Tractel HF 32/1/B Operating instructions

Other Tractel Safety Equipment manuals

Tractel

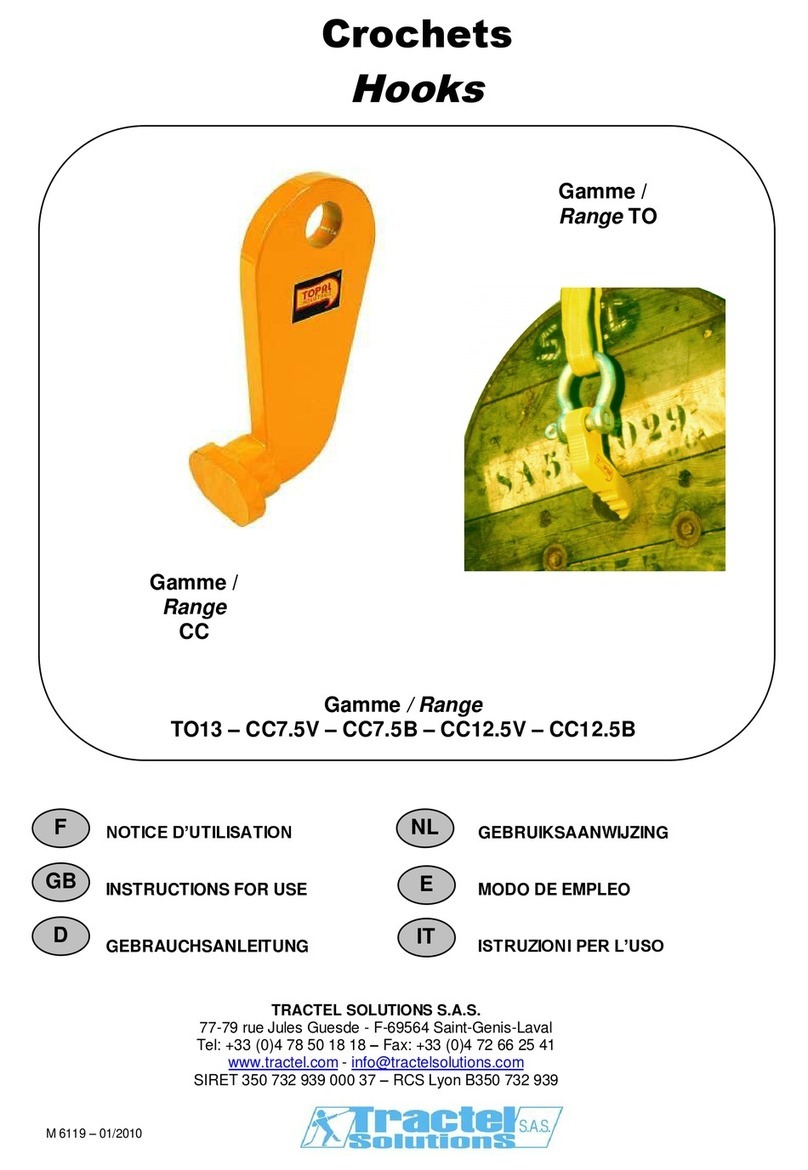

Tractel TO13 User manual

Tractel

Tractel ringsafe Manual

Tractel

Tractel blocmat TSD Installation guide

Tractel

Tractel HT9 Installation guide

Tractel

Tractel travsmart Installation guide

Tractel

Tractel LCR 06 Installation guide

Tractel

