pressor-driven riveting tools. On request, this training could be done by

dealer or directly by RIVETEC s.r.o.

This riveting tool is as per the latest technological standards. For the

device to function properly, it is necessary to operate it in an expertly

manner, with adherence to safety requirements.

Before using the riveting tool for the first time, read the guiding instruc-

tions carefully.

All the procedures necessary for the operation have been described in

these guiding instructions. You may carry out only those procedures,

which have been described here.

In case of obstructions, you may repair only those obstructions, which

have been marked with an O(Operator).

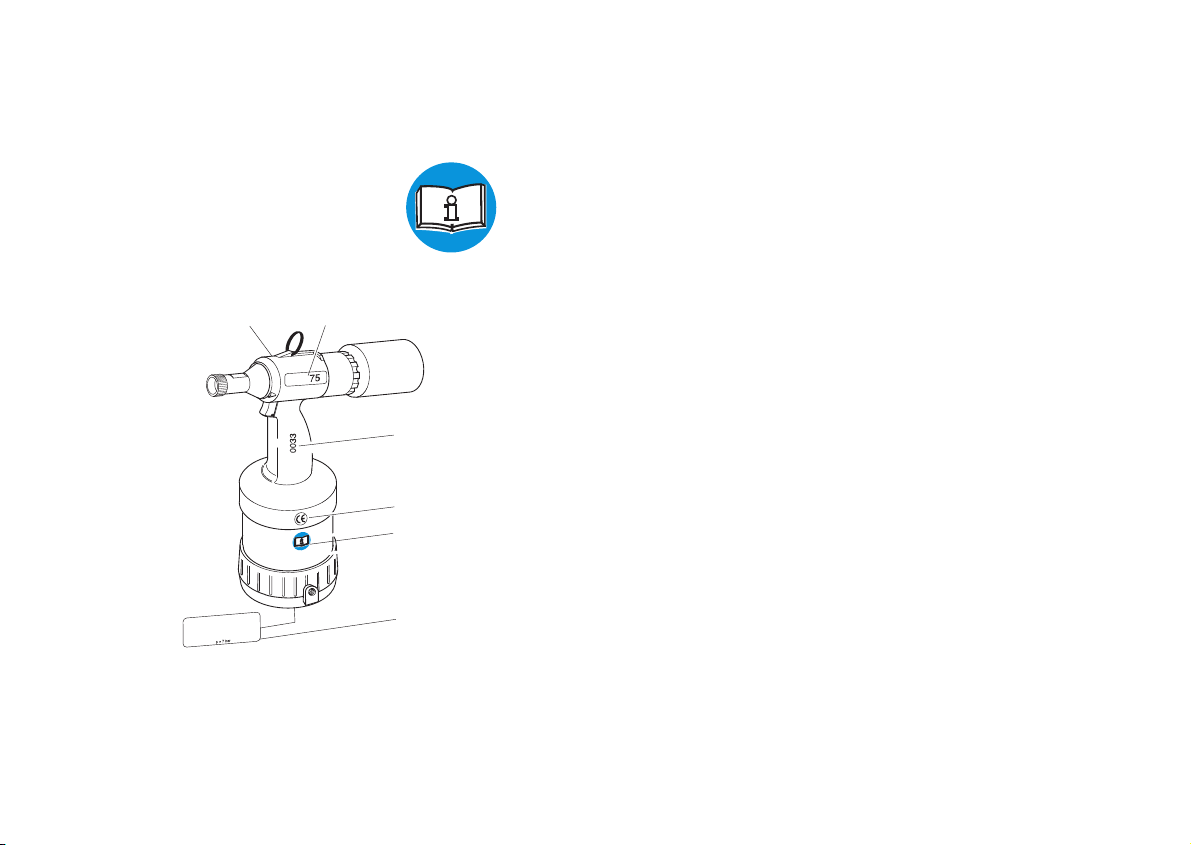

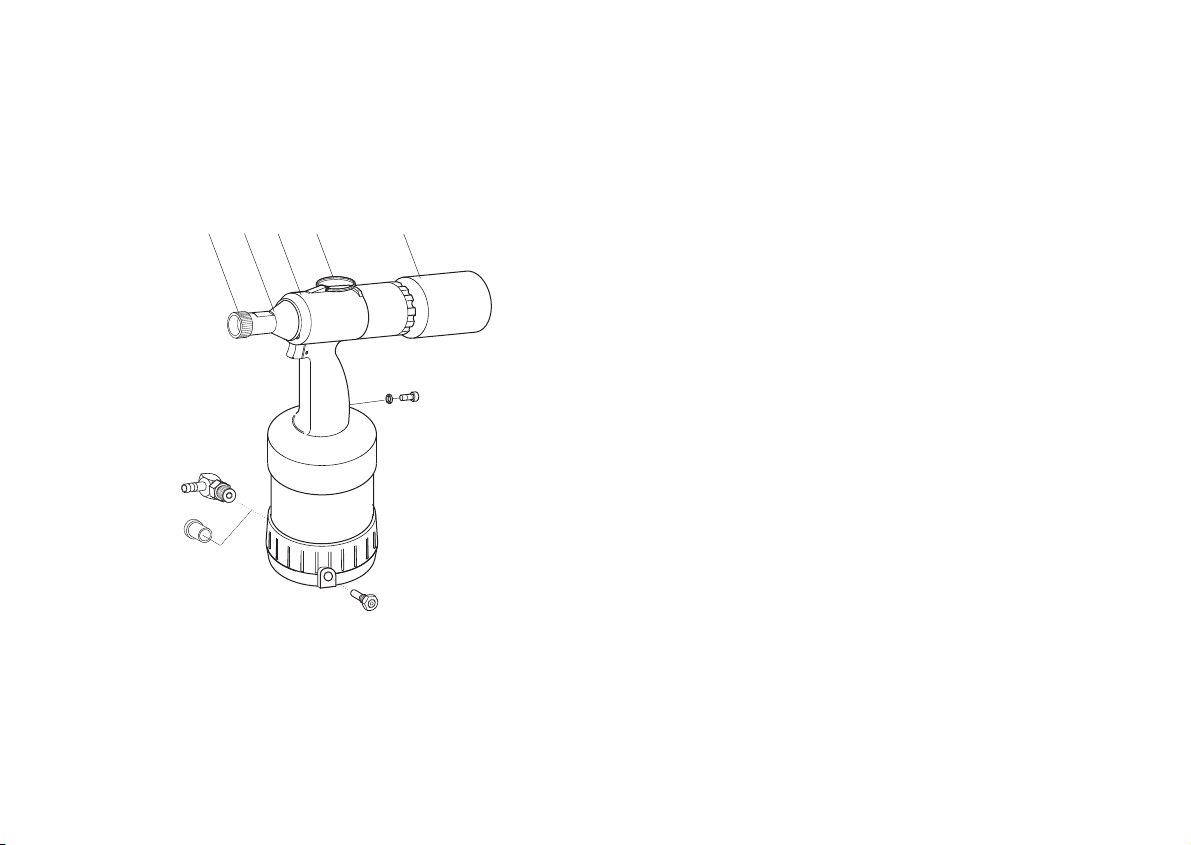

All the illustrations and position-codes in the individual diagrams take

reference from the list of parts in the last pages.

For sizes of screws and threads, you will find a table containing the torque

values in the chapter “Maintaining the riveting tool”.

Instruction

Technological level

Reading the guiding instructions

Procedures

Obstructions

Illustrations and position-codes

Table for torque values