Toro Sand Pro 5040 User manual

Other Toro Farm Equipment manuals

Toro

Toro 31526 User manual

Toro

Toro 138-2998 User manual

Toro

Toro MB-1600 User manual

Toro

Toro Greensmaster Flex 1820 User manual

Toro

Toro 22472 User manual

Toro

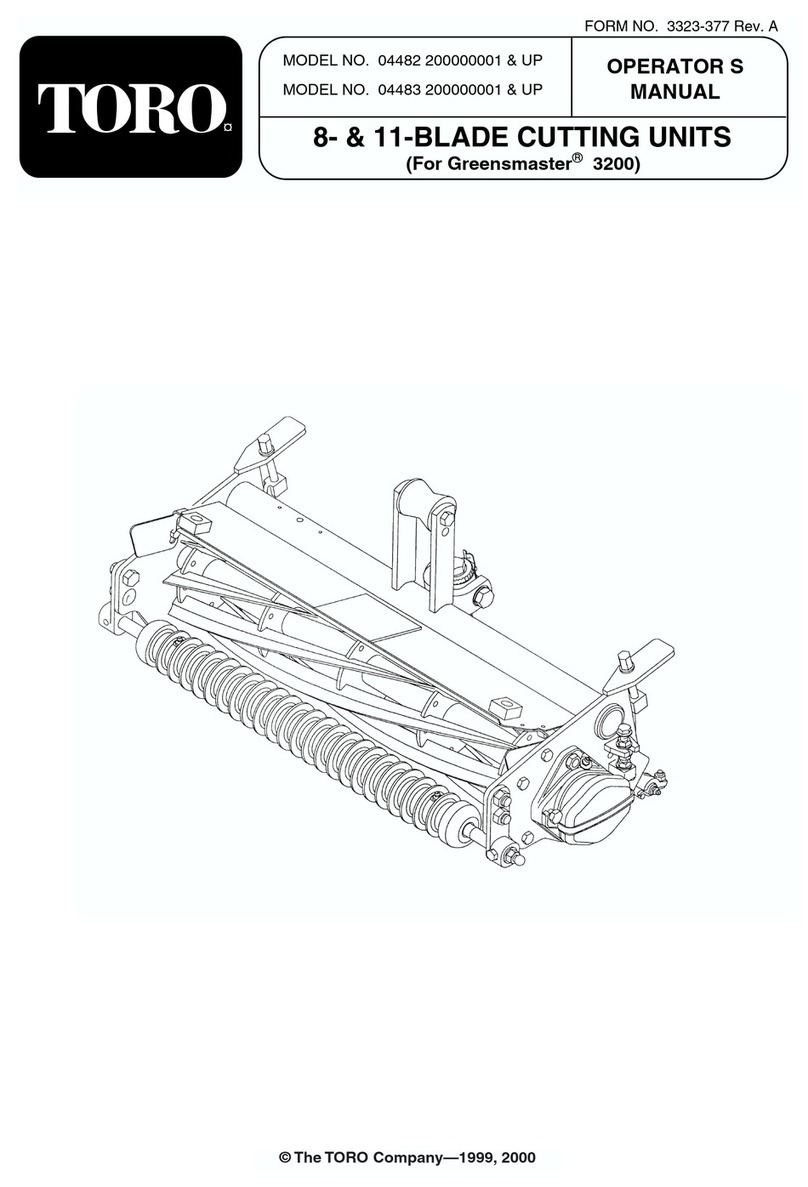

Toro Reelmaster 33455 User manual

Toro

