Toro GREENS AERATOR 09120 User manual

®

OPERATOR’S

MANUAL

FORM NO. 3318--399GB

MODEL NO. 09120—60001 & UP

GREENS AERATOR

©The Toro Company—1996

To assure maximum safety, optimum performance, and gain

knowledge of the product, it is essential that you or any other

operator read and understand the contents of this manual

before the engine is ever started. Pay particular attention to

the SAFETY INSTRUCTIONS highlighted by this symbol—

The safety alert symbol means CAUTION, WARN-

ING or DANGER—personal safety instruction.

Failure to comply with the instruction may result in

personal injury.

2

TABLE OF CONTENTS

Page

Safety Instructions 3

Safety and Instruction Decals 5

Before Operating 7

Check Crankcase Oil 7

Fill Fuel Tank with Gasoline 7

Check Hydraulic System Fluid 8

Controls 9

Operating Instructions 10

Starting/Stopping Engine 10

Install Tines 10

Adjust Coring Depth 11

Check Frame Height 11

Operating Procedure 12

Check Interlock System 12

Override System 13

Training Period 14

Before Aerating 14

Aerating Procedure 14

Transport Operation 14

Inspection and Cleanup After Use . 14

Lubrication 15

Troubleshooting 17

Foreword

The Greens Aerator has advanced concepts in engineering, design and safety; and if maintained properly, will give excel-

lent service.

Since this is a high-quality product, Toro is concerned about the future use of the machine and safety of the user.

Therefore, read this manual to familiarize yourself with proper set-up, operation and maintenance instructions. The

major sections of the manual are:

1. Safety Instructions 3. Operation

2. Before Operating 4. Lubrication

Certain information in this manual is emphasized. DANGER, WARNING and CAUTION identify personal safety relat-

ed information. IMPORTANT identifies mechanical information demanding special attention. Be sure to read this

directive because it deals with the possibility of damaging a part or parts of the machine. NOTE identifies general infor-

mation worthy of special attention.

This safety alert symbol means CAUTION, WARNING or

DANGER — “personal safety instruction.” Read and

understand the instruction because it has to do with safety.

Failure to comply with the instruction may result in per-

sonal injury.

Improper use or maintenance of the machine can result in

injury. To reduce the potential for injury, comply with the

following safety instructions.

BEFORE OPERATING

1. Read and understand the contents of this Operator’s

Manual before operating the machine. Become

familiar with all controls and know how to stop

quickly. A free replacement manual is available by

sending complete Model and Serial Number to:

The Toro Company

8111 Lyndale Avenue South Minneapolis,

Minnesota 55420

2. Do not allow children to operate the machine. Do

not allow adults to operate the machine without prop-

er instruction.

3. Before attempting to start engine, disengage the trac-

tion drive and move the gear shift to neutral.

4. Remove all debris or other objects that might inter-

fere with operation. Keep all bystanders away from

the work area.

5. Keep all shields and safety devices in place. If a

shield, safety device or decal is defective or damaged,

repair or replace it before resuming operation. Also,

tighten any loose nuts, bolts and screws to assure the

machine is in safe operating condition.

6. Do not operate the machine while wearing sandals,

tennis shoes, sneakers or shorts. Also, do not wear

loose fitting clothing that could get caught in moving

parts. Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes, ear protection

and a helmet is advisable and required by some local

ordinances and insurance regulations.

7. Fill the fuel tank with gasoline before starting the

engine. Avoid spilling gasoline. Since gasoline is

flammable, handle it carefully.

A. Use an approved gasoline container.

B. Do not fill the tank while the engine is hot or

running,

C. Do not smoke while handling gasoline.

D. Fill the fuel tank outdoors and up to about one

inch (25 mm) from top of the tank, not the filler

neck.

E. Wipe up any spilled gasoline.

WHILE OPERATING

8. Start the engine when the traction drive is disen-

gaged, and the gear shift lever is in neutral.

9. Do not run the engine in a confined area without ade-

quate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

10. Using the machine demands attention, and to prevent

loss of control:

A. Use only in daylight or when there is good arti-

ficial light.

B. Watch for holes or other hidden hazards.

C. Do not transport the machine close to a sand

trap, ditch, creek or other hazard.

11. If the tines strike a solid object or the machine

vibrates abnormally, shut the engine off. Remove the

high-tension wire from the spark plug to prevent pos-

sibility of accidental starting, Check the coring head

and traction unit for damage and defective parts.

Repair any damage before restarting the engine and

operating the tines. Be sure the tines are in good

condition and all bolts are tight.

12. Do not touch the engine or muffler while the engine

is running or soon after it is stopped. These areas

could be hot enough to cause a burn.

13. Before leaving the operator’s position—behind han-

dle or leaving machine unattended, raise the coring

head, raise the lockup brackets, disengage the traction

drive, move the gear shift to neutral and shut OFF the

engine.

Safety Instructions

3

Safety Instructions

4

MAINTENANCE

14. Disconnect the high-tension wire from the spark plug

to prevent accidental starting of the engine when ser-

vicing, adjusting or storing the machine.

15. If the traction unit must be tipped to perform mainte-

nance or an adjustment, drain the gasoline from fuel

tank and oil from crankcase.

16. To reduce potential fire hazard, keep the engine free

of excessive grease, grass, leaves and accumulations

of dirt.

17. Be sure the machine is in safe operating condition by

keeping nuts, bolts and screws tight. Check the tine

mounting bolts and nuts frequently to be sure they are

tightened to specification.

18. If the engine must be running to perform a mainte-

nance adjustment, keep hands, feet, clothing and

other parts of the body away from the tines and other

moving parts.

19. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition

before applying pressure to the system.

20. Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not hands, to search for

leaks. Hydraulic fluid escaping under pressure can

have sufficient force to penetrate skin and do serious

damage. If fluid is ejected into the skin it must be

surgically removed within a few hours by a doctor

familiar with this form of injury or gangrene may

result.

21. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be

relieved by stopping the engine and lowering the

implement to the ground.

22. Do not overspeed the engine by changing governor

settings. To be sure of safety and accuracy, have an

Authorized TORO Distributor check maximum

engine speed with a tachometer.

23. The engine must be shut off before checking oil or

adding oil to the crankcase.

24. Allow the engine to cool before storing the machine

in any enclosure such as a garage or storage shed.

Make sure the fuel tank is empty if the machine is to

be stored more than 30 days. Do not store the

machine near any open flame or where gasoline

fumes may be ignited by a spark. Always store gaso-

line in a safety approved, red metal container.

