FormNo.3437-125RevC

AutoSteerFinishKit

SerialNumber316000001through406294344MultiPro®5800Turf

SprayerwithGeoLink®

ModelNo.138-6246

InstallationInstructions

Thepartsandinstructionsdescribedinthismanualareforinstalling

boththeAutoSteerFinishKitandtheAutoSteerKit.

Introduction

TheAutoSteerkitisanaccessoryfortheGeoLink™spraysystem,usedforaturfsprayapplicationvehicle,and

isintendedtobeusedbyprofessional,hiredoperatorsincommercialapplications.Itisdesignedprimarilyfor

sprayingonwell-maintainedlawnsinparks,golfcourses,sportselds,andoncommercialgrounds.Usingthis

productforpurposesotherthanitsintendedusecouldprovedangeroustoyouandbystanders.

Visitwww.Toro.comforproductsafetyandoperationtrainingmaterials,accessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Contents

Introduction...............................................................1

Setup........................................................................2

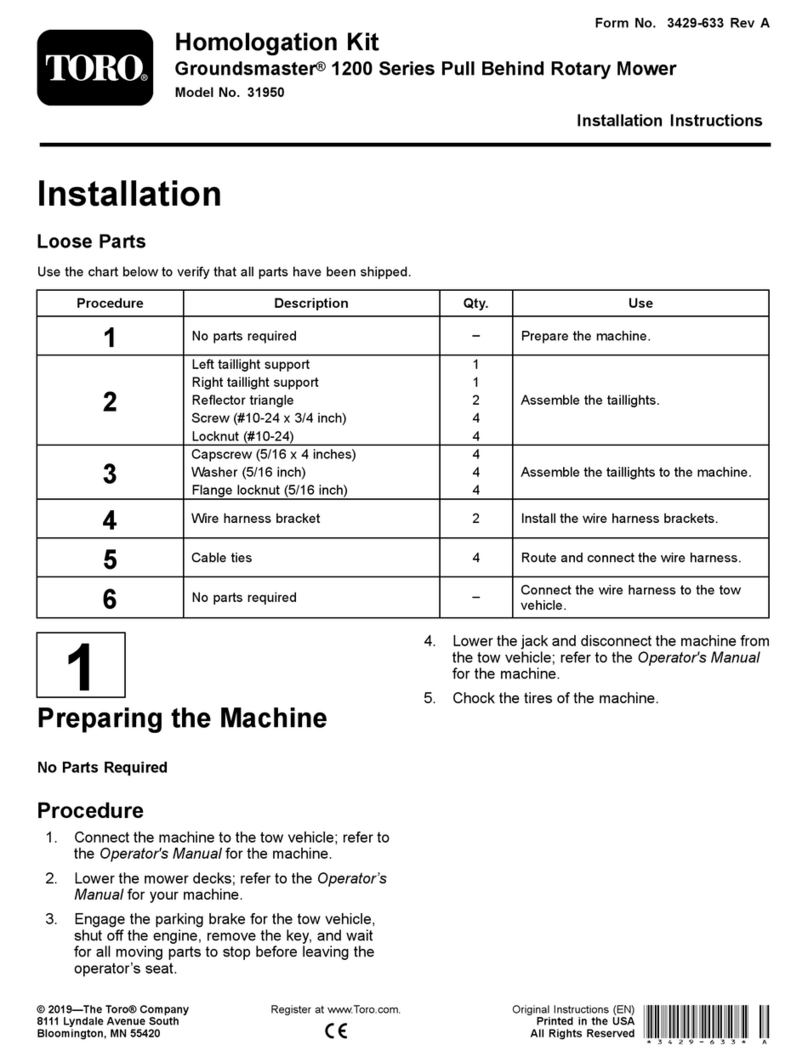

1PreparingtheMachine.....................................5

2VerifyingtheSoftwareVersion.........................5

3PreparingtheLaptopComputer.......................5

4RemovetheNegativeBatteryCable................7

5ReplacingtheLeftSpindle...............................7

6RemovingtheHood.......................................15

7RemovingtheHeatShieldand

UndercarriageShroud...................................15

8PluggingtheHydraulicPumpSuction

Hose.............................................................16

9RoutingtheISO-CANBusHarness................17

10RemovingtheCANBusResistor..................21

11InstallingtheAdapterHarnessand

TerminatingResistor.....................................22

12RemovingtheSteeringWheeland

SteeringValve...............................................23

13InstallingtheSteeringValve.........................25

14RemovingtheSteeringValveHoses............26

15InstallingtheEHISteeringValve..................29

16DrillingtheConsoleBase.............................32

17InstallingtheElectricalHarness...................33

18ReplacingtheHydraulicPump.....................42

19InstallingtheForwardPressureHosefor

theBoom-LiftManifold..................................46

20InstallingtheHoses......................................47

21InstallingtheNegativeBattery

Cable............................................................58

22PurgingAirfromtheHydraulic

System..........................................................58

23CheckingforHydraulicLeaks.......................58

24InstallingtheHood.......................................59

25InstallingtheHeatShieldand

UndercarriageShroud...................................59

26SettingUpandCalibratingthe

Software........................................................60

27CheckingtheHydraulicFluidLevel...............70

Schematics.............................................................71

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3437-125*