Toro MH-400SH2 User manual

FormNo.3418-742RevB

MH-400SH2orMH-400EH2

MaterialHandler

ModelNo.44931—SerialNo.401252001andUp

ModelNo.44954—SerialNo.401252001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3418-742*B

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ElectromagneticCompatibility

Domestic:ThisdevicecomplieswithFCCrulesPart15.

Operationissubjecttothefollowingtwoconditions:(1)This

devicemaynotcauseharmfulinterferenceand(2)thisdevice

mustacceptanyinterferencethatmaybereceived,including

interferencethatmaycauseundesirableoperation.

Thisequipmentgeneratesandusesradiofrequencyenergyand

ifnotinstalledandusedproperly,thatis,instrictaccordance

withthemanufacturer'sinstructions,maycauseinterferenceto

radioandtelevisionreception.Ithasbeentypetestedandfound

tocomplywiththelimitsforaFCCClassBcomputingdevice

inaccordancewiththespecicationsinSubpartJofPart15of

FCCRules,whicharedesignedtoprovidereasonableprotection

againstsuchinterferenceinaresidentialinstallation.However,

thereisnoguaranteethatinterferencewillnotoccurina

particularinstallation.Ifthisequipmentdoescauseinterference

toradioortelevisionreception,whichcanbedeterminedby

turningtheequipmentoffandon,theuserisencouragedto

trytocorrecttheinterferencebyoneormoreofthefollowing

measures:Reorientthereceivingantenna,relocatetheremote

controlreceiverwithrespecttotheradio/TVantennaorplug

thecontrollerintoadifferentoutletsothatthecontrollerand

radio/TVareondifferentbranchcircuits.Ifnecessary,theuser

shouldconsultthedealeroranexperiencedradio/television

technicianforadditionalsuggestions.Theusermayndthe

followingbookletpreparedbytheFederalCommunications

Commissionhelpful:"HowtoIdentifyandResolveRadio-TV

InterferenceProblems".ThisbookletisavailablefromtheU.S.

GovernmentPrintingOfce,Washington,DC20402.StockNo.

004-000-00345-4.

FCCID:W7OMRF24J40MDME-BASE,

OA3MRF24J40MA-HANDHELD

IC:7693A-24J40MDME-BASE,7693A-24J40MA-HANDHELD

Operationissubjecttothefollowingtwoconditions:(1)this

devicemaynotcauseinterference,and(2)thisdevicemust

acceptanyinterference,includinginterferencethatmaycause

undesiredoperationofthedevice.

JapanElectromagneticCompatibilityCertication

Handheld:

RF2CAN:

MexicoElectromagneticCompatibilityCertication

Handheld:

RF2CAN:

KoreaElectromagneticCompatibilityCertication(Decal

providedinseparatekit)

Handheld:

RF2CAN:

