7

Safety instructions

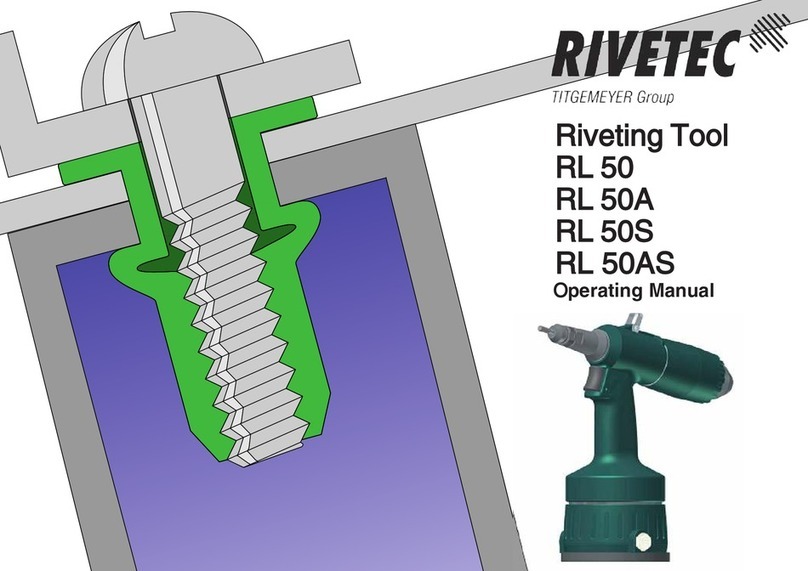

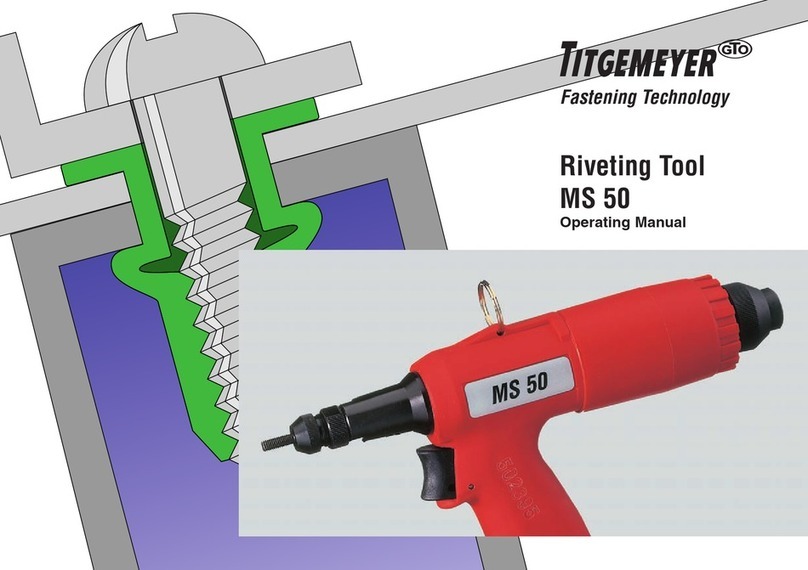

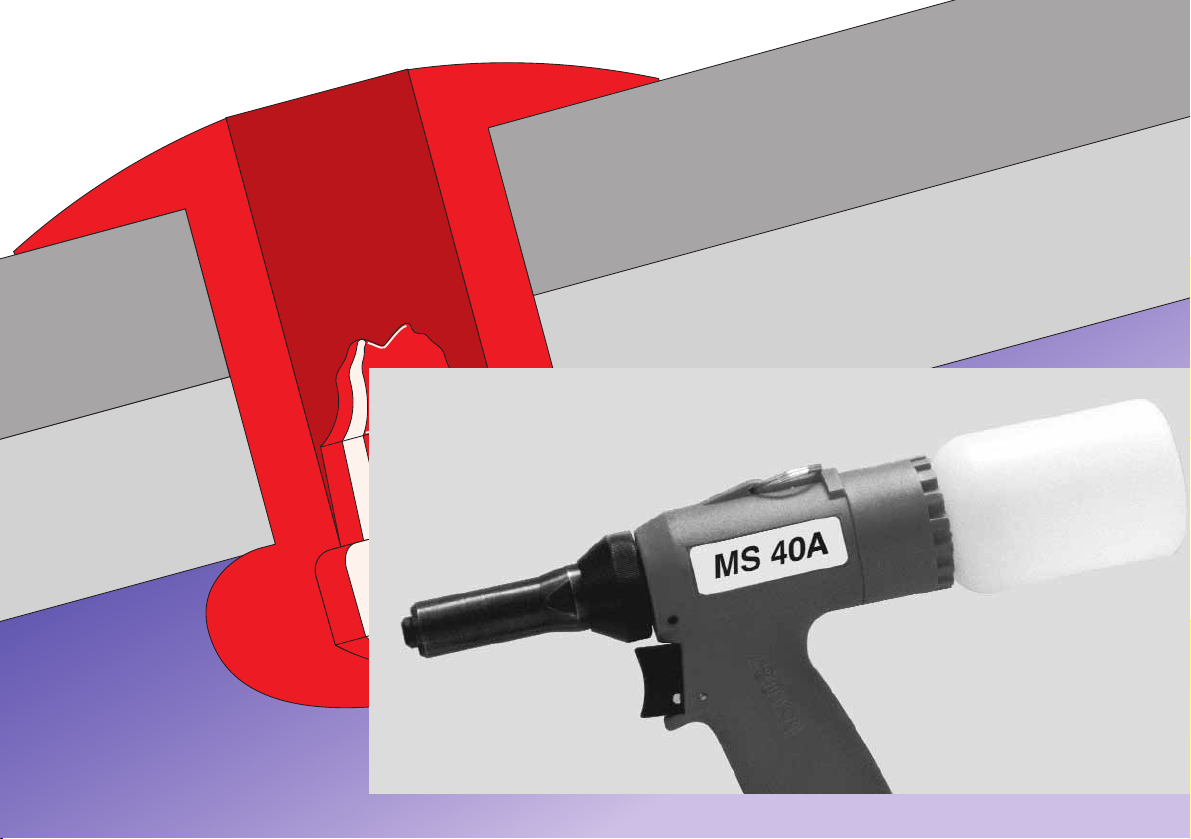

The riveting tool is meant exclusively for setting blind rivets.

The riveting tool MS 40A has been designed for setting all materials of

blind rivets with a shank diameter of 4.0 to 6.4 mm.

This riveting tool must be used only as a hand-held device!

The client is fully responsible for any modifications to the riveting tool!

Never throw away or drop the riveting tool!

Please take care that only clean and dry compressed air is let into the

riveting tool. Moisture and dirt can damage the riveting tool. Use only such

compressed air, which falls into class 2 of air quality as per ISO 8573-1.

Caution Hazard of injury because of explosion! Never use the riveting

tool in an atmosphere prone to explosions. Ensure that the

workplace is well lit and clean.

Hazard of injury due to the openly moving compressed air

hose. Connect and lay the compressed air hose properly.

Hazard of injury due to tripping over! Lay the compressed air

hose in such a way that nobody should trip over it.

Attention Material damage! The maximum operating pressure is 7 bar.

For increasing the durability of the riveting tool, it is recommen-

ded to fit a compressed air-maintenance unit in the compressed

air hose.

Application as per the purpose

Improper use

Clean and dry compressed air

H

E