Contents

Safety.......................................................................4

GeneralSafety...................................................4

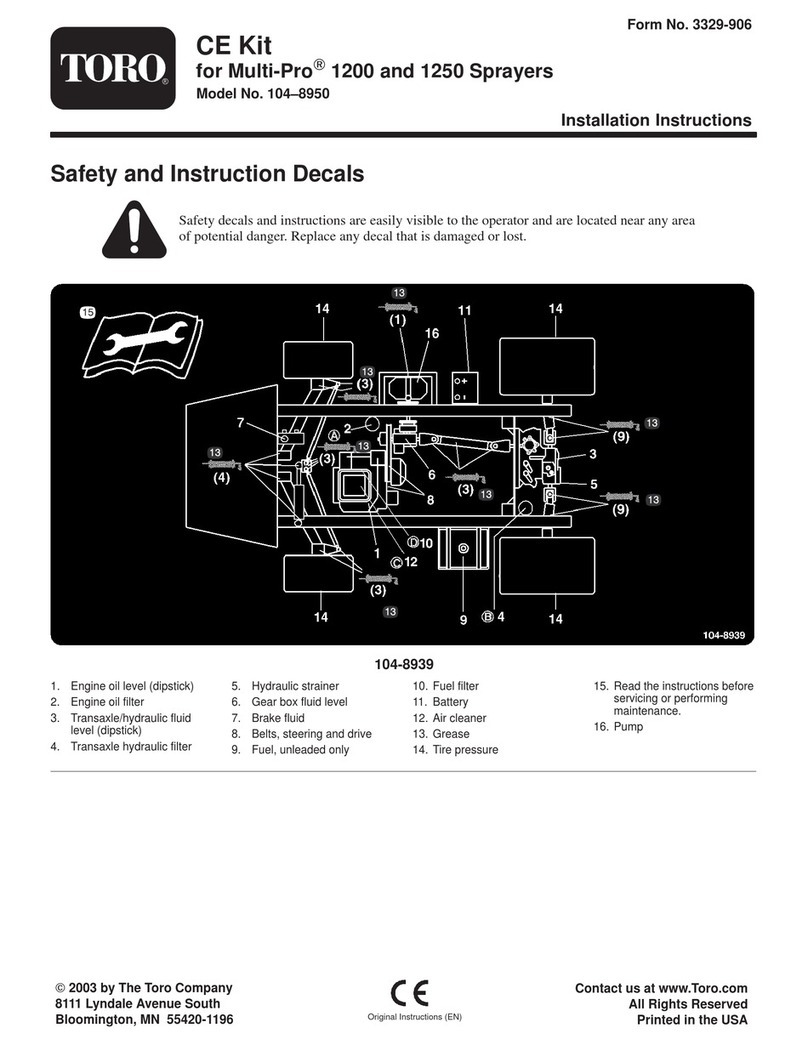

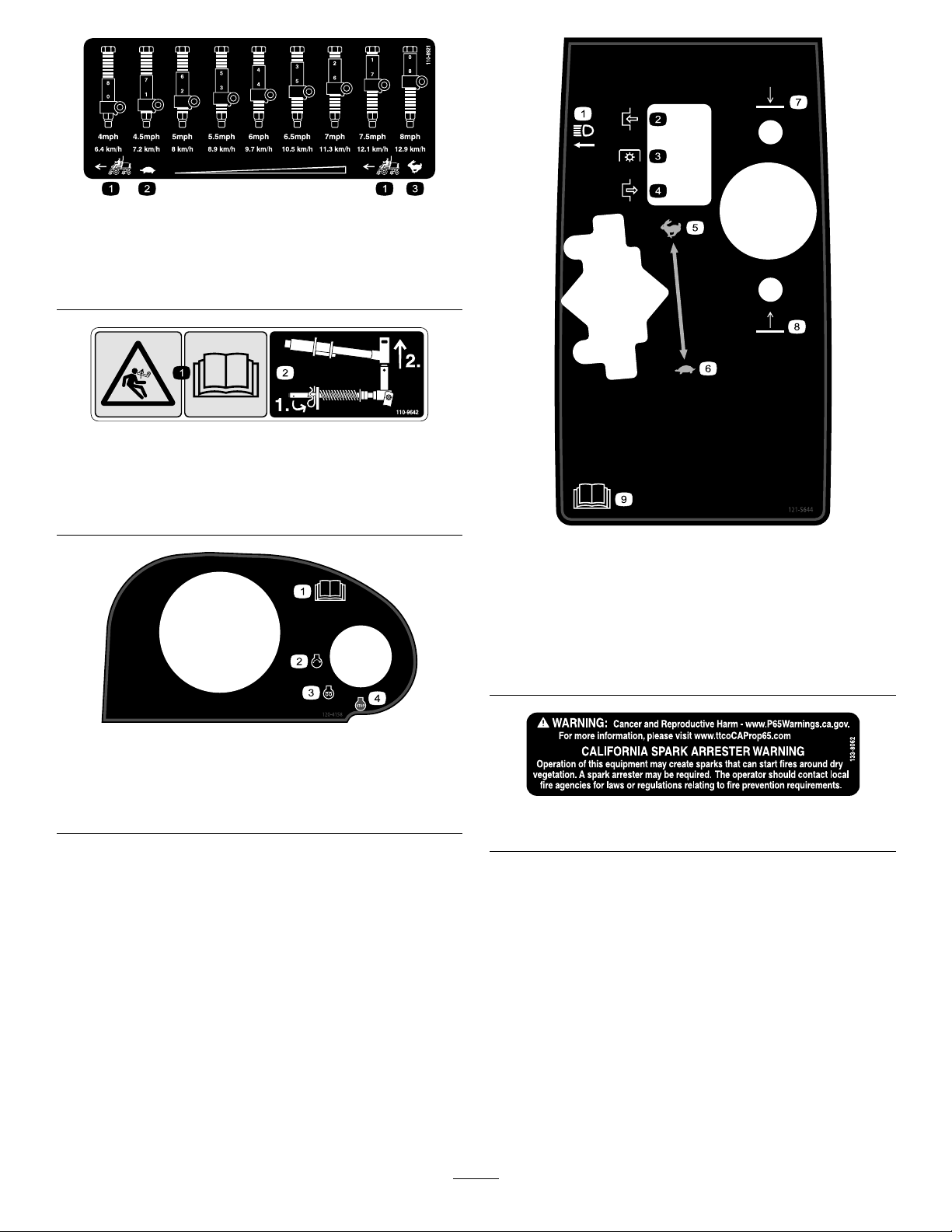

SafetyandInstructionalDecals..........................5

Setup......................................................................10

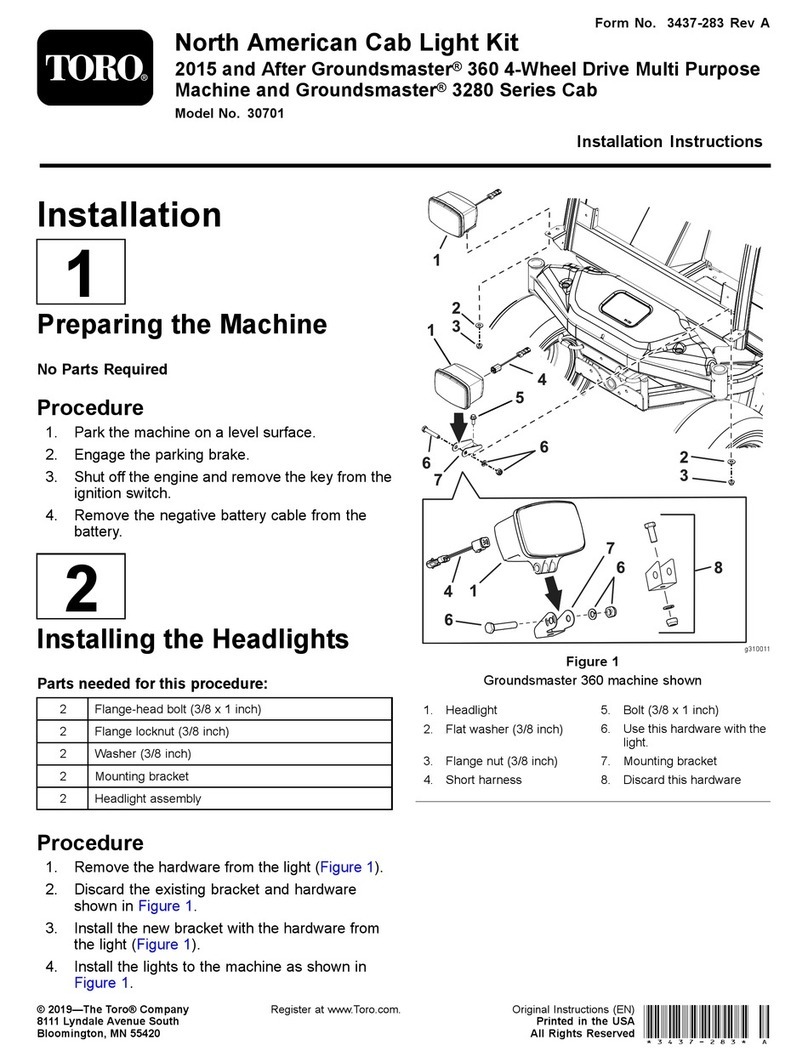

1PreparingtheMachine...................................10

2AdjustingtheControl-ArmPosition..................11

3InstallingtheCuttingUnits...............................11

4UsingtheCutting-UnitKickstand....................19

5InstallingtheCEHoodLock...........................19

6ApplyingtheCEDecals.................................21

ProductOverview...................................................22

Controls...........................................................22

SeatControls................................................24

UsingtheMenus...........................................25

Specications..................................................28

Attachments/Accessories.................................28

BeforeOperation.................................................29

BeforeOperationSafety...................................29

FuelSpecication.............................................29

FuelTankCapacity...........................................30

AddingFuel......................................................30

PerformingDailyMaintenance..........................30

CheckingtheInterlockSwitches.......................30

DuringOperation.................................................31

DuringOperationSafety...................................31