SingaporeElectromagneticCompatibilityCertication

Handheld:TWM-240004_IDA_N4020–15

RF2CAN:TWM-240005_IDA_N4024–15

MoroccoElectromagneticCompatibilityCertication

AGREEPARL’ANRTMAROC

Numerod’agrement:MR14079ANRT2017

Delivred’agrement:29/05/2017

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.Itis

primarilydesignedfortransporting,metering,and

dispersingmaterials,underarangeofmoisture

conditions,withoutcloggingordrasticallyaffecting

thedispersion.Usingthisproductforpurposesother

thanitsintendedusecouldprovedangeroustoyou

andbystanders.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

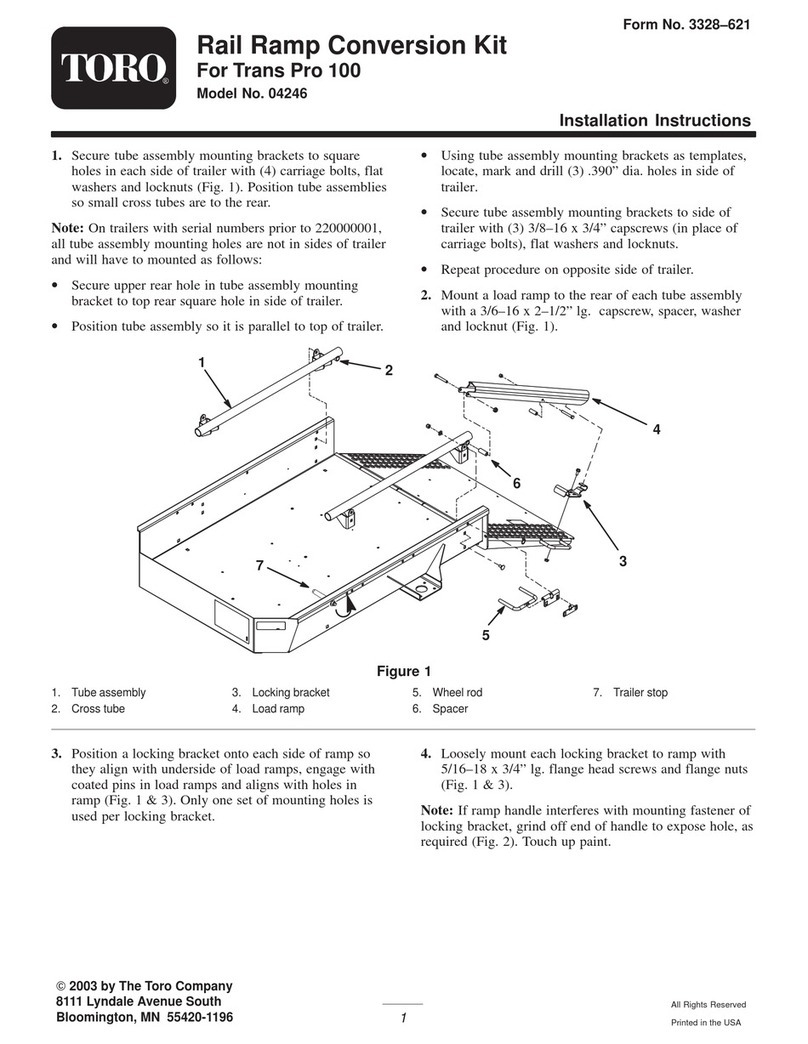

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

g234791

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

3

Contents

Safety.......................................................................5

GeneralSafety...................................................5

SafetyandInstructionalDecals..........................5

Setup........................................................................9

1InstallingtheHitch.........................................10

2InstallingtheWeightCase..............................10

3AdjustingtheMirror.........................................11

4WiringandInstallingtotheTow

Vehicle..........................................................12

5InstallingtheEHWirelessControlMounting

BracketontheTowVehicle............................13

6InstallingthePendantSwitch.........................14

7AssemblingtheHandheldRemote.................15

8AttachingtheHydraulicstotheTow

Vehicle..........................................................15

9Attachingthe7-pinCoiledPower

Cable............................................................16

10SettingtheElectricBrake

Adjustments..................................................16

ProductOverview...................................................17

Controls...........................................................17

Specications..................................................18

Attachments/Accessories.................................18

BeforeOperation.................................................19

BeforeOperationSafety...................................19

ConnectingtheMachinetotheTow

Vehicle..........................................................19

DuringOperation.................................................21

DuringOperationSafety...................................21

SlopeSafety.....................................................22

TurningtheMachinePowerOn/Off...................23

OperatingtheHydraulicControlValves.............23

OperatingtheHydraulicControlsand

OptionsonEHModels..................................24

OperatingtheFloorandOption.........................32

SettingthePreset1,2,and3Buttons................34

LoadingMaterial...............................................35

UnloadingMaterial............................................35

UsingtheTwinSpinner.....................................36

SettingUptheCrossConveyor/Swivel..............41

OperatingtheCrossConveyor..........................43

OperatingtheSwivelKit....................................44

AfterOperation....................................................45

AfterOperationSafety......................................45

DisconnectingtheMachinefromtheTow

Vehicle..........................................................45

Maintenance...........................................................46

MaintenanceSafety..........................................46

Pre-MaintenanceProcedures...........................46

Lubrication........................................................46

SafetyChecks..................................................47

HydraulicSystemSafety...................................48

HydraulicSystemMaintenance........................48

ChangingTires.................................................48

TrackingtheConveyorBelt...............................49

TensioningtheConveyorBelt...........................49

ChangingtheConveyorBelt.............................50

AdjustingtheConveyorDriveChain..................52

MaintainingtheElectricBrakes.........................52

Storage...................................................................54

Troubleshooting......................................................55

CheckingFaultCodes(EHModels

Only).............................................................55

HandheldRemoteMessages(EHModels

Only).............................................................57

4

Safety

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeusingthismachine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineawayfrombystanderswhileit

ismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Parkthemachineonalevelsurface;engagethe

parkingbrake;shutoffthetraction-unitengine;

removethekey;andwaitforallmovementtostop

beforeservicingoruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal119-6823

119-6823

SHmodelsonly

1.Reverseconveyorbelt4.Raisehopper

2.Advanceconveyorbelt5.Optionon

3.Lowerhopper

93-9899

decal93-9899

93-9899

1.Crushinghazard—installthecylinderlock.

decal119-6838

119-6838

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

decal119-0217

119-0217

1.Warning—shutofftheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal115-2047

115-2047

1.Warning—donottouchthehotsurface.

5

decal119-6819

119-6819

1.Spinnerspeedpercentage2.Beltspeedpercentage

decal93-9852

93-9852

1.Warning—readtheOperator’sManual.2.Crushinghazard—installthecylinderlock.

decal119-6836

119-6836

1.ReadtheOperator'sManual.

2.Locateweightsothatrearoftheweightcaseis28in(71

cm)fromthefrontfaceofhitchtube.

decal119-6833

119-6833

1.ReadtheOperator'sManual.

2.Maximumloadweight11,800lb(5.352kg);vehicleweight

3,000lb(1,361kg),Maximumgrossvehicleweight14,800

lb(6,713kg)

decal131-6766

131-6766

Model44954Only

1.7.5A3.Electricalaccessory—15A

2.7.5A4.TEC-2403—2A

6

decal119-6806

119-6806

1.Warning—readtheOperator'sManual.4.Warning—shutofftheengine,removethekey,andreadthe

Operator'sManualbeforeperformingmaintenance.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

5.Warning—donotcarrypassengers.

3.Thrownobjecthazard—keepbystandersaway.6.Warning—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

decal119-6835

119-6835

1.ReadtheOperator'sManual.

2.Donotstorethejackonrearleg.

decal119-6869

119-6869

1.Tailgateheightadjustment

decal119-6822

119-6822

Model44931Only

1.Belt

2.On

3.Off

decal119-6832

119-6832

Model44954Only

1.Adjustoorspeed

2.Lowerthehopper

3.Raisethehopper

4.Adjustspinnerspeed

7

decal119-6812

119-6812

1.Tippinghazard—donotturnfast;turnslowly;whenthe

hopperisempty,donotgofasterthan15mph(24kph);

whenthehopperisloaded,moveslowly;whenmovingover

roughterrain,moveslowly.

decal119-6863

119-6863

1.Towafullhopperinthe

loweredposition;donot

towaloweredhopperwith

thespinnerattachedinthe

loweredposition.

3.Towanemptyhopperin

theraisedposition;tow

anemptyhopperwitha

spinnerattachedinthe

raisedposition;donottow

afullhopperintheraised

position;donottowafull

hopperwiththespinner

attachedintheraised

position.

2.Towthefullhopperin

themiddlepositionwith

thespinnerattachedand

active.