Tractel rollclamp User manual

Tractel

Tractel Blocstop BS Installation guide

Tractel

Tractel blocfor ESD Series Manual

Tractel

Tractel LSA Series Operation instructions

Tractel

Tractel tracrod 150 Kg Installation guide

Tractel

Tractel HT Installation guide

Tractel

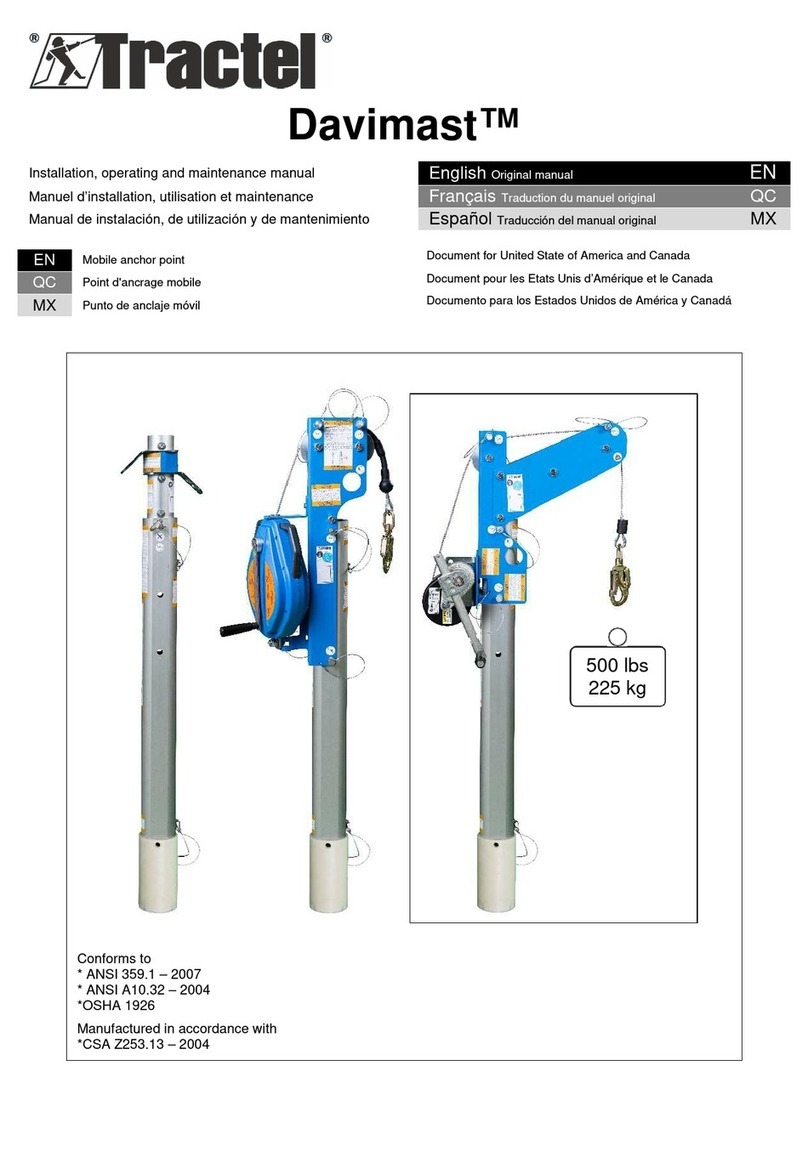

Tractel Davimast Installation guide

Tractel

Tractel AS19 S Installation guide

Tractel

