Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alertsymbol

(Figure2),whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Always

followallsafetyinstructionstoavoidseriousinjuryor

death.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthe

sourcewherepossible.Usewaterfordust

suppressionwheneverpossible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenyoucannoteliminatethehazards

frominhalation,youandallbystanders

shouldweararespiratorapprovedby

OSHAforthematerialthatyouare

handling.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichislethalifinhaled.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,andallow

themachinetocoolbeforeadjusting,cleaning,

storing,orrepairingthemachine.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingthem.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriestopeopleordamageto

property.

Towing

•Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Toreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,ensure

thatthetowingvehicleismechanicallysoundand

ingoodoperatingcondition.

•Shutofftheenginebeforetransportingthe

machine.

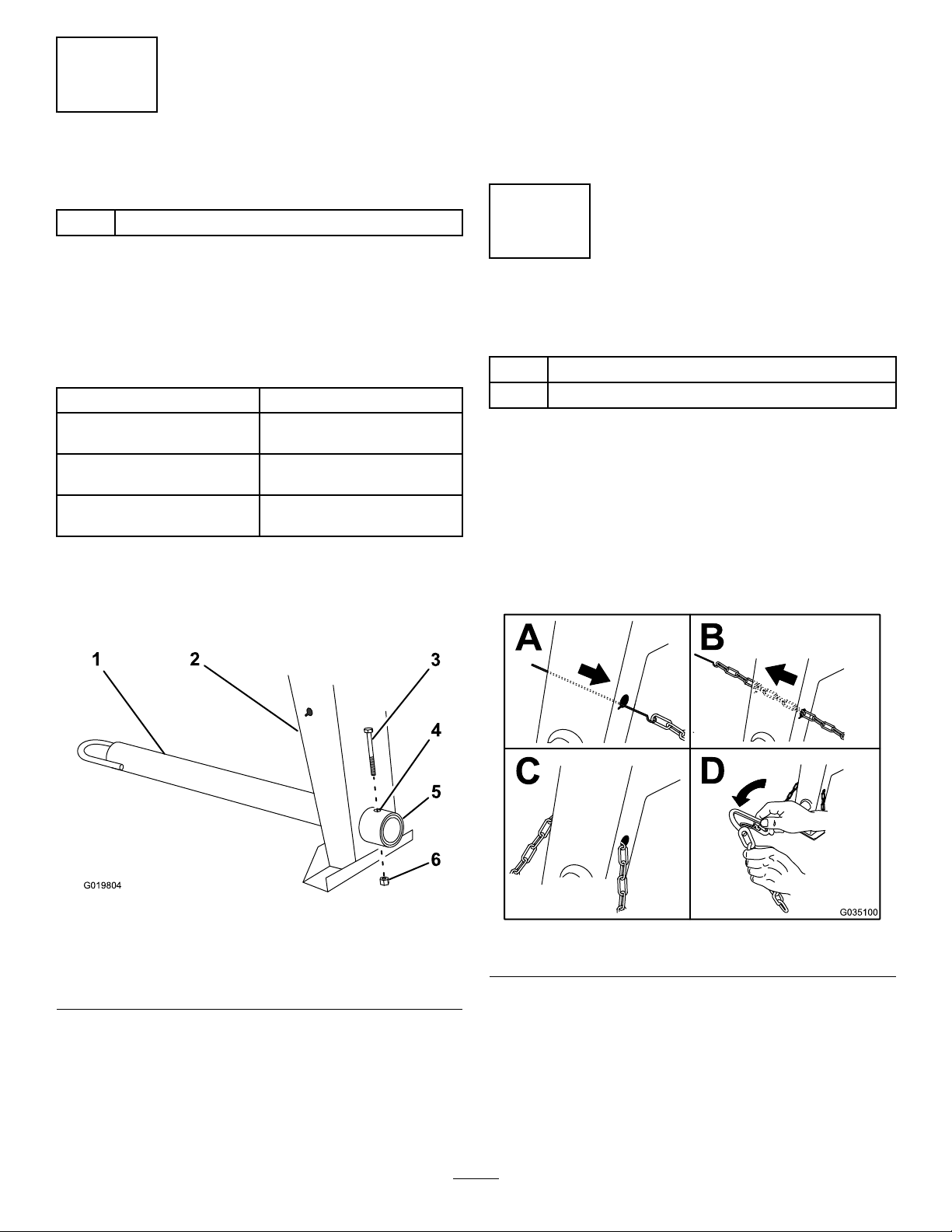

•Whentowingwithaballhitch,ensurethatitisthe

propersizeforthehitchcoupleronthemachine.

•Whentowingwithapintlehitch,ensurethatthe

eyeofthetowpoleisthecorrectdimensionfor

thepintlehook.

•Inspectthehitchandcouplingforwear.Donot

towthemachinewithdamagedorwornhitches,

couplings,chains,orothercomponents.

•Checktheairpressureofthetiresonthetowing

vehicleandadjustthepressureasneeded.

•Checkthetiretreadandsidewallfordamageand

wearandreplacethetireifnecessary.

•Properlyattachthesafetychainstothetowing

vehiclebycrossingthechainsandremovingany

extraslack.

•Ensurethatthedirectionalandbrakelightsare

workingproperly(ifequipped).

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly(if

equipped).

•Beforetowing,ensurethatyourmachineis

correctlyandsecurelyattachedtothetowing

vehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

4