25. Perform only those maintenance instructions

described in this manual. If major repairs are ever

needed or assistance is desired, contact an Authorized

Toro Distributor. To ensure optimum performance

and safety, always purchase genuine TORO replace-

ment parts and accessories to keep the Toro all

TORO. NEVER USE “WILL-FIT”’ REPLACE-

MENT PARTS AND ACCESSORIES MADE BY

OTHER MANUFACTURERS. Look for the TORO

Iogo to assure genuineness. Using unproved replace-

ment parts and accessories could void the warranty of

The Toro Company

Sound &Vibration Levels

Sound Levels

This unit has an equivalent continuous A-weighted sound

pressure at the operator ear of: 92 dB(A), based on mea-

surements of identical machines per 84/538/EEC.

This unit has a sound power level of 104 dB(A)/1pW,

based on measurements of identical machines per proce-

dures outlined in Directive 79/113/EEC and amendments.

Vibration Level

This unit has a vibration level of 8.0 m/s2at the posterior,

based on measurements of identical machines per ISO

2631 procedures.

5

Symbol Glossary

SAFETY ALERT

SYMBOL GENERAL HAZARD

SAFETY ALERT CRUSHING OF

WHOLE BODY,

APPLIED FROM

ABOVE

CRUSHING OF

FINGERS OR HAND,

FORCE APPLIED

FROM SIDE

CUTTING OF

FINGERS OR HAND CUTTING OF FOOT CRUSHING OR

PUNCTURE OF FOOT,

CORING HEAD

WHOLE BODY ENTANGLEMENT,

IMPLEMENT INPUT DRIVE LINE FINGERS OR HAND

ENTANGLEMENT,

CHAIN DRIVE

THROWN OR FLYING

OBJECTS, WHOLE

BODY EXPOSURE

RUNOVER/BACKOVER,

GREENS AERATOR RUNOVER/BACKOVER,

HC 4000 AERATOR SECURE LIFTING CYLINDER WITH

LOCKING DEVICE BEFORE

GETTING IN HAZARDOUS AREA

INSERT SAFETY LOCK

BEFORE GETTING IN

HAZARDOUS AREA

STAY A SAFE DISTANCE FROM MACHINE,

GREENS AERATOR STAY A SAFE DISTANCE FROM MACHINE,

HC 4000 AERATOR

STAY CLEAR OF ARTICULATION

AREA WHILE ENFINE IS RUNNING,

GREENS AERATOR

DO NOT OPEN OR REMOVE

SAFETY SHIELDS WHILE

ENGINE IS RUNNING

SHUT OFF ENGINE & REMOVE

KEY BEFORE LEAVING OPERATOR

POSITION, GREENS AERATOR

CONSULT TECHNICAL MANUAL

FOR PROPER SERVICE

PROCEDURES

READ OPERATOR’S

MANUAL HEARING PROTECTION

MUST BE WORN BRAKE SYSTEM ENGAGE DISENGAGE

Symbol Glossary

6

P

1 INCH (25mm)

P

ON/START OFF/STOP FAST SLOW CONTINUOUS

VARIABLE,

LINEAR

ENGINE START ENGINE STOP

PARK UNLEADED FUEL FUEL TANK FILL

LINE LOCK UNLOCK CORING HEAD

ALWAYS HAVE CORING HEAD

FULLY UP FOR TRANSPORT &

FULLY DOWN FOR CORING

TRACTION DRIVE MANUAL CHOCK WHEELS IN PARKED POSITION,

ALWAYS PARK ON LEVEL SURFACE,

FAIRWAY AERATOR

ALWAYS FORK FROM FRONT OR REAR

OF MACHINE, HC 4000 AERATOR LEVER OPERATION

Engine: Briggs & Stratton, Vanguard, 4-cycle, air-cooled,

2-cylinder 11.9 kW (16 hp) @ 3600 rpm, 74.4 cm3(29.3

cu. in) displacement. Electric start. Large capacity dual

element air cleaner. Full pressure lubrication 1.55 l (3.5

pint) oil capacity. Solid-state electronic ignition.

Electrical: 12-volt battery, 32-amp-hour. 16-amp alterna-

tor. Ignition switch and interlock switches on control han-

dle, transmission and coring head clutch.

Fuel Capacity: 17 l (4.5 gallons) unleaded gasoline.

Traction Drive: Double-banded V-belt from mechanical

clutch on engine to Peerless Model 2361 transaxle. Two

speeds forward and one reverse. Wheels driven individual-

ly by chains from transaxle.

Ground Speed:

1st Gear Forward: 1.8 km/h @ 3600 rpm (coring)

2nd Gear Forward: 5.3 mph @3600 rpm (transport)

Reverse: 3.1 km/h @ 1800 rpm.

Ground Clearance: 10.2 cm (4 inches).

Tires/Wheels: Two steering tires (front): 13 X 5.00-6, 2

ply, rib tread tubeless.

Two drive tires (rear): 18 X 9.50-8, 4 ply, Rib Terra

tubeless. Drop center demountable rims, greaseable

tapered roller bearings.

Recommended tire pressure for front and back tires is 69

kPa (10 psi).

Frame: Welded steel construction—tricycle.

Service Brake: Disc-type mounted to transaxle.

Controls: Traction clutch, coring head hydraulic lift and

key switch on control console. Throttle and choke on

engine. Transaxle shift lever on frame. Interlock switches

and service brake on steering handle.

Implement Drive: Triple banded V-belt from engine to

coring head.

Coring Unit Construction: Welded steel frame con-

struction with four crankshafts mounted in precision ball

bearings. Crankshafts drive four coring arms/tine heads.

Drive: No. 50 O-ring sealed roller chain from counter-

shaft to coring crankshafts.

Lift: Single hydraulic cylinder powered by a vane type

pump. Control valve actuated by lift control lever.

Tine Heads: 4 individual heads each holding three tines.

Deflector chutes direct cores rearward away from drive

components.

Coring Width: 27 inches

Hole Pattern: 2.25 inches X 2.5 inches

Coring Depth: Up to 3.5 inches.

Tines: Case hardened tubing, hollow tapered design. 5/8"

tines standard. 12 tines required per unit.

Dimensions:

Length: 193 cm (76 inches)

Width: 141 (55.5 inches)

Height: 99.1 cm (39 inches)

Wheelbase: 111.8 cm (44 inches)

Weight: 461.8 kg (1236 pounds)

Optional Accessories:

5/8" Tine Part No. 59-3670

1/2" Tine Part No. 94-3419

3/8" Tine Part No. 59-3690

3/8" Slotted Tine Part No. 94-3418

5/8" Long Wear Tine Part No. 59-9770

5/16" Solid Spiker Tine Part No. 77-5320

*3/4" Tine Part No. 62-4600

*3/4" Slotted Tine Part No. 92–7941

*Tine Block Part No. 62-4610

3/8" Slotted Tine Kit Part No. 94-6814

1/4" Spiker Tine Kit Model 09153

Windrower Model 09150

Coring Head Stand Model 09152

Tire Scrapers Model 09151

*3/4" tines requires 8 optional Tine blocks

7

Specifications

8

ACTIVATE AND CHARGETHE

BATTERY

1. Since the battery is not filled with electrolyte or acti-

vated, bulk electrolyte with 1.260 specific gravity

must be purchased from a local battery supply outlet.

