Note:Donotinstalltheplasticplugsuntilthe

spacerandstopplatesarepositionedunderthe

switches.

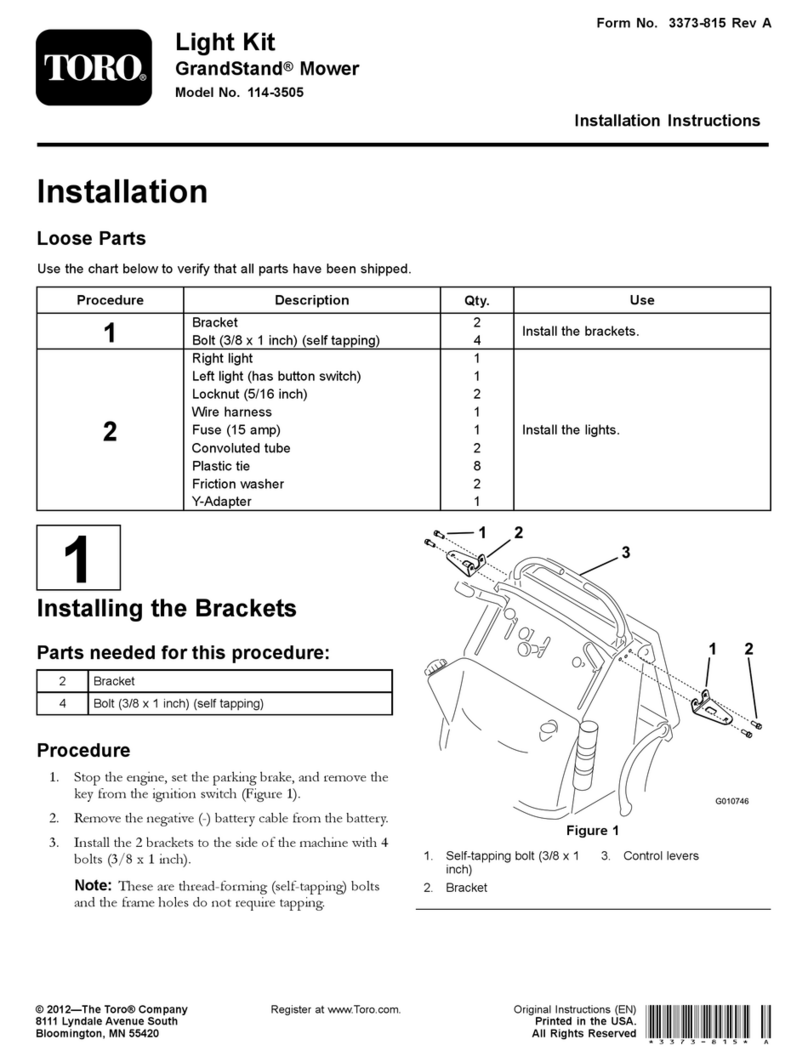

3.Whilealigningthemountingholes,positionthestop

plateontothespacerplate.Thestopplateshouldbe

positionedundertheswitches(Figure5).

4.Securetheplatestotheconsolewiththeplasticplugs

(Figure5).

4

AdjusttheCuttingDeck

PositionSwitches

NoPartsRequired

Procedure

1.Parkthemachineonahardlevelsurfaceandengage

theparkingbrake.

2.Raiseallthreedeckssothattheoutermost(highest)

cuttingbladetipcircleofeachdeckisnohigherthan

36cmabovetheoor.Placeajackstandunder

eachdecktopreventthemfromfallingiftheyare

accidentallylowered.

3.Turntheengineoff.

