TPI The Value Leader 716 User manual

TPI 716

Flue Gas Analyser

The Value LeaderTM

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Contents

Introduction........................................................1

General Overview.................................................1, 2

Instrument Overview............................................. 3 ~ 7

Front View...............................................3

Keypad...................................................4

Back View...............................................5

Side Views..............................................6

Top View................................................ 7

Basic Analyser Functions....................................... 8 ~ 10

Charging The Analyser................................8

Turning The Analyzer On ............................ 9 & 10

easurements.................................................... 11 ~ 24

Flue Gas................................................ 11 ~ 17

Temperature & Pressure.............................18 ~ 20

CO Room Test..........................................21

Tightness Test......................................... 22 & 23

Combustible Gas Leak Detection...................24

enu Navigation................................................. 25 ~ 28

emory................................................ 25

Fuel Type................................................26

Analyzer Setup.........................................27

Units of easure, Instrument Info................. 28

Turning The Analyzer Off........................................29

Specifications..................................................... 30 & 31

Calibration & Service............................................ 32

Warranty........................................................... 32

Appendix A General aintenance & Function Tests............32 ~ 35

Appendix B Error Codes and Troubleshooting....................36 & 37

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Introduction

Thank you for purchasing TPI brand products. The TPI 716 Flue Gas

Analyser is a state of the art, easy to use analyser designed not only to

display and calculate the required readings from a flue but also to cover

most of the other measurements associated with combustion. The

instrument is ruggedly constructed and comes with a 6 Year Guarantee

subject to annual servicing being carried out by TPI or one of their

approved service centres.

General Overview

The following guidelines will help prevent damage to your sensors:

Always use the mini pump filter when testing flue gases.

Periodically check and replace the mini pump filter as needed.

Always make sure the in-line filter / water trap is installed properly.

Periodically check and replace the in-line filter as needed.

Always remove water or condensation from the inside of the in-line

filter / water trap assembly prior to performing tests.

Always use the optional oil filter (p/n A773) when performing tests on oil

burning equipment unl ss you ar using th 716 with an NO

s nsor fitt d. Do not us th A773 on th 716 with NO s nsor fitt d

b caus th A773 will filt r out Nitric Oxid (NO).

Never over saturate your sensors by performing tests on equipment with

gas levels beyond the capability of you analyser.

Always keep the A796 water trap / filter assembly clean & dry and replace

the internal filter as necessary. (Replacement filter part number is A796-F.)

1

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

General Overview (Continued)

This manual will guide you through the functions of the TPI 716 which will

give you many years of reliable service.

Your TPI 716 Flue Gas Analyser comes complete with the following

standard accessories:

( ) Denotes part number

• TPI 716 Analyser

• Rubber Boot (A765) 1 each installed on analyser

• Soft Carrying Case (A768) - 1 each

• Flue Sampling Probe (A770) - 1 each

• In-Line Filter / Water Trap installed on Flue probe (A796) - 1 each

• Disc water filter installed in water trap (A796W) - 1 each

• Spare In-Line Filter - 1 each (A796F is a package of 10 filters)

• Temperature Probe (GK11M) - 1 each

• Battery Charger (A766) - 1 each

• Mini Pump Protection Filter Assembly (A763) - 1 each

• xhaust Spigot Removable (A764) - 1 each

• Pressure Adaptors - Pair (A772) - 1 pair

• PC Software and cable for communication to a PC (A807).

• Instruction Manual

Your TPI 716 Flue Gas Analyzer has the following options/upgrades

available:

• Plug-In Combustible Gas Sniffer Leak Probe (716-Leak)

• Upgrade to Bluetooth connectivity (716-BT)

• Upgrade to NO sensor for Calculated NOx (716-NO)

• Upgrade to High CO Sensor-up to 10% range (716-HCO)

• Infra Red Printer (A740)

• Temperature Pipe Clamps - pair (CK21M/Pair)

• CPA1 Probe Kit (CPK3)

• Smoke Pump (A788)

• Oil (Sulfur) Filter (A773)

2

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Instrument Overview

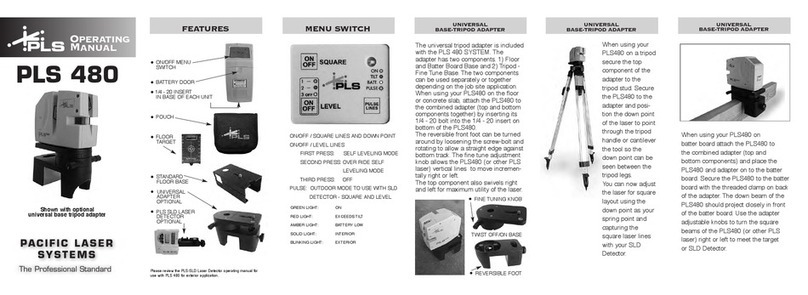

Front View

Rubber Boot Protects the instrument from accidental damage

Display Large graphical backlit LCD Display

Keypad Selects all available functions

Rubber

Boot

LCD

Display

Keypad

3

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Keypad

4

Blue Soft Keys - The function of these keys is shown in the

lower part of the display and changes depending on what

menu the analyser is in.