Toro Reelmaster 33455 User manual

Toro

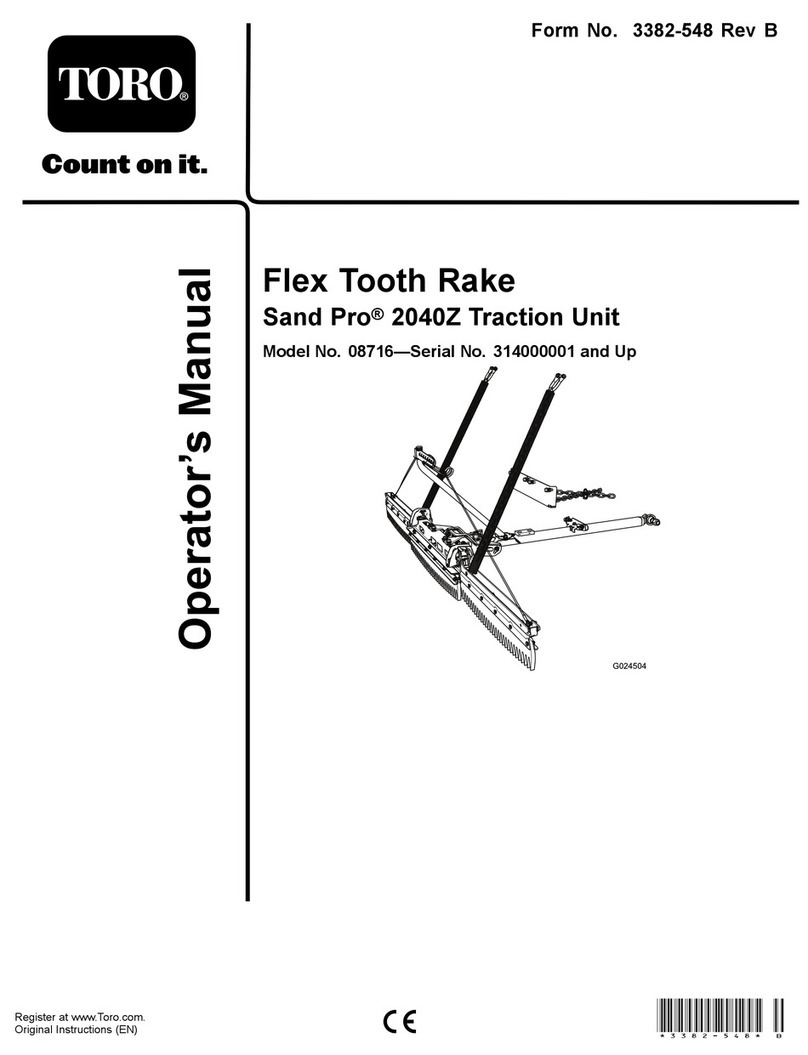

Toro Sand Pro 2040Z User manual

Toro

Toro Dingo TX 22306 User manual

Toro

Toro Workman 3000 Series User manual

Toro

Toro 22586 User manual

Toro

Toro Sitework 22447 User manual

Toro

Toro 23175 User manual

Toro