8

Setup

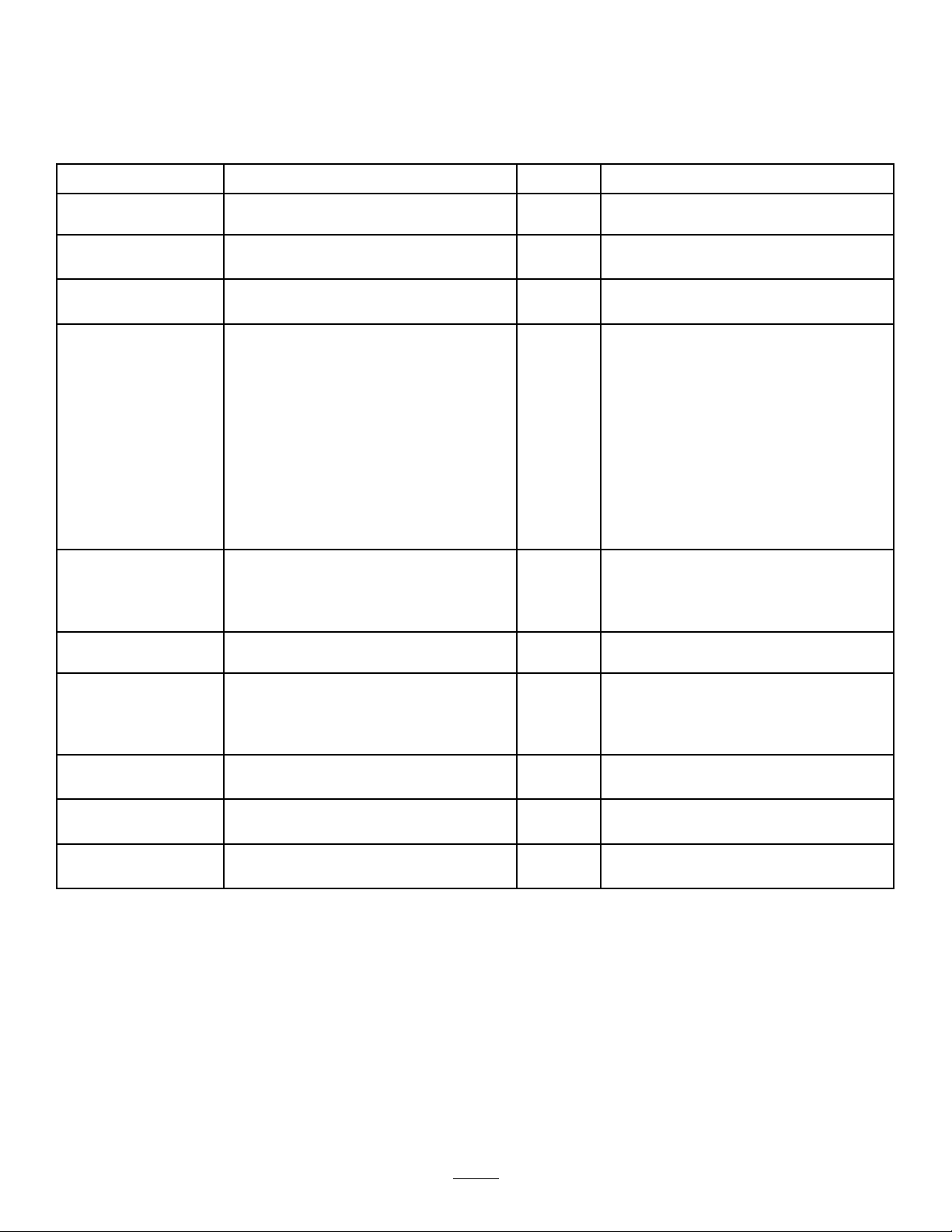

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

Bolt(1x6-1/2inches)2

1Locknut(1inch)2Installthehitch.

2Nopartsrequired–Installtheweightcase.

3Nopartsrequired–Adjustthemirror.

Footcontroller1

Brakecontroller1

Harnessassembly1

Socketbracket1

Screw(5/16x1inch)4

Nut(5/16inch)4

Wiresplices6

Cabletie10

Bolt(#10x7/8inch)2

Nut(#10)2

4

Hoseclamp1

Installthewiringtothetowvehicle.

Mountingbracketassembly1

Backingplate1

Flangeheadbolt(5/16x1-1/2inches)4

5Flangeheadlocknut(5/16inch)4

InstalltheEHwirelesscontrolmounting

bracketonthetowvehicle(Model44954

only).

Pendantswitch1

6SHwireharness1Installthependantswitch.

Handheldremote1

AAbatteries4

Magneticbracket1

7Screws,small6

Assemblethehandheldremote.

8Nopartsrequired–Attachthehydraulicstothetowvehicle.

97-pincoiledpowercable1Attachthe7-pincoiledpowercable.

10Nopartsrequired–Settheelectricbrakeadjustments.

9

MediaandAdditionalParts

DescriptionQty.Use

Operator'sManual1Readthemanualbeforeoperatingthemachine.

DeclarationofConformity1TheDeclarationofConformityservesasEUproofof

certication.

Attachmentclamps2Usetomountattachments.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1

InstallingtheHitch

Partsneededforthisprocedure:

2Bolt(1x6-1/2inches)

2Locknut(1inch)

Procedure

1.Locateandremovetheloosepartsboxshipped

onthefender.

2.Removetherearsupportlegfromtheshipping

positionandplaceitinthedownposition.

3.Removethehitchfromtheshippingposition

bycuttingbothstrapssecuringthehitchto

thefender(Figure3).Removebothmounting

bracketsfromthefenderanddiscard.

g014065

Figure3

1.Removehitchfromshippingposition

Note:2peoplearerequiredtoremovethehitch

assembly.

4.Slidethehitchtubetongueintoplaceatthefront

ofthemachine.Ensurethatthejackmounting

bracketfacesouttowardstheleftside.

5.Placeabolt(1x6-1/2inchrd)throughtheframe

andhitchtubeandsecureitwithalocknut

(Figure4).Torquethelocknutto976to1,193

N-m(720to880ft-lb).

6.Placeabolt(1x6-1/2inches)throughthetopof

theframeanddownthroughthehitchtubeand

secureitwithalocknut(Figure4).Torquethe

locknutto976to1,193N-m(720to880ft-lb).

g014066

Figure4

1.Hitchtube2.Mountingboltandnut

7.Removethejackassemblyfromtherearleg.

Installthejackassemblyontothehitchtube,

placingthepinhorizontally.

Note:Donotplacethepinthroughthetophole

ofthejack,oryouwillnotbeabletoremovethe

pinwhentheweightcaseissecuredtothehitch.

10

2

InstallingtheWeightCase

NoPartsRequired

Procedure

1.Removetheweightsfromtheweightcase.

2.Removethebolts(1/2x5-1/2inch)fromthe

mountingbracketholdingtheweightcase.

Discardthemountingbrackets(Figure5).

g014067

Figure5

1.Weightcase2.Weightcasemounting

bracket

3.Positiontheweightcaseonthehitch,asfar

forwardaspossible.

4.Mounttheweightcasetothehitchwith2bolts

(1/2x5-1/2inch)andlocknuts.T orquethe

locknutsto91to112N-m(67to83ft-lb).

5.Filltheweightcasewiththeweightsandinstall

thebarandpin(Figure6).

g014069

Figure6

1.Fillweightcase

3

AdjustingtheMirror

NoPartsRequired

Procedure

Themirrormountedonthefrontofthehopperallows

youtomonitortheloadandthespreadingaction.

Checkthemirrorfrequentlytomonitortheoperation

ofthemachine.

Adjustthemirror(Figure7)sothatyoucanviewthe

insideofthehopperfromtheoperatorposition.

