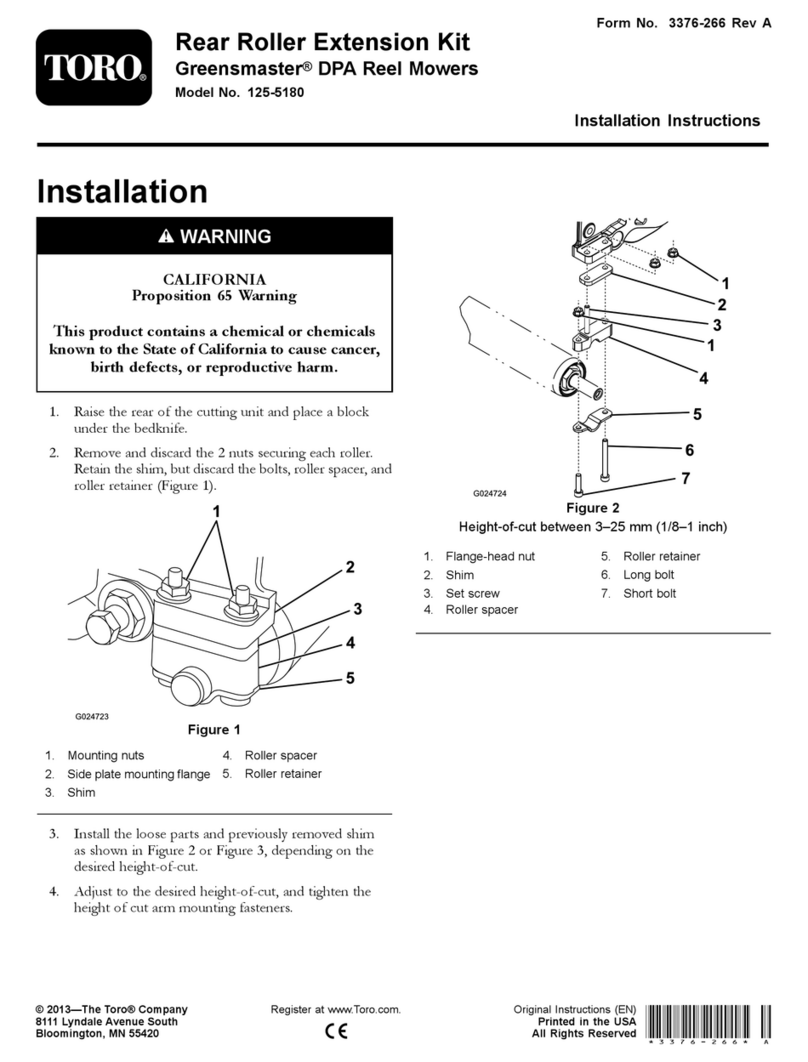

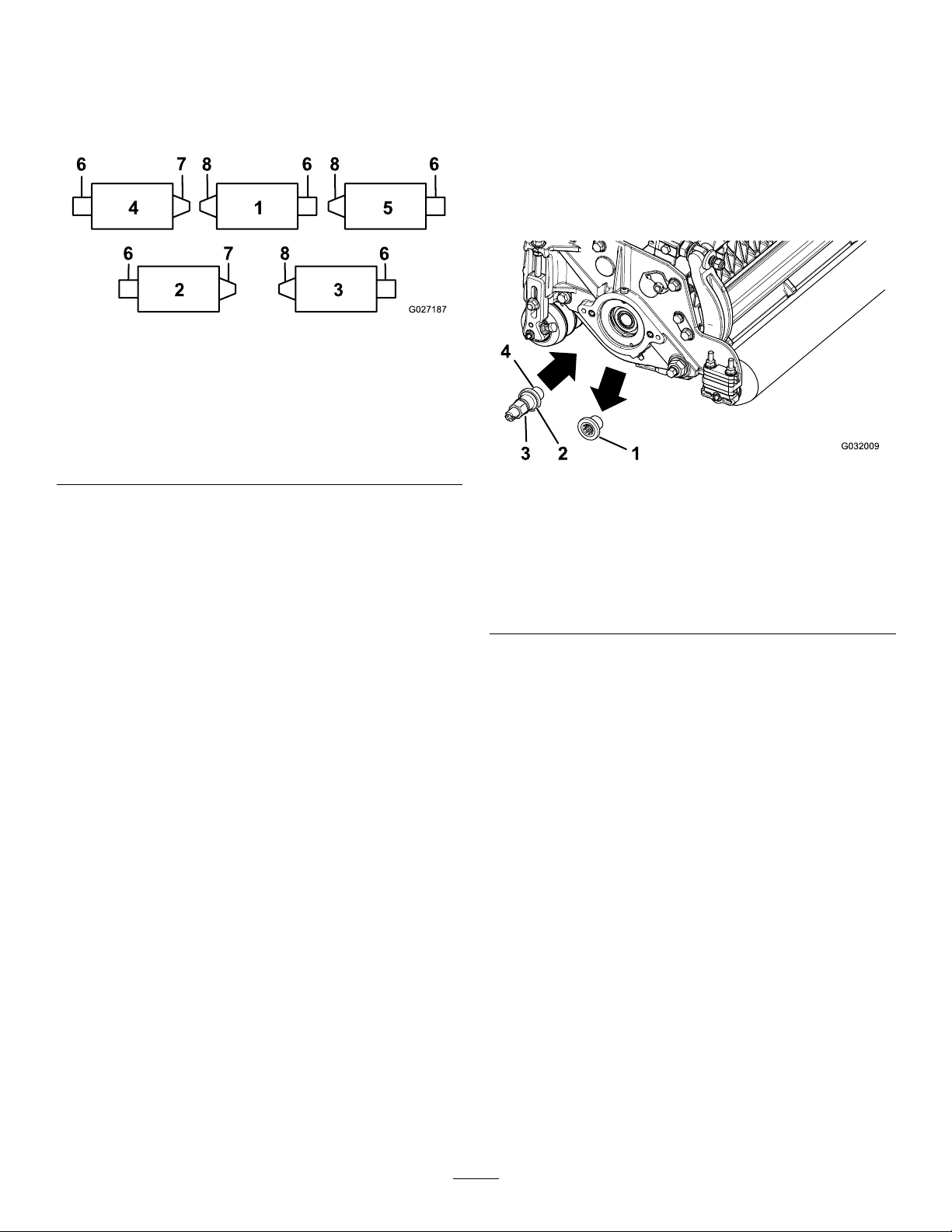

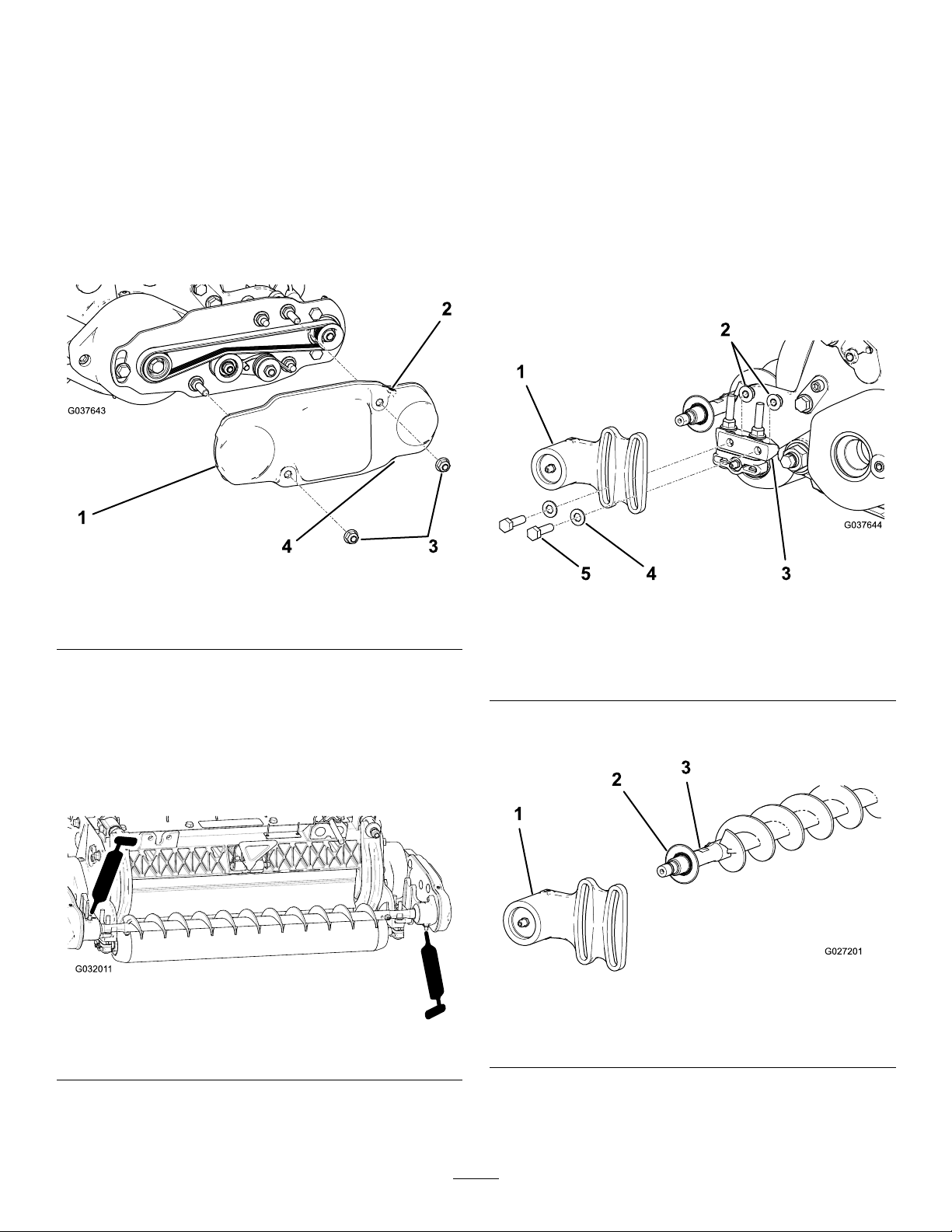

5.Loosenthe2bolts,washers,andnutssecuring

thedrive-bearinghousingtothebearing-housing

mountingbracket(Figure22).

6.Slidethehighheight-of-cutbrushontothebrush

shaft(Figure22).

7.Clampthebrushontotheshaftwiththe2J-bolts

andnutspreviouslyremoved(Figure22).

Important:Insertthethreadedendofthe

J-boltsthroughtheouterholesofthebrush

shaftwhilehookingthecurvedendsofthe

