12345

19

21

4

20

18 17 16 15

6

7

12

10

11

8

9

7

10

14

13

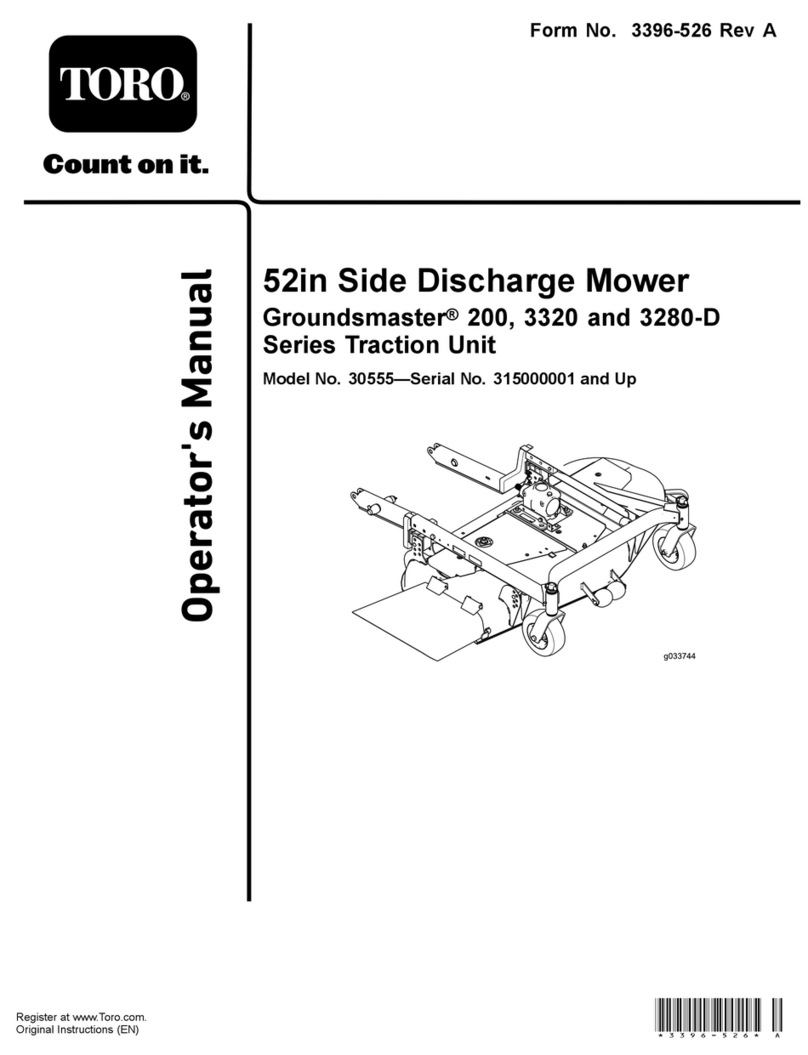

G025354

g025354

Figure15

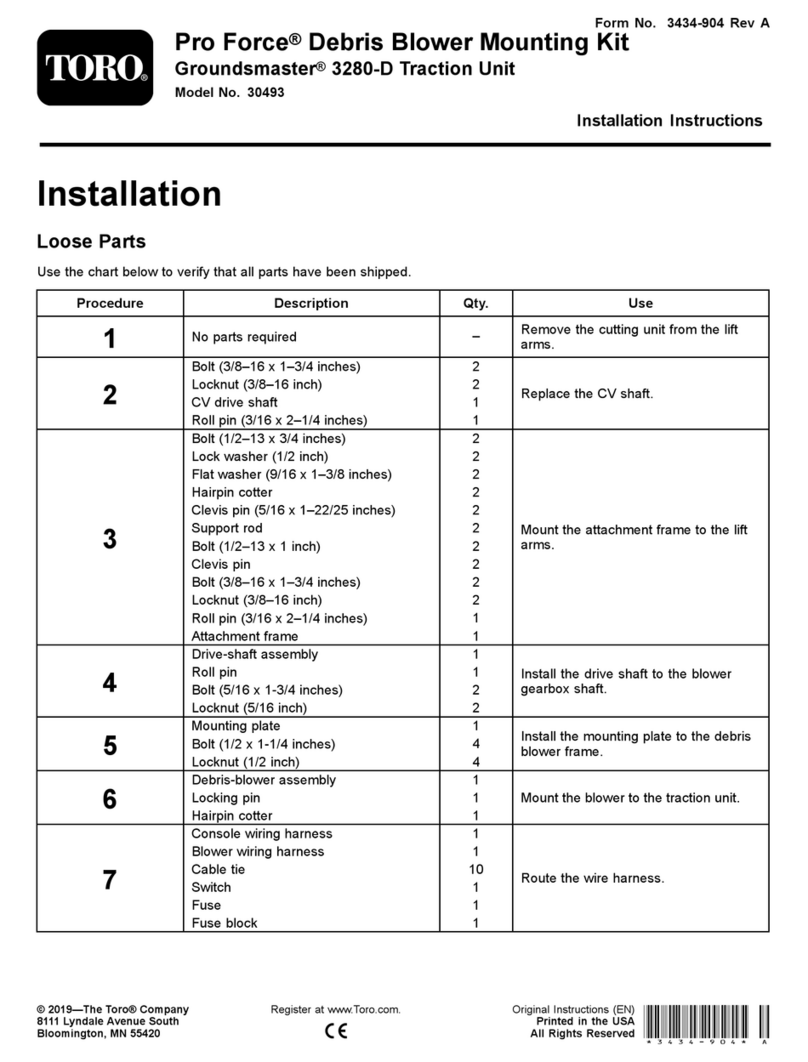

1.Solenoid(12volt)13.Bush

2.Solenoidvalve(closed)14.Valvecylinder

3.Linebody15.Bondedseal(3/4inch)

4.Bondedseal(3/8inch)16.Adapter(1/4inchmalex

3/4inchmale)

5.Adapter(1/4inchfemalex

3/8inchmale)

17.Swiveltee(1/4inchfemale

x1/4inchfemalex1/4

inchfemale)

6.Bondedseal(1/4inch)18.Adapter(1/4inchmalex

1/4inchmale),0.8mm

orice

7.Hose(1/4inchx38cm),

90°xstraight

19.Hose(1/4inchx2.156m),

tothefrontsolenoidvalve

8.Tee(1/4inchmalex

1/4inchmalex1/4inch

female)

20.Adapter(1/4inchmalex

3/8inchmale)

9.Adapter(1/4inchmalex

1/4inchmale),1.4mm

orice

21.Splitpin

10.Spring(existing)22.Cableties(8),notshown

11.Cylinderrodspringpin23.Largehosetie(368x4.8

mm),notshown

12.Washer(10mm)