11

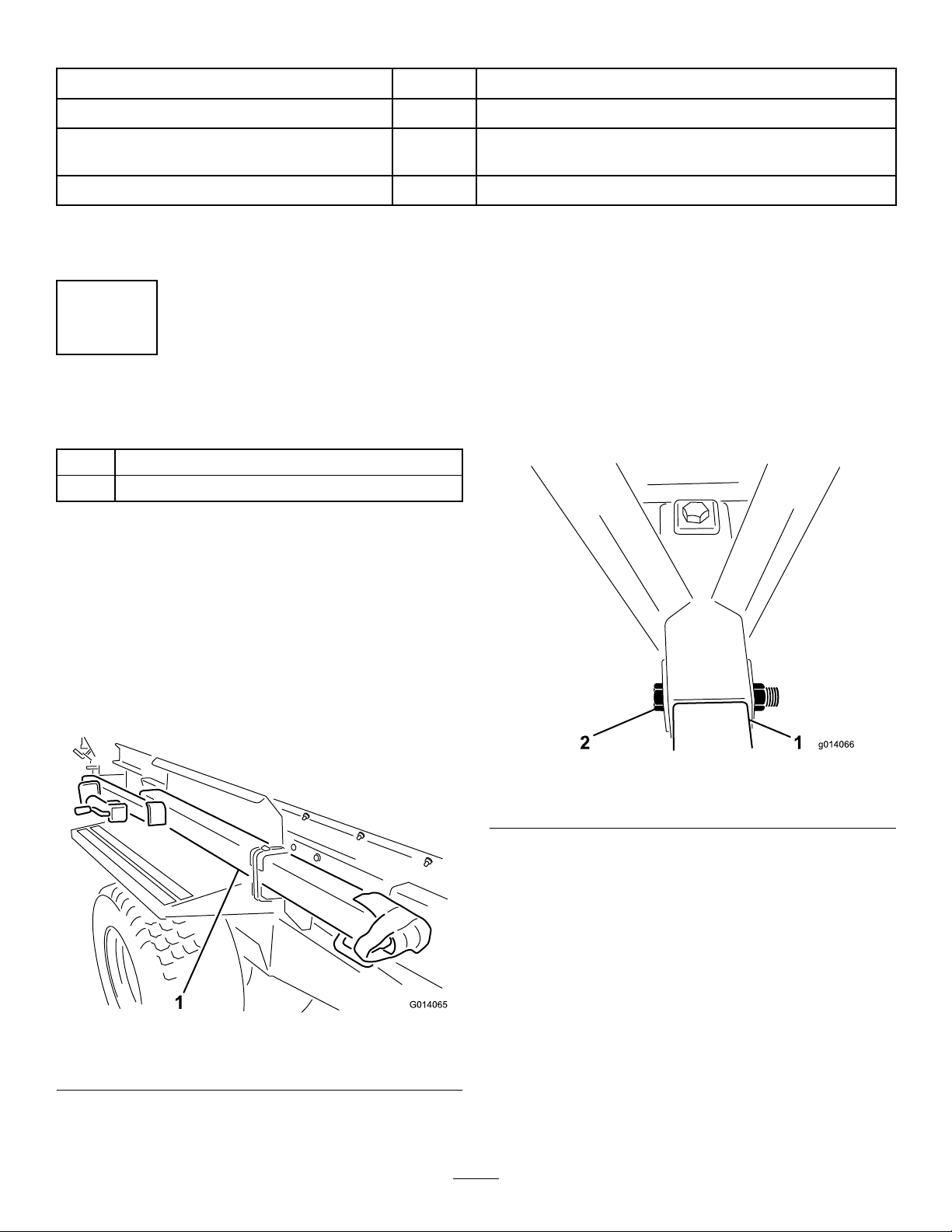

g015149

Figure7

1.Mirror

4

WiringandInstallingtothe

TowVehicle

Partsneededforthisprocedure:

1Footcontroller

1Brakecontroller

1Harnessassembly

1Socketbracket

4Screw(5/16x1inch)

4Nut(5/16inch)

6Wiresplices

10Cabletie

2Bolt(#10x7/8inch)

2Nut(#10)

1Hoseclamp

OutcrossTractionUnit

Mountthebrakecontroller(Figure8)tothelowerleft

areaofthedashboardwiththe2bolts(#10x7/8inch)

andnuts(#10).

ConnecttheOutcrosswireharnessconnectortothe

brakecontrollerconnector.

RefertotheOutcrosstractionunitOperator’sManual

foradditionalmountingandoperatinginstructions.

g235379

Figure8

1.Brakecontroller

Tractor

Note:Layouttheharnessonthetractortodetermine

themountinglocationsoftheharnesscomponents.

Cabletiesaresuppliedtoretainanysurpluscable

lengths.Also,wiresplicesareprovidedifthelength

oftheharnesshastobealtered(shortenedor

lengthened).Heattheshrinkconnectorsuntilthey

shrinktightontothewires.

Important:Iflengthisaddedtotheharness,

makesuretousethepropergaugewire.

1.Mountthesocketbrackettotherearofthetow

vehiclewith2bolts(5/16x1inch)andnuts.

2.Routethewireharnessconnectorthroughthe

holetothesocket.Slidethebootdownthe

harnessiftheconnectordoesnotgothrough

thehole.

3.Boltthewireharness,withthesocketconnector,

totherearofthesocketbracketwith2bolts

(5/16x1inch)andnuts.

4.Routetheharnessalongthetowvehicle.

5.Mountthebrakecontrollertothetractordashor

thefenderwiththe2bolts(#10x7/8inch)and

nuts(#10).

6.Usingthehoseclamp,securethefootcontroller

tothepadonthetowvehiclebrakepedal.

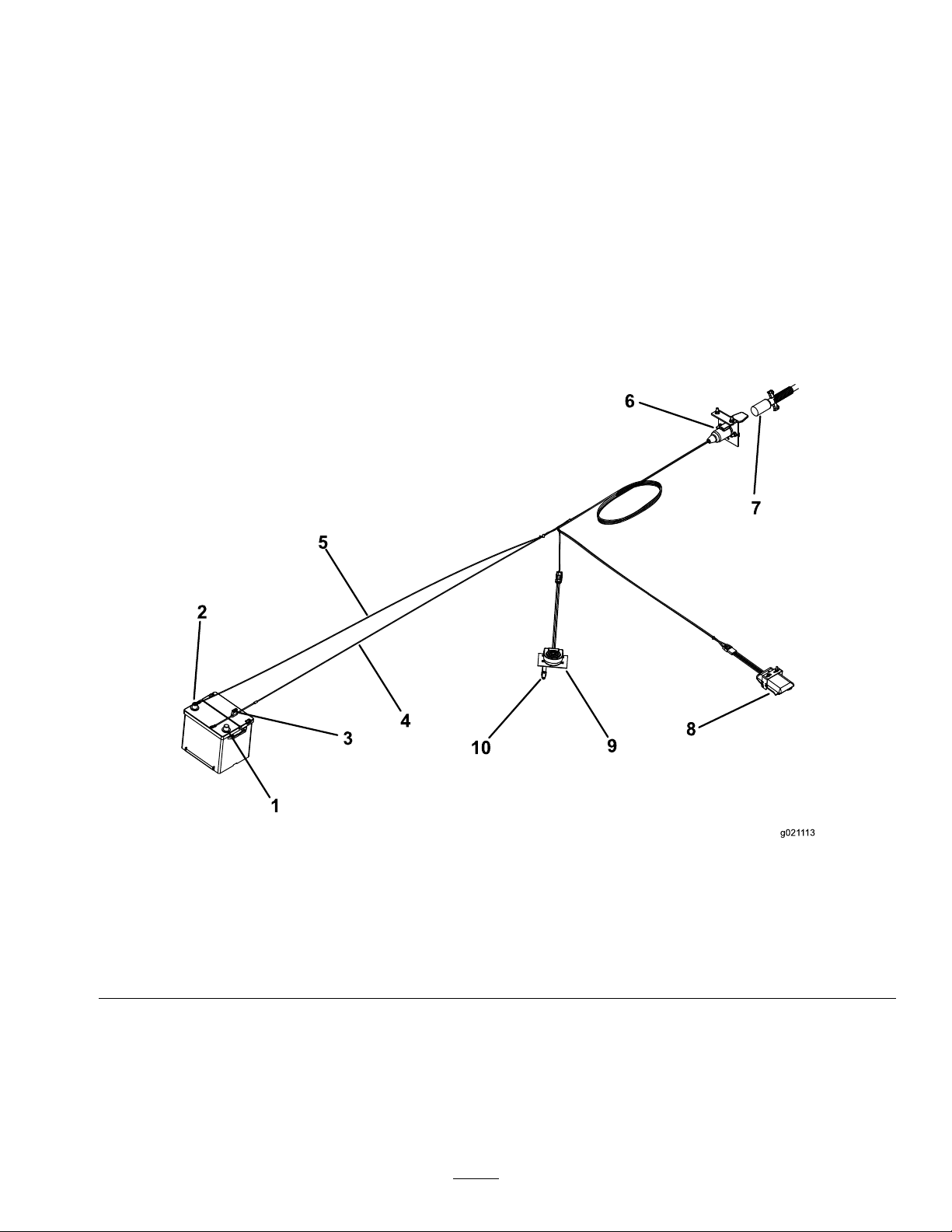

7.Connecttheharnesstothecomponents(Figure

9)asfollows:

12

A.Plugtheshorterwirefromtheharnessinto

thefootcontrollerwireconnector.

B.Connectthelongerwirefromtheharnessto

thebrakecontrollerwireconnector.

C.Select1ofthefollowingprocedureswhen

connectingtheringterminalwire,withthe

fuse,tothepositivebatteryterminal.

•Tohavethebrakecontrollerpowered

onlywhenthetowvehicleison,attach

theringterminalwire,withthefuse,to

anopenauxiliarypowersourcethathas

aratingof15Aormore.Usea10Afuse

fora2wheelbrakesystemanda15A

fusefora4wheelbrakesystem.

Note:Theringterminalmayneedto

beremovedandadifferentterminalend

mayneedtobeattachedtomatchthe

auxiliarypowersourceconnection.

•Tohavethebrakecontrolleralways

powered,attachtheringterminalwire,

withthefuse,tothepositivebattery

terminal.

Note:Ifthetowvehicleistobestored

foranextendedperiod,removethefuse

fromthebrakecontrollerwireharness

ordisconnectthewireharnessfromthe

brakecontroller.Thiswillpreventthe

batteryfrombeingdrained

D.Connecttheotherringterminalwire,

withoutthefuse,tothenegative(-)battery

terminal.

g021113

Figure9

1.Positivebatteryterminal(+)6.Socketconnector

2.Negativebatteryterminal(-)7.Powercable

3.Fuse8.Brakecontroller

4.Wireharness(+)9.Footcontroller

5.Wireharness(–)10.Hoseclamp

8.Securetherubberboottotheconnectorandto

thewireharnesswithacabletie.

9.Securealllooseharnesswireswithcableties.

10.A10Afuseisincludedintheharness.Ifusing

a4wheelbrakekit,replacethe10Afusewith

theprovided15Afuse.

13

5

InstallingtheEHWireless

ControlMountingBracket

ontheTowVehicle

Model44954Only

Partsneededforthisprocedure:

1Mountingbracketassembly

1Backingplate

4Flangeheadbolt(5/16x1-1/2inches)

4Flangeheadlocknut(5/16inch)

Procedure

1.Fortowvehiclemounting,determinean

appropriatelocationforthehandheldremote

mountingbracket.Thesurfaceshouldbeat

andsolid.

2.Usingthebackingplateasatemplate,locate,

mark,anddrill4holes(11/32inchdiameter)in

thetowvehiclemountingsurface.

3.Attachthemountingbracketandbackingplate

with4angeheadbolts(5/16x1-1/2inch)and

angelocknuts(Figure10andFigure11).

g028873

Figure10

1.Handheldremote3.Mountingbolts

2.EHhandheldremote

mount

g014103

Figure11

1.EHhandheldremotebackingplate

Note:Also,thewirelessremotemagnetwillstickto

anymetalcomponent.

6

InstallingthePendant

Switch

Model44931Only

Partsneededforthisprocedure:

1Pendantswitch

1SHwireharness

Procedure

Plugtheon/offpendantswitch(4prongend)intothe

socketatthefrontleftcornerofthemachine(Figure

12).

14

g014074

Figure12

1.On/offpendantswitch

Important:Alwaysremovetheon/offpendant

switchcordordisconnectthepowersupplywire

whenthemachineandtowvehiclearenotinuse.

Otherwise,thetowvehiclebatterywilllosepower.

7

AssemblingtheHandheld

Remote

Model44954Only

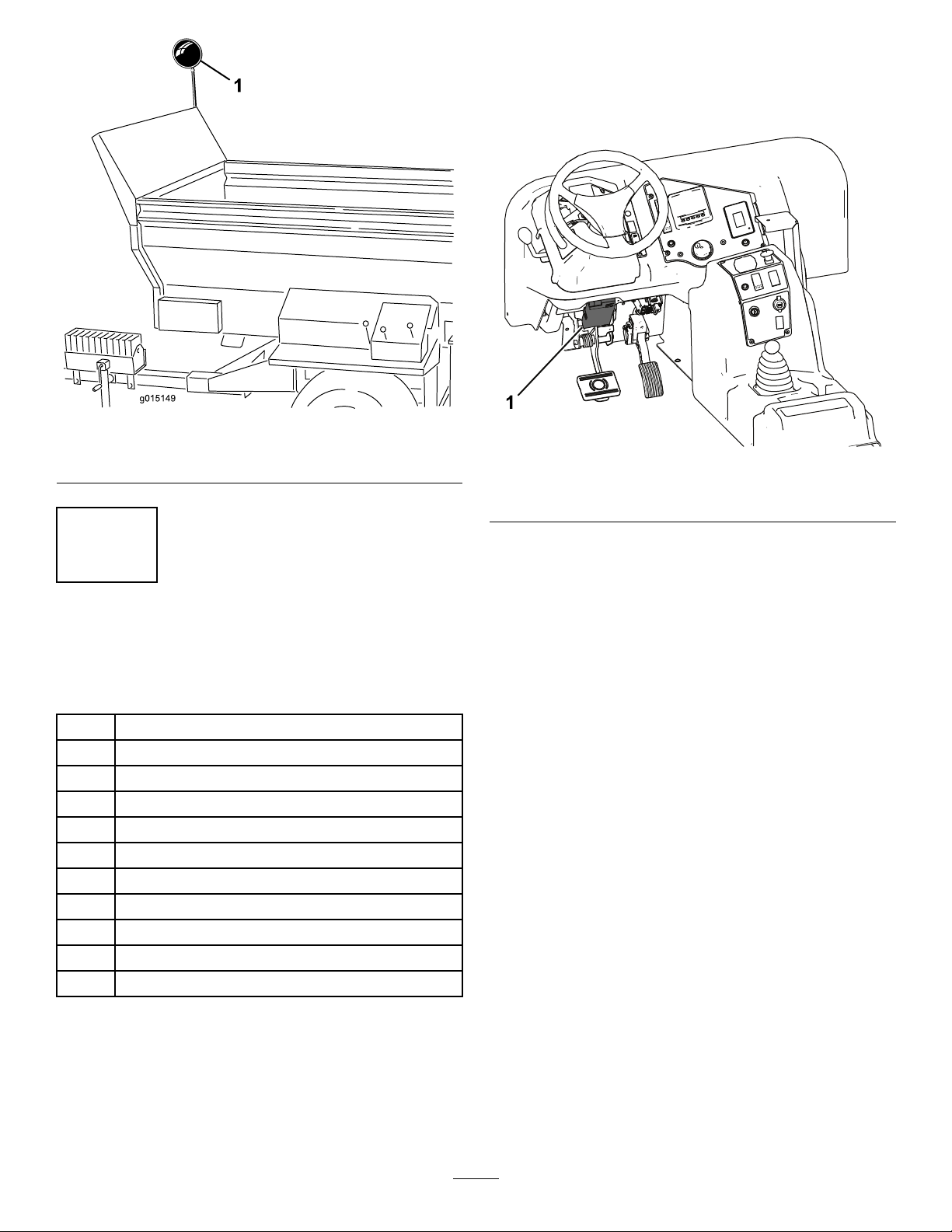

Partsneededforthisprocedure:

1Handheldremote

4AAbatteries

1Magneticbracket

6Screws,small

Procedure

1.Removetherubberbandssecuringtheremote

halvestogether,andremovethebackcover.

2.Plugeachbatteryintoaterminalcradle

observingproperpolarity.(Ifthebatteries

areimproperlyinstalled,theunitwillnotbe

damaged,butitwillfailtooperate.)Thecradle

isembossedwithpolaritymarkingsforeach

terminal(Figure13).

g028875

Figure13

1.Rubberseal3.Handheldremote

2.Steelgasket4.4AAbatteries

3.Ensurethatthesteelgasketandrubbersealare

seatedinthechannelintheremoteandsetthe

backcoverinplace(Figure13).

4.Securethecoverwith6screws(Figure13)and

torquethemto1.5to1.7N-m(13to15in-lb).

5.Installthehandheldremoteintothemagnetic

remotebracket,slidethehalvestogetherto

securetheremote,andtightentheboltinthe

magnet(Figure14).

g028874

Figure14

1.Handheldremote3.Boltinthemagnet

2.Magneticremotebracket

15

8

AttachingtheHydraulicsto

theTowVehicle

NoPartsRequired

Procedure

Note:Thetowvehiclemustbeequippedwithan

opencenterauxiliaryhydraulicvalve.

Forbestresults,useatowvehiclewithaxed

displacementhydraulicpumpwithapoweroutput

of138bar@38L/min(2,000psi@10gal/min).

Performancewillbereducedifthepumpoutputisless.

Connectthe2hydraulichosesfromthemachinetothe

towvehicle.Facingthefrontofthemachine,connect

therighthosetothepressuresideandthelefthoseto

thereturnside(Figure15).Thereturnhosehasanin

line1waycheckvalve.Also,thereisanarrowonthe

checkvalvewhichshouldfacetowardthetowvehicle.

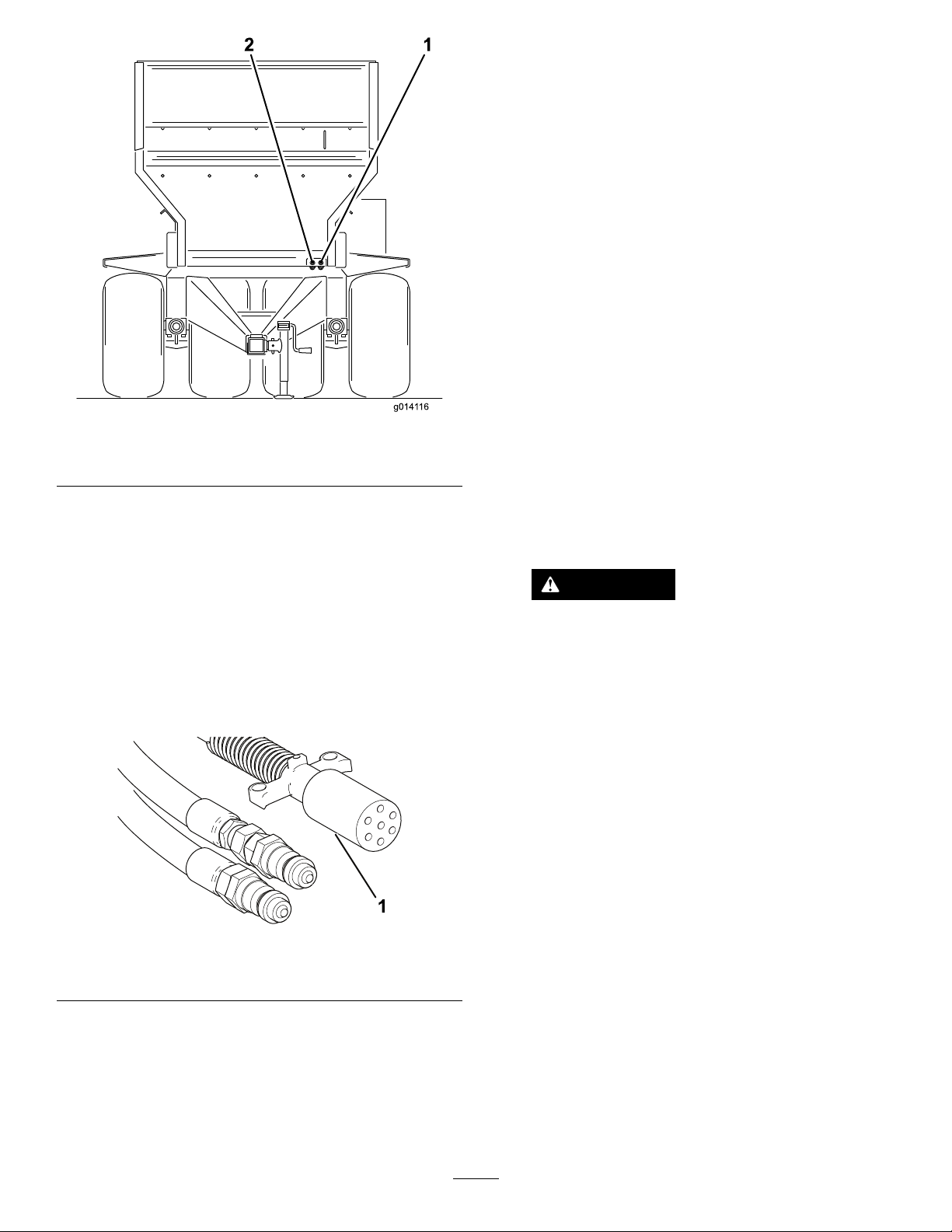

g014116

Figure15

1.Pressurein2.Returnout

Important:Donotallowthehydraulichoses

andthepowercabletodragonthegroundwhen

operatingthemachine.Avoidlocationswhere

theycouldbecomepinchedorcut.

9

Attachingthe7-pinCoiled

PowerCable

Partsneededforthisprocedure:

17-pincoiledpowercable

Procedure

Attachthe7-pincoiledpowercabletotheMH-400

materialhandler.

Attachthe7-pincoiledpowercabletothetowvehicle.

10

SettingtheElectricBrake

Adjustments

NoPartsRequired

Procedure

Beforeoperatingthemachineforthersttime,the

electricbrakesmustbesynchronizedtothetow

vehicle’sbrakes(sothattheyoperateatthesame

time).

Themachineandthetowvehiclewillseldomhavethe

correctamperageowtothebrakemagnetstoprovide

comfortable,safebraking.Changingtheloadweight,

aswellasunevenalternatorandbatteryoutput,can

resultinunstablecurrentowtothebrakemagnets.

TheBrakeControlcompensatesfortrailerload

variationsbylimitingthemaximumtorqueoutput

ofthebrakesbyaddingdroppingresistanceinthe

electricalcontrolline.Whentowingatrailerloadedto

brakeratedcapacity,theBrakeControlmustbesetat

maximumbraking.Whenpullinganemptyorpartially

loadedtrailer,theBrakeControlmustbesetbetween

maximumandminimumbrakingatapositionjust

beforethepointatwhichtrailertireskiddingoccurs

whenactuatingthehandcontrolfullyon.Failureto

installandusetheElectricBrakeControlwillresultin

excessivebraketorquewhenstoppingatrailerloaded

tolessthanbrakecapacity.

16

ProductOverview

Controls

HydraulicControlValves(SH

Model44931)

g014117

Figure16

1.Conveyorbeltdirection(leftcontrolvalve)

2.Raiseandlowermachine(centercontrolvalve)

3.Optionsonandoff(rightcontrolvalve)

4.Optionhydraulicquickconnectors

LeftValve

Theleftvalvecontrolsthemachineconveyorbelt

direction(Figure16).

CenterValve

Thecentervalveraisesandlowersthemachine

(Figure16).

RightValve

Therightvalvecontrolstheoption(Figure16).

OptionHydraulicQuickConnectors

Connecttheoptionhydraulichere(Figure16).

E-Stopbutton(EHModel44954)

Whennishedworkingwiththemachine,always

presstheE-STOPbutton(Figure17)todisablethe

electricalsystem.Whenbeginningworkwiththe

machineyoumustpulltheE-STOPbuttonbackout

beforeturningonthehandheldremote.

g234789

Figure17

1.E-STOPButton

DiagnosticLEDFunction(EH

Model44954)

AfteryoupulluptheE-STOPbutton,thediagnostic

LED(Figure18)willilluminateandremainonfor5

seconds,turnofffor5seconds,andthenwillbegin

ashingat3Hz(3ashesasecond)untilyouturnthe

handheldremoteon.Ifthelightturnsonfor5seconds

andthenstartsblinkingat10Hz(withorwithouta5

secondpause),thereisafaultwiththemachine;refer

toCheckingFaultCodes(EHModelsOnly)(page55).

Note:Ifyouhadthehandheldremoteonwhenyou

pulleduptheE-STOPbutton,thelightwillnotash

at3Hz(3ashespersecond)afterturningofffor5

seconds.

g234788

Figure18

1.DiagnosticLED

17

HandheldRemote(EHModel

44954)

g028671

Figure19

1.LCDdisplay11.Floorstop

2.RemotestatusLED12.Decreaseoorspeed

3.Allstart:startsoorand

option

13.Increaseoorspeed

4.On/Off14.Floorreverse

5.Store:savespreset

settings

15.Tiltbeddown

6.Preset116.Tiltbedup

7.Preset217.Optionstart

8.Preset318.Optionstop

9.Allstop:stopsallfunctions19.Increaseoptionspeed

10.Floorstart20.Decreaseoptionspeed

Specications

Weight1,721kg(3,794lb)

Radio

Frequency2.4GHz

MaxOutputPower19.59dBm

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformance,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

18

Operation

BeforeOperation

BeforeOperationSafety

•Themachinehasdifferentbalance,weight,and

handlingcharacteristicscomparedtosomeother

typesoftowedequipment.Readandunderstand

thecontentsofthisOperator'sManualbefore

operatingthemachine.Becomefamiliarwithall

controlsandknowhowtostopquickly.

•Neverallowchildrentooperatethemachine.Do

notallowadultstooperatethemachinewithout

properinstructions.Onlytrainedandauthorized

personsshouldoperatethismachine.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisillegibleormissing,

repairorreplaceitbeforeoperatingthemachine.

•Themachineisdesignedonlyforoff-roaduse.

Themaximumrecommendedspeedis24km/h

(15mph)withoutaloadand13km/h(8mph)with

afullload.

•Tightenanyloosenuts,bolts,andscrewsto

ensurethatthemachineisinsafeoperating

condition.Ensurethatthemachinetongue

mountingpins,hitchpins,andtonguejackarein

placeandsecure.

•Donotmodifythisequipmentinanymanner.

•Thetongueistheareaonthemachinewherethe

hitchconnectstothetowvehicle.Theweightof

thetongueaffectsthestabilityofthemachine.

–Anegativeorpositivetongueweightcancause

injurywhenconnectingordisconnectingthe

machinetothetowvehicle.Wheninstalled,

ensurethatthejack-standsareproperly

engaged.

–Whentheweightofthetongueisforcedupinto

thehitchofthetowvehicle,thisproducesa

negativetongueweight.

Negativetongueweightmayalsoresultwhen

attachmentsaremountedontherearofthe

machine.

–Whentheweightofthetongueisforceddown

ontothehitchofthetowvehicle,thisproduces

apositivetongueweight.

•Neverattachthemachinetoorremovethe

machinefromthetractionunitifthereismaterialin

thehopper.Thetonguemayipup,causinginjury.

ConnectingtheMachineto

theTowVehicle

1.Connectthemachinehitchtothetowvehicle

usinga25mm(1inch)diametersafetyapproved

hitchpinandsafetyclip(notsupplied).

2.Adjustthehitchheightbyturningthejackstand

handletokeepthemachinelevel.

3.Lowerthehitchusingthejackstand.

4.Whenthefullweightofthemachinehasbeen

transferredtothetowvehicle’sdrawbarfrom

thejackstand,pullthepinholdingthejackstand

inplace.

5.Turnthejackstand90degreescounterclockwise

untilthebottomofthejackstandpointsto

therearofthemachine.Thisisthetraveling

position.

CAUTION

Raisethejacksintothetravelingposition

beforetowingthemachine.

Beforeoperatingthemachine,raisethe

frontjackandrearjackleg.Removethe

jackfromthejacklegandstoreitonthe

tongueduringoperation.

6.Connectthe2hydraulichosesfromthemachine

tothetowvehicle.Facingthefrontofthe

machine,connecttherighthosetothepressure

sideandthelefthosetothereturnside(Figure

20).Thereturnhosehasanin-lineone-way

checkvalve.Thearrowonthecheckvalve

shouldfacethetowvehiclereturnconnector.