J-boltsintotheinnerholes.

8.TorquetheJ-boltlocknutsto2to3N∙m(20to

25in-lb).

g037645

Figure22

1.Highheight-of-cutbrush3.Loosenthesebolts.

2.J-bolts4.Nuts

9.Installtheexcludersealandthenon-drive

bearinghousingontothebrushshaft(Figure21).

10.Mountthenon-drivebearinghousingtothe

bearing-housingmountingbracketwiththe2

bolts,washers,andnutspreviouslyremoved.

Note:Becarefulnottoknockthesealspring

off.

11.Tightenthe2bolts,washers,andnutssecuring

thedrive-bearinghousingtothebearing-housing

mountingbracket.

Maintenance

•Ensurethatthebrushisparalleltotherollerwith

1.5mm(0.060inch)clearancetolightcontact.

•Greasethettingsevery50hoursandafterevery

washing.

•Whenreplacingarollerbrush,torquetheJ-bolts

to2to3N∙m(20to25in-lb).

•Whenreplacingthebrush-shaft-drivenpulley,

torquethenutto36to45N∙m(27to33ft-lb).

•Whenreplacingthebrush-drivepulley,apply242

Loctite(blue)andtorquetheboltto47to54N∙m

(35to40ft-lb).

Note:Therollerbrush,theidlerbearing,andthebelt

areconsideredconsumableitems.