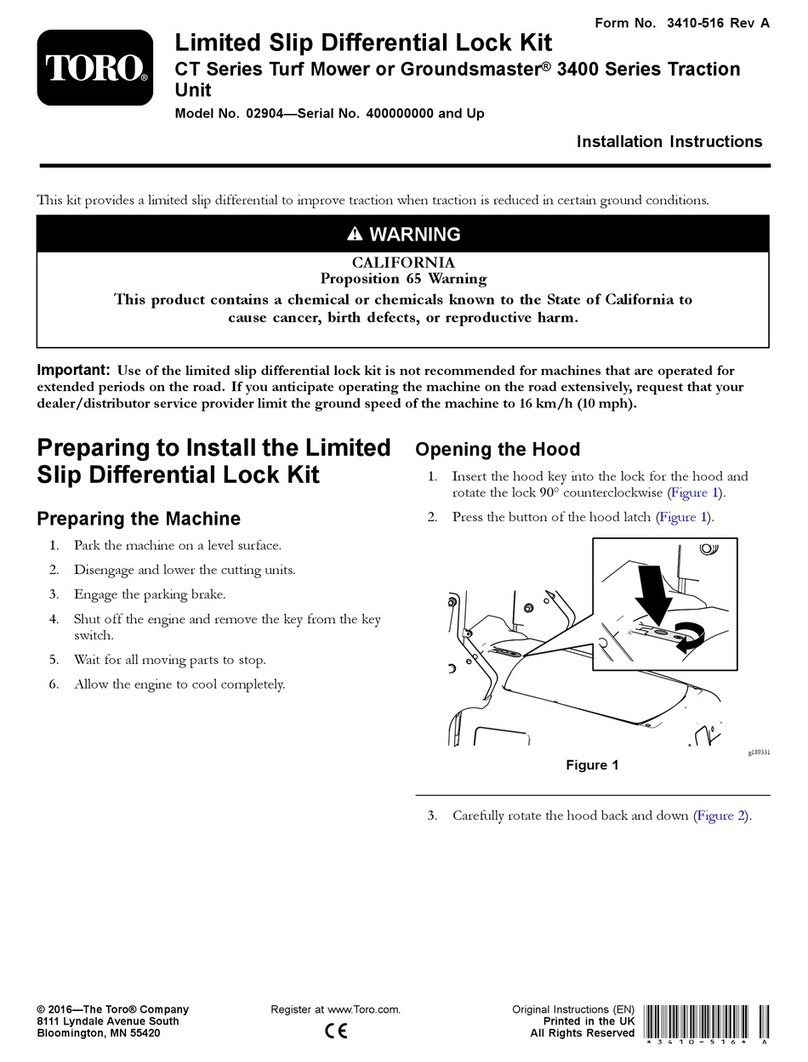

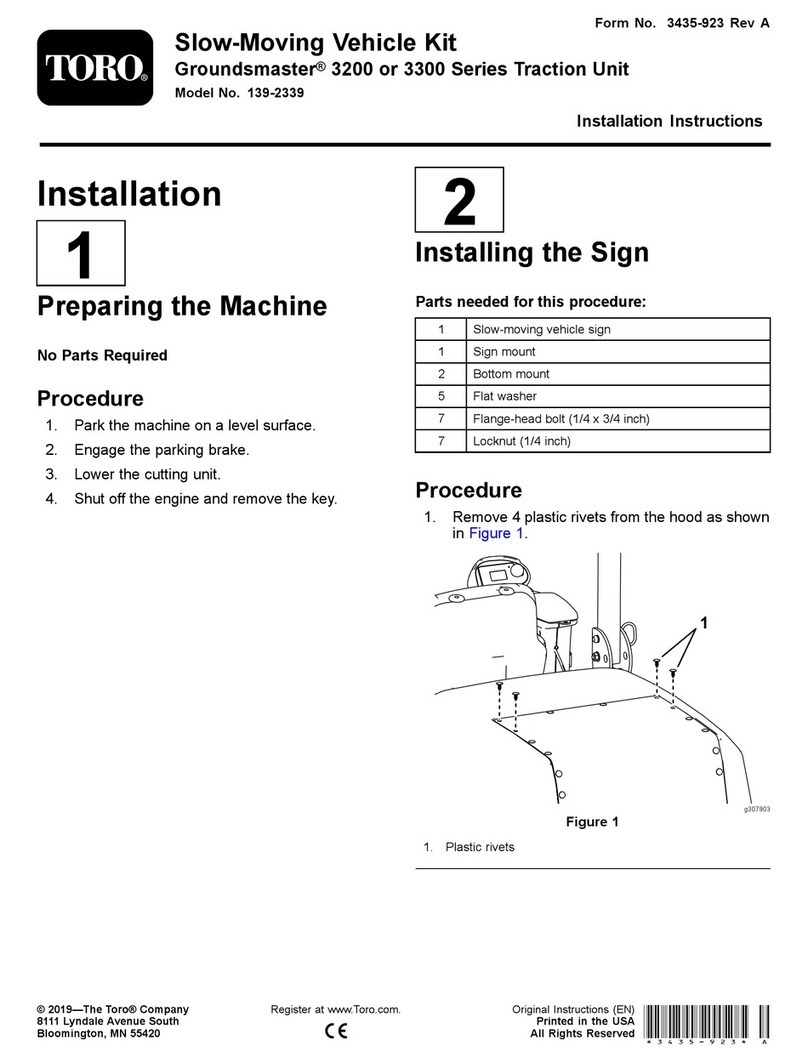

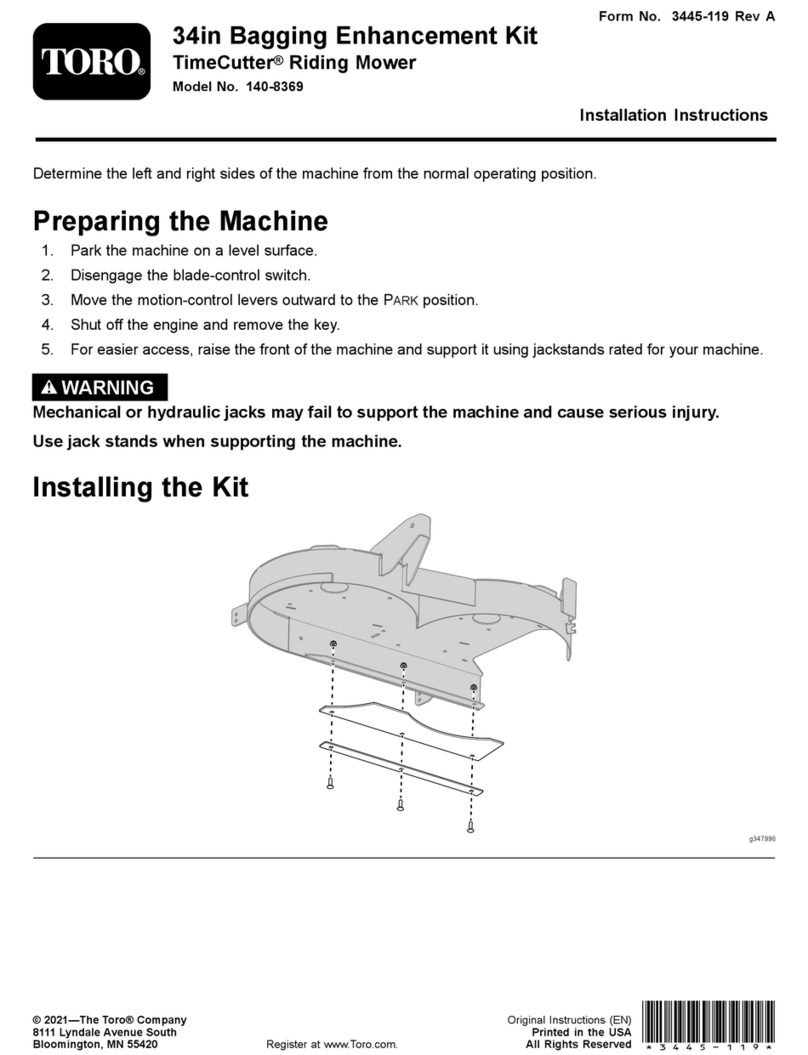

9.Removethebacklapreleaseleverfromtherearhole,

andinstallitintothefronthole(Figure16).

