Table of Contents

1. FUNDAMENTALS ABOUT THE SYSTEM ..................................................................1

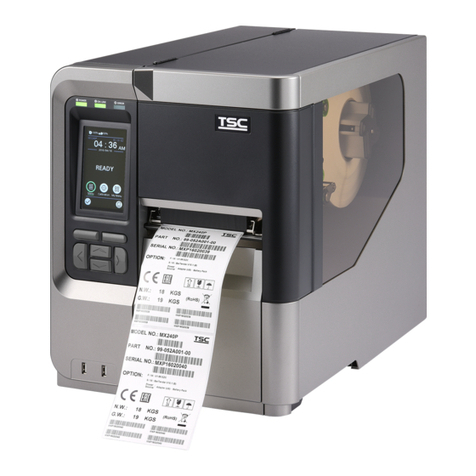

1.1 Overview ....................................................................................................................1

1.1.1 Front View...........................................................................................................1

1.1.2 Rear View...........................................................................................................2

1.2 Basic Specifications....................................................................................................3

1.3 Available Bar Codes...................................................................................................4

1.4 Various Sensors.........................................................................................................4

2. SUPPLY SPECIFICATIONS.............................................................................................6

2.1 Media Specifications...................................................................................................6

2.2 Ribbon Specifications.................................................................................................7

3. ELECTRONICS ................................................................................................................8

3.1 Summary of Board Connectors ..................................................................................8

3.2 Pin Configuration......................................................................................................10

4. MECHANISM..................................................................................................................12

4.1 Mainboard Replacement...........................................................................................12

4.2 DC Motor Replacement............................................................................................14

4.3 Print Head Replacement ..........................................................................................18

4.4 Ribbon Rewind Spindle Encoder Replacement ........................................................20

4.5 Felt Fabric Replacement ..........................................................................................21

4.6 Stepping Motor Replacement ...................................................................................23

4.7 Black Mark Sensor / Gap Sensor (Receiver) Replacement ......................................24

4.8 Ribbon Sensor (Receiver) Replacement...................................................................25

4.9 Ribbon Sensor (Transmitter) / Gap Sensor (Transmitter) Replacement ...................27

4.10 Platen Replacement ...............................................................................................28

4.11 Cutter Installation (Option / Not available for TTP-243E/244 Pro model)................30

5. TROUBLE SHOOTING...................................................................................................33

5.1 Trouble Shooting......................................................................................................33