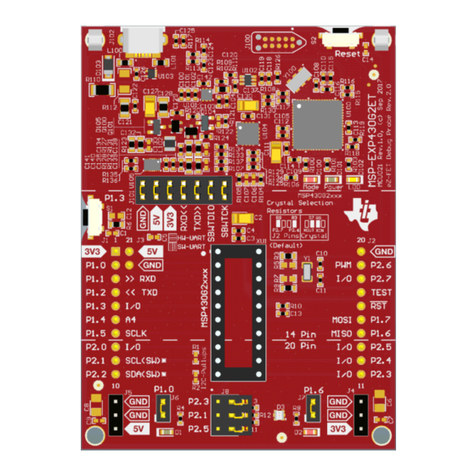

Texas Instruments LaunchPad MSP430G2553 User manual

Texas Instruments

Texas Instruments Vision SDK Linux User manual

Popular Microcontroller manuals by other brands

Novatek

Novatek NT6861 manual

Espressif Systems

Espressif Systems ESP8266 SDK AT Instruction Set

Nuvoton

Nuvoton ISD61S00 ChipCorder Design guide

STMicrolectronics

STMicrolectronics ST7 Assembler Linker user manual

Lantronix

Lantronix Intrinsyc Open-Q 865XR SOM user guide

NEC

NEC 78GK0S/K 1+ Series Application note