StartingtheEngine...........................................32

HydraulicFilter-RestrictionIndicator.................32

ShuttingOfftheEngine.....................................32

AdjustingtheTurf-Compensation

Spring...........................................................32

AdjustingtheLift-ArmCounterbalance.............33

AdjustingtheLift-ArmTurnaround

Position.........................................................33

SettingtheReelSpeed.....................................34

UnderstandingtheDiagnosticLight..................35

OperatingTips.................................................35

AfterOperation....................................................36

AfterOperationSafety......................................36

Tie-DownPointLocations.................................36

HaulingtheMachine.........................................36

PushingorTowingtheMachine........................36

Maintenance...........................................................38

MaintenanceSafety..........................................38

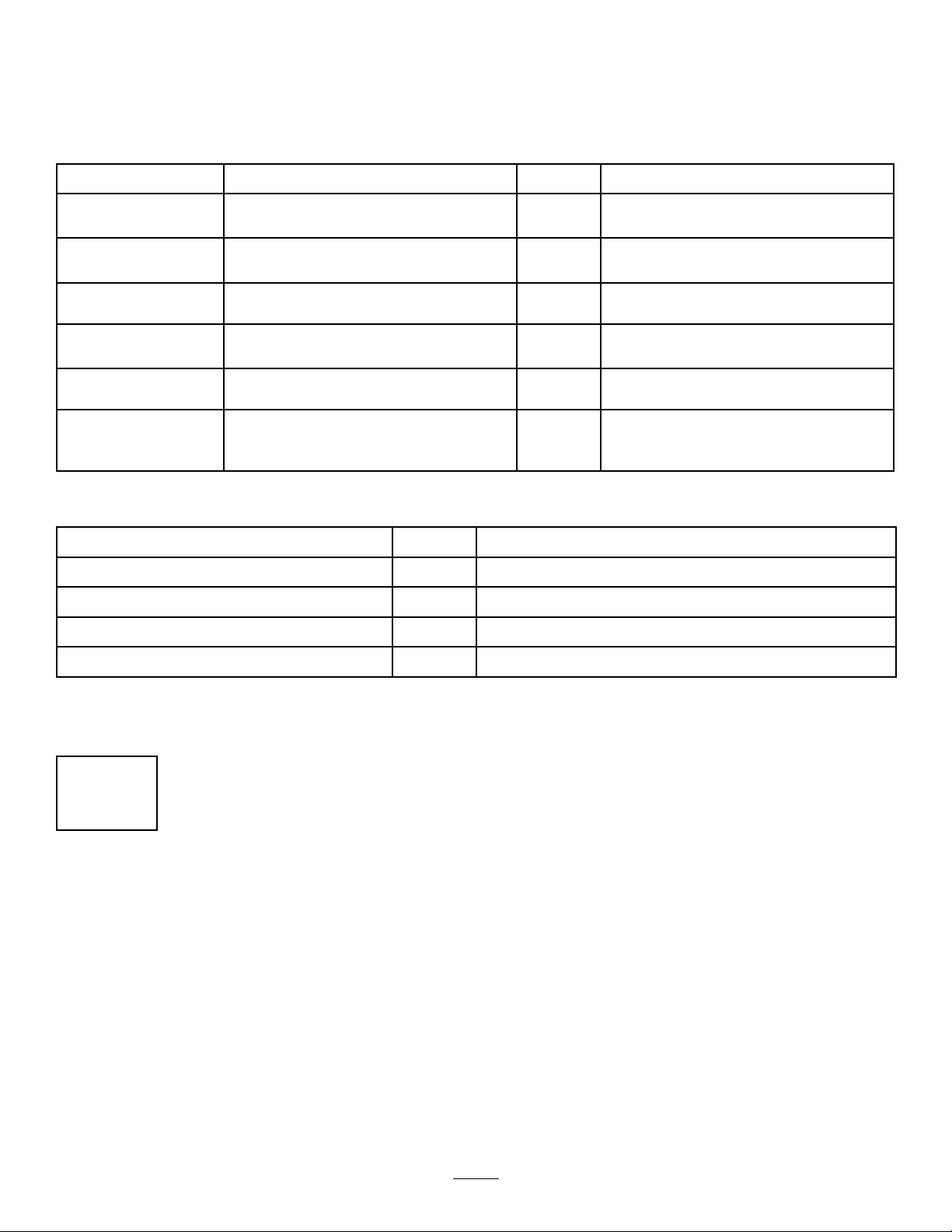

RecommendedMaintenanceSchedule(s)...........38

DailyMaintenanceChecklist.............................40

Pre-MaintenanceProcedures..............................41

PreparingforMaintenance...............................41

OpeningtheHood............................................41

ClosingtheHood..............................................41

OpeningtheScreen..........................................41

ClosingtheScreen...........................................42

TiltingtheSeat..................................................42

LoweringtheSeat.............................................42