In the picture center soft key controls the start function and

the left and right soft keys are disabled.

Up Arrow Key -

This key is used

to scroll up in

menus.

Down Arrow

Key - This key

is used to scroll

down in menus.

Home Key - This key is

used to return to the

Main Menu from any

other menu.

Back Key - This key is

used to go back one

menu level.

On/Off Key - This key is

used to turn the analyser

on and off.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Back View

Calibration and Information Label: Displays calibration information and

serial number

Battery Compartment: Holds rechargeable battery

Rubber Boot Protects the instrument

5

Rubber

Boot

Information

Label

Thermocouple

Sockets

Infrared

Window

Battery

Compartment

Exhaust

Port

Calibration

Information

Gas, Pressure, USB &

Leak Probe Ports

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Side Views

Exhaust Port Port for connection of xhaust Adapter

Infrared Window Window for sending stored data to IR Printer

Rubber Boot Protects the instrument from accidental damage

6

Rubber Boot

Exhaust Port

Infrared Window

Rubber Boot

Left Hand

Side

Right

Hand Side

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Charger Socket Connection for 220V/115V charger

T1 Socket Connection for thermocouple plug on flue probe

Connection for any 'K' type thermocouple probe

T2 Socket Connection for ambient 'K' type thermocouple probe

Connection for any 'K' type thermocouple probe

Gas Sample Port Connection for Mini Pump Protection Filter and Flue Probe

P (+) Port Connections for Pressure Tubing

P (-) Port

USB Port Connection for A807 cable for communication

to a PC or connection for 716-Leak combustible gas leak

detection sniffer probe.

Top View

7

Charger

Socket

USB Port

P(+)

Port

P(-)

Port

Gas

Sample

Port

T1 Socket

T2 Socket

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

BASIC ANALYSER FUNCTIONS

Charging The Analyser

Plug the charger into the charger socket on the instrument (see page 7). When the

charger is plugged in the battery level display will turn on. This display indicates

the analyser is being charged and the status of the charge.

The plug symbol confirms the

analyser is connected to the charger.

The battery symbol shows the charge

level when the analyser is on too.

The charge level is represented in

graph form as well. The charge is

displayed in percentage. (0 to 100%)

During operation the analyser will display charge status and battery condition in

the top right corner of the display.

Battery is at full capacity.

Battery is at 2/3 capacity.

Battery is at 1/3 capacity. The charger should be connected soon.

Battery is very low and needs to be recharged immediately

Indicates the analyzer is connected to the charger.

If a beeping noise is heard during charging disconnect the charger. This is an

indication the battery pack needs to be replaced.

8

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Turning The Analyser On

Always: - B for turning on pl as nsur that ONLY th in-lin pump prot ction

filt r is conn ct d to th Gas Sampl Port. This in-lin pump prot ction filt r

MUST b fitt d to th instrum nt at all tim s!!

Please DO NOT have the gas sampling probe attached at this point. The gas

sampling probe needs be fitted to the 716 only at the point where combustion

analysis begins. See page 14

Press and hold the ON/OFF key down for approximately 3 seconds. The 716 will

beep and the initial start up screen will be displayed.

After approximately 5 seconds the Main menu will be displayed & the 716 is ready

to use. However, as the Next Calibration Due Date Approaches or is Overdue one

of the following screens may appear:-

The initial start up screen displays the

following information:

Model number of the analyser

Firmware version

Firmware date

Serial number of the analyzer

Date Last Calibration was carried out

Date Next Calibration is due

9

Pump Protection Filter

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Turning The Analyser On (continued)

The main menu displays the following

information:

Battery status

Date (dd.mm.yyyy format) and time

(24hr clock)

Menu Selections

Left blue soft key activates Bluetooth

(Only models equipped with this option.)

Center blue soft key confirms selection

10

Choosing “Next” will move you onto the Main Menu Screen as displayed below.

Please Note: It is a requirement of BS7967 that an FGA is within calibration and used

in conjunction with the manufacturers instructions therefore it is NOT recommended

that “Next” be chosen by the user if the “Calibration Overdue” Screen appears. Doing

so will contravene the requirements of BS7967.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

EASURE ENTS - Flue Gas

Note: It is recommended you perform routine general maintenance on your

analyser to ensure proper function. Please refer to Appendix A for further details

The pump will start and the Zeroing screen will

display. The analyser is initializing and self

testing the sensors during this 30 second cycle.

