Note:Reducedfootingcouldcauseslipping.

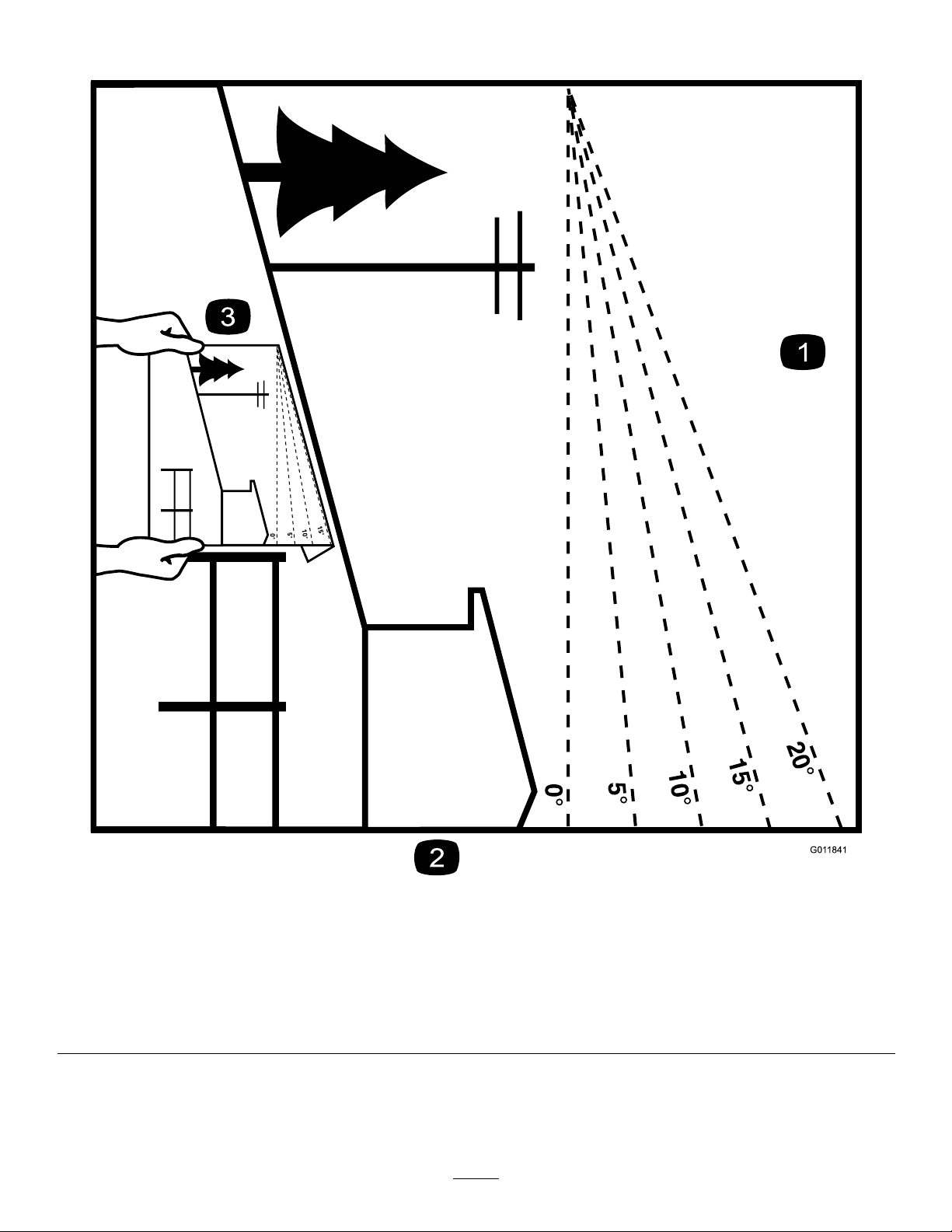

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

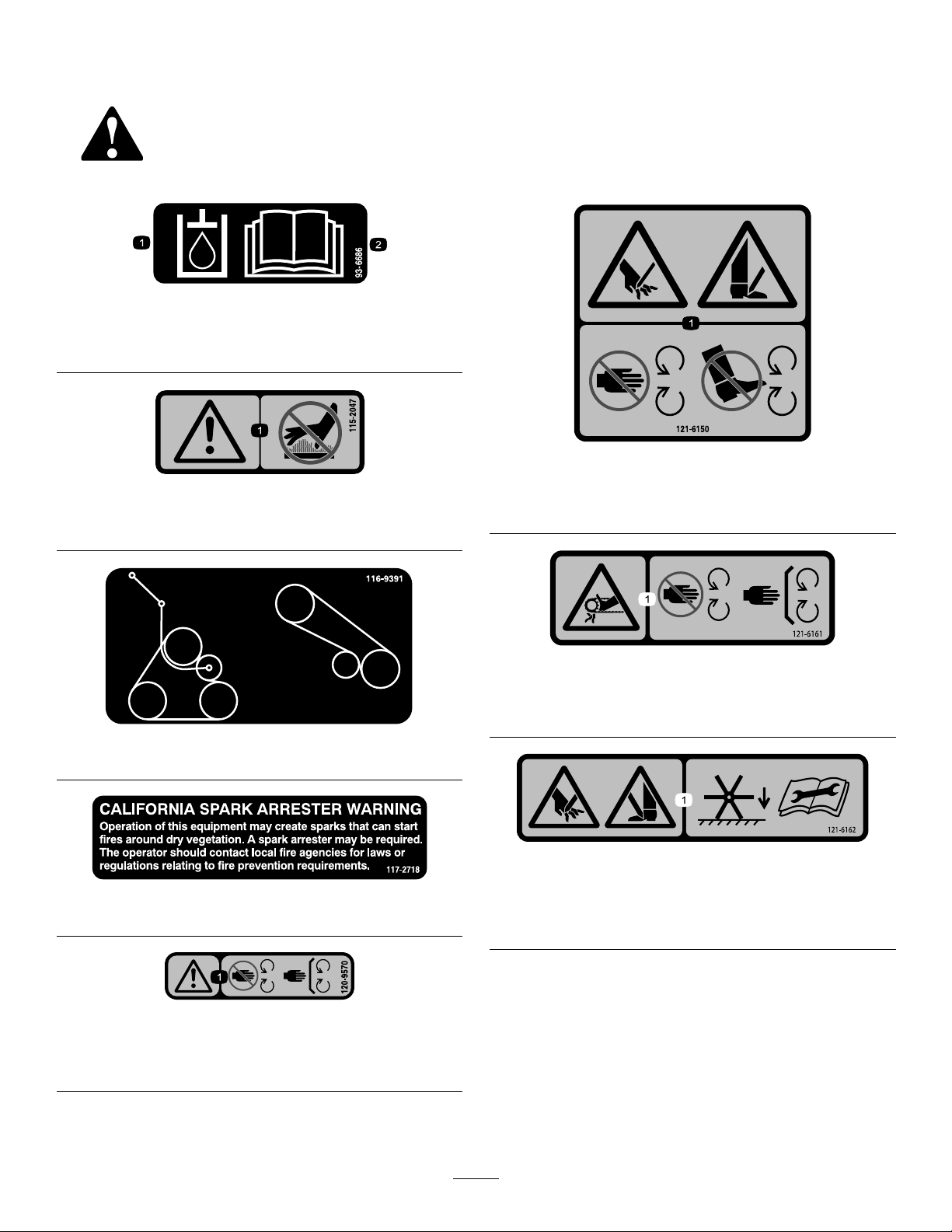

•Donotoperatethemachinewithouttheshields

orotherguardssecurelyinplace.Besureall

interlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Beforeleavingtheoperator’sposition:

–Stoponlevelground.

–Disengagetheparkingbrake(ifprovided).

–Shutofftheengine.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),shutofftheengine

beforeleavingtheoperator'spositionforany

reason.

•Stopequipmentandinspectthetinesafterstriking

objectsorifanabnormalvibrationoccurs.Make

thenecessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthetine

assembly.

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Fullyraisethe

tinesifyouarenotaerating.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelisextremely

ammableandthevaporsareexplosive.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowtheenginetocoolbeforefueling.

•Neverrefuelordrainthemachineindoorsanddo

notsmokewhilerefuelingordraining.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlightsuchas

onawaterheateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,

oronatrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,

thenaddfuelwithsuchequipmentasaportable

container,ratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapand

tightensecurely.

MaintenanceandStorage

•Donotallowuntrainedpersonneltoservice

machine.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowallofthepartsof

themachinetocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Disengagethedrives,raisethetines,engagethe

parkingbrake,shutofftheengine,andremove

thekeyordisconnectthespark-plugwire.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Reconnectthepositiverstandnegativelast.

•Usecarewhencheckingthetines.Wrapthetine(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacetines;donotstraightenorweld

them.

•Cleangrass,dirt,anddebrisfromthetines,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Parkthemachineonlevel,hardground.Never

allowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Lettheenginecoolbeforestoring.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

5