Toro 08720 User manual

Other Toro Tractor Accessories manuals

Toro

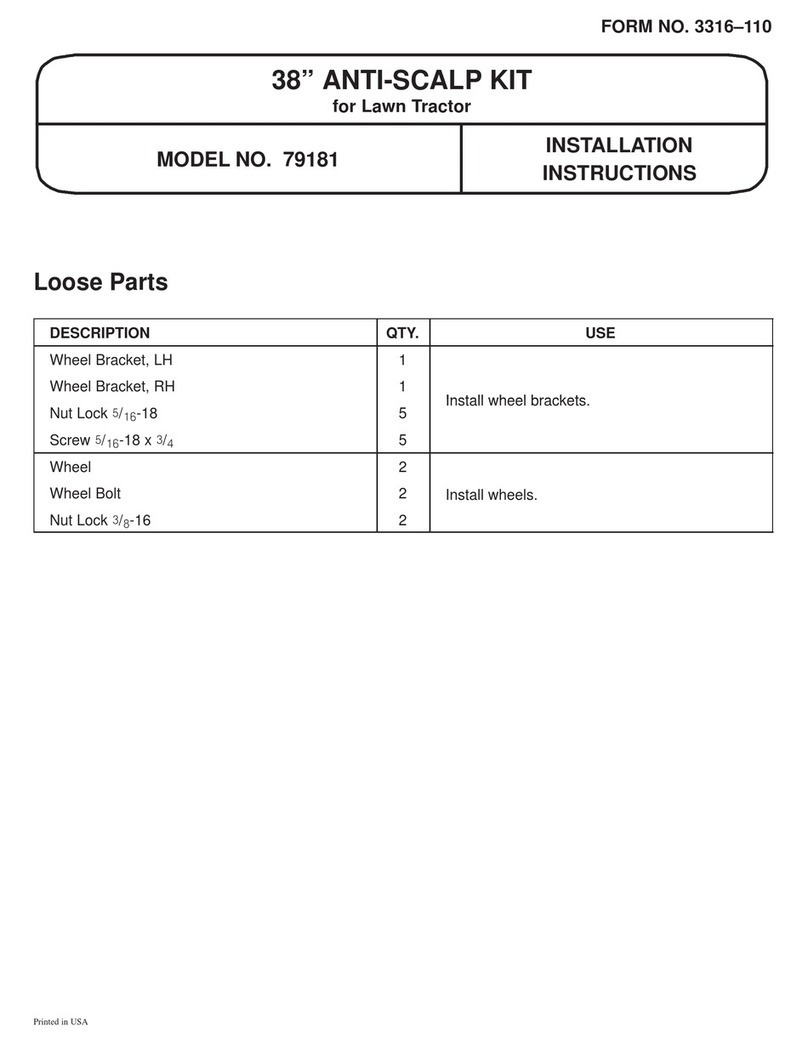

Toro 79181 User manual

Toro

Toro 119-9604 User manual

Toro

Toro 04504 User manual

Toro

Toro Sitework Systems 22420 User manual

Toro

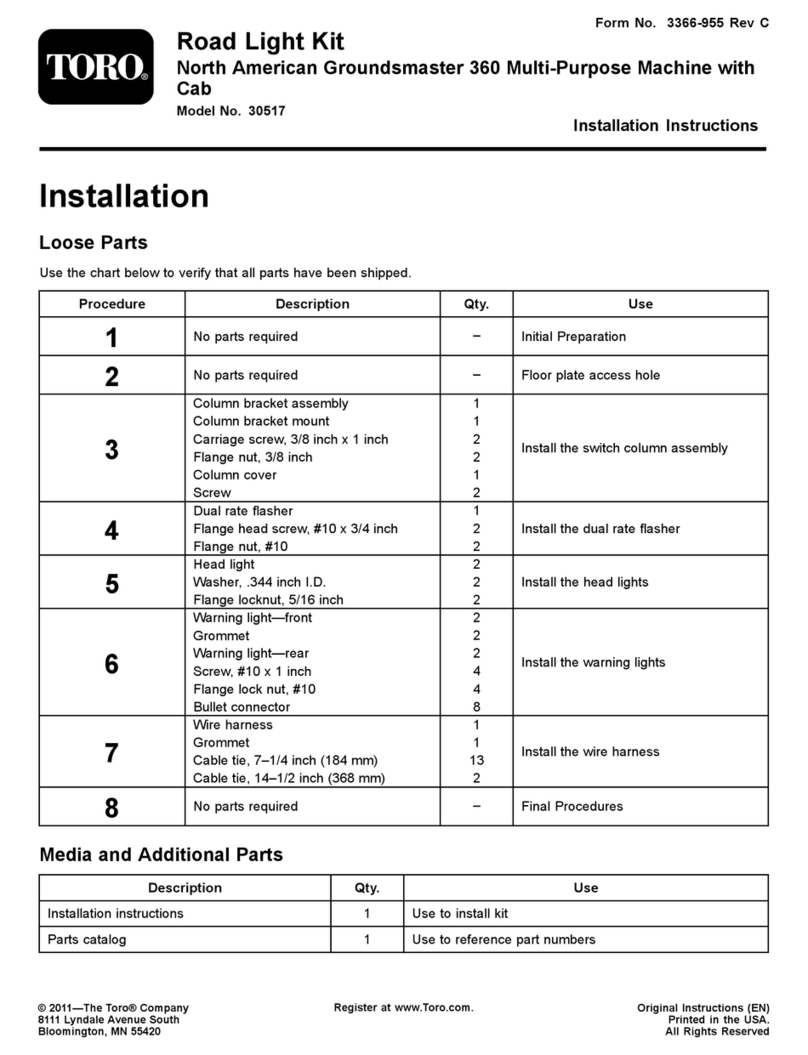

Toro 30517 Instruction Manual

Toro

Toro BU-003867 User manual

Toro

Toro Direct Drive Power Box Rake User manual

Toro

Toro Wheel Horse XT Series User manual

Toro

Toro 04720 User manual

Toro

Toro Field Pro 604 User manual

Toro

Toro Greensmaster 04654 Series User manual

Toro

Toro Z MASTER 79402 User manual

Toro

Toro 30728 User manual

Toro

Toro 04651 User manual

Toro

Toro 136-6311 User manual

Toro

Toro 25427 User manual

Toro

Toro Greensmaster TriFlex 3300 Series User manual

Toro

Toro 23172 User manual

Toro

Toro Wheel Horse 79361 User manual

Toro

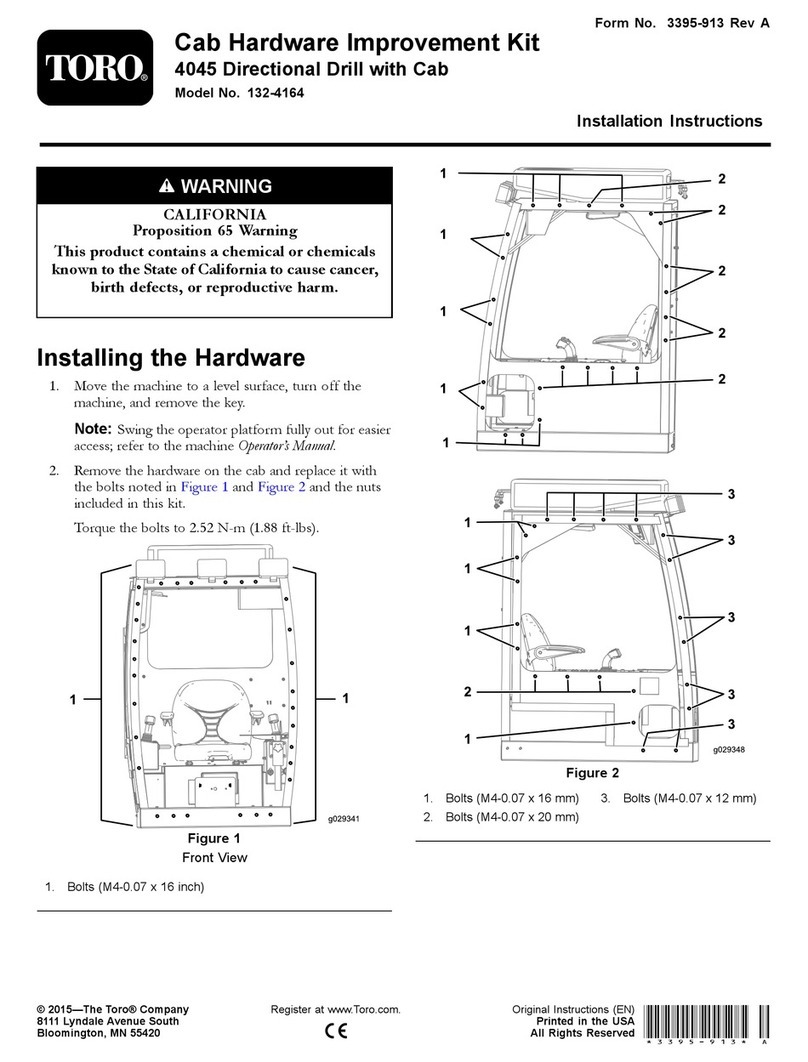

Toro 132-4164 User manual

Popular Tractor Accessories manuals by other brands

Original Tractor Cabs

Original Tractor Cabs 4421381 Assembly instructions and parts list

Grouser Products

Grouser Products 760 Owner's manual & parts book

Degelman

Degelman Landroller Operator's & parts manual

Bush Hog

Bush Hog BS1 Series Operator's manual

MX

MX MX A104 user manual

Bush Hog

Bush Hog DSP8 Operator's manual