JackingPointLocations....................................43

Lubrication..........................................................43

GreasingtheBearingsandBushings................43

EngineMaintenance...........................................45

EngineSafety...................................................45

CheckingtheAirFilter.......................................45

ServicingtheAirCleaner..................................45

ResettingtheAirFilterServiceIndicator............46

OilSpecication................................................46

CheckingtheLeveloftheEngineOil.................46

CrankcaseOilCapacity....................................47

ChangingtheEngineOilandFilter....................47

FuelSystemMaintenance...................................48

DrainingWaterfromtheFuel-Water

Separator......................................................48

ReplacingtheWater-SeparatorFilter................48

BleedingtheFuelSystem.................................49

CheckingtheFuelLinesand

Connections..................................................49

DrainingtheFuelT ank......................................49

CleaningtheFuel-PickupTubeScreen.............49

ElectricalSystemMaintenance...........................52

ElectricalSystemSafety...................................52

DisconnectingtheBattery.................................52

ConnectingtheBattery.....................................53

ChargingtheBattery.........................................53

ServicingtheBattery.........................................53

ReplacingaFuse-BlockFuse...........................53

ReplacingtheTelematicFuse...........................54

ReplacingtheTECControllerFuse...................54

DriveSystemMaintenance..................................55

CheckingtheTireAirPressure..........................55

CheckingtheT orqueoftheWheel

Nuts..............................................................55

AdjustingtheTractionDriveforNeutral.............55

CheckingtheRear-WheelAlignment................56

AdjustingtheRearWheelT oe-in.......................56

CoolingSystemMaintenance..............................57

CoolingSystemSafety.....................................57

CoolantSpecication........................................57

CheckingtheCoolantLevel..............................58

RemovingDebrisfromtheCooling

System..........................................................58

BrakeMaintenance.............................................59

AdjustingtheParkingBrakes............................59

AdjustingtheParking-BrakeLatch....................60

BeltMaintenance................................................61

TensioningtheAlternatorBelt...........................61

HydraulicSystemMaintenance...........................62

HydraulicSystemSafety...................................62

HydraulicFluidSpecications...........................62

CheckingtheHydraulic-FluidLevel...................62

CheckingtheHydraulicLinesand

Hoses............................................................63

ReplacingtheHydraulicFilters.........................63

HydraulicFluidCapacity...................................64

ChangingtheHydraulicFluid............................64

CuttingUnitSystemMaintenance........................65

BladeSafety.....................................................65

CheckingtheReel-to-BedknifeContact............65

BacklappingtheCuttingUnits...........................65

3