10

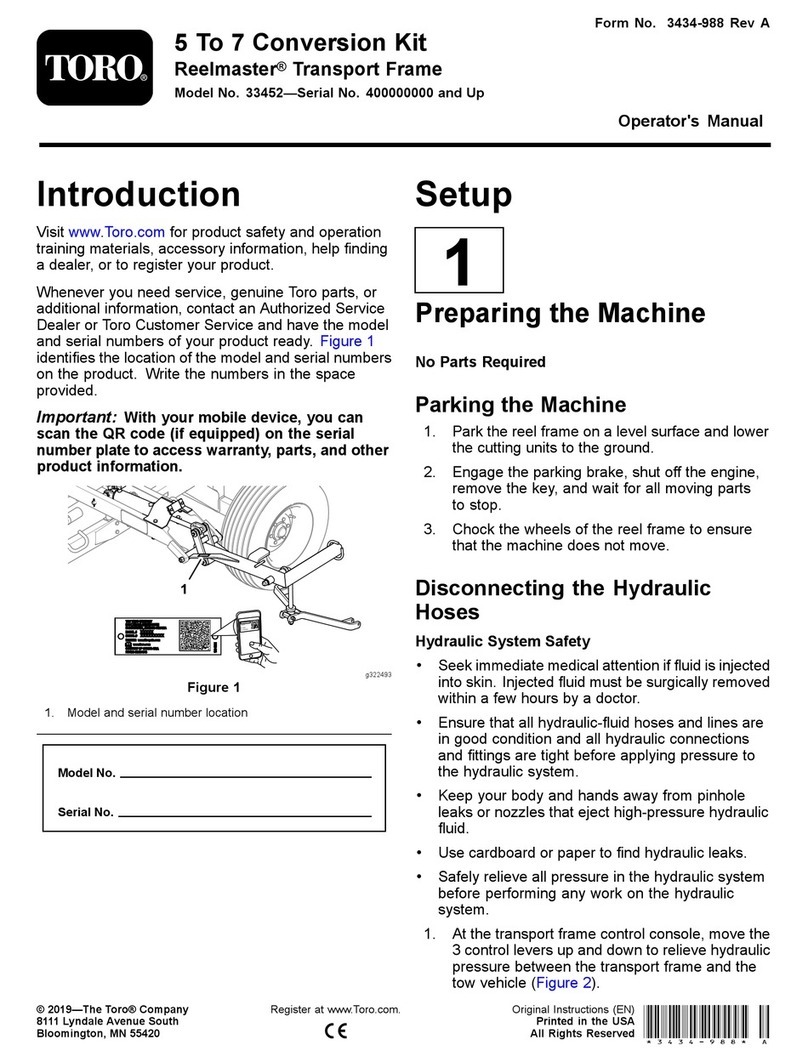

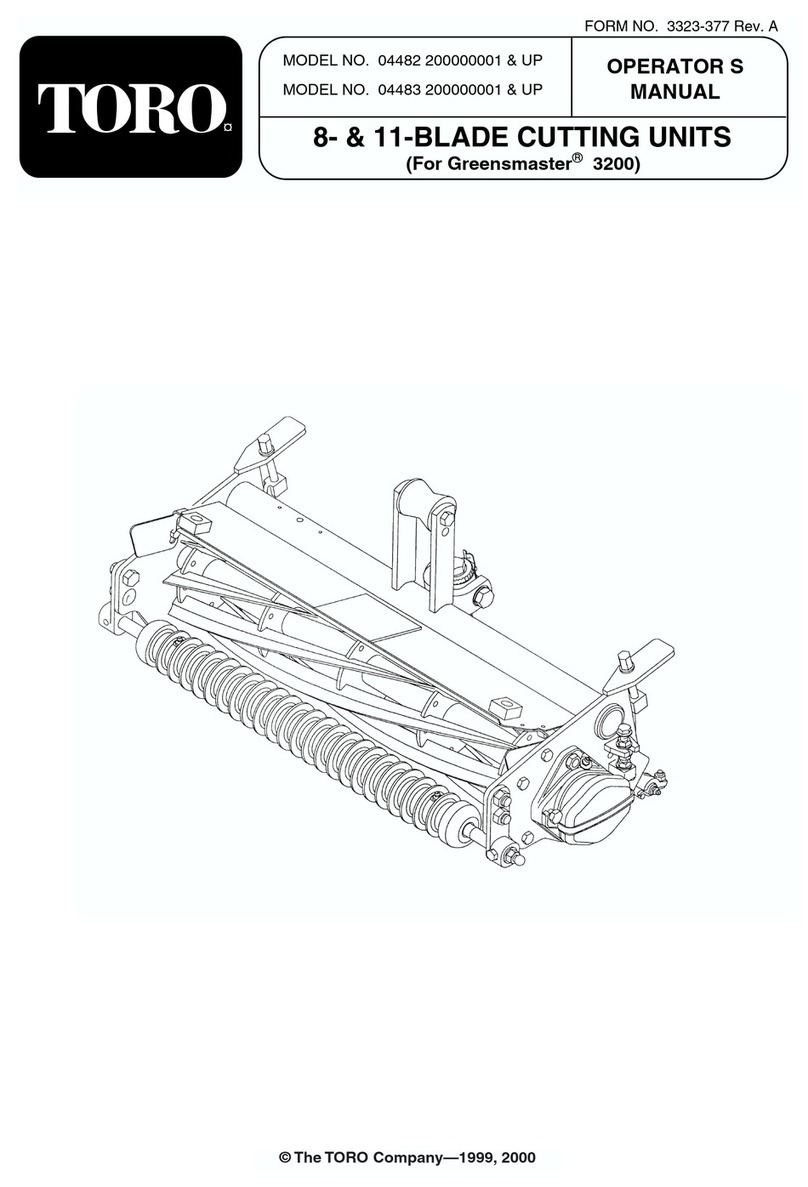

FIG. 1

1. Split Eyelet Connector 3. Foam Marker Hose

2. Hood Opening 4. Boom Extension

Feed Hose

5"

1

2

4

3

Drill

hole

2. Drill 5/8" hole in the plastic shroud 1" over from

the Boom Feed Hose on each Boom Extension.

3. Additional hose is required to install the Foam

Marker on the ENCLOSED BOO hich is

included ith the ENCLOSED BOO . Connect

the 78" length of 3/8" Hose supplied ith

ENCLOSED BOO to the Split Eyelet Connector

on the boom, secure ith Hose Clamp provided

ith FOA ARKER KIT. Route the Hose ith

the Right and Left Boom Feed Hose to the front of

the Center Boom, securing Foam Marker Hose to

Boom Feed Hose and Actuator Wire Harness ith

Plastic Ties, ensuring that Ties do not squash

Hoses.

4. Connect to Foam Marker Boom Feed Hoses

coming from Compressor using (2) 3/8" Hose

Connectors and (4) Hose Clamps supplied ith

the ENCLOSED BOO .

RINSEATE NOZZLE MOUNT:

NOTE: If the INJECTOR-PROTM SYSTE is

being installed, the Rinseate Nozzle must be

mounted on the Center Boom section Left

Castor ount as per the following instructions:

1. Assemble the Rinseate Nozzle Mounting Bracket

on to the Left Castor Mount of the Center Boom as

per FIG. 18. Assemble the Rinseate Nozzle, 1/2"

Female Pipe Coupling and 1/2" 900 Male Hose

Coupling included ith the Enclosed Boom

Mounting Kit. (refer to the Single Nozzle Assembly

in the INJECTOR-PROTM SYSTEM PARTS

MANUAL). Mount Nozzle Assembly onto Mounting

Bracket using (1) R-Clamp and 1/4" x 3/4" hex hd.

cap scre , flat asher, lock asher and nut.

1"

5. Connect the male three pin connector on the

main Wiring Harness to the Female plug on the

Brake Controller iring harness.

6. Connect the Red Wire Ring Terminal connector

to the same terminal as the red Po er Wire located

at the lo er rear of the Starter Solenoid.

NOTE: Ensure that the terminal you are

