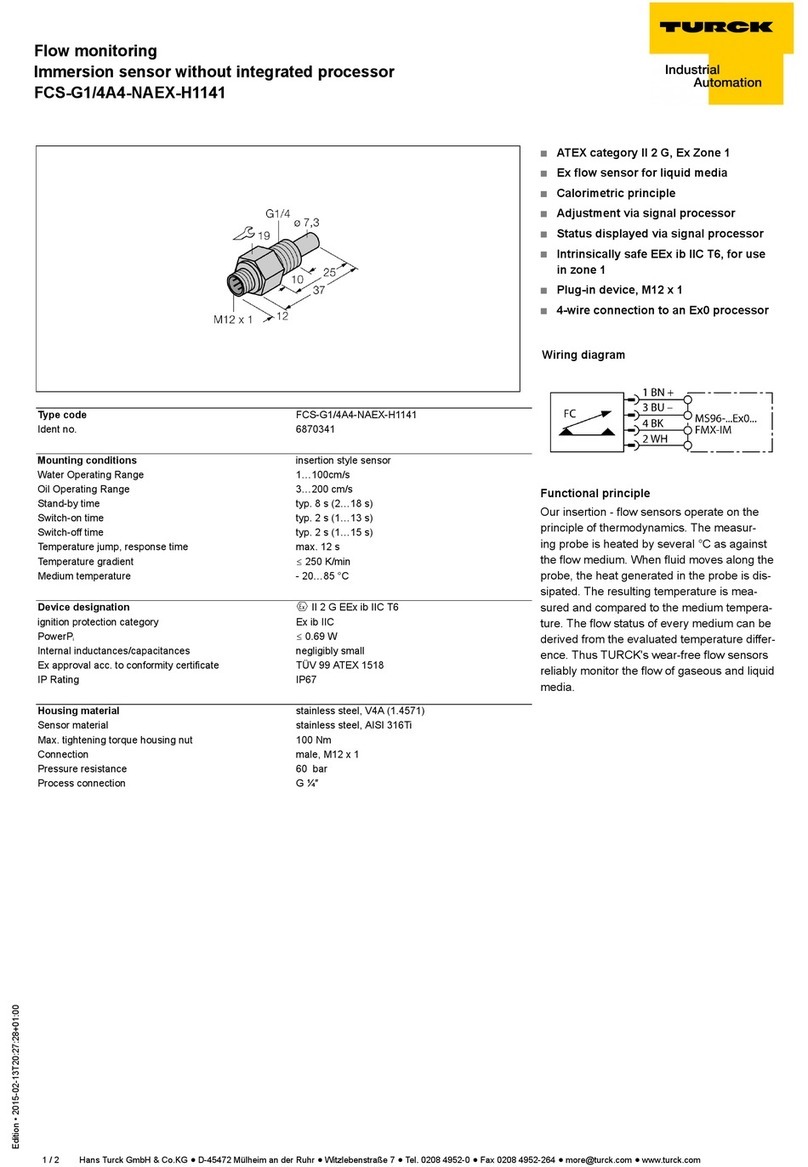

Flow monitoring

Immersion sensor without integrated processor

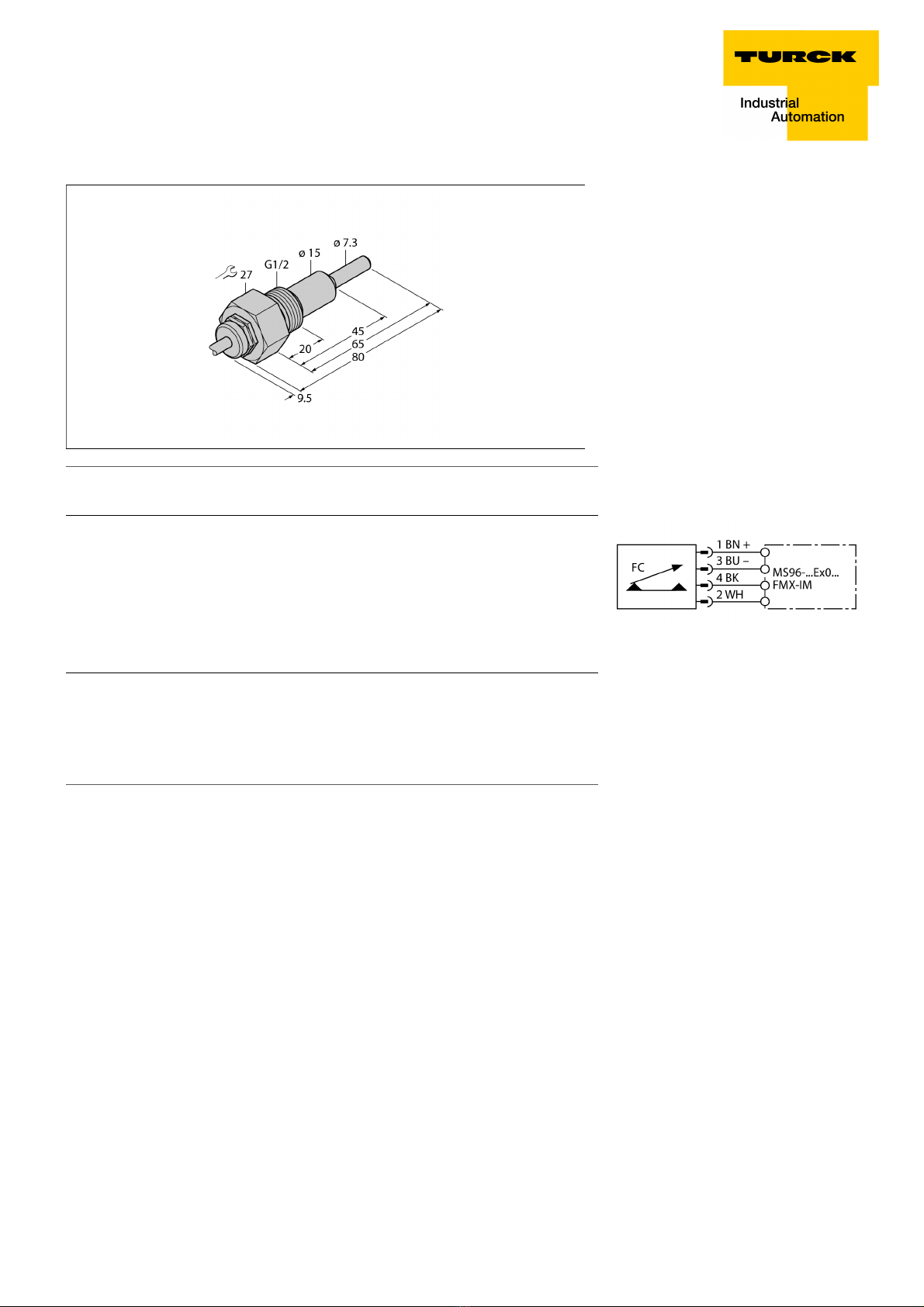

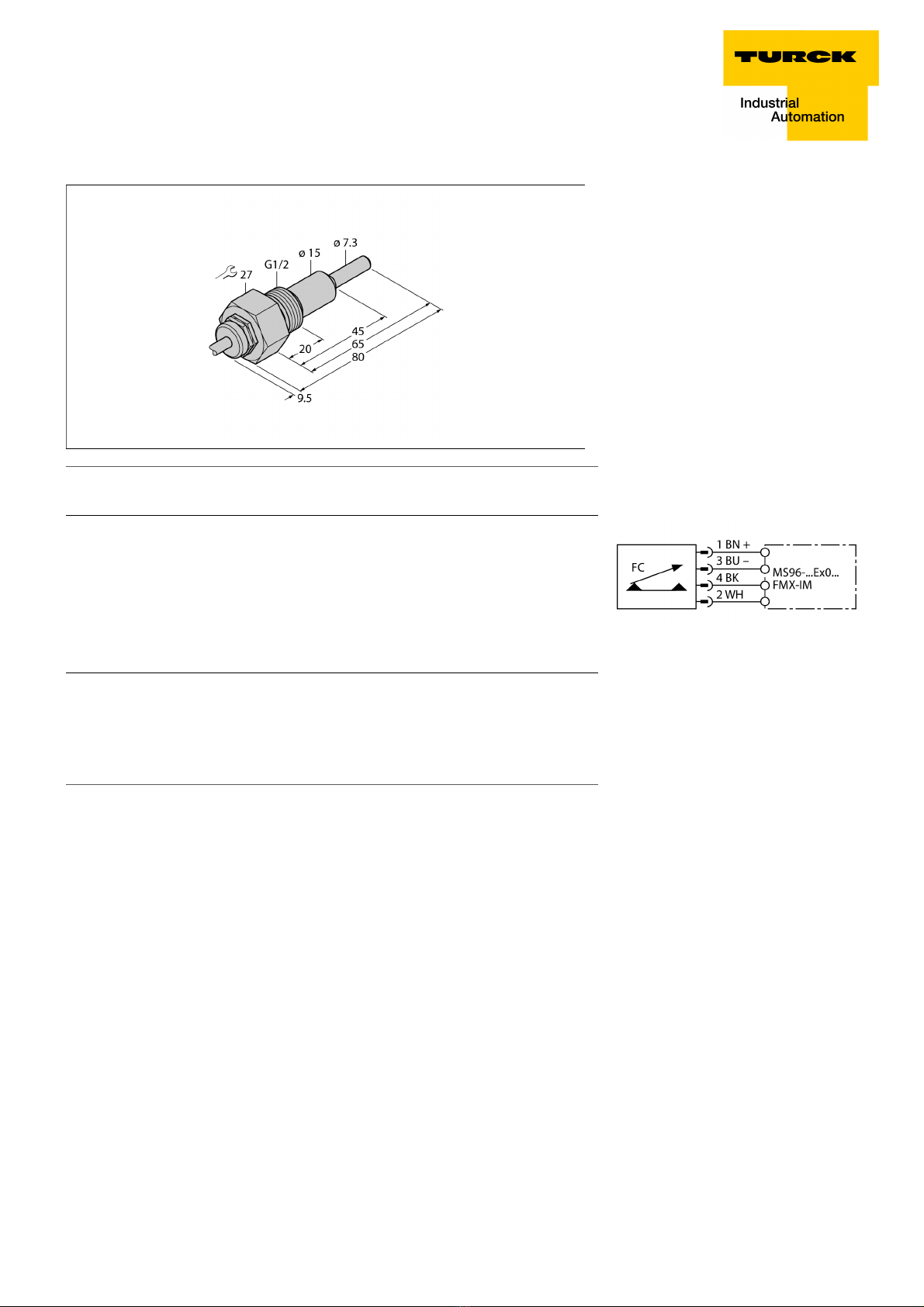

FCS-G1/2HC4-NAEX0/L065

Edition • 2016-06-25T23:44:57+02:00

1 / 2

Hans Turck GmbH & Co.KG

ñ D-45472 Mülheim an der Ruhr

ñ Witzlebenstraße 7

ñ T

el. 0208 4952-0

ñ Fax 0208 4952-264

ñ [email protected] ñ www