19

g014116

Figure20

1.Pressurein2.Returnout

Important:Donotallowthehydrauliclines,

thepowercable,andthependantcablesto

dragonthegroundduringoperation.Avoid

locationswheretheycouldbecomepinched

orcut.

7.OnSHmodelsplacetheon/offpendantwithin

reachofthedriver’sseat.Ensurethattheswitch

isoff.

8.Connectthe7-pincoiledpowercabletothe

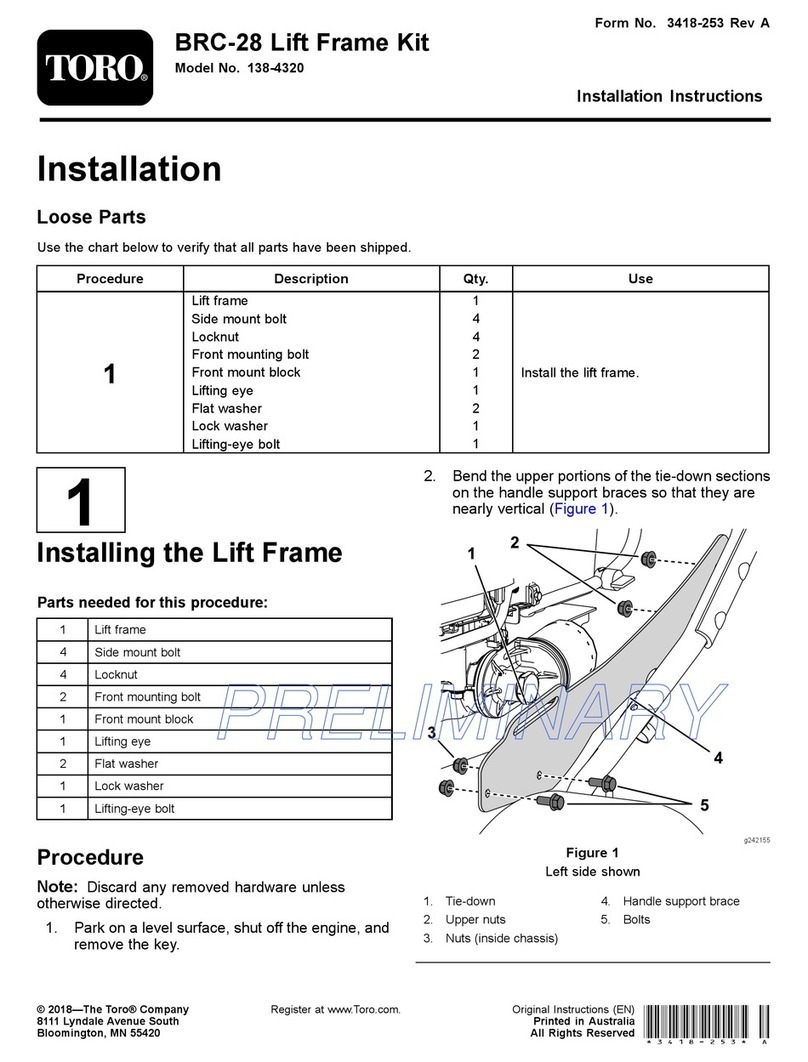

socketonthemachineandthetowvehicle

(Figure21).

g234790

Figure21

1.7-pincoiledpowercable

9.Checkthehydraulicoillevelinthetowvehicles

tankandaddmoretollit,ifnecessary;referto

thetowvehicleowner’smanual.

10.Testthehydraulicsbeforeoperatingthemachine

forthersttime.

11.Settheelectricbrakeasfollows:

•Beforeoperatingthemachineforthe

rsttime,theelectricbrakesmustbe

synchronizedtothetowvehicle’sbrakes(so

thattheyoperateatthesametime).

•Themachineandthetowvehiclewillseldom

havethecorrectamperageowtothe

brakemagnetstoprovidecomfortable,safe

braking.Changingtheloadweight,aswell

asunevenalternatorandbatteryoutput,can

resultinunstablecurrentowtothebrake

magnets.

•TheLoadControlcompensatesfortrailer

loadvariationsbylimitingthemaximum

torqueoutputofthebrakesbyadding

droppingresistanceintheelectricalcontrol

line.Whentowingatrailerloadedtobrake

ratedcapacity,theBrakeControlmustbe

setatmaximumbraking.Whenpullingan

emptyorpartiallyloadedtrailer,theBrake

Controlmustbesetbetweenmaximumand

minimumbrakingatapositionjustbefore

thepointatwhichtrailertireskiddingoccurs

whenactuatingthehandcontrolfullyon.

FailuretoinstallandusetheElectricBrake

Controlwillresultinexcessivebraketorque

whenstoppingatrailerloadedtolessthan

brakecapacity.

CAUTION

Ifyouhearanoisefromthetowvehicle

hydraulicsandthemachinecontrols

donotoperate,thehoseshavebeen

connectedincorrectlyandmustbe

reversed.

Note:Youmayhavetorelievethepressurein

thehosesofthemachineconnectingtothetow

vehicle,toensureacompletedconnection.

Important:Whenmakingsharpturns,

thehydraulichosesmaycontactthetow

vehiclewheels.Avoidmakingsharpturns,

ifnecessary,useabungeecord(arubber

strapwithhooksonbothends)topullback

thehosestowardthecenter.

Thecapabilitiesofthemachinemayvarydepending

onthesizeandtypeoftowvehicle.

•Forbestresults,useatowvehiclewithatleast

45hpand4-wheeldrive.Atowvehiclewithless

than45hpwilllimitwhereyoucangoandhow

muchpayloadyoucandeliver.Forexample,a27

hptowvehiclecantowafullyloadedmachineover

atterrain,butnotonsteephills.A4-wheel-drive

vehiclewillalsoimproveperformanceonhills.

•Withasmallertowvehicle,youmayneedto

reducethepayloadto2m3(2.6yd3)ofmaterial

forspreadingindifcultterrain.Anotheroptionis

20

Other manuals for MH-400SH2

1

This manual suits for next models

3

Table of contents

Other Toro Industrial Equipment manuals

Toro

Toro BRC-28 User manual

Toro

Toro OSMAC G3 Satellite User manual

Toro

Toro 60216C User manual

Toro

Toro 22590 User manual

Toro

Toro MH-400SH2 User manual

Toro

Toro 04246 User manual

Toro

Toro 110-5076 User manual

Toro

Toro LAC TM User manual

Toro

Toro Workman 07224-90001 Instruction Manual

Toro

Toro 301 High Lift User manual

Toro

Toro FM 330 User manual

Toro

Toro Greensmaster eFlex 1021 User manual

Toro

Toro Groundsmaster 3320 User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro MB TX 2500 User manual

Toro

Toro Workman Topdresser 1800 User manual

Toro

Toro Ultra Buggy e2500 User manual

Toro

Toro 22340 User manual

Toro

Toro TX 1300 User manual