connecting to is the one directly connected to

the battery and has 12 volts (nominal) at all

times.

Connect the Black Wire Ring Terminal to the

5/16" x 3/4" Hex Hd. Cap Scre located at the lo er

right hand corner of the Left Hand Side Panel. (Also

refer to the MULTI-PRO® 1100 Parts Manual)

7. Secure the Wire Harness, ith plastic cable ties,

to the Vehicle Frame.

8. Replace Rear Panel on Steering Console and

reinstall (4) 1/4" x 5/8" asher hd. cap scre s.

ELECTRIC BRAKE WIRIN

CONNECTION:

1. Route the iring harnesses coming out of the

back of the Left and Right Brakes along the Boom

Mounting Bracket and the square tube on the front

of the Center Boom. Connect to the t o pin

Connector Plugs at the back of the right side of the

Vehicle.

NOTE: The Connector for the Right Brake has

the Orange & White wire. The Connector for

the Left Brake has an Orange wire.

Confirm that the plugs are connected correctly by

stepping on the brake pedal and observing the

Brake Operation Indicator Lights on the Brake

Controller. The lights ill only come on if po er is

flo ing to the brake.

I PORTANT: Readjust the Brake Switch

position if necessary so that the Electric

Brakes engage as soon as the Brake Pedal is

pressed. The Electric Brakes should engage

before the vehicle brakes.

FOAM MARKER OPTION:

NOTE: The installation of the optional Foam

arker on the ENCLOSED BOO requires

that one alternative step, and one additional

step be done when compared to the SET-UP

AND PARTS LIST included with the FOA

ARKER KIT for use on the ULTI-PRO® 1100

VEHICLE.

Follow the instructions included with the

FOA ARKER KIT except for the applicable

steps as follows:

1. The installation of the Foam Marker ith the

EXTENSION BOO on the ULTI-PRO® 1100

requires that the 9/32" hole, hich must be drilled

in the Right and Left Boom Pipes, be located on

the bottom side of the tube 5" over from the hood

opening as per FIG. 17.