.turck.com

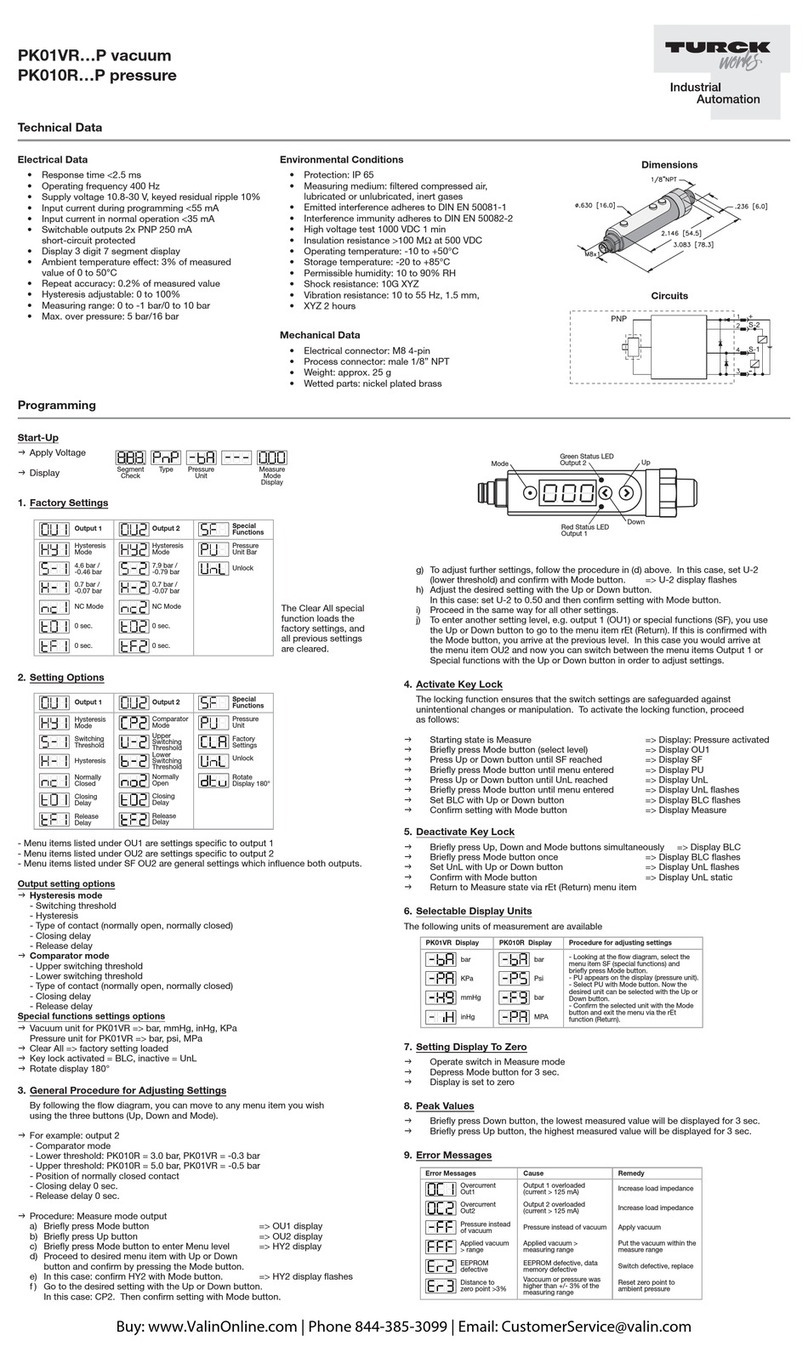

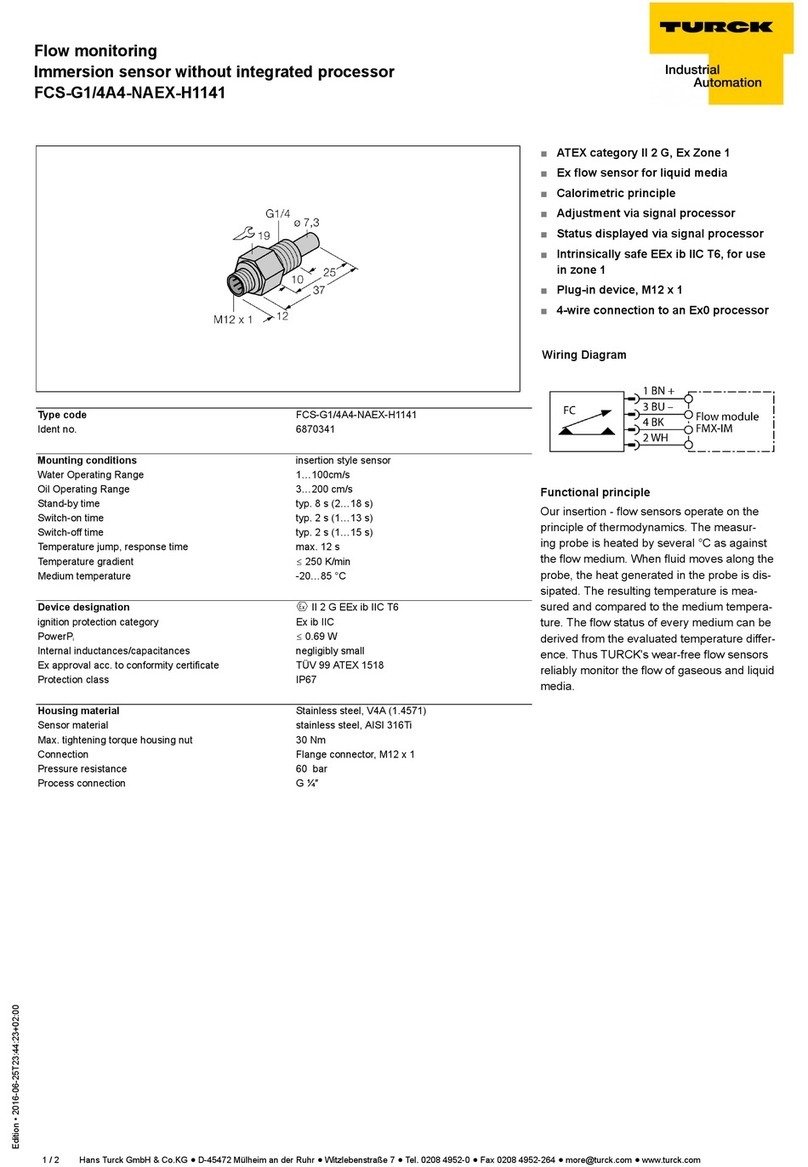

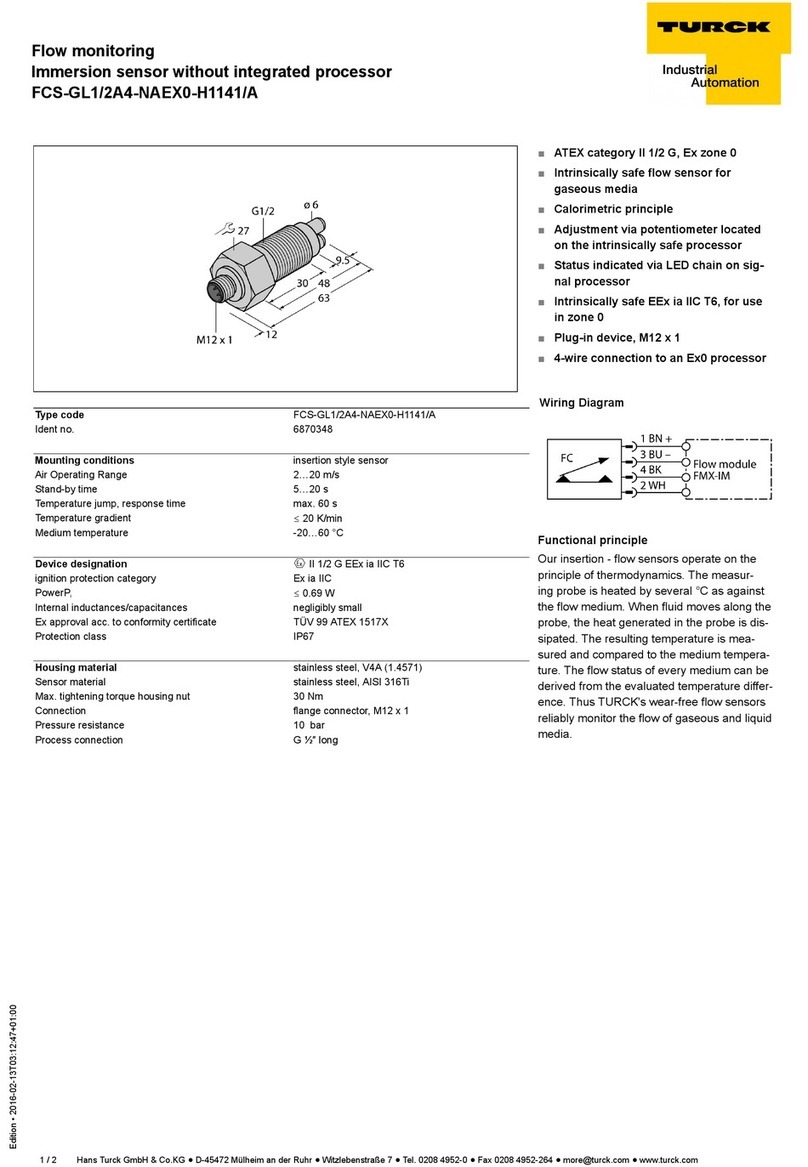

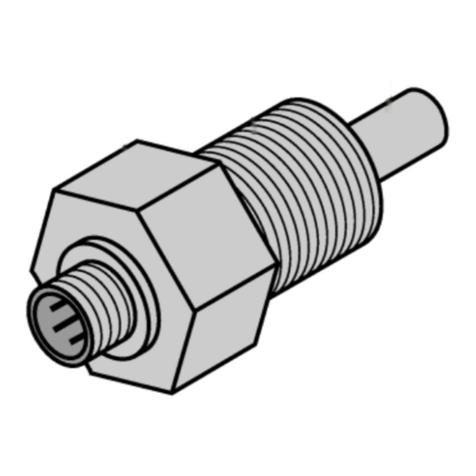

Type code FCS-G1/2HC4-NAEX0/L065

Ident no. 6870355

Mounting conditions insertion style sensor

Water Operating Range 1…100cm/s

Oil Operating Range 3…200 cm/s

Stand-by time typ. 8 s (2…15 s)