2. Remove the wing nuts and washers securing the bat-

tery clamp to the battery bolts and remove the battery

from the machine. Remove the filler caps from the

battery and slowly fill each cell until electrolyte is

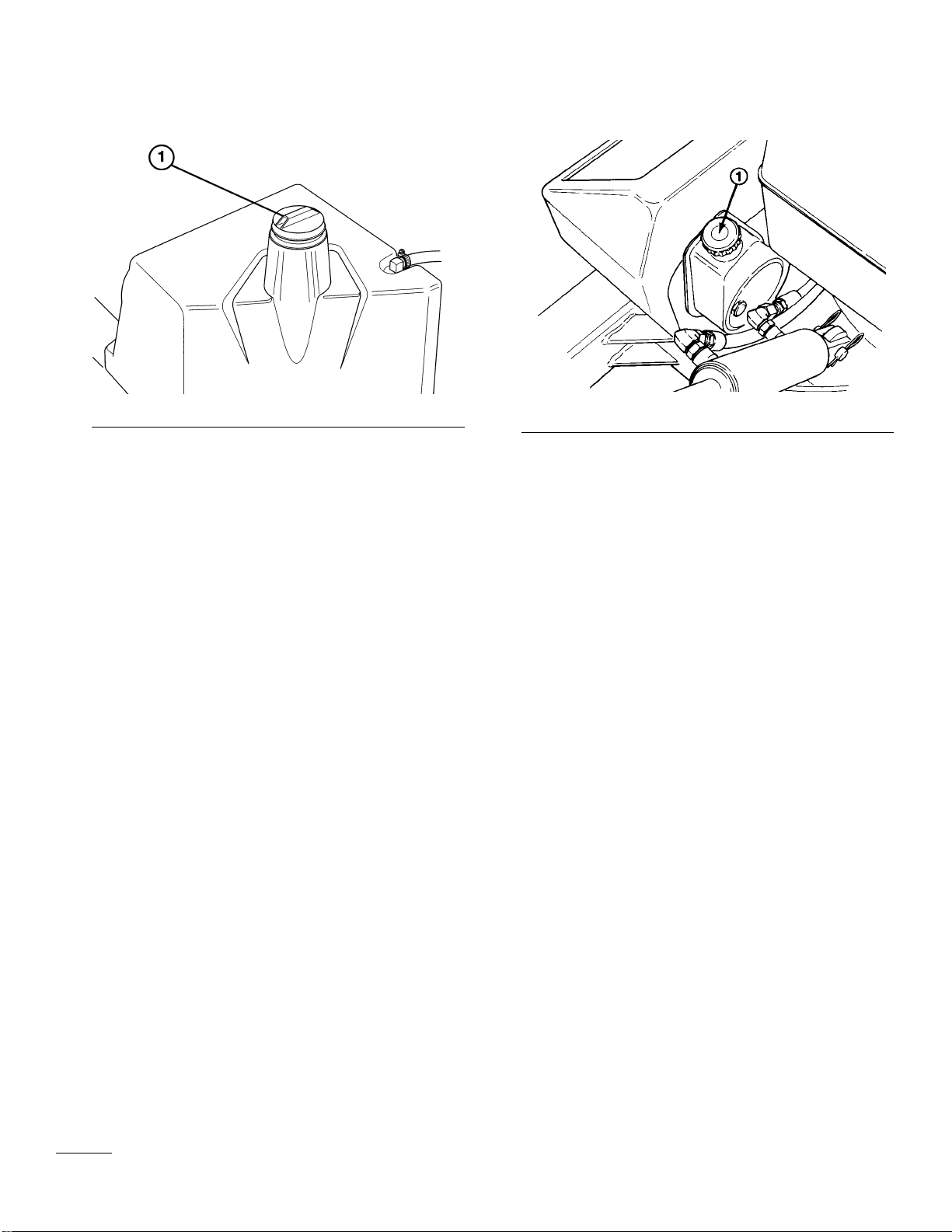

just above the plates (Fig. 1)

Figure 1

1. Wing nuts & washers 3. Battery pad

2. Battery clamp 4. Support rods

3. Replace filler caps and connect a 3- to 4-am battery

charger to the battery posts. Charge the battery at a

rate of 3 to 4 amperes for 4 to 8 hours.

4. When the battery is charged, disconnect the charger

from the electrical outlet and battery posts.

5. Remove the filler caps. Slowly add electrolyte to each

cell until the level is up to the fill ring. Install the

filler caps.

Important: Do not over-fill the battery. Electrolyte

will overflow onto other parts of the machine and

sever corrosion and deterioration will result.

6. Mount the battery on the battery pad with the termi-

nal posts toward the rear of the machine.

7. Secure the battery with the battery bolts, clam, wash-

ers and wing nuts (Fig 2).

8. Install the positive cable (rubber boot over the end) to

the positive terminal and the negative cable (black to

the negative terminal of the battery and secure with

carriage bolts, lockwashers and nuts. Slide the rubber

boot over the positive terminal to prevent possible

short-out.

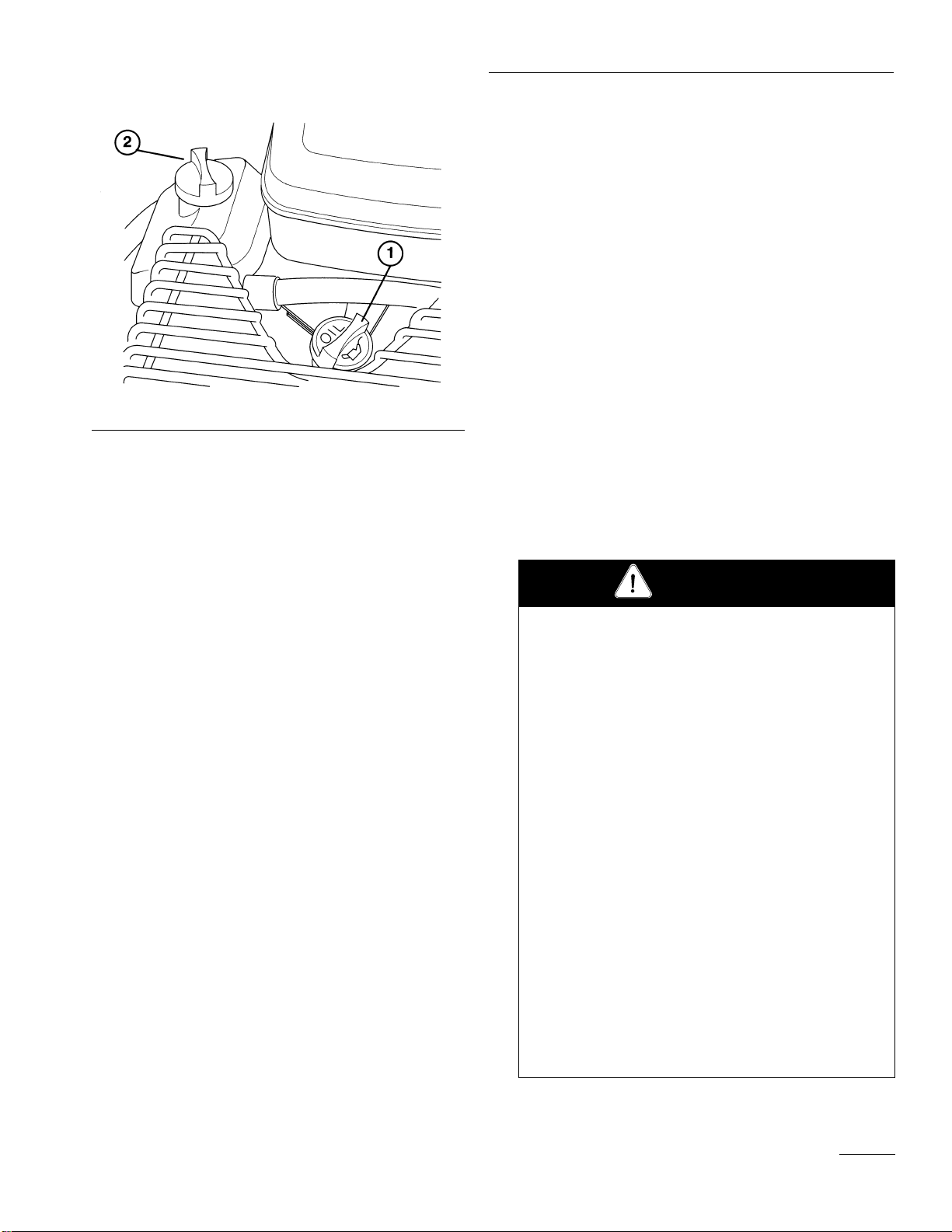

CHECKTHE CRANKCASE OIL

The engine is shipped with 1.5 l of oil in the crankcase;

however, the oil level must be checked before and after the

engine is first started.

1. Position the machine on a level surface.

2. Remove the dipstick and wipe it with a clean rag.

Push the dipstick down into the dipstick tube and

make sure it is seated fully. Pull the dipstick out and

check the level of oil (Fig. 2). If the oil level is low,

add enough oil to raise the level to the FULL mark

on dipstick.

Before Operating

Wear safety goggles and rubber gloves when work-

ing with electrolyte. Charge the battery in a well-

ventilated place so gases produced while charging

can dissipate. Since the gases are explosive, keep

open flames and electrical spark away from the bat-

tery; do not smoke.

Nausea may result if the gases are inhaled. Unplug

the charger from the electrical outlet before connect-

ing or disconnecting charger leads.

CAUTION

Before Operating

9

Figure 2

1. Dip stick 2. Filler cap

3. Remove the filler cap and pour oil into the filler neck

until the level is at the FULL mark on the dipstick.

The engine uses any high-quality oil having the

American Petroleum Institute—API- “service classifi-

cation” SF. Oil viscosity—weight —must be selected

according to ambient temperature. Temperature/ vis-

cosity recommendations are:

A. Above +32°F (0° C)—Use SAE 30, and if it is

not available, 10W-30 or 10W-40 are acceptable

substitutes.

B. Below +32°F (0° C)—Use SAE 5W-20 or 5W-

30, and if they are not available. 10W30 or

10W-40 are acceptable substitutes.

IMPORTANT: Check the oil level every eight (8)

operating hours or daily. Initially, change the oil

after the first 8 hours of operation; thereafter,

under normal conditions, change the oil after each

50 hours of operation and the filter after every 100

hours of operation. However, change the oil more

frequently when the engine is operated in extreme-

ly dusty or dirty conditions, under heavy load or

in high ambient temperatures.

FILLTHE FUELTANK WITH

GASOLINE

This engine is certified to operate on unleaded gasoline.

Use clean, fresh, unleaded gasoline with a minimum of 85

octane. Do not mix oil with gasoline. Purchase fuel in

quantity that can be used within 30 days to assure fuel

freshness. Use Briggs & Stratton Gasoline Additive (See

your authorized Briggs & Stratton Service Dealer for Part

No. 5041 or the single-use pouch.)

In countries other than the U.S.A., leaded gasoline may

be used if it is commercially available and unleaded is

unavailable.

Note: Some fuels called oxygenated or reformulated

gasolines, are gasoline blended with alcohols or ethers.

Excessive amounts of these blends can damage the fuel

system or cause performance problems. Do not use

gasoline which contains Methanol. If any undesirable

operating symptoms occur, use gasoline with a lower

percentage of alcohol or ether.

1. Remove the cap from the fuel tank (Fig. 2) and fill

the 4.5 gallon tank to within 1 inch from the top with

unleaded gasoline. Install the fuel tank cap tightly.

Because gasoline is flammable, use caution when

storing or handling it. Do not fill the fuel tank

while the engine is running, hot or when the

machine is in an enclosed area. Vapors may build

up and be ignited by a spark or flame source many

feet away. DO NOT SMOKE while filling the fuel

tank to prevent the possibility of an explosion.

Always fill the fuel tank outside and wipe up any

spilled gasoline before starting the engine. Use a

funnel or spout to prevent spilling gasoline before

starting the engine and fill the tank to about 1 inch

(25 mm) below the filler neck. Store gasoline in a

clean safety-approved container and keep the cap in

place on the container. Keep gasoline in a cool,

well-ventilated place; never in an enclosed area such

as a hot storage shed. To assure volatility, do not

buy more than a 30-day supply of gasoline.

Gasoline is a fuel for internal combustion engines;

therefore, do not use it for any other purpose. Since

many children like the smell of gas, keep it out of

their reach because the fumes are explosive and dan-

gerous to inhale.

DANGER

10

Figure 3

1. Vented fuel tank cap

2. To prevent a fire hazard, wipe up gasoline that may

have spilled.

CHECK HYDRAULIC SYSTEM

FLUID

The hydraulic system is designed to operate on SAE 10

W-30 engine oil or, as a substitute, SAE 10 W-40 engine

oil. The machine’s reservoir is filled at the factory with

2.7 pints of SAE 10 W-30 engine oil. However, check the

level of hydraulic fluid before the engine is first started

and daily thereafter.

1. Position the machine on a level surface and raise the

coring head to the full up position.

2. Remove the dipstick cap (Fig. 4) from the filler neck

and wipe it with a clean cloth. Insert the dipstick cap

into the filler neck; then remove it and check the level

of fluid. If the level is not within 1.25 cm (1⁄2inch)

from the full mark on the dipstick, add SAE 10W-30

engine oil to raise the level to full mark. Do not

overfill.

3. Install the dipstick filler cap onto the filler neck.

4. Run the engine for one minute, recheck the level of

fluid and add oil as needed.

Figure 4

1. Dip stick cap

11

Ignition Switch (Fig. 5)—The ignition switch, which is

used to start and stop the engine, has three positions: OFF,

ON and START. Rotate key clockwise—START posi-

tion—to engage starter motor. Release key when the

engine starts. The key will automatically return to the ON

position. To shut the engine off, rotate key counter-

clock–wise to the OFF position.

Choke (Fig. 5)—To start a cold engine, close the carbure-

tor choke by pulling the choke control outward to the ON

position. After the engine starts, regulate the choke to

keep the engine running smoothly. As soon as possible,

open the choke by pushing it inward to the OFF position.

A warm engine requires little or no choking.

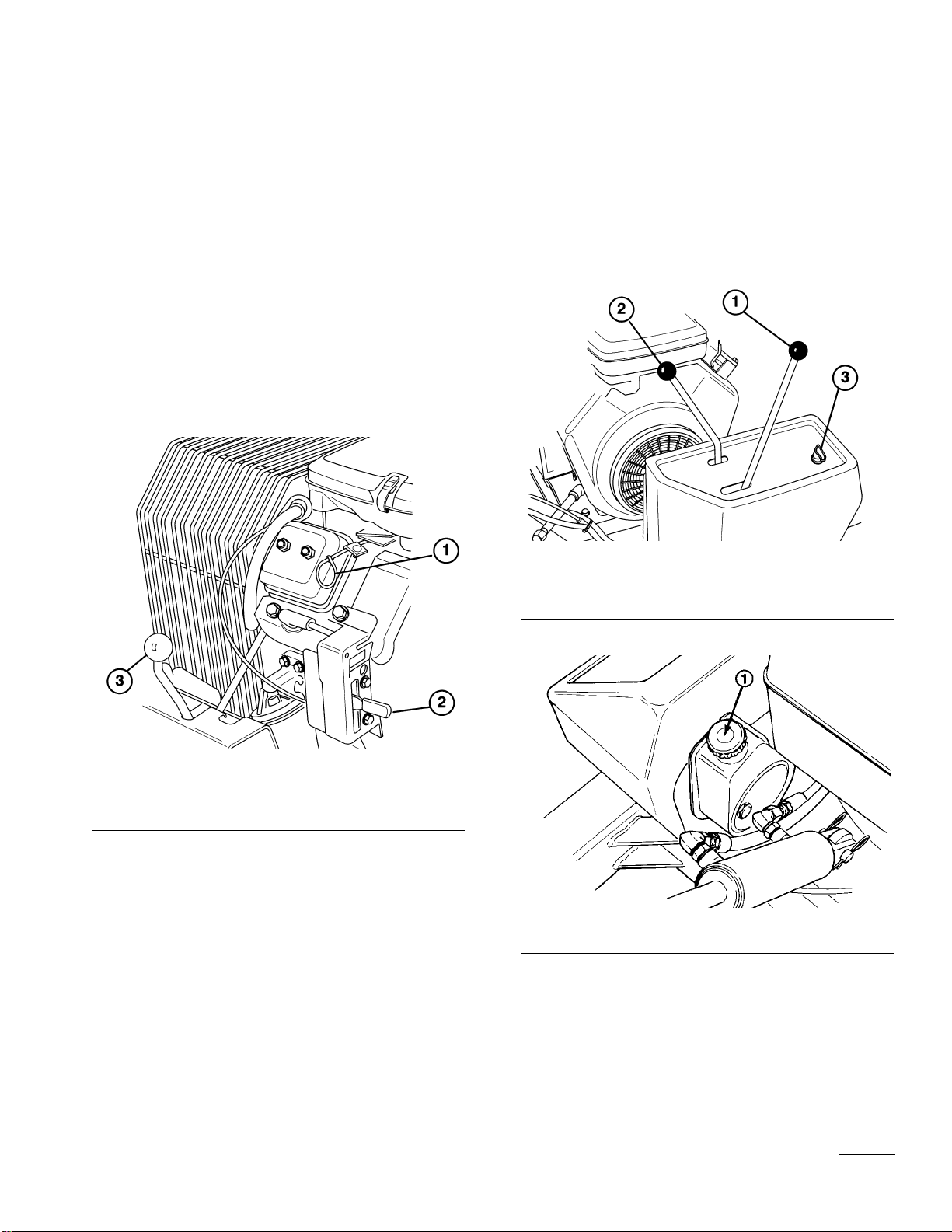

Figure 5

1. Choke

2. Throttle

3. Gear shift lever

Throttle (Fig. 5)—The throttle is used to operate the

engine at various speeds. Moving the throttle upward

increases engine speed—FAST; rearward decreases engine

speed—SLOW. The throttle controls the speed of the cor-

ing head and, in conjunction with traction clutch, controls

the ground speed of the machine.

Gear Shift Lever (Fig. 5)—The transmission has two for-

ward speeds, neutral and reverse, and has an inline shaft

pattern. Do not shift while unit is moving, because trans-

mission damage may occur.

Traction Drive Lever (Fig.6)—Shift to the desired gear

and move the traction drive lever to the engage position to

move forward or reverse. One of the hand-operated inter-

lock levers (Fig. 7).

Coring Head Lever (Fig. 6)—Raises and lowers the cor-

ing head and engages and disengages the drive.

Figure 6

1. Traction drive lever

2. Coring head lever

3. Ignition switch

Figure 7

1. Interlock lever switches 2. Service brake

Interlock Lever Switches (2) (Fig. 7)—Switches permit

engine operation when the coring head is lowered. They

also hold the traction drive lever in the engaged position.

One handle switch must be activated before engaging the

traction drive or lowering the coring head when engine is

running.

C

on

t

ro

l

s

12

Operating

Service Brake (Fig. 7)—Used to slow the traction opera-

tion.

STARTING/STOPPING ENGINE

1. Make sure both wires are installed on the spark plugs.

2. Make sure the traction drive is disengaged and the

gear shift lever is in Neutral.

3. Pull the choke lever out to the ON position—when

starting a cold engine—and the throttle lever to the

mid position.

4. Insert the key into the ignition switch and turn it

clockwise to start the engine. Release the key when

the engine starts. Gradually return the choke lever to

the OFF position (lever all the way in) after the

engine starts and warms up.

IMPORTANT: To prevent overheating of the

starter motor, do not the starter longer than 10 sec-

onds. After 10 seconds of continuous cranking,

wait 60 seconds before engaging the starter again.

5. Make sure the coring head is in the raised position.

Note: When starting the engine for the first time, or

after engine, transmission or axle overhaul, operate

the machine in forward and reverse for one to two

minutes to be sure all parts operate correctly.

6. To stop the engine, move the throttle control down-

ward to the SLOW position and turn the ignition key

to “OFF”,

INSTALLTHE TINES

1. Start the engine: refer to Starting/Stopping instruc-

tions.

2. Move the coring head lever to the “UP” position to

raise the coring head.

3. Stop the engine and raise the lock-up brackets on

each side of the chassis (Fig. 8). Lower the coring

head until it rests on brackets.

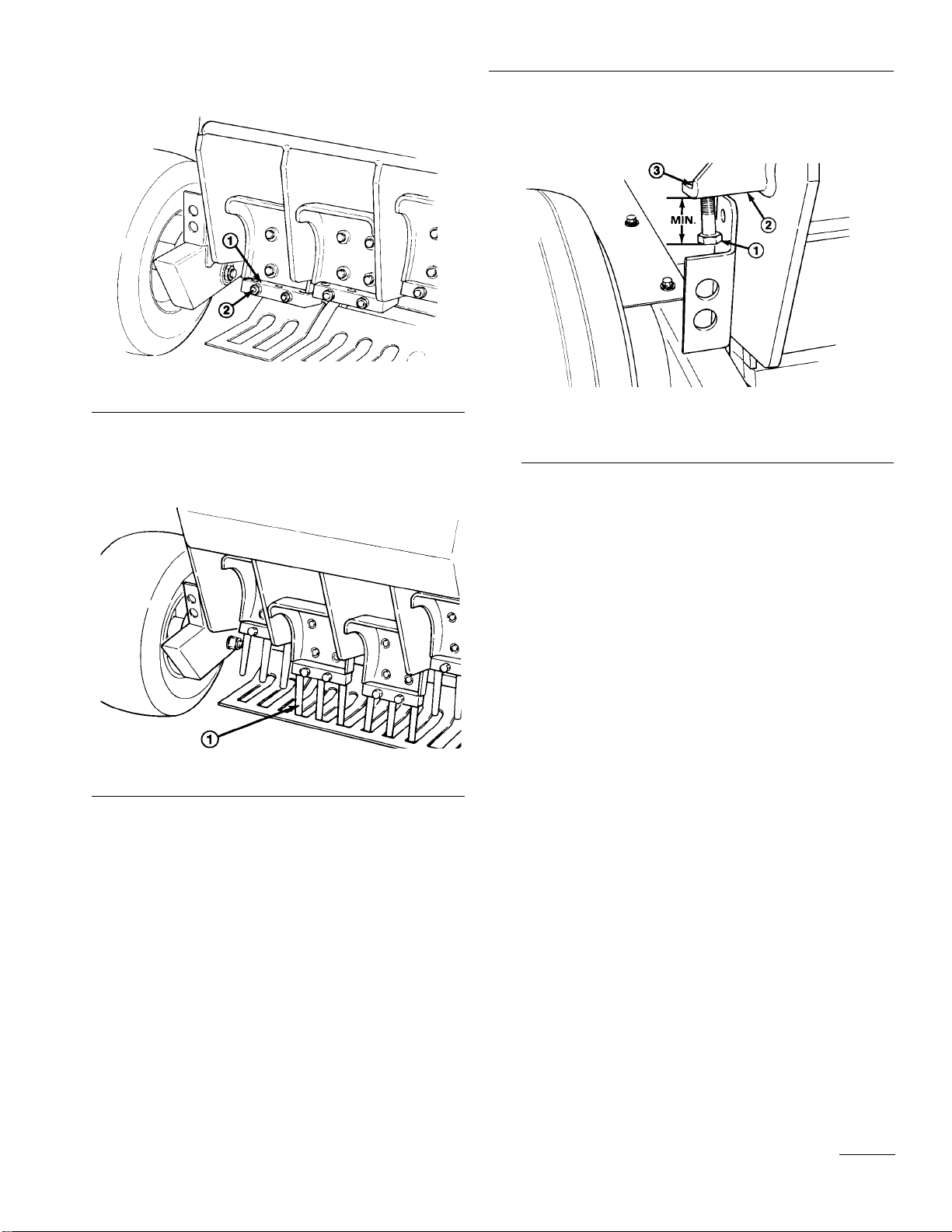

Figure 8

1. Lock-up bracket

4. Loosen (2) hex nuts on each tine block until tines can

be inserted. Insert tines until they bottom out on the

flange in the tine block (Fig. 8).

Operating Instructions

Operating

13

Figure 9

1. Tine block

2. Mounting nut

5. Tighten the mounting nuts to 100-110 ft/lb. torque

(Fig. 10).

Figure 10

1. Tine

ADJUSTTHE CORING DEPTH

1. Raise the coring head and engage the lock-up brack-

ets.

2. Loosen the jam nut on top of the adjusting bracket

(Fig. 11).

3. Thread the adjusting screw into the bracket to

increase coring depth. Thread it out to decrease

depth (Fig.11).

4. Repeat this procedure using the long end of the

height gauge on each rear wheel spindle (Fig. 13).

Figure 11

1. Coring depth adjustment screw

2. Adjusting bracket

3. Jam nut

5. Best recommended coring depth is achieved when the

distance from the end of the screw head to the brack-

et is 11⁄16” (Fig. 11).

IMPORTANT: Do not adjust the screw to a setting

less than 11⁄16” or damage to turf guards may

occur.

6. Make sure adjustments are the same on both sides of

the coring head and tighten the jam nuts.

CHECK FRAME HEIGHT

1. Position the machine on a level surface.

2. Slide the short end of the frame height gauge under

the front axle to verify height. The gauge should

contact the axle when on the floor. Check both sides

(Fig. 12).

14

Operating

Figure 12

1. Front axle 2. Height gauge

3. Increase or decrease tire pressures to attain the

required height.

4. Repeat the procedure using the long end of the height

gauge on each rear wheel spindle (Fig. 13).

5. Regulate tire pressure as required.

Figure 13

1. Rear wheel spindle

2. Height gauge Regulate tire pressure as required.

OPERATING PROCEDURE

1. Make sure wire is installed on spark plug and fuel

valve is open.

2. Start the engine: refer to Starting/Stopping instruc-

tions.

3. Make sure coring head is in the up position.

4. Squeeze left interlock lever against handle.

5. Move shift lever to “L” (low) for Coring or “H”

(high) for Transport.

Note: If you encounter resistance during gear selec-

tion, jog the clutch handle until the gears align. Do

not shift gears while machine is moving. DO NOT

FORCE SHIFT LEVER AS DAMAGE WILL

OCCUR.

6. Move traction drive lever to engage position.

7. To engage and lower coring head, move coring head

lever to down position and hold until coring head is

completely lowered.

CHECK INTERLOCK SYSTEM

The safety interlock system’s purpose is to prevent the

engine from cranking or starting unless the traction drive

lever is disengaged and the coring head is raised. It also

interrupts engine operation if a handle-mounted interlock

lever is not activated when the coring head is lowered.

To check the interlock system:

1. Position the machine on a flat, open area. Start the

engine; refer to Starting and Stopping instructions.

2. Check the clutch switch (Fig. 14) with a continuity

tester or ohm meter and replace it if damaged. The

switch must be closed when the gear shift lever is in

a gear. The switch must open when shifting between

Neutral, First, and Second gears.

3. To adjust the switch, loosen the mounting screws and

reposition the switch as required.

4. If the coring head is in the raised position and the

engine will not start, or continues to run when the

coring head is down and the interlock lever(s)

released, there is a defect in the interlock system, pro-

ceed to step 5.

5. Check the coring head switch (Fig. 15) with a conti-

nuity tester or ohm meter and replace if damaged.

The switch plunger must be depressed when the cor-

ing head is in the raised position.

Operating

15

Note: Before coring head switch can be adjusted,

coring head drive belt must be correctly adjusted..

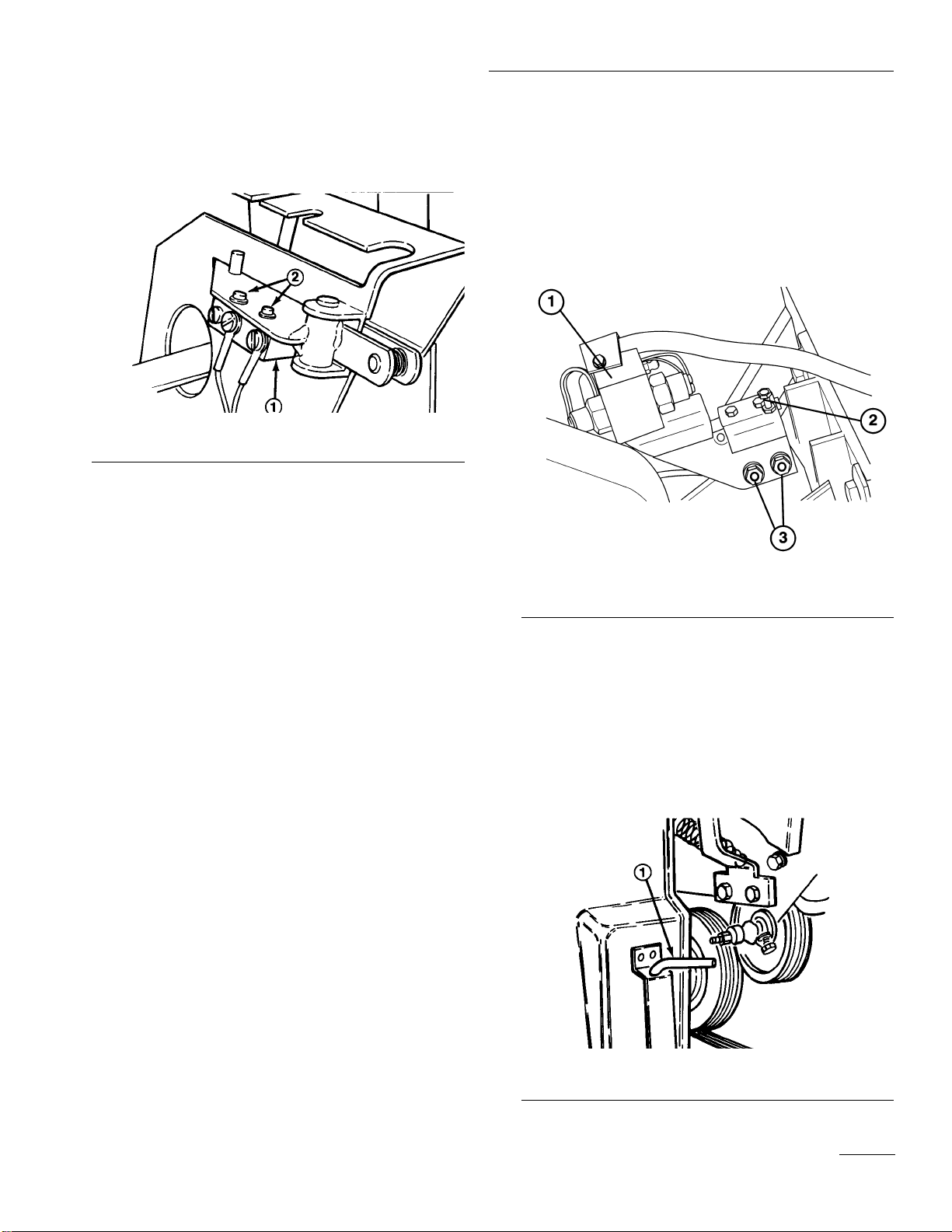

Figure 14

1. Traction switch

2. Mounting screws

6. If an adjustment to the switch is required, proceed as

follows:

A. Stop the engine and lower the coring head onto

the stand.

B. Remove the override pin from the storage brack-

et on the front of the coring head cover

(Fig. 16).

C. Push down on the override lever (Fig. 14) until

the holes in lever bracket and the coring bracket

are aligned, then insert the pin through the

holes.

D. Loosen the adjusting screw jam nut and (2)

flange nuts (Fig. 12).

E. Turn the ignition switch to the START position,

but do not start the engine.

F. While holding the ignition switch in the START

position, tighten the adjusting screw until the

engine cranks.

G. Release the ignition switch and tighten the

adjusting screw one more turn.

H. Tighten the adjusting screw jam nut and (2)

flange nuts.

I. Restart the engine and raise the coring head.

J. Stop the engine, remove the override pin and

reinstall it in the storage bracket.

K. Start the engine and check all modes of opera-

tion. The coring head should not run when on

coring head lock-up brackets.

Figure 15

1. Coring head switches

2. Adjusting screw & jam nut

3. Mounting screws

OVERRIDE SYSTEM

The coring head is equipped with a release mechanism

that allows the engine to be started when the coring head

is in the lowered position.

1. Remove override pin from storage bracket on front of

coring head cover (Fig. 16).

Figure 16

1. Override pin

16

Operating

2. Push down on override lever until holes in lever

bracket and coring head are aligned, then insert pin

through holes (Fig. 17).

Figure 17

1. Override lever

2. Lever bracket

3. Override pin

3. Restart the engine and raise the coring head.

4. Stop the engine, remove the pin and reinstall in stor-

age bracket.

TRAINING PERIOD

Before aerating greens with the Greens Aerator, find a

clear area and practice starting and stopping, raising and

lowering coring head, turning, etc. This training period

will help the operator gain confidence in the performance

of the Greens Aerator.

BEFORE AERATING

Inspect the green for debris and determine the best direc-

tion and pattern to operate machine.

AERATING PROCEDURES

1. Approach the green with the gear shift lever in the

“L” (low) position.

2. Lower the coring head after you attain the desired

starting position. Make sure the coring head is

engaged before the tines are within one inch of the

turf.

3. Use the rubber guides hanging from front of chassis

to align rows.

TRANSPORT OPERATION

Make sure the coring head is in the up position and the

coring head lock-up brackets are up. Set the gear shift

lever in the “H” (high) position if faster ground speed is

required. Use the service brake to slow the machine while

going down steep hills to avoid loss of control. Always

approach rough areas at a reduced speed and cross severe

undulations carefully.

INSPECTION AND CLEAN-UP

AFTER USE

At completing operation, thoroughly wash the machine

with a garden hose without a nozzle so excessive water

pressure will not cause contamination and damage the

seals and bearings. After cleaning, inspect the machine

for possible hydraulic fluid leaks, damage or wear to

hydraulic and mechanical components and check the tines

for sharpness.

Always have the coring head fully raised when

transporting and fully lowered when coring so the

safety interlock system functions correctly. If the

coring head lowers by itself, correct this malfunc-

tion before continuing operation.

CAUTION

Lubrication

The Greens Aerator has grease fittings that must be lubri-

cated daily with No. 2 General Purpose Lithium Base

Grease. Damper pivots must be lubricated every 4 hours

of operation.

The bearings and bushings that must be lubricated are:

front wheels (Fig. 18), rear wheel spindles (Fig. 19), front

handle shaft (Fig. 20), damper pivots (4) (Fig. 21), traction

roller latch pin (Fig. 22) speed control lever (Fig 23) and

coring head switch (Fig. 24).

Figure 18

Figure 19

Figure 20

Figure 21

Figure 22

Figure 23

Figure 24

17

Maintenance

18

Maintenance

✓Safety interlock operation

✓Brake operation

✓Fuel level

✓Engine oil

✓Frame height

✓Air Filter/pre-cleaner condition

✓Clean the engine cooling fins

✓Hydraulic system oil level

✓Unusual operating noises

✓Tine & stomper arm condition

✓Hydraulic hoses for damage

✓Fluid leaks

✓Tire pressure

✓Instrument operations

✓Tighten loose fasteners

✓Lubricate dampener pivots1

✓Lubricate all grease fittings1

✓Touch-up damaged paint

1 = Immediately after every washing, regardless of the

interval listed

Maintenance Procedure Maintenance Interval & Service

✝Initial break in at 8 hours

Change the engine oil filter

Service the spark plugs

Grease the wheel bearing

Grease the steering handle spindle

Check the battery fluid level

Check the battery cable connections

Check the coring head chain tension

Check the hydraulic pump belt tension

Replace safety switches

Change transaxle gear lubricant

Replace the hydraulic oil

Adjust the valves and torque the head bolts

Decarbon the combustion chamber

✝Change the engine oil

Service the air filter cartridge

Lubricate the coring head switch assembly

Service the Air Filter Pre-Cleaner

Lubricate the Dampener Pivots

Check the condition of the tines

Check the engine oil level

Every

50 hours Every

100 hours

Every

25 hours

Every

5hours

Minimum Recommended Maintenance Intervals

Annual Recommendations:

Items are recommended every 500 hours or

one year, whichever occurs first.

Check Daily:

Maintenance

19

ENGINE CARE

The Engine Manual supplied with your Greens Aerator

provides the maintenance procedures for service of the air

cleaner, oil requirements, ignition components, etc.

Note: If the Greens Aerator is to be operated at altitudes

of 3000 feet or above sea level, it may require a high alti-

tude carburetor main jet. Order Part No. 8055537 from

your Authorized Briggs & Stratton Service Dealer.

CHANGING HYDRAULIC SYSTEM

OIL

The hydraulic system oil must be changed immediately

when any contamination, sludge, water or condensation

appears.

1. Remove the tines from the tine blocks and lower the

coring head; refer to Install Tines.

2. Position a drain pan under the chassis below the

pump assembly (Fig. 25).

3. Remove the hose clamp securing the return hose to

the pump. Disconnect the hose from the pump, allow-

ing oil to flow into the drain pan.

4. Connect the return hose to the pump and secure it

with the hose clamp.

Figure 25

1. Pump reservoir

5. Fill pump reservoir; refer to Checking Hydraulic

System Fluid.

6. Check all connections for possible leaks.

CHANGINGTRANSAXLE OIL

Each year oil in transaxle must be changed. If possible,

run the machine just before changing oil. Warm oil flows

more freely and carries more contaminants than cold oil.

1. Place a drain pan below the drain plug on the axle.

Clean the area around the drain plug (Fig. 26).

Figure 26

1. Drain plug

2. Fill plug

2. Remove the drain plug and allow oil to flow into the

drain pan. After oil is drained, install the drain plug.

3. Remove the fill plug (Fig. 26) and pour approx. 1.89 l

(64 oz.) of SAE E.P. 90 wt. oil into the extension

tube. Stop when the oil level reaches the top of the

tube.

4. To check the oil level in the future: remove the plug

and add oil as required to bring the level to the top of

the tube.

Before servicing or making adjustments to the machine,

stop engine and remove key from the switch.

CAUTION

20

Check front and rear

axle heights Check engine RPM

(3600 max, no load)

Bent, worn, loose or

plugged tines or

loose tine holder

Check gear selec-

tion

Depth-adjustment

bolts set equally

Adjust axle height

using height gauge.

(Regulate tire pres-

sure).

Adjust RPM using

tachometer.

Unplug, tighten, or

replace tines or

tighten tine holder

Coring to be done in

“L” (low) gear

Adjust depth bolts

Check freeplay in tine

arm and crank bear-

ings.

Check coring head

chain tension.

Check coring head

timing.

Loose coring head

pivot points.

Check damper

length and freeplay

in bushings and

bearings.

Replace bearings Adjust chain.Adjust timing.

Tighten or replace if

bent or damaged.

Make sure damper

is adjusted to cor-

rect specification.

Check wheel assem-

blies for loose bear-

ings or tire runout.

Replace bearings or

tires.

Hole QualityTrouble Shooting

Other manuals for GREENS AERATOR 09120

1

Table of contents

Other Toro Tiller manuals

Popular Tiller manuals by other brands

WOLSELEY

WOLSELEY Merry Tiller Major Instructions for operation and use

Gearmore

Gearmore ARENA-VATOR III AV3-4 Assembly/operators/parts manual

Cub Cadet

Cub Cadet FT 24 R Front-Tine Garden Tiller Operator's manual

Craftsman

Craftsman Incredi-Pull 316.29256 Operator's manual

AL-KO

AL-KO BF 5002R user manual

Craftsman

Craftsman 917.293482 owner's manual

MTD

MTD 216-100A Owner's operating service instruction manual

Stiga

Stiga SILEX 75-G Instructions for use

Villager

Villager VTB 375 Original instruction manual

SNOWJOE

SNOWJOE sunjoe 24V-TLR-SJG-RM Operator's manual

Craftsman

Craftsman 247.29933 Operator's manual

McCulloch

McCulloch 532 43 21-09 Operator's manual