The selected fuel type will be displayed and can be

changed as necessary (see pg 12).

The selected unit of efficiency is displayed

and can be changed as necessary (see pg 13).

If the analyser is ready for use, “Skip” will

appear above the center soft key. Pressing this

will bypass the 30 second countdown.

Turn the 716 on as outlined on page 9. After

the initial start up screen the Main Menu will

be displayed.

Using the Arrow keys select Measurements by

highlighting it.

Press the nter key (centre soft blue key) to

confirm the selection.

The Measurements menu will be displayed.

Using the Arrow keys select Flue gas by high

lighting it.

Make sure the analyser is in a clean air environment

with only the in-line pump protection filter

connected to the input.

Press the nter key (centre soft blue key) to confirm

the selection.

11

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

EASURE ENTS - Flue Gas (continued)

As necessary, the fuel type can be changed to match

the fuel type of the equipment under test. The fuel

type is used in the CO2, Ratio & efficiency calculations

and therefore it is important the fuel type is correct in

order for the calculation to be accurate.

To change the fuel type use the Arrow keys to

highlight “Fuel change”.

Press the Chang key (left soft blue key) and the fuel

menu will display.

The Arrow keys are used to scroll through the

available fuel types.

The available fuels are Natural gas, Light oil, Heavy

oil, LPG, Bituminous coal, Anthracite coal, Coke,

Butane, Wood (dry), and Bagasse.

Once the desired fuel type is highlighted press the

center soft key (OK) to confirm the selection.

The analyser will return to the Zeroing display and the

countdown will continue.

12

NOTE: When selecting oil as fuel be su e to use the optional

oil filte (A773) o eadings could become e atic. See

Appendix E fo installation inst uctions.

Do NOT use the A773 with a 716 analyse with the NO

Senso Upg ade.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

After the initial purge cycle is complete or skip is

pressed the Flue gas measurement screen will

display.

This screen displays all combustion parameters

including NO & NOx (if fitted), temperature, pressure,

excess Air and Pump Speed.

If an NO sensor is fitted then the Right Hand Down

Arrow Key needs to be pressed to see Pressure &

Pump Speed as well as Temperature.

EASURE ENTS - Flue Gas (continued)

The unit of efficiency can be changed as needed

between Nett, Gross & Condensing. Nett efficiency

doesn’t take into account wet losses while Gross

efficiency does. Condensing efficiency is a common

calculation applied is some uropean Countries.

Press the right soft key (Next) to highlight “ fficiency

change” in the display.

Press the Chang key (left soft key) and the efficiency

menu will display.

Use the Arrow keys to select the desired efficiency

unit and press the center soft key (OK) to confirm the

selection.

If only CO & O2 sensors are fitted then the bottom 2

spaces on the initial front Flue Gas Measurements

Screen will display Pressure & Pump Speed. Pressing

the Right Hand Down Arrow Key will scroll through

and display the other parameters such as

Temperature etc...

13

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

EASURE ENTS - Flue Gas (continued)

Connect the Gas Sampling Flue Probe Tubing complete to the In-Line Pump Protection

Filter (see below) and the 'K' Type Thermocouple Plug from the Flue Probe into

Thermocouple (T1) Socket. The GK11M ambient air temperature probe is connected to

the (T2) socket.

WARNING: - nsure the 'K' type thermocouple probes are inserted into the sockets

correctly (see page 7). The plugs are polarity marked and forcing the plug into the

socket the wrong way may result in damage to the instrument.

In-line Filter

Assembly

Ambient Air

Connection (T2)

Flue Probe

Tubing

G 11M Probe Thermocouple

Connection from

Flue Probe

Pump Protection Filter

Press the center Blue Soft Key (Start) and the pump

will start. The following screen will display:-

Press the Left Blue Soft Key to send the Displayed

Readings Directly to the Optional A740 IR Printer

Press the Right Blue Soft Key to Hold the desired

readings on the screen giving you the option to Save

or Send them to Memory, IR Printer or PC.

Press the Centre Blue Soft Key to Stop the Pump

Running. The Pump will only stop running if the CO

level is below 10ppm otherwise this option is disabled.

14

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

EASURE ENTS - Flue Gas (continued)

Insert the flue probe into the sample hole of the device under test. The probe tip

should be in the middle of the flue pipe or exhaust stream.

nsure the In-Line Filter / Water Trap hangs below the analyser in the proper vertical

position when readings are being taken. Failure to comply reduces the effectiveness of

the water trap and may result in damage to the instrument. Refer to the pictures below

for correct and incorrect use.

