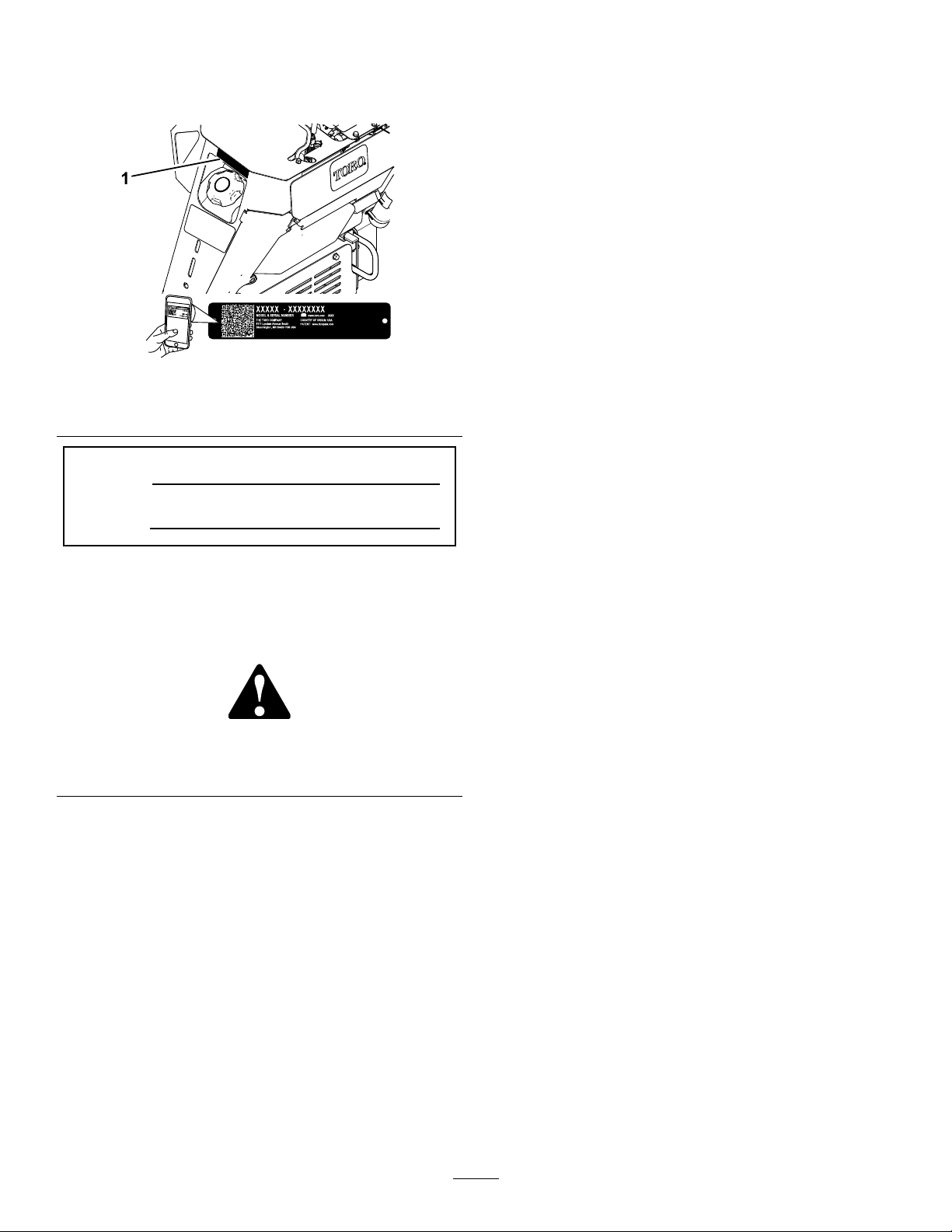

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g272571

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup......................................................................10

1InstallingtheBoomandChain........................10

2CheckingtheFluidLevels...............................11

3ChargingtheBattery.......................................11

ProductOverview...................................................12

Controls...........................................................12

Specications..................................................14

Attachments/Accessories.................................14

BeforeOperation.................................................15

BeforeOperationSafety...................................15

AddingFuel......................................................15

PerformingDailyMaintenance..........................16

DuringOperation.................................................16

DuringOperationSafety...................................16

StartingtheEngine...........................................18

DrivingtheMachine..........................................18

ShuttingofftheEngine......................................18

DiggingaTrench..............................................19

OperatingTips.................................................19

AfterOperation....................................................20

AfterOperationSafety......................................20

SecuringtheMachineforTransport..................20

LiftingtheMachine...........................................20

Maintenance...........................................................21

MaintenanceSafety..........................................21

RecommendedMaintenanceSchedule(s)...........21

Pre-MaintenanceProcedures..............................23

RemovingtheCoverPlate................................23

Lubrication..........................................................23

GreasingtheMachine.......................................23

GreasingtheTrencherHousing........................24

EngineMaintenance...........................................24

EngineSafety...................................................24

IdentifyingtheEngine.......................................24

ServicingaKohler®Engine...............................25

ServicingaT oroEngine....................................29

FuelSystemMaintenance...................................33

UsingtheFuel-ShutoffValve.............................33

DrainingtheFuelT ank......................................34

ReplacingtheFuelFilter...................................34

ElectricalSystemMaintenance...........................35

ElectricalSystemSafety...................................35

ServicingtheBattery.........................................35

ReplacingtheFuses.........................................37

DriveSystemMaintenance..................................38

ServicingtheTracks.........................................38

BrakeMaintenance.............................................41

TestingtheParkingBrake.................................41

HydraulicSystemMaintenance...........................41

HydraulicSystemSafety...................................41

HydraulicFluidSpecications...........................41

CheckingtheHydraulic-FluidLevel...................42

ReplacingtheHydraulicFilter...........................42

ChangingtheHydraulicFluid............................43

TrencherMaintenance.........................................44

ReplacingtheDiggingTeeth.............................44

CheckingandAdjustingtheDiggingChain

andBoom.....................................................44

ReplacingtheDriveSprocket...........................45

Cleaning..............................................................46

RemovingDebrisfromtheMachine..................46

Storage...................................................................46

Troubleshooting......................................................48

3