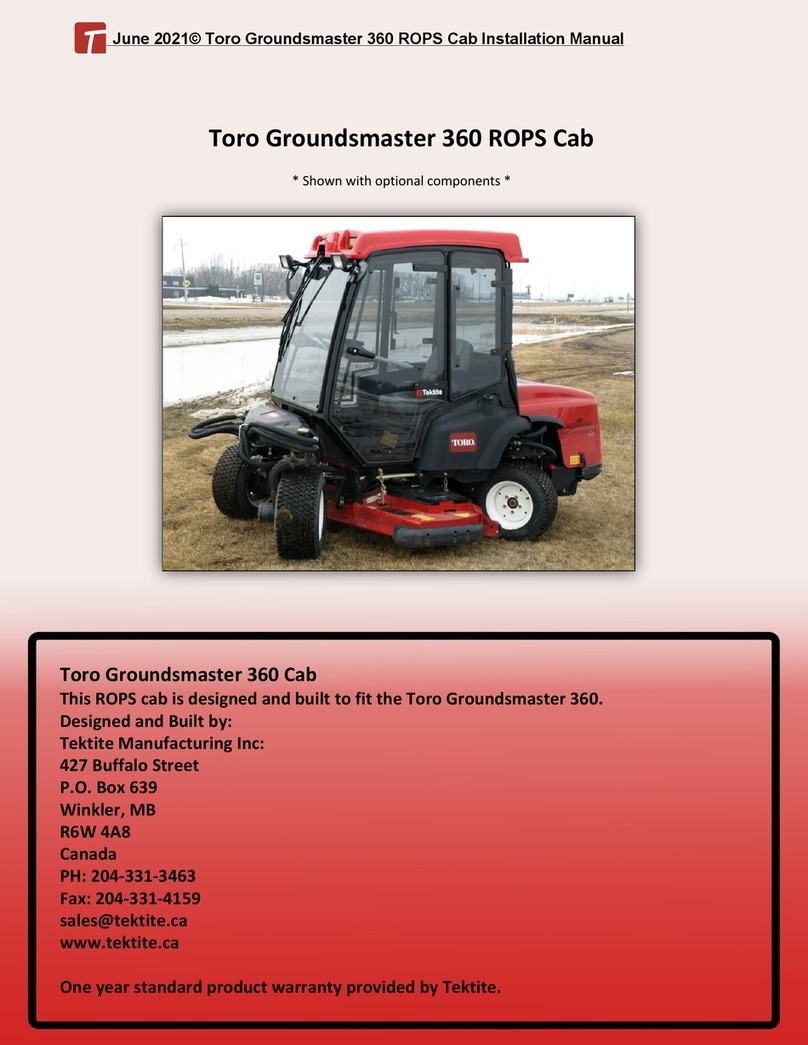

Toro Groundsmaster 360 ROPS Cab User manual

Toro

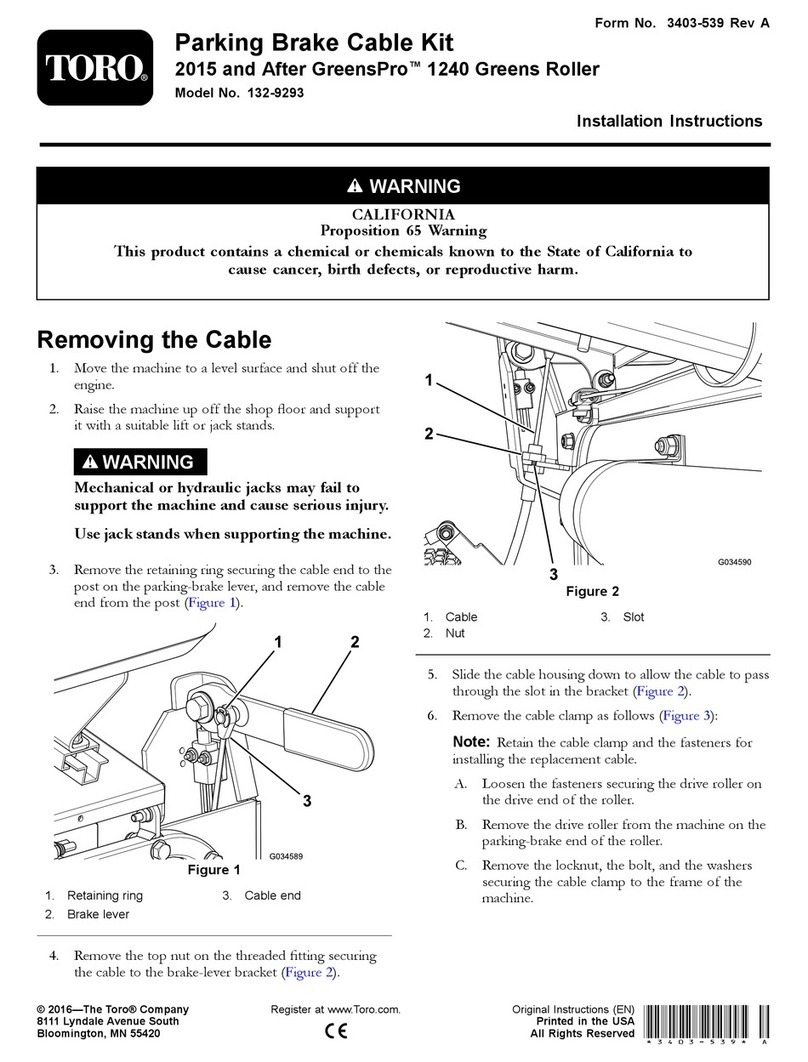

Toro 132-9293 User manual

Toro

Toro VS-400 User manual

Toro

Toro 25464 User manual

Toro

Toro Groundsmaster 4500-D User manual

Toro

Toro Reelmaster 5510 User manual

Toro

Toro Multi Pro 5800 User manual