WARNING: - Should the CO reading rise above 2,000ppm a continuous series of Alarm

Beeps will be heard. The Probe should immediately be disconnected from the

instrument and the instrument returned to a clean air environment. This Alarm alerts

the user that there is a high concentration of CO, and this procedure will protect the

sensors within the instrument. The alarm level can be changed. Please see Appendix D

Make sure to check the water trap periodically during testing to ensure it does not fill

with condensate and empty it as necessary. If the filter begins to fill during a test, open

the lid and empty out the condensate. After closing the lid, allow readings to stabilize

again.

I PORTANT: The water trap is fitted with a water block filter (p/n A796-D) in the lid to

prevent water from flowing down into the pump. If the water trap fills the water block

filter will stop the flow to the analyzer and FLO RR will display. The water trap should

be emptied immediately if this happens. The water block filter may need to be dried out

or replaced before testing can resume.

15

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

EASURE ENTS - Flue Gas (continued)

Allow the readings to stabilise. Multiple parameters can be seen in the display.

16

• Carbon Monoxide (CO) reading in parts per million

(ppm)

• Carbon Dioxide (CO2) figure in percentage (%)

(calculated)

• CO/CO2 (Ratio) figure.

• Calculated fficiency ( ff.) figure in percentage

• Oxygen (O2) reading in percentage (%)

• xcess Air (X Air) in percentage

• Nitric Oxide (NO) (measured) and Nitrogen Oxide

(NOx) (calculated). If Fitt d.

• Carbon Monoxide (CO) reading in parts per million

(ppm)

• Carbon Monoxide Air Free (COAF) in parts per million

(ppm) (calculated).

• Nitric Oxide (NO) (measured). If Fitt d

• Temperature T1-ST (stack temperature)

• T2-AT (ambient temperature).

• Temperature T1 - T2 (DT)

• Pressure (Prsu)

• Pump speed in cc/min.

Pressing the Up / Down Arrow keys enables the rest of the screen to be displayed.

Once the combustion readings have stabilised they can be “Printed” directly to the

optional IR (A740) Printer by lining up the IR window on the side of the FGA (see page

6) & the IR window on the Printer. Alternatively the stabilised readings can be “H LD”

on the screen. Once the readings are held on the screen the following options are

available:- “Send” the held readings to the A740 Printer or to a Compatible PC or

“Save” the readings to a memory location of your choice. These options are explained

in further details on page 17.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

EASURE ENTS - Flue Gas (continued)

The “Held” data can be saved to a memory location

by pressing the Save key (right blue soft key) and

“Real Data Save” and “Address:” will be displayed.

Using the Up and Down Arrow keys select the

memory location to save the data.

Press the OK key (center blue soft key) to save the

data to the 716 internal memory.

Press the “Back” key at anytime to go back to

“Held” Readings

The “Held” data can also be sent to an optional

infrared printer (p/n A740) or to a PC using optional

cable and software by pressing the Send key (left

blue soft key) and “Print Out” and “PC Out” will be

displayed.

Using the Up and Down arrow keys select the type of

output you require. If sending data to a PC, connect

the USB cable to the analyzer and computer and run

the 716 PC software.

Press the OK key (center blue soft key) to print or

send data to a PC.

Press the “Back” key at anytime to go back

to “Held” Readings

Choosing the “HOLD” option will display the following screen:-

Please note the 3 new options on the Soft Blue Keys

The TPI 716 will continue to monitor live readings in

the background whilst the “Held” readings are on the

display until the “unHold” option is chosen.

You can “Save”, “Print” or “Send” out as many sets

of these readings as you require whilst the 716 is in

“Hold” mode.

Once the “unHold” button is pressed then the 716 will

return to Live readings as explained on Page 16.

17

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

easurements - Temperature & Pressure

18

From the Main menu screen using the Up / Down

Arrow keys select “Measurements” in the menu.

Press “ nter” (center blue soft key) to confirm the

selection.

From the Measurements menu use the Up / Down

Arrow keys to select “Temp/Pressure” in the menu.

Press “ nter” (center soft blue key) to confirm the

selection.

The Temperature / Pressure screen will display.

This screen displays both T1 and T2 channels of

temperature as well as the difference between T1 and

T2 (DT).

If no probe is connected to the input “-----” will be

displayed indicating an open connection.

Pressure (Prsu) is also displayed in this screen.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Table of contents

Other TPI Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Ametek

Ametek Dycor DM100 user manual

Wetekom

Wetekom 79 71 59 instruction manual

Optima Home Scales

Optima Home Scales VITALIZE user manual

Agilent Technologies

Agilent Technologies N5242A Service guide

Air Comm Systems

Air Comm Systems ACS 296 installation manual

Dwyer Instruments

Dwyer Instruments Series APM instruction manual