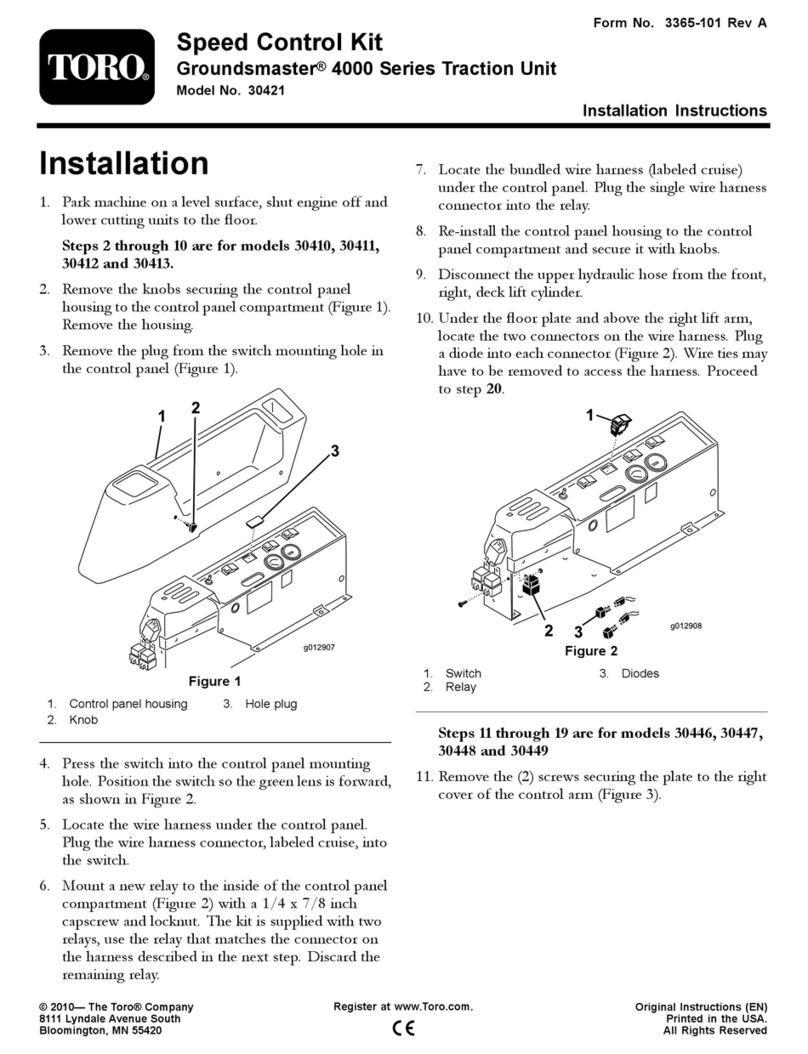

4.Toadjustthewingdeckswitch,proceedasfollows;

A.Loosenthefastenerssecuringthesensorplateto

theliftarm(Figure6).

Figure6

1.Sensorplatemounting

fasteners

3.Positionswitch

2.Sensorplate

B.TurntheignitionkeytotheRUNposition.

Important:Thedeckswilllowerifthelift

switchisactuatedwhentheoperatorisin

theseatandtheignitionkeyisintheRUN

position.

C.WhileusingtheHigh/LowRangediagnostic

screenontheInfoCenter,rotatethesensor

platejustuntiltheappropriaterightorleft

DeckDowninputreadsOFF.Refertothe

Groundsmaster5900ServiceManualfor

informationonInfoCenteroperation.

Thisisthepointintheraisesequenceofthedeck

wherethedeckpositionswitchwillshutoffthe

deckmotor.

D.Tightenthesensorplatemountingfasteners.

E.Repeattheprocedureontheotherwingdeck

switch.

5.Toadjustthefrontdeckswitch,proceedasfollows;

A.Loosenthefastenerssecuringtheswitchbracket

totheframe(Figure7).

Figure7

1.Positionswitchmounting

fasteners

3.Positionswitch

2.Positionswitchmounting

bracket

4.Sensorplate

B.TurntheignitionkeytotheRUNposition.

Important:Thedeckswilllowerifthelift

switchisactuatedwhentheoperatorisin

3