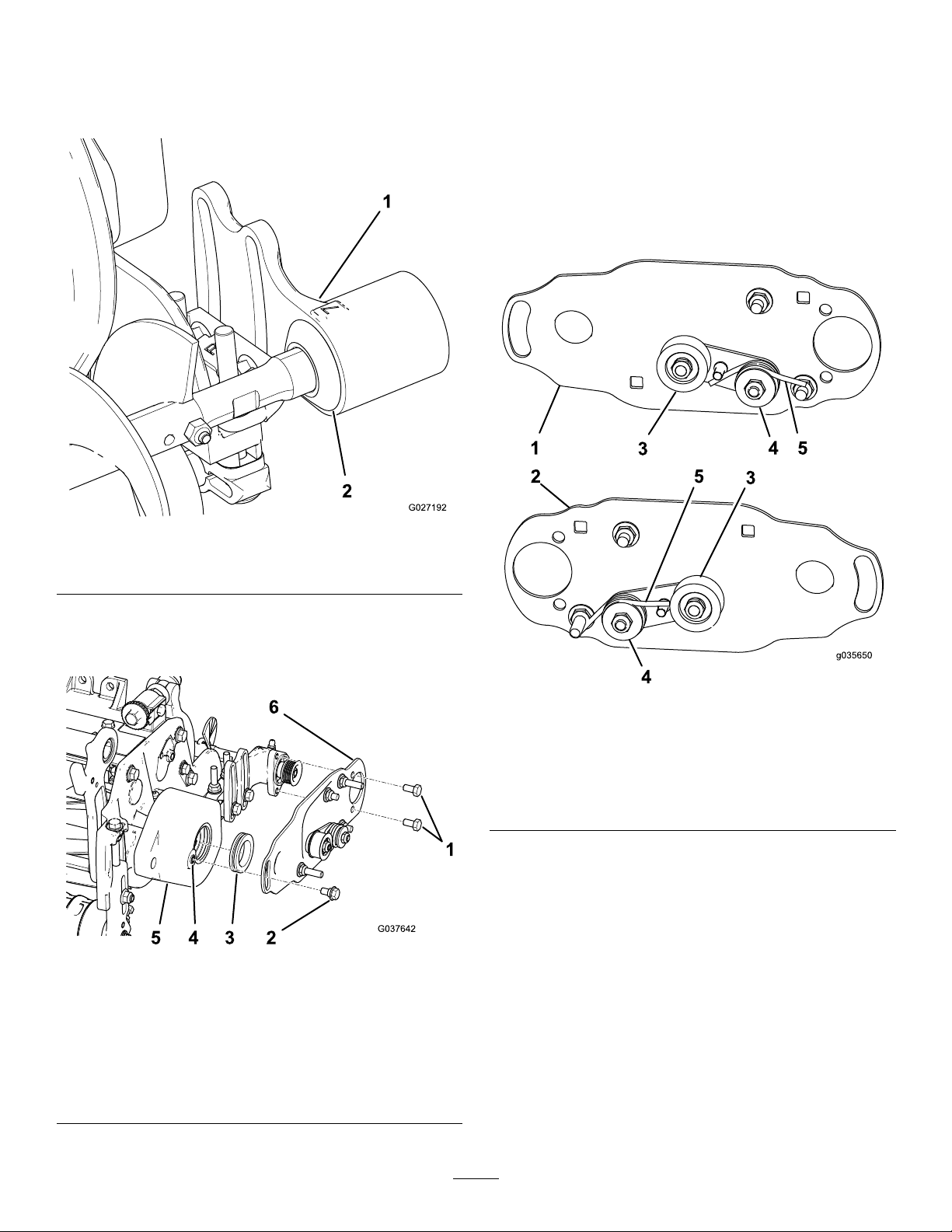

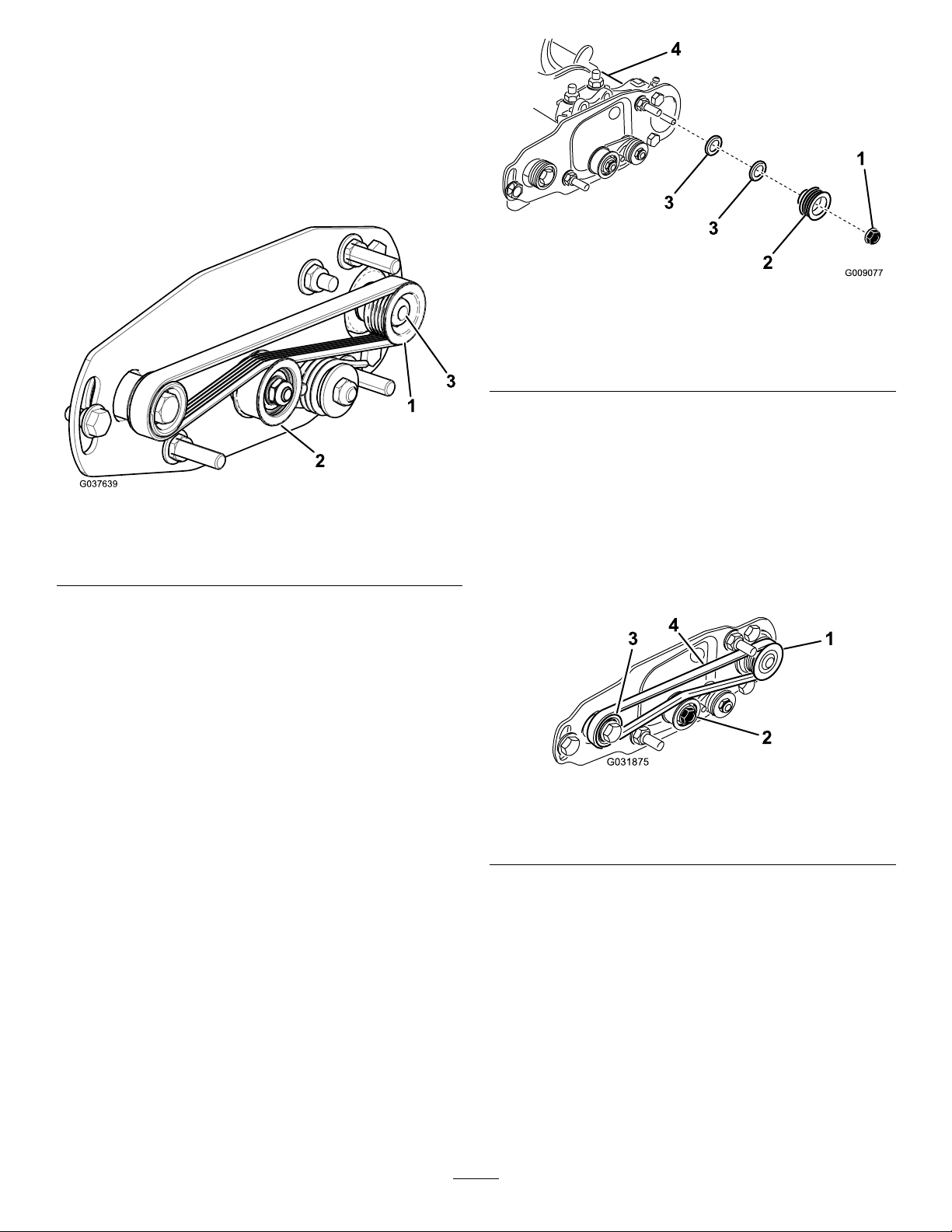

CheckingthePulley

Alignment

Important:Ensurethatthebeltisproperly

tensionedpriortocheckingthealignment.

1.Layastraightedgealongtheouterfaceofthe

drivepulley(Figure23).

Important:Onlylaythestraightedgeacross

thedrivepulley,donotlayitacrossthedrive

andthedrivenpulley.

2.Ensurethattheouterfacesofthedrivepulley

andthedrivenpulleyareinlinewithin0.76mm

(0.030inch).

Important:Donotusetheidlerpulleyto

checkthealignment.

3.Ifthepulleysarenotaligned,refertoAdjusting

thePulleyAlignment(page10).

Important:Thebeltmayfailprematurelyif

thepulleysarenotproperlyaligned.

g027197

Figure23

9