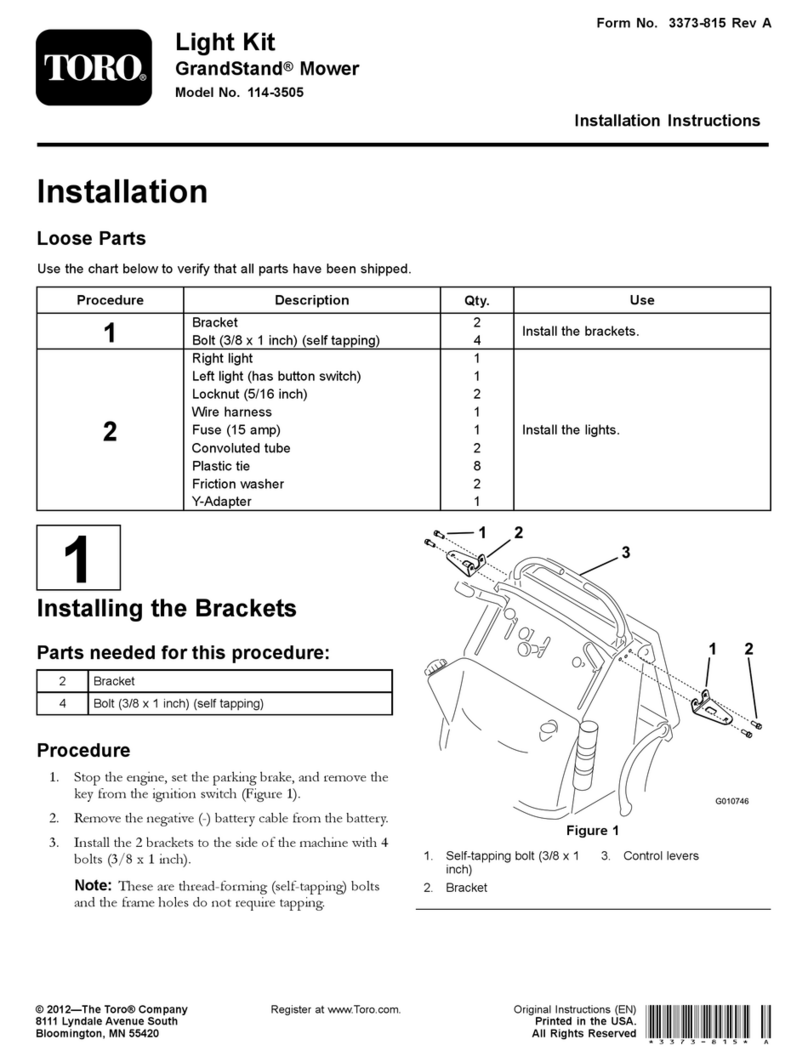

g025364

Figure16

1.Frontslot3.Fronthole

2.Rearhole

10.Fittherotaryvalvecylinderassemblyinthefrontslot

(Figure16),andsecureitusingtheoriginalboltand

slidebush.

11.Attachthecylindertotherotarybracketusingthe

washer(10mm)andthesplitpin.

12.Fitthe1/4inchfemaleteeandthe1/4inchmale

adapter(0.8mmorice)tothecylinderport,and

connectthehosefromthefrontsolenoidvalve.

13.Disconnectthehoseonthelower1/4inchportofthe

rearmanifold.Fita1/4inchmaleteetotheport,and

connectthehose.

14.Assemblealinebodywithasolenoidvalveand

solenoid.Fita3/8inchbondedsealanda3/8inchx

1/4inchmaleadapter(existing),toport1oftheline

body.Fita3/8inchbondedseal,a3/8inchx1/4inch

adapter,a1/4inchbondedseal,anda1/4inchmale

adapter(1.4mmorice)toport1ofthelinebody.

Connecttheassemblytothevalvecylinderlinebody.

15.Connectthehosetotheteeontherearmanifold.

Connecttheotherendtothettingsonthevalve

cylinderlinebody.

16.Runthecablesfromthecontrolboxtotherear

solenoidvalveandtheproximityswitchbracketalong

thecenterofthemachine(underthehydraulictank)to

therear.Connectthecablestothesolenoidandthe

switch,respectively.

17.Keeptherearsolenoidcableandtherearcylinderhose

tidybyusingthe8cabletiesandthelargehosetie(368

x4.8mm)tosecurethemtotheexistinghosesunder

thehydraulicoiltank.

18.Checkallthefastenersandhoseconnections,and

tightenthemasnecessary.

9