Switch-on time typ. 2 s (1…15 s)

Switch-off time typ. 2 s (1…15 s)

Temperature jump, response time max. 12 s

Temperature gradient ð 250 K/min

Medium temperature -20…60 °C

Device designation É II 1/2 G EEx ia IIC T6

ignition protection category Ex ia IIC

PowerPið 0.69 W

Internal inductances/capacitances negligibly small

Ex approval acc. to conformity certificate TÜV 99 ATEX 1517X

Protection class IP67

Housing material Metal, Hastelloy C4 (2.4610)

Sensor material metal, Hastelloy C4 (2.4610)

Max. tightening torque housing nut 30 Nm

Connection PUR cable

Cable length 2 m

Cable cross section 4 x 0.25 mm2

Pressure resistance 60 bar

Process connection G ½″

■ATEX category II 1/2 G, Ex zone 0

■Intrinsically safe flow sensor for liquid

media

■Calorimetric principle

■Adjustment via potentiometer at Ex sig-

nal processor

■Status indicated via LED chain on sig-

nal processor

■Sensor made of Hastelloy C4

■Sensor length 65 mm

■Intrinsically safe EEx ia IIC T6, for use

in zone 0

■Cable device

■4-wire connection to an Ex0 processor

Wiring Diagram

Functional principle

Our insertion - flow sensors operate on the

principle of thermodynamics. The measur-

ing probe is heated by several °C as against

the flow medium. When fluid moves along the

probe, the heat generated in the probe is dis-

sipated. The resulting temperature is mea-

sured and compared to the medium tempera-

ture. The flow status of every medium can be

derived from the evaluated temperature differ-

ence. Thus TURCK's wear-free flow sensors

reliably monitor the flow of gaseous and liquid

media.