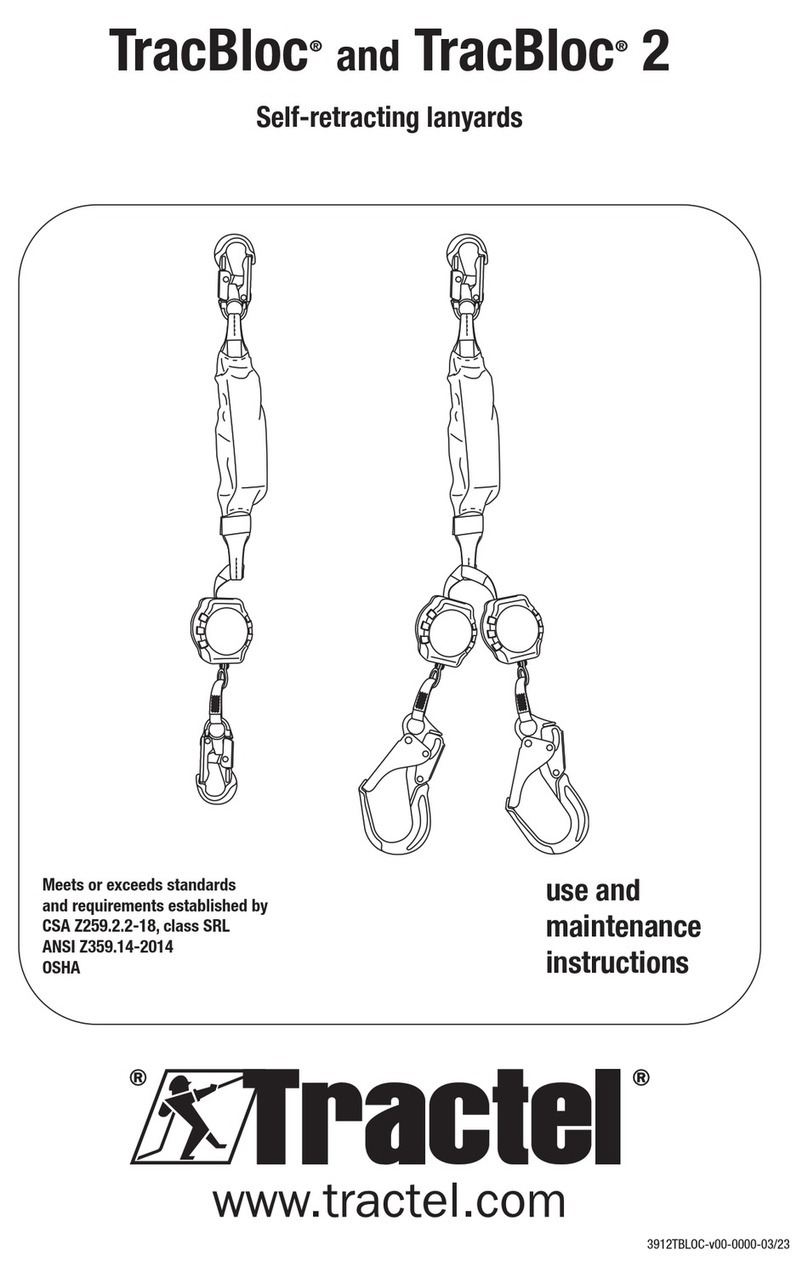

Tractel TracBloc Operation instructions

Tractel

Tractel blocfor AES Series Manual

Tractel

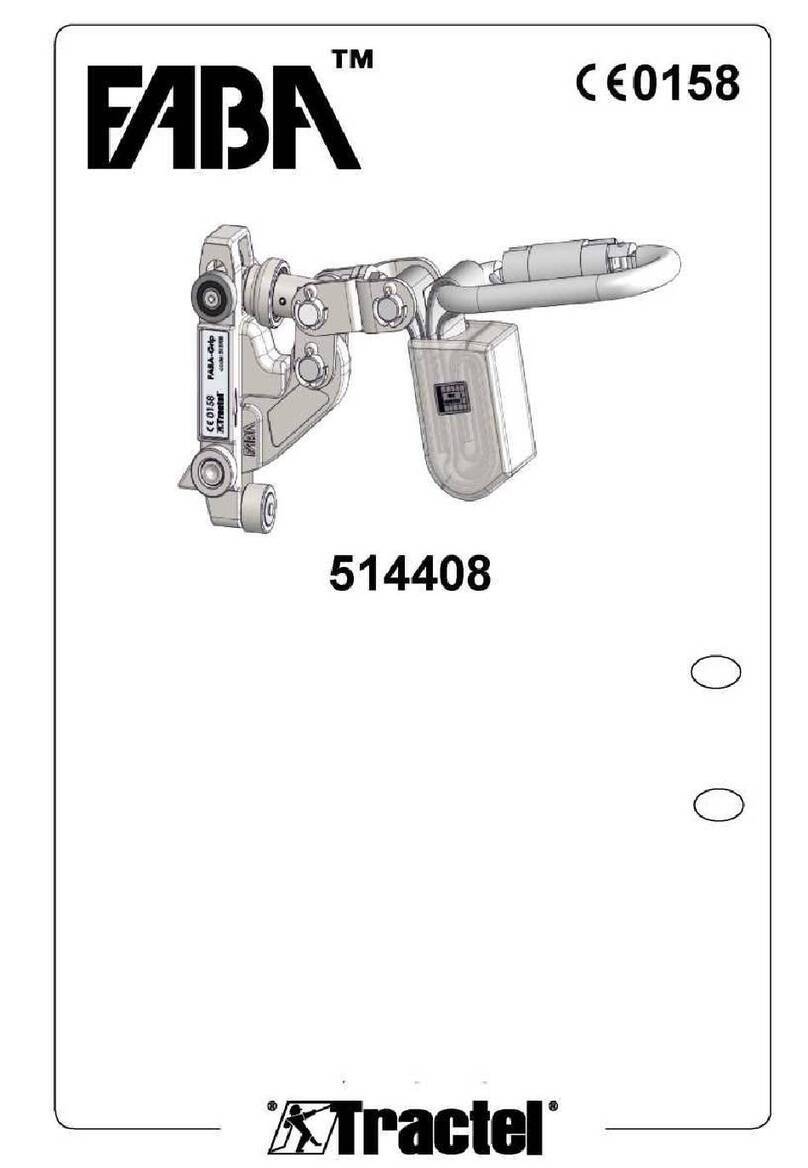

Tractel FABA 514408 Manual

Tractel

Tractel travsafe PA Installation guide

Tractel

Tractel Magfor Auto 200 User manual

Tractel

Tractel tracrod base User manual

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual